The cost of the set is 8000 rubles. Box dimensions: 90 x 60 x 26 (cm).

Assembling the frame

Where to start?

When you open the parcel, do not rush to cut the rubber bands that tie up the parts of the rocking chair frame, but untie it. You will still need them when assembling the frame.

Take out the contents being careful, as all the screws are on the frame parts themselves.

Attention: bent parts are tied with bow tensioners to keep the bend shape during transportation. Remove them only immediately before refitting.

Otherwise, this can result in additional difficulties in assembling the rocking chair, since even dry bent parts tend to unbend in a free state.

- First, assemble the two side posts made up of three parts.

Connect parts 1 and 2 with super PVA glue. This operation is convenient to perform in a vice. Tighten the screws and wrap the bonding area tightly with a rubber band to squeeze the bonded parts well. The tourniquet can be removed after three hours.

2. Next, three ready-made prefabricated parts are involved in the assembly, which are visible in the photo.

I recommend assembling with a manual screwdriver. This will prevent the screws from turning, which usually occurs when working with electric screwdrivers. Take a screwdriver with a short handle. It will be convenient for you to work with.

3.Now connect the two side posts with a trapezoidal intermediate piece.

4. Next, install the crosspiece.

5. Following the images in the photo, we continue the assembly. Installing the first U-shaped part

6. Behind it we install the second U-shaped part.

7. The next operation is the installation of the front subbeam. Some bent parts have bow tensioners. They serve to maintain the shape of the parts during transport.

Remove the bow tensioner before installing the front underbeam.

8. Now put the wicker seat back in place. But before that, it is necessary to partially braid the frame. Prepare "universal" PVA glue (stationery PVA, which is sold in small tubes, is also suitable), a brush and a stationery awl. Soak the willow tape for 1 minute and it is ready for work. While weaving, dampen the ribbon with a wet sponge. Now, following the pictures, complete the braiding.

Apply super PVA glue to one of the surfaces to be glued, screw the part with screws and immediately tighten the gluing place with a rubber band to press the glued surfaces more tightly. This operation should be performed within no more than 2-3 minutes, since super glue tends to quickly harden on dry wood. First glue one side and only then proceed to the other.

Materials (edit)

The production of wicker furniture is very widespread in the world. Such products are formed from various materials, among which the most popular are:

- Vine. This product is represented by young shoots of willow of small thickness. The material perfectly tolerates moisture, which allows the chairs to be used outdoors. Vine products are especially popular in our country, as it is a fairly affordable material.

- Bamboo is comparable in strength to hardwood. Furniture tolerates moisture very well and is also durable.

- Seaweed. The furniture is woven from special plants that grow in the Pacific Ocean. Algae chairs are pleasant to the touch and completely safe for humans.The material does not lead to allergies, therefore, the cost of products made from it is very high. Algae products belong to the elite class.

- Rattan is a palm tree that can grow up to 600 m in length. The material is completely environmentally friendly, which affects the cost of the chairs.

- Artificial rattan. This product is a plastic tape, inside which silk threads are placed. Artificial rattan chairs are durable and have a low price.

Construction creation

A wicker chair should be durable, the basis of which will be correct manufacturing. The order of forming the skeleton of the structure is as follows:

- The assembly begins with a wooden base. The frame often looks like a single piece that includes the seat and back of the rocking chair. Support legs are attached to it with self-tapping screws.

- To strengthen the structure, cross bars are mounted between the front and rear legs.

- Armrests and other elements are installed on the chair body using self-tapping screws, according to the drawing.

- Once the frame components are securely in place, the temporary attachment is removed.

Braid construction

This fun process begins when the skeleton is fully assembled. The braiding procedure includes the following steps:

- Giving softness to the shanks. To do this, use a cylindrical shape, behind which they throw the vine, stretch it a little and stretch it several times in different directions.

- Coating the braid with two-component glue or PVA. After that, the body of the chair is weaved.

- Frame winding in three rods. This will strengthen the fastening of the structure, and also facilitate the process of carrying out internal weaving, which is performed in different ways: single, openwork or combined.

- Braiding the body using several techniques: pigtail, checkerboard, simple linear, etc.

When the braid is ready, the support skis and supports are attached.

Installation of runners

To increase the life of the rocking chair, it is recommended to install runners that are durable. The procedure is as follows:

- Turn the structure upside down.

- Heat the skis with a hair dryer, place them on the runners one by one and wrap the entire length with cotton tape.

- After the linings have cooled down and have taken the desired shape, glue them to the runners, after removing the fabric. For high-quality fastening, fasten the ends of the planks with nails.

- Allow the glue to harden for 48 hours, then remove the nails and put self-tapping screws in their place. Cover the installation sites with a mixture of glue and sawdust.

Final steps

The finished structure is treated with an antifungal agent and a liquid that will prevent the appearance of wood pests.

To increase moisture resistance, special varnishes with water-repellent characteristics are used. Before covering with a protective agent, the product is given the required shade. To do this, use a stain or paint.

A ready-made rocking chair will bring beauty, coziness to your home and will become a favorite resting place for every family member.

Peculiarities

Wicker furniture has been known to man for a very long time. But recently, its popularity has skyrocketed. It began to be used almost everywhere - from home to large restaurants. Several significant advantages of such products should be highlighted:

- Environmental friendliness. This applies to almost all types of such structures, since the materials used in their manufacture do not emit harmful substances into the external environment. But it should be understood that if the chair is painted, then this may be one of the options to doubt its high quality.

- Durability. The service life of such a chair exceeds 5 years.But these parameters depend only on the material used and production technology.

- Strength. Almost all types of seats are capable of withstanding significant loads. This can be said for both rattan and natural vine. It should also be noted that it is highly resistant to moisture. The chairs can be used both indoors and outdoors (terraces, balconies, etc.).

- Ease of maintenance. To keep the chair looking great for as long as possible, you should periodically wipe it with a slightly damp cloth and remove dust. This will increase the service life by several years.

- Low weight.

Tips for beginners

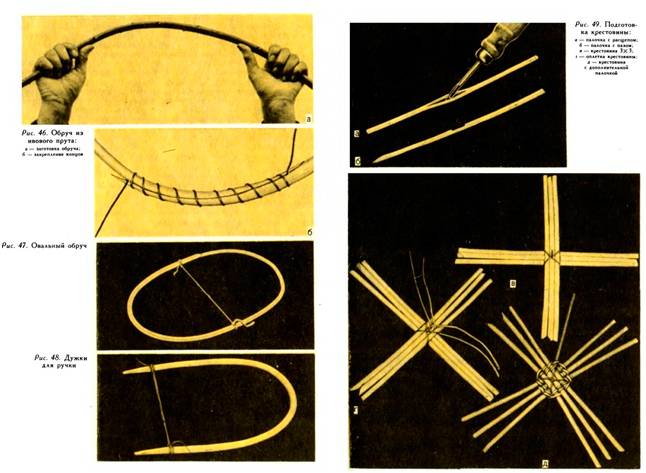

Before you start making furniture from a vine, you need to master the basic techniques and techniques of weaving, which can be carried out in 1, 2, 3 and 4 rods, be straight, oblique, spiral. The basic techniques of simple weaving are braiding, rope, pigtail, herringbone. Openwork can be done with a cross, a rhombus, an oval, a wave, an angle. For the manufacture of one product, all the techniques are hardly needed, so it is better to master the minimum set perfectly, and then gradually expand it. Beginners should not start with openwork weaving, it is more difficult. For a start, it is better to practice weaving dishes in order to master and consolidate the techniques. For example, a flat bottom of a basket and a round table top are woven according to the same principle.

The textbooks recommend making a simulator - insert a row of thick stand-up rods along the edge of a wooden blank. For simple weaving in 1 bar, their number should be odd, for checkerboard in 2 bars - even. On the simulator, you can first practice using a rope or braid instead of a vine in order to understand the principle of operation, and then move on to the rods.

Material preparation

Several types of trees are used for weaving furniture items. Most often it is willow (due to its wide distribution). In addition to her, hazel, rakita, alder and bird cherry are used. Alternatively, a vine from grape or raspberry bushes will do.

The best time to collect raw materials begins with the arrival of cold weather and ends with the onset of a thaw. At this time, the sap inside the tree does not move and the material is easily processed. The harvested vines are kept outdoors in an upright position for 3-5 days.

Sorting of material is carried out based on the purpose of the rods. For the manufacture of the frame of the structure, a vine with a diameter of up to 4 cm is used, for weaving - 0.5-1 cm.

Raw material processing

Weaving from a vine is possible after the harvested material has undergone a certain preparation. The order is as follows:

- Water is boiled in a metal container.

- The prepared rods are lowered into the vat and boiled for 10-12 hours.

- The bark is removed from the stems processed in hot water.

- A thin vine is cut with a spike into several strips (shanks). A cut is made at one end of the rod, into which a splitter is inserted. With this tool, the vine is split into 3-4 ribbons.

- Tires are pulled through a press, resulting in the same size and appearance.

- Thick welded rods are installed in pre-prepared templates, which are made in full size in accordance with the drawing.

- Making a template is easy. A frame pattern is applied to a wood surface (preferably chipboard). In accordance with the scheme, wooden cylinders or pipes are fixed to the base. Bending of the frame rods will be carried out around these fasteners.

- The vines bent in the template are connected to each other for some time with the help of bars or a strong thread.

- A frame with ties, and thin vine bars are placed in a drying chamber.

The complete drying period lasts about 72 hours. After that, they start assembling the rocking chair.

Rocking chair: material and manufacturing features

Let's see what feature this or that rocking chair can have. Initially, natural wood was used as raw material for its production. For the buildup, the former craftsmen came up with the idea of installing skids-skis attached to the legs - they still have not lost their relevance.The current rocking chair, in addition to everything in its design, can be equipped with bumpers or a closing rear arc, the role of which is to exclude overturning during strong swing.

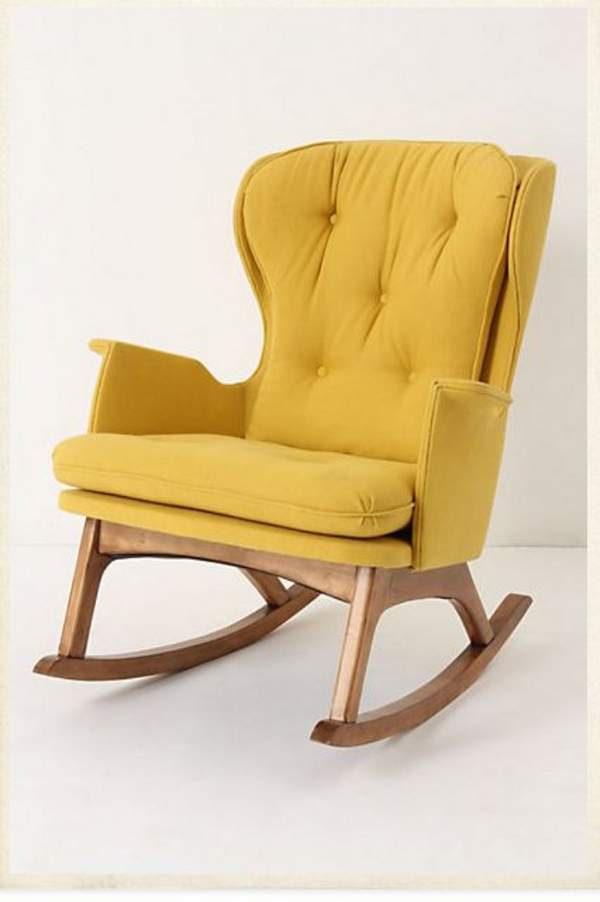

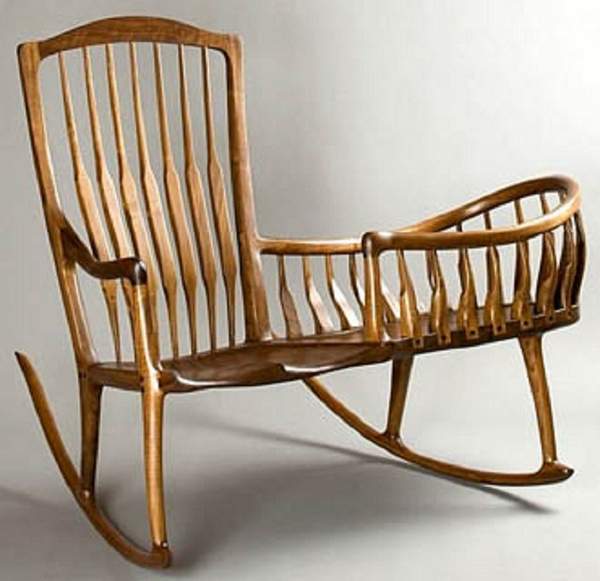

Interesting models, designed for mothers and babies, with a cradle. The most modern version is a multifunctional rocking chair, the photo of which is posted in the article, it can transform from a standard chair to a lounger. You can also see in the photo various design designs that are particularly original.

Materials for manufacturing, today, can be both wood and three-layer dense plywood, flexible plastic, metal, willow rods (vine) and polirotang.

Varieties of rocking chairs

A rocking chair is a convenient, useful item that can be easily placed in almost any room or even a country garden. Such furniture is used mainly for recreation of people of different ages.

The main types of swing chairs:

- massage - used for healing, as it is equipped with massage rollers, vibration elements;

- on radius runners - the most commonly used option, the easiest to assemble, but with strong rocking, such furniture falls;

- on elliptical runners - the product is equipped with bumpers that prevent it from overturning;

- with variable curvature - almost any landing height is allowed here, the probability of an object overturning is low;

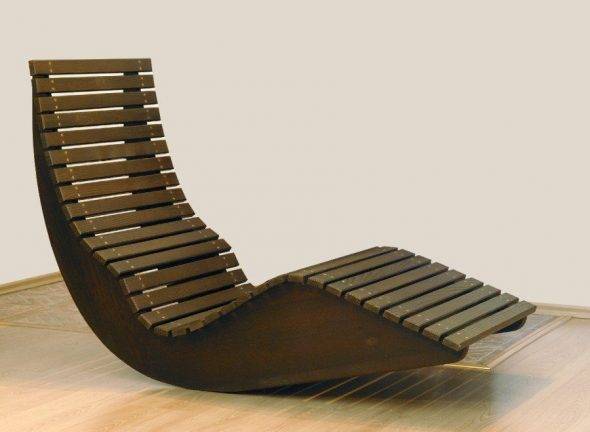

- multifunctional - this is a "three in one" design, with an adjustable backrest inclination, if necessary, it can be turned into a couch, therefore it is used only in large rooms;

- glider is an item of increased comfort with a special footrest, soft armrests, and other elements.

A wicker rattan chair will become an indispensable attribute of a summer cottage, soft, upholstered in leather, leatherette will be located in the office recreation area.

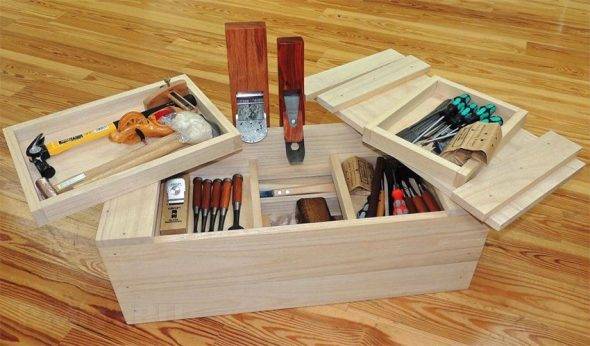

Required tool

We will assume that you have decided to make a rocking chair that is not inferior in quality to the factory rocking chair. Therefore, high-quality tools of labor will also be needed:

- Knife, the end of which is "inclined" to the edge of the blade at an angle of 30-40 degrees. It must be perfectly sharpened, because they will have to work with vines, twigs.

- A tool that is very simple in design is a pinch breaker. This is a twig about 50 cm long and up to 5 cm thick, split at the end. The crusher is used to sand the rocking rods. You can easily make it, and it will be your own tool that you can always work with.

- Plows. A tool to ensure a level surface of seat elements and runners.

- Glue brush.

- Hammer.

- Fixing materials.

Dimensions (edit)

The manufacturing technology of wicker-type chairs does not imply compliance with any standards. Often, all models are unique and differ in many details. As for the sizes, they vary widely.

On the market you can find designs with dimensions:

- 620/1200/1100 mm;

- 620/1350/1200 mm;

- 700/1700/950 mm, etc.

A large number of models are adapted to customer requests. If you purchase a Papasan-type armchair, then it should be borne in mind that its main size is considered to be its diameter. This value can vary from 50 to 200 cm depending on the model.

Where to begin? Preparation of materials and tools

First of all, it is worth deciding on the material. The easiest and fastest way is to purchase artificial rattan for weaving. Then you don't have to waste time looking for and harvesting rods and branches. The cost of such material, depending on the thickness of the rod and the design, can be quite inexpensive. But it will look like natural only externally.

In order for a thing to have all the advantages of furniture made from real wood, you need to be patient. It is necessary to prepare sticks for the frame (diameter - from 10 to 40 mm) and rods (up to 10 mm in thickness). The most suitable tree for weaving a chair with your own hands is willow. Cut branches and twigs between October and April. It is better to choose young trees, they can be found on the banks of the river.You can use birch bark and lime bark to decorate and combine different elements.

Then you need to take care of the tools that will be needed in order to make a wicker rocking chair. The list of essential items is as follows:

- garden shears, pruning shears;

- vat or tank in which the rods will be boiled;

- pliers, awl, knife, screws, screwdriver (with a short handle), splitter, electric drill;

- pencil, ruler or tape measure;

- wood stain, joiner's varnish, brushes.

Having prepared the raw material and tools, you can proceed to the next stage - processing rods and sticks. The fastest way is to boil in a vat for 3 to 4 hours. After that, you need to remove the bark. Thick frame sticks should be sanded. For this, irregularities are processed with a knife and sanded with sandpaper. Immediately after boiling, the sticks for the frame should be measured, cut into pieces of the desired size and given the desired bent shape. To do this, you can use strips of fabric with which the ends of the sticks are pulled together so that they are fixed in a certain position. Very thick sticks will have to be fixed with something like a vice. Now you need to let them dry. This usually takes 3 to 4 days.

Weaver knife

Splinter with three and four incisors

Thin rods are also stripped of bark and split into separate strips. To do this, it is convenient to use a splitter, which is attached to the root end of the rod and, with the help of a hammer, moves along its entire length until it separates it.

Top manufacturers

Making wicker furniture is a complex process that requires special skills. The modern market is oversaturated with manufacturers of such products. Among all this diversity, several popular companies should be distinguished:

- "Athena furniture". The company is a renowned manufacturer and supplier of wicker furniture. The products are distinguished by their unique design and wide assortment. Here you can buy both individual chairs and whole garden sets made of rattan or vine.

- "Obi". The products are highly resistant to atmospheric precipitation, as they are obtained from artificial rattan. Perfect for decorating an open terrace or balcony.

- Beatrice. The company specializes in the production of wicker chairs, armchairs, tables, etc. Artificial rattan is used as the main material. The furniture is characterized by white furnishings and aluminum frames. The products are complemented by high-quality glass and textiles.

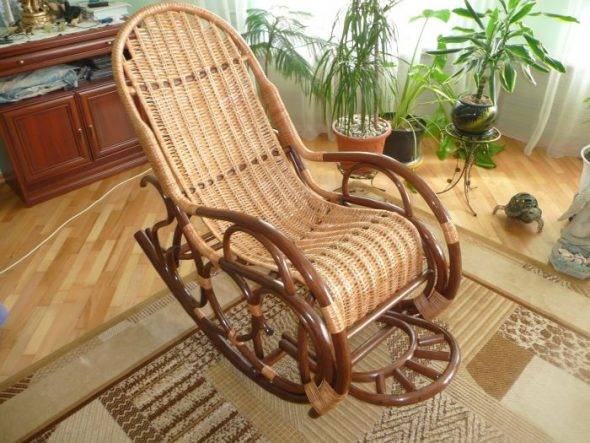

Features and scope

The wicker rocking chair is considered an original piece of furniture that embodies the hearth and comfort. It is a comfortable seat equipped with a backrest, armrests, high stability and low weight. The base of the structure of such chairs is usually semicircular; a vine is used for its manufacture. Thanks to this, while in the chair, you can choose a comfortable position, bend over and swing. For the first time, models of such furniture appeared in Southeast Asia, they were used in the interior design of houses and terraces of landowners, but now rocking chairs have become an integral part of the design in offices, living rooms, offices and nurseries.

Rattan wicker products are ideal for relaxation, as their even, rhythmic and calm swaying has a beneficial effect on the human body, helping to relax tired muscles and joints. To increase the comfort of the chairs, many manufacturers equip them with soft pillows. In addition, this type of furniture allows you to distract yourself from extraneous thoughts and is used during training of the vestibular apparatus.

Popular colors

The design of wicker chairs depends not only on their shape, but also on the external design. Many manufacturers prefer not to change the color of the frame. Therefore, this characteristic often depends on the material used.

So, for example, rattan can be either light golden or brown. As for other natural materials, shades of red, yellow and brown prevail here. Some bamboo chairs have green stripes that form stripes with other colors.

But standard shades are not the mainstream of design. Today, furniture is coated with special varnishes or paints to change the color. Therefore, you can find both white and black armchairs on the market.

It is important to take into account the type of paints and varnishes that must be safe for human health. It should be noted that artificial rattan is made in almost any shade, which allows you to select products to suit your taste.

7photos

How to choose?

Before you buy a wicker rocking chair for a summer residence or apartment, it is important to determine its purpose and take into account the design of the room where you plan to put it. To make the right choice in favor of a particular model

The following factors should also be considered.

Price. Usually, products made from natural raw materials are expensive, but they are environmentally friendly. If you buy furniture at a low price, then you need to be prepared for the fact that it is most likely of poor quality and contains harmful substances in the decoration. To avoid this, it is recommended to ask the seller for a quality certificate.

Quality. All joints in the design of the rocking chair should be small. If a slight creak occurs when using the product, then there is no need to be frightened. It is it that adapts to the physique and weight of the future owner.

It is important to check the density of the weaving of the vine.

Do-it-yourself rocking chair from a vine

Many people, no matter young or old, love or at least dream of wrapping themselves in a warm blanket on a pleasant winter evening and watching their favorite movies on DVD, sitting in a fabulous rocking chair. This picture can also be supplemented with wood burning and crackling in the fireplace and a cup of hot chocolate, tea or coffee.

And if the latter, along with a blanket, is not difficult to organize for yourself in one evening, then with a fireplace and a rocking chair, things are much more complicated

This picture can also be supplemented with wood burning and crackling in the fireplace and a cup of hot chocolate, tea or coffee. And if the latter, along with a blanket, will not be difficult to organize for yourself in one evening, then with a fireplace and a rocking chair, things are much more complicated.

The fact is that people who have their own houses, a garden and a vegetable garden, having seriously thought about buying this type of furniture and going to a specialized store, sadly discover that the prices for this type of product are very burdensome for the budget of an average family.

In this case, the best way would be to build a rocking chair with your own hands from a vine. Moreover, having received the necessary information, it will not be difficult to cope with the task.

Diy rocking chair diagram.

Vine rocking chair: how to make?

The first thing that comes to mind when you start doing something with your own hands is the question of acquiring the material and tools necessary for work.

In this particular case, the rocking chair must be very lightweight, mobile and the structure must be characterized by a particular flexibility, which can only be achieved after the use of appropriate materials.

Someone can make it out of metal, but this process will be too long, expensive and, most importantly, will require special tools, which will have to spend additional money.

Start assembling the frame with two side posts, which have three parts.

Wicker rocking chair options.

It is better and more convenient to connect the parts with PVA glue. It will be more convenient to perform such an operation in a vice.

Then tighten the screws tighter and wrap tightly around the joint with a rubber band so that the parts to be glued have a chance to adhere well to each other. This tourniquet can be removed in three hours.

To do this, stock up on screws and a manual screwdriver. This will eliminate the possibility of turning the screws, which often happens when working with an electric or automatic screwdriver. It is more convenient to take a screwdriver with a short handle.

Now connect the side posts to the intermediate trapezoidal piece. To organize the backrest on furniture such as a rocking chair made of a vine, it is necessary to use a cruciform piece, again from a vine. It should be fixed between the two side panels.

It is recommended to remove the existing bow tensioner before installing the front underbeam.

Rocking chair: seat and backrest fasteners

Rocking chair drawing.

Now you can install the wicker seat in the resulting place. However, before that, it is worth partially braiding the frame. For this process, prepare universal PVA glue, a brush, a sponge and a stationery awl. The prepared willow tape must be soaked for no more than 1 minute, and you can start working. In the process of weaving, the tape, if necessary, should be moistened with a sponge dipped in water.

The next task is to install the lumbar part. The bow tensioners can only be removed after the part is attached to a suitable location. By turning the boom, it will be possible to adjust the degree of alignment of the parts to be fastened together.

Then PVA glue is applied to one of the surfaces to be glued, after which the parts are screwed in with screws and immediately the place of gluing is tightened with the existing rubber band in order to ensure a more tight pressing of the surfaces glued to each other.

This operation is performed no more than 3 minutes, as superglue hardens quickly when used for gluing dry wood. First, one side is glued, and only then you can proceed to the other.

When all the parts are glued together, all that remains is to tighten the screws in those places of the frame where the back is fixed. On this, a self-made rocking chair from a vine is considered complete. All that remains is to cover it with alkyd furniture varnish.

It will strengthen the structure and improve the appearance.

Rocking chair materials

There are many materials from which the chair can be made. There are popular models most commonly used in the manufacture of rockers.

Consider all possible options and dwell on the most popular in more detail.

- Willow vine is an easy-to-manufacture material, it looks beautiful on a finished product, the main drawback is moisture intolerance, i.e. it is not recommended to install it outdoors.

- Rattan is a liana native to Southeast Asia, in beauty they are not inferior to willow materials, but not durable. When working with rattan, glue and special knitting are used - you cannot use nails, screws.

- Forged metal is a durable and durable material, forged products are decorated with a variety of metal patterns. Exclusively outdoor version of the rocking chair.

- Soft (leather) parts - there are plywood rocking chairs covered with other material, for example, leather - they can be attributed to strict office options;

Some chairs can be easily transformed.

So, the most popular materials are rattan and willow. Let's try to understand their properties.

Rattan is a liana from the palm family that grows in a humid region, its structure is porous and moisture resistant. Rattan is not afraid of rains and furniture from it is often installed in garden plots and yards. Furniture made from this material is environmentally friendly, beautiful and comfortable. However, due to porosity, the material can quickly fail, and the repair of such furniture will cost half the cost of the product.

Its wood is very flexible and amenable to processing.

Willow is a well-known tree for all of us, the structure is homogeneous, accordingly, such a material is less flexible in comparison with rattan.It is also not recommended to leave the willow vine chair in the rain, as the structure of the wood can swell and deteriorate. In rattan, the porous structure does not allow using anything other than glue, so you have to fix the lashes with special knots. It is also worth noting that willow material will come out much cheaper than rattan.

In the manufacture of willow furniture, craftsmen use self-tapping screws and special glue.

Now, knowing the main indicators of different types of wood, you can decide for yourself which of the materials is closer to you and is right for you.

The variety of materials allows you to create a large number of excellent copies.

To make a rocking chair with your own hands, especially if this is your first such job, the easiest way is from plywood. As a first experience, we recommend using maple plywood, as it is a very hard material with a high density and beautiful texture - pattern.

With this type of material, making the chair will bring you great pleasure.

Let's consider the features of working with plywood. For the strength of the structure, three layers of plywood are used, and the middle layer should be twice as thick as the extreme ones, for example, if we need a total thickness of 20 mm, then we glue 5-10-5 mm, we need to glue it with a special waterproof glue and can be additionally strengthened with small nails.

When connecting parts, you can use self-tapping screws in addition to glue.

Also, the structure of the plywood allows you to design unusual shapes. It is enough to draw the desired workpiece and cut it out with a jigsaw.

Also, when working with plywood, it is important to take into account that it must be impregnated with a water-polymer emulsion and varnish at least twice.

Such a product will be much stronger and more resistant to external influences.

Below we offer for consideration step-by-step instructions on how to make a rocking chair with your own hands. Consider 2 options for chairs, for both we will use plywood as the main material

Before starting production, it is important to decide on the necessary equipment so that your work does not stop in the middle of the cycle due to the lack of some materials or tools. So, you need:

- Templates for parts of the frame;

- Plywood boards and bars;

- Jigsaw;

- Reed threads;

- Grinder;

- Screws, small nails, screws;

- Sandpaper;

- Drill - for drilling side holes;

- Water-repellent impregnations, varnishes.

DIY tools for creating a rocking chair.

Weaving materials

Today, wicker chairs are made from a wide variety of materials, each of which gives the product its own advantages and disadvantages. This furniture is most often produced from vines, rattan, but the following raw materials can also be used:

- spruce, fir and pine roots;

- bark of birch (birch bark) and linden;

- bamboo.

This material is characterized by light weight, varying thickness, beautiful shade, but expensive. In this regard, many manufacturers began to use not only natural, but also artificial material for weaving furniture. It outwardly does not differ in any way from natural, but the cost for it is available for all categories of the population.