Materials (edit)

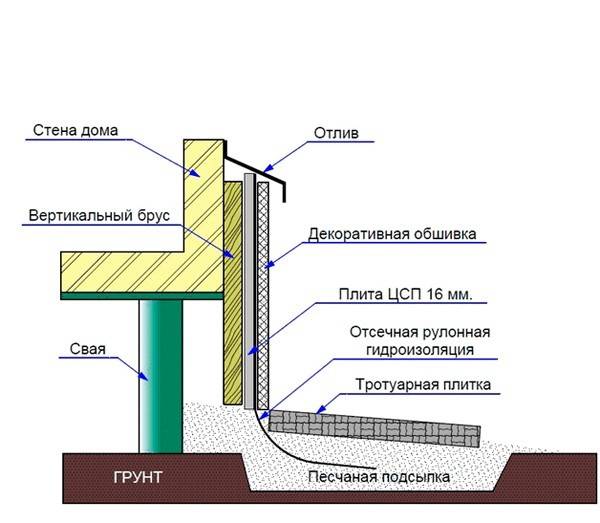

The hinged plinth is lightweight and does not require any excavation work

The hinged plinth is lightweight and does not require any excavation work

Consider how to close the pile foundation from the outside

It is important that the material used for finishing is durable and frost-resistant, does not lose its qualities under the influence of temperature extremes and ultraviolet radiation.

More reliable is the finishing of the basement of the pile foundation with stone, brick, cinder block, concrete. This will require the implementation of earthworks like the device of a shallow foundation.

The hinged structure is lightweight and does not require excavation work. Polymer, wood and composite materials are used, which are quick and easy to assemble.

Basement siding

The most commonly used for finishing a screw foundation is basement siding.

The most commonly used for finishing a screw foundation is basement siding.

It is produced in the form of decorative panels with a thickness of 1 to 2.5 mm.

Advantages:

- the ability to use in any climatic zone, including in the north;

- resistance to mechanical stress;

- light weight, ease of installation;

- has low thermal conductivity, retains heat;

- durability 40-50 years;

- does not collapse under the influence of moisture, ultraviolet radiation.

The possibility of facing the foundation of a house with semicircular shapes is provided. For this, a technology was launched into production, thanks to which the material is easily bent. The panels are produced with a small thickness (1.1 mm) with the addition of synthetic threads.

Profile decking

One sheet of corrugated board will cover a significant space

One sheet of corrugated board will cover a significant space

Sometimes the question arises of how to close the screw piles so that the work can be done during the day.

In 4-7 hours, you can close the pile foundation with profile sheets.

The width is available from 1 to 4 m, due to this, a significant space can be covered with one sheet.

Advantages:

- polymer coated sheet has a service life of 30-50 years, galvanized sheet serves for 10-15 years;

- available in various shades and sizes;

- a light weight.

The disadvantages include:

- in places where the coating is damaged, the sheet is subject to corrosion;

- the zinc coating gradually evaporates.

Flat slate

Asbestos boards are not environmentally friendly material

Asbestos boards are not environmentally friendly material

Every year this material loses its popularity, it is being replaced by modern, environmentally friendly materials.

Advantages:

- resistant to atmospheric influences;

- durable.

Disadvantages:

- asbestos is dangerous to human health and pollutes the environment;

- fragile;

- unattractive appearance.

Frame system

It is a budget option. For the installation of the battens, we use vertical racks made of timber (metal) with horizontal rails and metal profiles attached between them. We attach the acrylic and vinyl siding to the prefabricated frame. For more information on how to close the basement space in a house on screw piles, see this video:

Leaf system

Tiles can be laid on the mounted profile

It is cost effective to use a sheet system.

Stages of the device:

- we fix vertically a metal profile (corner, pipe) or a wooden bar;

- we fix cement-bonded or asbestos-cement slabs;

- we lay tiles, porcelain stoneware, bituminous tiles on the slab.

Composite materials

We use as a composite material:

- lightweight polymer-sand panels reinforced with cellulose threads;

- fiber cement sheets have great strength, reliability;

Facing brick

Facing brick

Facing brick

Brickwork is a reliable but costly and time-consuming method of finishing a foundation on screw piles. To correctly and evenly lay the cladding, you need to have construction skills.

Advantages:

- durability, strength, reliability;

- high thermal insulation qualities;

- additional support for housing construction;

- aesthetic appearance.

Disadvantages:

- high price;

- labor intensity.

How to close the basement space with a brick:

- remove the fertile layer by 30-40 cm;

- we fall asleep a pillow of sand, crushed stone, ram;

- we insulate the sole;

- we put a brick.

The masonry should be connected with piles by means of metal pins. The metal is welded to the lathing, adhered to the brick by means of cement mortar.

Flat slate

Previously, flat slate was used in almost all types of finishes. Now this option is used in rare cases, as it is considered unreliable. Among the main advantages, it is worth highlighting:

- the possibility of self-installation with a special set of tools;

- increased resistance to decay and negative environmental influences;

- slate allows the use of thermal panels for insulation;

- practically unlimited service life.

However, this type has many disadvantages. The main ones are worth highlighting:

- Increased fragility of the material. It is quite dense, but with improper cutting or poor-quality drilling, the slate crumbles and collapses.

- Increased difficulty of fastening to piles.

- The price for flat slate is significantly higher than for most other materials.

- Requires additional work using other materials to give the slate a presentable look.

Thermal insulation of the screw foundation

One of the main negative characteristics of this technology for creating a foundation for a house is that the foundation structure on screw piles has an underground space, and this, in turn, promotes the penetration of cold air from below, which will certainly affect the comfort and microclimate throughout the building.

The implementation of thermal insulation of the foundation on screw piles has its own characteristics. The first step is to create a structure like an absent base, which is subsequently insulated. Insulation must be carried out in a complex - from the inside and outside.

The scheme of thermal insulation of the foundation with expanded polystyrene.

So, the whole thermal insulation procedure is divided into the following stages:

- treatment of piles with a waterproofing agent;

- construction of a structure that will replace the capital base;

- sheathing of the constructed basement with decorative panels;

- installation of insulation plates from the inside of the base;

- foaming the joints of the insulation.

Experts recommend two ways to build an imitation basement:

- lightweight brickwork;

- the use of support bars or rails.

The first method involves digging a small depression (150-200 mm) between the support posts, then pouring a reinforced foundation in it. After it grabs, it is necessary to lay in half a brick and glue the insulation material on this wall.

The second method consists in fixing wooden beams on the piles in a horizontal position using bolts or metal guides, but then a welding machine will be needed. After that, insulation sheets are attached to the constructed structure. According to experts, the insulation can be fixed directly onto the cladding material. It is best to use penoplex or polystyrene as a material for insulation. In addition to excellent thermal insulation properties, these materials have good sound insulation.

Basement siding

A building on screw piles is the easiest and cheapest to sheathe with such material. The cladding has the following advantages:

- low cost (even taking into account the components);

- ease of do-it-yourself installation;

- durability;

- wear resistance;

- resistance to decay and mold;

- a wide range of colors;

- ease of use.

Basement siding

Basement siding

But along with the advantages, siding also has a number of disadvantages. For example, it will not work if you need to insulate the basement of the house on screw piles.

Installation technology

It is quite simple to make the cladding of a house, you just need to know the order of work and the nuances of their implementation. The base / plinth arrangement is carried out in the following order:

- Installation of lathing for siding. First of all, the lower bar is fixed. It is parallel to the ground. The distance from the soil surface is set equal to 150-200 mm. Such a gap is necessary to raise the skin above the ground. The distance from the panels to the ground after installation should be 50–70 mm. This layer compensates for soil swelling in winter. In warm regions or on coarse substrates, the gap can be reduced.

- Wooden boards are attached to the piles. To do this, special brackets must be welded to the heads in advance. Also, as a frame, you can use a metal profile, which is welded to the foundations without additional elements.

- Similarly to the first, a plank is fastened in the upper part of the basement of the house on a screw foundation.

- A vertical crate is sometimes made between the longitudinal guides. The need for it depends on the height of the base. With a high rise of the building from the ground, it is worthwhile to provide additional elements as reinforcement.

- Siding begins to mount from the bottom starting bar. Basement panels are installed on it. The elements are fastened to the crate using self-tapping screws. For the device of the corners, special profiles are required.

- To divert precipitation from the basement, ebb tides are installed on the siding.

- The finishing of the lower part of the house is completed after the clearance between the ground is made. The space must be closed so that there is an opportunity for air to enter, but small debris, insects and other living creatures did not have access.

All wooden elements are treated with antiseptic compounds before starting work. This is necessary to prevent damage by fungus, mold and decay. As an additional measure, fire retardant treatment can be performed.

Siding is the most common option. In this case, finishing the building is easy and fast. The device should be started after the completion of the construction of the house, when all communications have already been connected. To prevent the pipes from freezing in a ventilated underground, they are wrapped in heat-insulating material. Most often, mineral wool is used for these purposes. You can use ready-made elements of thermal insulation for pipes, or you can make insulation using mineral wool mats (wrapped in rolls).

Pay attention to the soft waterproofing of the blind area

Siding is a great option to close the space under the house. To fasten the panels to the crate, it is necessary to prepare self-tapping screws.

Other options for finishing the basement of a house on screw piles

In addition to basement siding, the finish of the basement of the screw foundation can be made from other materials. At the same time, they have advantages and disadvantages, having familiarized themselves with which, everyone chooses the appropriate option.

Brick finish

Brick is considered a reliable building material. But to make an even and high-quality masonry, you need work experience. Therefore, for such a case, it is better to use the services of professionals.

The cladding is laid on a concrete base or on a metal beam, which will act as a support. It is imperative to leave ventilation gaps in the brickwork. The process takes time and money.

Plastic panels

This option is an affordable and quick way to finish a basement. The panels are versatile and can be attached to any foundation. They reliably protect against external influences, including biological and chemical. The finish is flexible because it can withstand heavy loads.

Corrugated board

Another way of arranging the basement is corrugated board.For wooden and frame houses, this option is not suitable, because the material is hardly considered universal. But it is durable, excellent protection from wind and water. Installed on the crate, which makes the process quick and easy.

Flat slate

The appearance of such a finish wants to be the best. But slate is used as a base for other decorative finishes, such as tiles or special plaster.

Several options for such a finish can be seen in the photo on the Internet. The asbestos-cement sheet is fixed with slate nails or bolts. But during installation, you need to remember that slate is quite fragile and does not withstand strong blows.

Cement particle board

Instead of flat cement boards, cement-particle boards are chosen. They are more durable, but at the same time lightweight. They are much easier to work with. DSPs are easy to drill and cut. Nails and screws are used as fasteners. It is an excellent base for decorative material.

Moisture resistant plywood

This is another option that is used as a base for decorating. Plywood is suitable for the construction of frame houses. The material does not deform when exposed to water. Some craftsmen do not even apply a primer before applying the cladding.

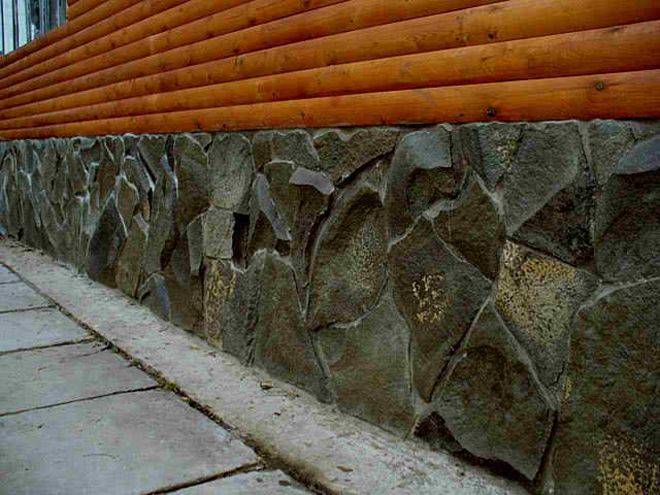

Facing the plinth with a stone

It doesn't matter natural or artificial stone, but it is difficult to lay it. Therefore, it is better to use the services of a professional team.

The material is reliable, durable and resistant to all external influences. But natural stone will be quite expensive, while artificial stone will be cheaper.

Finishing types of screw pile foundations

There are quite a few finishing options, but there are only two types:

- hinged type screen;

- shallow strip foundation.

Screw pile foundations form a basement or basement. With the help of piles, a small space is created between the soil and the lower supports of the structure.

During the construction process, the foundation is closed with a hinged or tape structure. With the help of this, a semi-basement room is obtained, which is subsequently used for its intended purpose.

Closing the plinth is necessary. Screw piles are used in three ways:

- screw compartment at the tip;

- fully screw construction;

- blade tip.

With all these options, the hinged type is more often used, which is the most popular. This is because the hinged screen is more practical and easier to install. Sometimes mixed options are used when a secondary foundation is laid between the cladding. This is especially true when insulation is required.

Also, regardless of what types of piles or the method of sheathing were chosen, to strengthen the base, a crate from a profile pipe should be used. The profile can be selected in accordance with the parameters and lower elements of the house, including pile sections. This must be done for durability.

In this video, you will learn how to close the plinth:

Finishing largely depends on the type of building and the requirements for the basement floor

The availability of materials is also important. Each type has its own characteristics due to different installation work

The hinged version aligns with the walls of the house and does not sink into the ground. Fastening occurs due to self-tapping screws and other additional elements.

The standard installation time is equal to days, installation is simple and economical. The finish can be in the form of any material, including stone or wood.

For a strip foundation, a certain set of materials will be required. Typically, such a foundation is built using masonry or brickwork in conjunction with concrete elements.

This type of finish is deepened into the ground, for this reason certain properties of the soil under the house are required, as well as a flat surface in the area where the bearing piles are installed.

The ways

A screw pile is a metal pipe with a thread at one end and a flat head at the other, somewhat reminiscent of a huge nail. Piles can be up to 2.5m long and have blades at the end rather than threads or threads throughout the body. To prevent corrosion, the products are covered with ship's soil - black.

The empty space under the building not only does not look aesthetically pleasing, but also poses a threat to the structure. Evaporation of wet soil, falling of snow and rain under the building, germination of grass - all this does little to preserve the building, and small animals, from lizards to cats, willingly use this space.

But how the basement basement is insulated from the outside, and how to do the work with your own hands, can be seen here.

On the video finishing of the base of the pile screw foundation:

Finishing allows you to solve the listed problems. The general principle of cladding is very simple and cost-effective.

- First of all, the crate is mounted. It is allowed to use a wooden beam pre-impregnated with an antiseptic and a metal profile. The latter option is much more durable, since the tree will not withstand constant contact with wet soil. But how the crate for siding occurs is described in more detail in this article.

- The dimensions of the frame are determined by the dimensions of the finishing sheets.

- Insulation is attached to the frame, if necessary, and then the selected finishing material is mounted.

But how the foundation is insulated from the outside with penoplex, and what you should pay attention to during work is indicated here. Brick, basement siding, and even simple plaster are used as cladding.

Brick, basement siding, and even simple plaster are used as cladding.

Brick finish

This is the most expensive method, and it also requires certain knowledge and skills. If they are there and the costs do not scare the owner of the building, then this option is easy to implement. He has a lot of advantages:

The disadvantages include the cost of such a solution and the duration of installation: masonry takes time.

Basement siding

This option successfully imitates brick and masonry, but at the same time it is much lighter and costs much less.

Basement siding is a vinyl panel with increased strength and rigidity. It is distinguished by a more reliable docking method and high resistance to wind loads.

Their advantages are as follows:

- ease of installation - finishing can be completed in one day, and on its own;

- relatively affordable cost;

- an excellent choice of colors and textures, you can choose the best option for any type of building;

- strength and good durability: plastic does not rot, does not corrode, is resistant to ultraviolet radiation and is designed for 50-60 years of service;

- the plinth can be cleaned with plain water or detergents.

It will also be interesting to learn about how the basement of the house is insulated from the outside with expanded polystyrene.

The only disadvantage is that the basement panels are still inferior to brick in terms of durability.

Corrugated board

This is a metal profiled sheet with a zinc coating that protects the steel from corrosion. It can be painted in a variety of colors, has a thickness of 9.5 to 0.7 mm and is more than affordable.

Material pluses:

- these are lightweight materials, so there are no difficulties with installation;

- the finishing process itself takes several hours, no more;

- low cost;

- complete fire safety;

- rich colors.

Disadvantages of the product:

- The corrugated board is afraid of damage: a deep scratch damages the polymer coating and the zinc layer. As a result, moisture can get to the steel and in such an area the metal begins to rust;

- leaf shape varies within very small limits;

- the paint loses its intensity and shine over time;

- In fairness, such cladding is only suitable for buildings finished with plastic or metal slats.

And this is what it looks like corrugated canopy adjacent to the house, and how it can be done, you can read and see the video in this article.

On the video finishing of the base of the pile screw foundation with corrugated board:

Decorative plaster

This option can only be carried out together with the insulation of the basement. Its essence boils down to fixing a heat insulator from a dense material to the frame and applying a plaster layer on them.

The plates are pre-primed. It is better to use silicone or fiberglass as a plaster mixture, since they are most resistant to moisture. And here is how facade plaster is used on polystyrene, you can see here.

Communities ›DRIVE2 Na Dacha› Blog ›Closing the pile-screw base.

All drayvovchanam fiery summer cottage greetings. I went through different variants of the subject, as a result I stopped at this. To embed it with extrusion and close it with Aceid. On top of the aceid, you can then stick anything or just paint it. And so, in stages. We dig a trench 30-70 cm deep, depending on how heaving the soil is. We have clay with mel1971, so I dug 50 cm (I didn't have enough strength for more).

The upper board goes along the top of the piles and is attached with self-tapping screws directly to the harness of the house, the lower one is parallel to it above the ground level by 5 centimeters at the lowest point.

Since the piles protrude or go away from the vertical in one way or another, we adjust the intersections with the lower board so that they are in the same plane from the upper one.

Creating a shallow tape plinth

Stage 1. Preparatory work.

Before starting work, a trench is dug around the perimeter of the house, the depth depends on the type of soil, usually 30-60 cm is made, after which a sand cushion with a thickness of 10 cm is poured onto the bottom of the trench.

2. Stage. Formwork creation.

This stage is typical for any type of monolithic base. Planks are most often used to create formwork.

3. Stage. Reinforcement

For reinforcement, metal rods with a diameter of 10-16 mm are usually used, which are laid along the entire trench

4. Stage. Fill.

The formwork is filled with concrete. You should be careful not to allow the formation of voids in the concrete, compacting the poured solution every 20-30 cm. After 2-3 days, the formwork is removed, the top and side are waterproofed with mastic or roofing material.

5. Stage. Masonry.

On the finished shallow strip foundation, brick or cinder block masonry is laid, vents are created, the brickwork is brought under the log.

6. Stage. Finishing work.

After the whole structure is ready, the front part of the basement is finished (plaster, sheathing with decorative stone or panels).

When sheathing the plinth with siding, you should use a metal crate, and in the formed cavity, between the plinth and the siding, place a heat insulator. This will allow the basement of the building to be insulated to a high degree.

Conclusion

In conclusion, I can say that there are many options for closing the basement of the foundation made of screw piles. Everything depends on the financial component, the type of soil and the terrain. In most cases, the hinged type of base wins, since it gives a wide choice in the use of materials, is suitable for any area, independent installation is possible, and most importantly, you will save the family budget. I hope this article will help you make the right choice in such a difficult issue as closing the base of a foundation made of screw piles.

How to make a hinged plinth with your own hands?

Soil preparation

Soil preparation

- The site is cleared of vegetation and debris.

- A 50 * 40 cm trench is dug along the perimeter of the screw foundation, the inner border of which goes under the walls of the house. The bottom of the trench deepens in the direction from the walls by 3 cm. Every 2 cm.

- The moat is waterproofed. Possible materials: roofing material, galvanized steel, PVC film.

- Drainage is installed - perforated polyvinyl chloride pipe. Lay it on a 10 cm layer of crushed stone.

- Drainage wells are brought to the surface to flush the system.

- The drainage is covered with rubble (10 cm).

- A sand pillow is formed along the perimeter with a slope from the walls with a thickness of 10-50 cm.

- A blind area is being constructed - a waterproof strip along the perimeter of the house with a slope from the walls. Purpose - protection from rain and melt water. Width not less than 50 cm. Materials: concrete, asphalt, paving stones, tiles.

Suspended structure - frame for finishing

- Guides are attached to the piles with self-tapping screws or welding, for example, wooden beams, metal profiles. Metal parts are installed in the immediate vicinity of the ground. The step between the vertical guides is 90 cm, between the horizontal guides - 45 cm. For the plinth, it is recommended to use a horizontal crate.

- The crate is constructed from metal corners, wooden boards or pipes. The lathing covers the visible part of the screw foundation. First, the starting bar is attached at a height of 15-20 cm from the vegetation layer, then the vertical slats are mounted. The step between the slats is 40-45 cm.

- The wooden frame is treated with a protective compound, for example, an antiseptic.

Finishing

- Finishing materials are fixed on the crate layer by layer: from insulating to decorative. Insulating: asbestos-cement slabs, sheet slate, thermal panels. Before small-piece finishing, for example, natural stone, plinth panels are installed. The base is polystyrene or thermal insulation polyurethane foam.

- The corners are formed to match the corners of the house.

- Seams are treated with a protective compound such as a sealant.

- Additional elements, ebbs, drippers are installed - optional components.