Material selection

Absolutely any building material intended for the construction of permanent and temporary structures is suitable for the construction of a gazebo. It is also permissible to use a variety of leftovers after the construction of a country house, etc., including all kinds of their combinations. However, it is imperative to take into account the individual properties characteristic of each individual building material.

Metal

Almost any metal structure is characterized by increased rigidity and wear resistance. This material is ideal for erecting a gazebo, since in this case it can be made as quickly as possible, no more than in a few days.

Learn how to design a seating area.

In addition, the metal is also distinguished by its high ductility, so almost any form of structure can be created from it. Also, an undoubted advantage will be a fairly wide list of all kinds of forged elements that can be easily fixed to the main structure.

- Pros of building a gazebo made of metal:

- a metal building does not require a solid foundation

- all elements are firmly connected into an integral structure, which gives it special wear resistance

- the gazebo can be made in almost any style

- such structures allow full glazing of the structure

- Cons of erecting a gazebo made of metal:

- cannot boast of being cheap

- in the case of self-erection, it requires the skills of welding metals or the involvement of appropriate specialists

- over time, the metal becomes corroded

- the metal is characterized by high thermal conductivity, therefore, during the heat and in autumn, such a gazebo will not be able to provide the necessary comfort

Wood

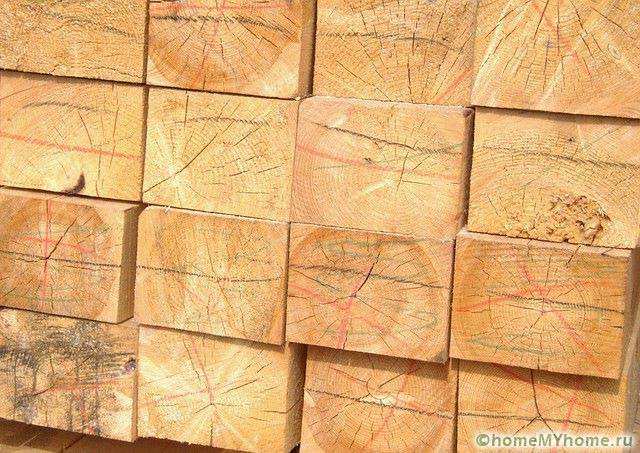

Wood is considered the most popular building material, it is perfectly exposed to all kinds of processing, and also creates the necessary comfort on the site. Such a gazebo will always look rich and solid, despite the fact that it can be made practically from construction waste. This contributes to the fact that wooden gazebos and are the most popular and found in the garden.

At the same time, the most popular basis for such a design is a pine board. But, massive structures made from solid logs look the most aesthetically pleasing, but in this case, it will not be possible to do without the involvement of individual specialists.

- Pros of creating a wooden building:

- low cost

- the tree best of all creates the necessary microclimate and comfort inside the room

- installation of timber structures can be done with a minimum of tools

- a wooden building does not require a solid foundation

- Cons of creating a wooden building:

- the material needs to be treated against moisture and insect pests, including throughout the entire service life

- increased fire hazard

- wood cannot boast of durability

- over time, the decorativeness of the material decreases

Did you know? The most ancient architectural structure on the planet is the Barnenes mound, located on the territory of modern France. According to the calculations of archaeologists, it was erected between 4800-4000. BC e., about 2000 years before the construction of the Egyptian pyramids.

Brick and stone

Natural stone or brick for the construction of a gazebo is not often used. These materials do not allow you to create a miniature and lightweight structure, however, they can be used to build a solid structure, for almost any type of recreation.

Most often, red, silicate or special decorative bricks are used for this. Crushed natural stone (granite, limestone, etc.) can also be used as an alternative. To reduce the cost of the construction process, all kinds of foam and cinder blocks are used.

- Advantages of a brick or stone gazebo:

- durability and reliability

- brick or stone does not corrode or fester

- almost complete environmental safety of materials and their components

- minimal fire hazard

- Cons of a brick or stone gazebo:

- a brick structure requires a solid concrete foundation

- high cost of material and components

- laying stone requires certain skills and knowledge

- the final design almost always looks the same

Stages of work

Construction process

In order to make a hexagonal gazebo, you need to decide on the choice of material. In this case, a spruce or pine is suitable, since by its properties this material is quite durable and relatively inexpensive.

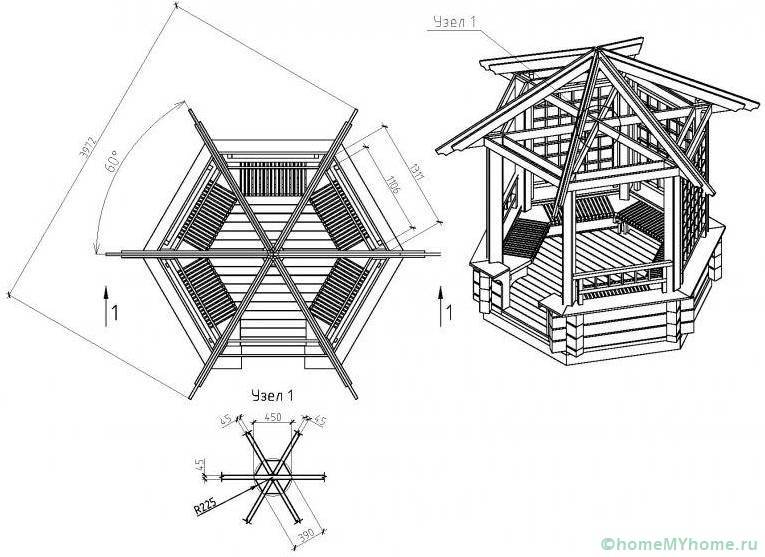

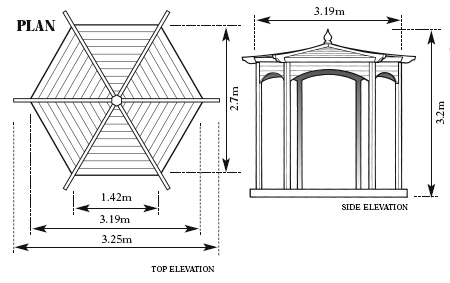

- Before starting work, it is necessary to draw up drawings, which will reflect the dimensions. For example, the height of a structure may be 2.6 m.

- When you decide on the dimensions of the future structure, on a circular machine you should saw boards and beams of the required size and trim them using an electric plane.

- Then you need to mark the site for construction. To get a hexagon of the correct shape, you need to draw a circle of a given diameter using two wooden pegs and a rope. On the circle, it is necessary to draw six lines equal to the diameter of the circle and make notches at the intersection of the lines.

- In places marked with notches, holes are dug under the foundation about 50 cm deep. A layer of sand about 10 cm thick is poured onto the bottom and rammed. As a support for the supporting posts, you can lay paving slabs 30 × 30 cm into the pit and tamp them slightly. After installing the support bars, the pits can be filled with sand, followed by tamping and watering.

Concrete block 40 × 20 × 20 for foundation

You can also use concrete blocks as a base for the gazebo.

- In order to give strength and stability to the wooden structure, one reinforcing bar 1–1.5 m long must be driven in at the corners of the marking in the dug holes with compacted filling. The diameter of the reinforcement can be from 10 mm, but in this case it is difficult to hammer it how it will vibrate. To do this, a piece of pipe can be put on the reinforcement and a rod can be hammered into it. The pipe must be removed, and then holes are drilled in the concrete blocks and put on the reinforcement.

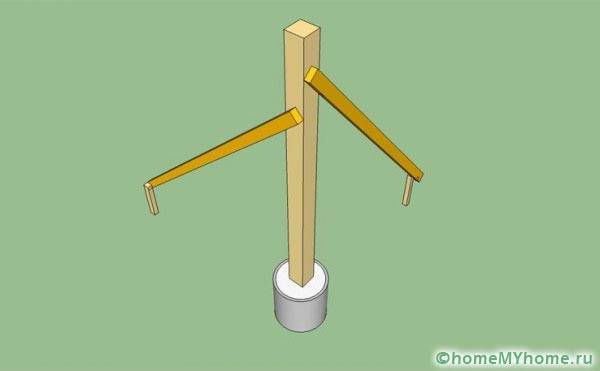

- It is necessary to lay a layer of waterproofing on concrete pillars - it can be two layers of a simple roofing material. Then, using an electric drill, they drill holes in each wooden beam and put them on fittings like a well, and cut them off at the intersection of the beams. For strength and alignment, cutouts are made in advance for the "half-bar" connection. Then the bars are collected and fixed with nails. For supports, beams with a section of 100 × 100 cm are suitable.

- The next step is the construction of the base. If the gazebo is large, then in the middle you need to make a support pillar, which will serve as a support, and then lay the logs, having previously treated them with a protective impregnation from the destructive action of moisture. As a flooring, tongue-and-groove wooden boards, moisture-resistant plywood, as well as moisture-resistant chipboard and OSB boards are widely used.

- After fixing the flooring, you can put the pillars of the support, having previously drilled the holes for the reinforcement, and then put the bars on it. Using a plumb line, you need to check how vertically these pillars are installed, and then fix them in this position with temporary jumpers.

Installation of rafters

- The crown is made according to the same principle as the lower ring of the frame. It fits on the uneven bars and is secured with self-tapping screws.

- The final stage of construction is the installation of the roof. This happens as follows - the tops of the vertical posts are connected with bars, aligning them with the end part at an angle of 60 degrees with a hacksaw, and then fixed with self-tapping screws. When the frame is completely ready, the gazebo is covered with roofing material. For convenience, the roof is best done on the ground, and then the finished structure should be installed on the upper ring of the structure.In the event that the roof is assembled at the top, two boards are attached to the upper ring, a support post is installed on them, and then guide bars are brought out onto it and fixed. The finished crate is sheathed with sheet material or slats. For the roof, metal tiles, corrugated board or other material are used.

Fencing and decoration of the gazebo

- The gazebo around the entire perimeter must be fenced with a railing with a height of 0.9 m. The railing is made of ordinary boards, and using a special template, they can be given an unusual shape.

- Vertical beams can be sheathed with clapboard or decorative lattice made of wooden battens.

- To protect the wooden structure from decay and give it a beautiful look, it is imperative to varnish or paint it - the choice is yours.

You can equip a path for convenience and make a small porch, fill the internal volume with floor and wall vases with fresh flowers, and decorate with evergreen climbing plants from the outside of the wall.

Preparation for work

Collapsible metal gazebo

Metal gazebos are temporary and capital. Temporary ones are arranged for the summer period, and they are removed for the winter. The foundation for such structures is not needed. Sometimes hollow pipes are driven into the ground as a foundation, which will serve as the basis for the frame. For the winter, the top of the pipes must be closed to prevent precipitation and debris from getting inside.

For capital gazebos, a reliable foundation is required, which is arranged before construction. The base can be wood flooring or concrete flooring. It is imperative that the elements of the base made of wood be impregnated with an antiseptic, and the metal parts must be primed to avoid corrosion.

Welding machine

During the work, the following tools and materials will be required:

- welding machine;

- drill and drill bits for metal;

- Bulgarian;

- roulette;

- building level;

- metal pipes of square or round cross-section;

- primer and paint for metal;

- roofing material.

The installation of a metal gazebo requires a competent and responsible approach. First, you need to draw up a drawing indicating the dimensions and calculate the required number of pipes for the frame and supports, the amount of roofing material. You need to buy building materials with a drawing in order to acquire everything you need and properly dispose of funds.

What to build a hexagonal gazebo from?

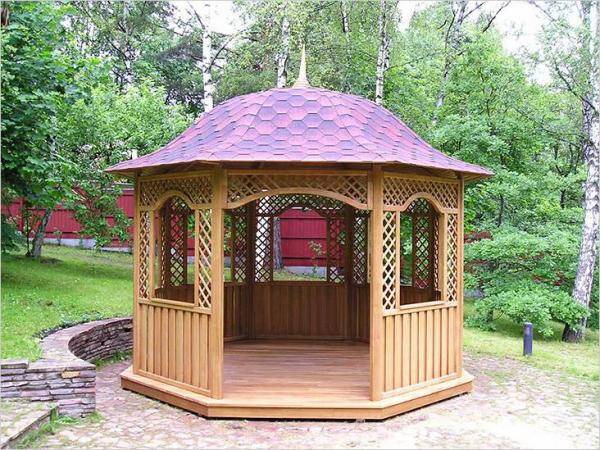

The hexagonal canopy is really beautiful and laconic. Of course, it is easiest to build a rectangular structure. But it loses out to the hexagonal in all respects. There is no need to look far for an example - it is not by chance that the honeycomb has the shape of a hexagon. And no one under any circumstances will force a bee to make a square or pentagonal honeycomb.

With proper construction, the structure will serve you for more than a decade. Before we build a hexagonal gazebo, let's decide on the materials. You can take a brick or wood, order a forged base or assemble it from a professional pipe. Let's consider each option in more detail.

Forged metal structures. A great option for those who like lightweight, visually weightless structures. To make the gazebo really elegant, you need not only to know the basics of construction, but also to be able to handle a welding machine. Forged hexagonal gazebo with its own hands are durable and not afraid of fire. From the point of view of composition, this is the most perfect option. But keep in mind that from time to time the metal needs to be treated with an anti-corrosion compound. In winter, it is quite cold inside the gazebo, on sultry, summer days it can be stuffy.

Sheds from a professional pipe. One of the strong advantages of such a hexagonal gazebo design is quick assembly. As a rule, it takes no more than 2-3 days.A professional pipe with a diameter of 8x8 centimeters is used as support pillars. Other sizes are acceptable. Other advantages include stability, the ability to show imagination. There is also a drawback - a certain limitation when creating winter-type gazebos.

Brick hexagonal gazebos. They look like small but very cozy houses. Suitable for summer residents who are familiar with the basics of brickwork. This design can be used for a long time without updates. It is temperature stable - it does not get very hot in the sun and at the same time retains heat. You can experiment with brick, natural stone. However, you will be building such a gazebo for more than one week, and the brick is not cheap. In addition, a brick gazebo cannot be disassembled and moved to another place - it is static.

Wooden buildings. This option is the most popular among novice builders. It involves the use of sustainable raw materials, which is already good for allergy sufferers and health-conscious people. The wooden gazebo will perfectly fit into any site design, it is characterized by long-term operation. It is not recommended to install a brazier in it - there is a high probability of fire. Material can deteriorate under the influence of precipitation.

Therefore, it is important to process it in a timely manner with special compounds that prevent decay.

Phased construction of a gazebo

Therefore, we will consider step by step the stages of building a hexagonal arbor made of wood.

- According to the drawings, it is necessary to make wood blanks using a circular machine, and then trim the boards with an electric plane.

- Treat the material with an antiseptic and impregnation against decay.

- At the place where it was decided to put the gazebo, it is necessary to make markings in the form of a future building - the basis for the foundation. It is easy to get a hexagon from a circle, therefore, using a rope and two pegs, you need to draw a circle on the ground. The radius of this circle is equal to one side of the hexagon - based on this rule, it is easy to construct a hexagon from the resulting circle.

- Further, inside the resulting figure, they dig a foundation pit, about half a meter in diameter. A sand and gravel cushion is formed, which compresses well.

- Support pillars are installed at six designated points. It is best if they are made of concrete. You can use wooden round timber, but in the ground they tend to rot and deteriorate over time.

- For the stability of the structure, a reinforcing bar is driven into the concrete pillars in the middle. It is on it that elements of wood will then be planted.

- The horizontal supports are seated along the perimeter of the future gazebo on the reinforcement in two rows in an "overlapping" manner.

- Next, the lag is installed for the floor. In order for the coating to be strong and stable, additional concrete supports are installed under the intersections of the logs.

- The lag structure must be embedded in ready-made horizontal supports.

- In the uprights, holes are made for reinforcement using a drill. Further, these supports are installed and, with the help of wood scraps, are aligned clearly perpendicular to the future floor.

- The temporary measure for aligning the vertical axes is removed after the strapping is installed on top of the structure.

- The middle harness is the future railing. For better stability of the building, the railings are installed in the middle of the structure.

- Next, the installation of the roof frame begins. A board is cut along the diameter of the hexagon, on which a hexagonal post is installed in the center. The rafters will diverge from it.

- The six rafters should fit snugly against the edges of the support post. On the other hand, they should cut into the support top harness.The whole structure is reinforced with self-tapping screws.

- The roof frame is ready, you can start installing the roof. As a material, you can choose bituminous tiles, slate, metal profiles, corrugated board and so on. In the first case, it is necessary to make a base from an OSB board. The slab should be cut on the ground, cutting out the elements strictly along the edges. Next, the OSB is installed and fixed on top of the roof frame, treating the joints with a sealant.

- For any heavy roofing material, a metal cornice should be made.

- The roofing material can now be laid.

- Before finishing work on the floor, it is necessary to protect the structure from below from moisture; for this, the voids between the logs are sewn up with a vapor barrier.

- Deck or tongue-and-groove planks are suitable for floors.

- The lower part of the gazebo is decorated in the chosen style, the entire structure is painted or varnished.

The wooden hexagonal gazebo is ready! It remains to lay a garden path to the building, plant flower beds and shrubs around. As an additional detail, you can install benches around the perimeter. If the gazebo is large and spacious, it is better not to do this, but to arrange garden furniture inside, for example, a dining group.

Metal structures are similar in installation to wooden buildings, only the set of tools differs, but brick arbors require a reinforced concrete foundation. The secret of the stability of a brick structure is reinforced pipes, which are used as vertical supports, and bricks fastened with cement are already laid around them. The iron pipes are also the uprights for the roof frame.

Step-by-step instructions for making a wooden gazebo

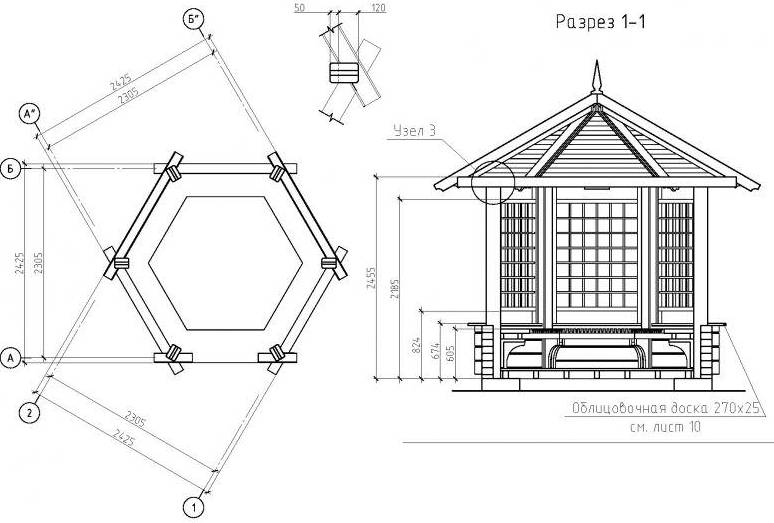

Project

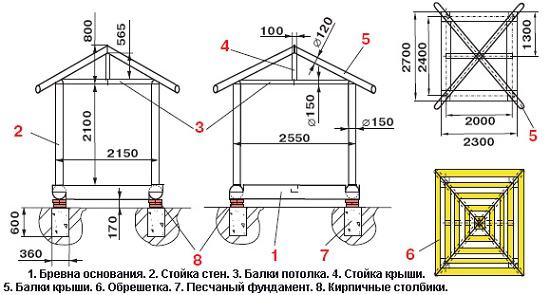

Analyzing the above, we can confidently conclude that a do-it-yourself wooden gazebo is suitable for self-production without special skills. The drawings and dimensions of the roof dome are as follows:

Hex base marking

The position of the frame struts is oriented along its extreme points. The advantage of the hexagonal dome is its interesting appearance, better wind and snow resistance.

Hexagonal gazebo project

Materials (edit)

To manufacture a budget option, you will need:

- Rack bar 150 * 150 mm - 6 pcs, 2 m each;

- Tying and rafter beams for roof elements - 100 mm and 40 mm for lathing;

- Roofing iron or shingles;

- Carved shields;

- Edged board;

- Fasteners - screws, bolts;

- Impregnating and decorative compounds - varnish, stain and others.

Beam for the frame

The tool that you need to carry out the work

Depending on the complexity of the design, a reinforcing bar, steel corners, logs are additionally required. Next, we will consider the algorithm for erecting a hexagonal gazebo with our own hands according to individual sizes and drawings.

Layout and preparation of the site

Marking a site for a hexagonal gazebo

Sod is removed from the surface of the soil and leveled. The markings for the racks are carried out using stakes and a cord. In a hexagonal shape, the triangles formed by the string are equal - see the drawing of the dome. After making sure of the correct position, proceed to the next stage.

Foundation and installation of racks

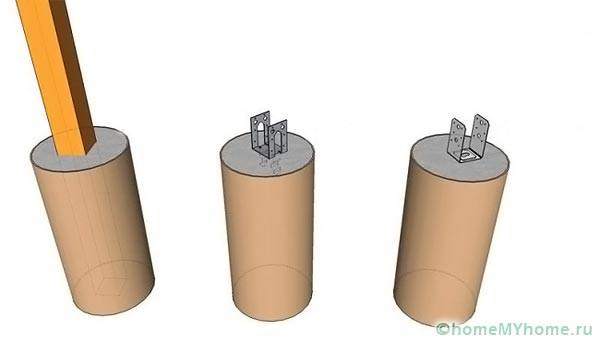

Installation of supports in prepared pits and grouting

Various options for attaching racks to the foundation

For recesses under the rack frame, use a hand drill. By rotating it to a depth of 0.7 m, 6 identical holes are obtained. The ends of the prepared racks are coated with liquid bitumen or wrapped with roofing material to prevent decay. The installed timber is poured with a liquid cement mortar and left to set for about 1 week.

Installation of a strapping bar

Frame strapping

Using the punching method, the upper strapping bar is attached to the paw, and then the lower one to install the sex lags. The knots are reinforced with steel corners. If you use self-tapping screws, then holes of a smaller diameter are pre-drilled, and then the fasteners are screwed in, otherwise the bar will crack.

The finished skeleton of the gazebo

For reliability, a hexagonal gazebo with your own hands, the drawings and dimensions of which are indicated on its own plan, must have an average strapping bar installed at half the height of the object. It will be a reference point for the installation of carved shields.

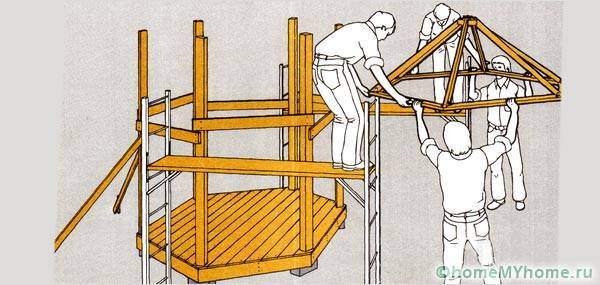

Assembling the dome

Assembly and installation of the dome

The roof is assembled at the bottom and installed completely at once. To do this, the rafter is cut at the desired angle and connected with the ends at one point. The other ends fit into the grooves on the posts, with the remainder outside the gazebo by 30–40 cm to protect against dripping moisture at the time of rains. They are reinforced with bolts - the roof requires reliability. Between themselves, the rafters are reinforced with their own strapping. It remains to fill the crate on the sectors and cover the roof with tiles or ondulin.

Ondulin roof

Installation of floor and fittings

Installation of the floor in the gazebo

Floor logs are fixed to the lower strapping bar in the grooves cut in advance. They should not closely interact with the ground, in order to avoid dampness. Next, the floorboard is laid. From the outside, wooden carved shields are strengthened, and inside, benches are mounted along the walls of the gazebo, unless otherwise provided.

Protection and decor

Impregnation of wood with a protective compound

The finished gazebo is cleaned with a grinding wheel or paper, then impregnated with compounds from moisture penetration and prevent mold and decay. It remains to decorate your own brainchild. It's a matter of taste - the woody pattern itself is already good. However, if secondary materials were used for the gazebo, then it makes sense to varnish the cleaned wood or reveal the pattern with the help of a stain. In extreme cases, paint in dark noble colors.

Complex variants are made on the basis of simple ones. For clarity, a home craftsman is offered a detailed video instruction for assembling a summer cottage to help.

Brickwork technology

Laying the walls of the gazebo

The next step after the foundation will be brick laying. It is carried out both from ordinary and from facing bricks (in the first case, the appearance will suffer).

If you use bricks of different colors, then you can give the gazebo a decorative and sophisticated look.

The bricks are laid on the cement mortar using a trowel. The cement slurry consists of:

- 1 part of M400 cement;

- 3 pieces of sand;

- water (added as needed).

To give the building a complete look, you can use curly lattices as a decor, as well as decorative architectural elements. If wood products are used, then they must be impregnated with an antiseptic in order to avoid rotting and the appearance of mold. Also, products can be varnished.

As you can see, if you try hard, you can achieve the desired result, and then the gazebo will become a source of pride, and using it will bring a lot of joy and pleasure.

Final work

The main part of the activities has been completed, it remains only to erect the railings according to your taste and color, as well as to carry out manipulations to decorate both the internal space and the external. In addition, in the case of making an excessively high floor, especially if children are planning to visit the gazebo, it will be useful to build steps at the entrance. Since the structure being erected is a street structure, it should be protected as much as possible from the harmful effects of natural phenomena.

As you can see, building a gazebo with your own hands at a summer cottage is quite difficult, however, with the right approach and due diligence, the installation process in accordance with the attached instructions can turn into a pleasant hobby for every owner, the result of which will delight every member of your family and guest.

Construction of a hexagonal gazebo

After the diagrams have been drawn up, you can start buying materials. It can be made from metal and wood. Sometimes there are brick options, but it will be more beautiful to make the brick an additional material that will add color to the structure. You can make supports with bricks. A completely brick structure will look bulky and somewhat rough. An example of a gazebo

An example of a gazebo

One of the options is to be made of metal elements. But this will require the use of welding, as well as experience in this direction. To build a structure with your own hands, it will be optimal to use wood as the main material. For the construction you will need:

- Brick from which the foundation will be taken out.

- Cement for anchoring.

- Beams for the manufacture of handrails.

- Lining for cladding.

- Softwood for additional elements.

- Roofing material for your own taste.

Let's give an example of construction step by step:

- At first, the project should be adapted to the existing terrain. Mark the hexagon on which the foundation pit will be dug.

- The best way to make the foundation is brick. You can make a solid base or use pillars. The weight of the entire structure will not exceed 800 kg if it is made in accordance with the following dimensions: each side is 1.7 m long; height - 2.5 m, which is quite enough for convenient operation; roof height - 1 m.

- Support pillars are installed in the corners. If the gazebo is wooden, you can use wooden beams. They must be set strictly vertically so that there is no curvature of the structure. At the bottom, the pillars are connected to the floor, and the top of them must be joined using beams.

- The frame can be made of coniferous wood. The material is little exposed to insect attacks, resistant to liquids.

- Fences are installed along the edges. Railings 90 cm high can be used. They are made of timber. The bottom can be closed with clapboard or sheathed with wooden slats.

- The roof must be selected taking into account the materials that cover the dwelling. As an option - covering with an awning.

- All elements are treated with a composition that prevents decay.

- Adding extra beauty: painting and varnishing.

A gazebo built with your own hands

A gazebo built with your own hands

If you make a little effort for construction, then the structure will delight not only with its appearance. At the very least, there will be pride in the fact that this convenient and functional structure was made by hand.

Below are other options for drawings of a hexagonal building with dimensions. Gazebo option

Gazebo option Hexagonal building

Hexagonal building Gazebo drawing

Gazebo drawing Gazebo drawing

Gazebo drawing