Let's get down to preparatory work

Without preparing the facade for work, you should not start cladding. Remove obstructions such as window shutters, external sills, cornices, window sills, drain pipes. Seal old cracks with mortar or foam. Mold, rot, old paint, and peeling plaster should be removed from a home built long ago.

After that, treat the walls: with a fire retardant, antiseptic, the walls of a wooden house, with a special primer, brick or concrete. Further, it is necessary to carefully examine the facade in order to understand whether the cladding of the facade with siding needs an additional frame. It may not be installed only for smooth log walls, in other cases, especially when insulating, its installation is mandatory.

Installing the frame

As we just said, in most cases you need a frame: from slats for a log house and from a galvanized profile in the case of concrete or brick walls of the house.

So, how to sheathe the facade of a private building with siding:

- make a marking of lines for a closed contour using a tape measure and a level;

- put a mark on the lower point of contact between the wall and the plinth, making a second contour, where in the future we will set the initial bar;

- layers of hydro and vapor barrier of a wooden house are laid with do-it-yourself siding;

- between the crate, layers of rolled mineral wool or foam plates are laid, if necessary, fixed with clamps.

Plinth trim

If you want to use this material for finishing the basement, use the following instructions:

- install horizontal profiles on the frame;

- attach the initial strips on top;

- measure the supporting parts with a level and a corner;

- fasten the profiles and knees together;

Attention: for a strong fastening, use a dowel-nails up to 8 cm long for this process. if you want to end up with a stable base, fix the profiles horizontally

if you want to end up with a stable base, fix the profiles horizontally.

Recommendations for beginners

If this is your first time faced with the need to perform cladding with such material, and are not sure how to properly sheathe a house with siding, study the following material:

while fixing the panels, observe the gap between the siding and the self-tapping screw of 1 mm

Attention: if finishing the house, forget about the thermal gap, the finishing will soon be covered with cracks due to expansion when heated. leave 0.3–0.5 cm of space between the edge and end joint;

leave 0.3–0.5 cm of space between the edge and end joint;

Tip: if the cladding of a frame house with siding is done in winter, the gap distance is increased due to the temporary compression of the material.

fasten all self-tapping screws in the center of the hole, with the exception of one at the top of the pediment, which is driven into the center of the panel itself and the self-tapping screws of the upper panels.

Without these simple rules, the technology of siding the house with siding will be incorrect, and the frame will not hold the material well.

Let's start cladding the facade with panels

Step by step, you have come to the main point that siding has - fastening the main panels, for this:

- attach the initial profile using the level;

- put panels on it, attach each of which to the crate;

Attention: the mount is done using self-tapping screws in the color of the siding, when choosing which, attention is drawn to the cap - for strong fastening, it must be large and with corrugations

- fasten the panels from the bottom until you reach the pediment;

- assemble the cornice, for which serifs are applied to the pediment and the installation of the starting panel;

- attach the crate to the bar;

- mount the cornice with self-tapping screws.

Next, the pediment is finished. The place of the facade from the eaves to the roof is called the pediment or attic wall. The finishing of the pediment is almost identical to the finishing of those parts of the house that we have already done.

What to do with openings

For finishing the slopes of doors and windows with panels, if present, there are special accessories that include the following elements:

- slope profiles;

- window aquilons;

- platbands and others.

For facing slopes, after repairing windows and doors, you can use two mounting options. Ways to sheathe slopes with siding:

- on the side - it is more reliable to protect against moisture;

- end-to-end - has a more beautiful appearance.

Against the background of the complexity and high cost of implementing the previous options, the technology of siding a wooden house can exclude them. To do this, frame the frame along the perimeter of the opening and arrange it with a J-profile. In this case, the siding bypasses the slopes, which are lined separately using a different technology.

We mount J-profiles

The starting guides must be perfectly secured because the quality of the entire cladding depends on the correctness of their installation.

Starting profiles must be installed strictly horizontally

First step. Take the level and find the lowest point on the crate. We step back from it up to 50 mm and put a mark. To do this, screw a self-tapping screw into the rail a little.

Second step. We consistently move around the building and continue to put marks with self-tapping screws to fix the starting profiles. We also screw in self-tapping screws in the corners of the house.

Third step. Pull the rope between the corner marks.

Fourth step. We mark on the rails the boundaries of the installation of the corner profiles. We take the profile itself, apply it to the corner of the frame structure and place marks along the edges with a pencil.

Mark the location of the edges of the fastening strips on the battens

Fifth step. Moving further along the rope, we make a 6 mm horizontal gap from the edge of the corner profiles and fix the starting guide to the frame rails.

Leave a gap between the starting guides and the nail strips.

Technological indents when installing starting siding profiles

In order not to make a 6 mm indent, you can cut off parts of the nail strips so that during temperature changes they do not rest against the J-profile.

Instead of an indent, it is possible to cut the profile fixing strips

If you set the guides with deviations from the level, the siding will also warp. It will be extremely difficult to fix this in the future.

How to work with siding

After installing all the profiles and checking the building level, you can start fixing the panels. Siding installation is carried out in several stages.

- First element. At first, it is better to revet the most inconspicuous part of the facade. This will help you practice, and if there are small defects, you can leave them without alteration. It is necessary to mount the panel in the grooves of the corner profile and the lock of the starting rail. In this case, it is necessary to step back 6 mm from the bottom edge of the corner product and fix the element as indicated in the instructions.

- Extension of panels. At this stage, it is necessary to build up the products with an overlap or by means of a special H-shaped profile. In the first case, you need to cut the fastening frames and locks, so that you end up with an overlap of 25 mm. If a rail is used, then the build-up occurs in the same way as the installation of corner profiles. In this case, there must be a 5 mm gap between the element and any obstacle.

- Installation of other parts. Further cladding with siding is carried out using the same technology as the installation of the first panel. When the process comes to the openings, you just need to apply the part and mark the part that enters the window or door area. You need to cut it off and install the panel. An additional platband is installed in the lower part of the opening.

- How to attach siding under a roof. It is necessary to measure the distance between the bottom of the lock joint on the finishing profile and the last installed panel. Subtract 2 mm from the resulting number. According to these dimensions, you need to cut the siding, removing the part with the lock, and at the top of the finishing rail, make slots every 20 cm and bend the bridges.The prepared panel should be placed in the installed element, then pull it up and thus fix it on the profile.

Gable trim

In this case, it is necessary to mount the siding around the perimeter. For pre-cladding, starting or corner profiles are suitable. Further work is the same as for the rest of the facade. The only difference is that the last panel is nailed directly through the entire thickness to the crate, but this can be done 1 time and only in this place. The siding is complete.

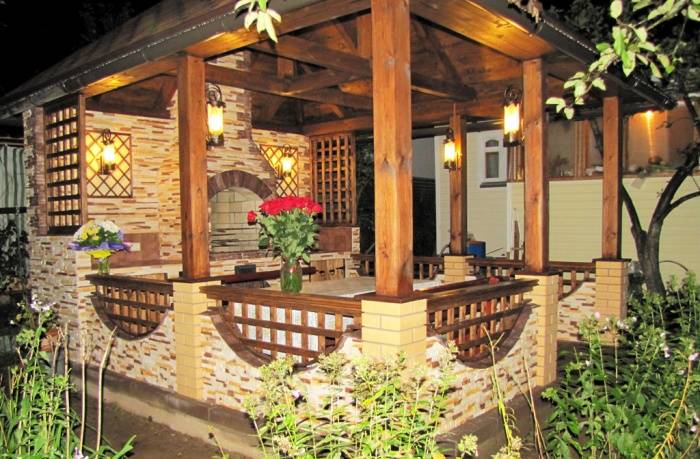

Floor finishing methods

There are many ways to arrange the floor of gazebos. In most cases, a reliable leveled base is made under it. Coating materials can be used in a variety of ways, and each is good in its own way. Their choice depends on the budget, the design features of the gazebo and the wishes of the owner.

Learn also about the features of the landscape design of a summer cottage with a vegetable garden.

Dumping

The simplest way to arrange the floor of the gazebo is to fill it. At the same time, the fertile layer of the earth is removed, the soil is leveled and tamped. Then a layer of gravel or sand is evenly covered. To avoid the germination of unwanted vegetation, geotextiles should be laid under it.

Adobe floor

An inexpensive and simple option is to install a clay floor. It will be an environmentally friendly and warm coating. First, a small layer of rubble is poured under it and leveled, and then a clay layer is made. The coating mix is made from clay, chaff and water.

Pay attention to the information on the landscape design of the entrance area of a private house.

A layer of crushed stone is made with a thickness of only 3-4 cm, and clay - about 8 cm. After drying, the cracks are rubbed with clay, and also rubbed with a lime-clay solution. This will increase the moisture resistance of the coating. Such a floor will serve for more than one year, but it can get wet from the abundance of precipitation and moisture. It cannot be placed in a low-lying area.

Wooden floor

Wood flooring is a popular material for gazebo flooring. A floorboard is taken from 2 cm thick and laid on wooden logs, which are attached to the base. In open gazebos, small cracks are made in such a floor so that water does not stagnate in the structure.

Did you know? As early as 3 thousand years BC, in ancient India, China and Egypt, they began to replace natural stone with gypsum and lime. The ancient Greeks produced artificial stone from concrete poured into wooden or iron molds. In the Middle Ages, stone chips began to be added to concrete mortar..

Wood for the floor of the gazebo is taken well dried and treated with an antiseptic. An anti-rotting treatment is recommended annually. It will be good to varnish the tree - this will extend its durability. For open and semi-open gazebos, it is also good to use a terrace or deck board, garden parquet.

Paving slabs

One of the most popular materials for outdoor gazebos. It can also be used to decorate other paths and sites on the site. Paving slabs perfectly cope with loads and environmental conditions, they are fireproof and durable. It is easy to lay on a lined cushion of sand and gravel. At the final stage, cement is used.

Porcelain stoneware

An excellent material for arranging the floor of the gazebo is artificial stone slabs. An excellent imitation of natural stone is porcelain stoneware. Due to its strong and dense structure, it can carry a heavy load, is fireproof, and successfully withstands open area conditions. They can decorate not only the floor surface, but also the basement of buildings and structures, a barbecue.

We suggest that you familiarize yourself with the information on creating a rockery on a site with your own hands.

Its laying is carried out on a leveled concrete base, and a moisture-resistant grout is used between the seams. This coating belongs to the elite and is not cheap, but it is recommended to use it for wrought iron furniture. Such material serves for a long time.

A wide variety of materials can be used to decorate the gazebo. Their choice depends on the frame of the gazebo, its style, and the presence of a barbecue. The selected materials must be compatible with each other and with other structures on the site.

Winter gazebo finishing

- The type of building, and this is not discussed - it must be closed. All finishing elements must fit snugly together so that cracks and drafts do not appear.

- You cannot do without additional insulation, and for this we advise you to use:

- Styrofoam. The material, albeit of artificial origin, is inexpensive, and became famous for its moisture-repellent properties. It can be used for both external and internal insulation.

- Mineral wool. Luxurious insulation due to the low level of thermal conductivity, material of natural origin and moisture resistant.

- Felt. Differs in its incredible heat-insulating properties and no less

- high price, but note that the cost is justified by the quality at 100%.

For the interior decoration of the gazebo, I would like to recommend a wooden lining.

Hedge

One of the options for the aesthetic arrangement of the gazebo, which has not lost its popularity for a long time, is a hedge made of curly decorative vines. In this case, lattice materials are used as its decoration, which give climbing plants sufficient support - a wooden slatted lathing, various options for a metal mesh.

Decking

Another modern polymer - wood material imitating a floorboard, intended for the arrangement of floors exposed to atmospheric moisture. Of course, decking will be very appropriate when installing floors in garden gazebos.

Paints and varnishes

As a complement to other facing materials and solutions, a variety of paints and varnishes are widely used in the practice of decorative finishing. In addition, they often play a very important role in protecting metal and wood structures from the damaging effects of atmospheric moisture. Of course, for painting gazebos, including their interior decoration, paints and varnishes should be used, intended exclusively for external work. In general, due to the relative architectural simplicity of the gazebo arrangement, and due to the wide variety of modern building and finishing materials, as well as the vast experience gained in architectural solutions, the widest flight of architectural thought and aesthetic imagination is possible during their arrangement and decoration.

Frame device

A beam with a section of 100 x 100 mm is laid over the installed piles. Fastening is carried out depending on the type of foundation. The screw piles have special “tops” with holes. In the tape version, before pouring, wooden blocks are laid along the perimeter with a certain step, to which the timber is then nailed.

In the photo - a bar with a section of 100x100 mm

The choice of base device depends on the material. If it is a brick, then it is laid directly on the strip foundation, having previously laid waterproofing from roofing material. A wooden building covered with decorative materials is mounted on a timber frame.

After the device of the lower strapping, a frame is assembled from a bar of the same section. First, pillars of the required height are installed in the corners. Between themselves, they are fastened with transverse beams and braces. Above is mounted a beam of equal length for the base under the roof.All work is carried out with constant horizontal and vertical zeroing.

Photo of the assembly of the frame of the gazebo from the bar

After assembling the frame, the floors are laid from boards with a thickness of at least 40 mm. The wood must be planed on one side if used as the main floor covering. If subsequent finishing with other materials is envisaged, then you can put an ordinary unplaned board.

No. 4 - reinforcing mesh

The installation of the material is carried out in this way:

- First you need to find a grid with a mesh size of 10 * 10 cm or 15 * 15 cm and with a thickness of about 0.6-0.8 cm.

- Using pliers, chisels and a hammer, the roll must be cut to the size of the arbor and cut into the desired parts.

- Grind off those edges of the canvas that are sharp and bend.

- Attach the mesh to the timber frame with nails, and if the frame is made of metal, weld everything using a welding machine.

Metal and steel structures

Metal (iron, steel, cast iron) is the second most durable and durable material used for the device and decorative facing of arbors. But still it (iron, steel) a significant drawback is its susceptibility to corrosion. Therefore, as a rule, metal structures and metal elements require protection from atmospheric moisture, which in the overwhelming majority of cases is achieved by painting them. Openwork, columnar, lattice metal structures made of metal pipes, profiles, rods, strips, wire can act both as load-bearing structural and decorative elements. Forged metal parts, panels and structures can look very impressive in the same quality. Artistic forging is a very stylish, but at the same time quite expensive architectural and design solution. One of the most budgetary options for finishing the gazebo is sheathing with a metal profiled sheet. But the aesthetic value of such a solution, as a rule, wants to be the best.

Frame installation

Finishing a wooden house begins with the installation of guides. For the vast majority of siding, the sheathing needs to be fastened vertically. Its step is selected depending on the insulation. The clean distance between the guides should be a couple of centimeters less than the width of the mineral wool. For polystyrene, the distance is matched exactly to the width.

For the manufacture of wooden lathing, most often they take bars with dimensions of 40x40 mm or 50x80 mm. When using the metal version, you will need a set of special profiles of different sections.

Frame slats are installed in 40 cm increments, incl. around openings. At the very bottom of the rail should not be

Frame slats are installed in 40 cm increments, incl. around openings. At the very bottom of the rail should not be

To fasten the frame to a wooden wall, use nails or self-tapping screws. In this case, the first must necessarily have an anti-corrosion coating made of zinc or aluminum. Before starting the fastening of the lathing with a construction steller, a vapor barrier is mounted. To do this, you can use ordinary plastic wrap, but it is better to buy a special vapor barrier membrane. The choice of materials in a wooden house should be taken extremely responsibly. It is not recommended to use those that block the movement of air through the walls. For this reason, a membrane is better than a film.

When decorating a wooden house with siding, the vapor barrier is attached with an overlap of 10 cm. Before starting work, it is recommended to read the manufacturer's instructions. Next, the guides are fixed with the required step, starting the installation from the corners. The flatness check is performed using a building level.

Insulation is placed between the guides of the crate. It is better if it is mineral wool - due to its good air permeability. On top of the cotton, it is required to fix a layer of waterproofing and wind protection.The best option would be modern vapor diffusion (not to be confused with vapor barrier) windproof membranes.

Calculation of the number of siding elements

It is better to purchase siding for finishing a wooden house in one go. If later some parts have to be bought, they may not match the color of the main set, since two batches of even the same color usually differ somewhat in shade. And the additional investment of time and money for the delivery of missing elements is unlikely to please the homeowner

Based on this, it is very important before buying with sufficient accuracy to calculate the required number of all parts.

Number of panels

Determined by the formula: N = (Sst - Sok - Sdv + Sfr) / Spanel,

where

Sst - wall area;

Sok - the total area of window openings;

Sдв - total area of external doorways;

Sfr is the total area of all pediments;

Spanels - useful (!) Area of one siding panel.

illustration for calculating the required amount of ordinary siding

illustration for calculating the required amount of ordinary siding

If the panels in a row will be joined end-to-end, then the usable area should be taken equal to the actual one. This value is indicated on the packaging and in most cases is 0.85 m2. If the panels are supposed to be installed with an overlap, then when calculating S panels, the overlap must be subtracted from the actual area.

Number of outer and inner corners

Scheme for determining the lengths of corner elements

Scheme for determining the lengths of corner elements

Corners can be calculated in one of two ways:

- Economy option: add up the lengths of all outer corners of the building and divide them by 3 m (the length of one corner). But with this approach, the framing of all corners, except for the first one, will be made of several fragments of corners (at least two), unless their lengths are exactly 3 m. merits. If the user wants to get a flawless finish, they should not skimp and purchase one whole corner for each corner.

- As a compromise option, you can purchase whole parts for the corners on the street side, and those located on the side of the yard or hidden, for example, by green spaces, can be laid out from several pieces left after trimming.

Total length of starting bars

It is calculated according to the following formula: Lst = P + Wok,

where

P is the perimeter of the building;

Wok - the total width of all window openings.

Example: for cladding a house, which is a rectangle with dimensions of 10x6 m and has 8 window openings 1 m wide, the starting bar will be needed:

Lst = 10 + 6 + 10 + 6 + 8x1 = 40 m.

Starting bar parameters

Starting bar parameters

The number of parts is easy to determine by dividing 40 m by their standard length of 3.8 m. For the house in our example, you will need to purchase 11 starter strips.

Calculation of the need for other elements

The number of other elements is calculated as follows:

- The number of J-strips, if any, is determined by dividing the total length of all ends, except for those converging at the corners, by the length of one part 3.8 m.

- Planks with a T-shaped and H-shaped section are counted individually on the cladding scheme, which must be previously drawn.

- The perimeter strips are calculated individually so that they, like the corners, are used only in one piece. The same goes for platbands.

- When calculating spotlights, their area in m2 is determined: the total length of all parts is multiplied by the width determined by the design features of the cornice.

The length of the wind board is taken to be equal to the total length of the slopes of the gables.

Geometric dimensions of the wind board

Geometric dimensions of the wind board

Experienced craftsmen add 7-10% of the stock for trimming to the estimated volumes. It is better for a novice installer to throw 15%.

Choice of materials

Before sheathing a wooden house with siding, it is worth studying the basic information about the types of material. You can give the following brief description:

- plastic siding - the cheapest, most practical, but afraid of mechanical stress;

- metal - strong and durable, but protection from rust is needed (does not apply to aluminum);

- wooden - fits perfectly into the properties of a wooden house and will be the best option, but buyers may be scared off by the price;

- fiber cement - not so popular, not flammable, durable, but difficult to install and has a large mass.

Next, it is worth choosing the material of the crate. It can be made of wood or light metal profiles. The installation of metal battens is easier for uneven subfloors. Such a frame will be strong and reliable.

But siding a wooden house with your own hands on a wooden frame will be cheaper. Also, you do not have to worry about the protection of the wall element and the crate in the places of their contact, since they are made of a material with similar properties.

When buying and selecting wood for the crate, it is important to control that the tree is:

- without bundles;

- no deformation;

- free from bluish spots or rot.

Before starting work, the wooden crate is impregnated with fire retardants and antiseptics. The former increase resistance to fire, and the latter to mold and mildew.

The technology of finishing the gazebo with clapboard

For the exterior and interior decoration of the gazebo, quite a few parts use different types of wood, and this is very beautiful, but the cost is such that not everyone can afford a wooden gazebo. For this reason, it is recommended to consider a cheaper, but no worse in appearance analogue, namely lining.

Among the main advantages are the following:

- Beautiful appearance, neatness that fits perfectly into the interior of the garden plots.

- High level of thermal insulation.

- Reasonable price (unlike wood).

- Environmental friendliness of the material.

General information

The lining is a calibrated board with a tongue-and-groove double-sided connection, designed specifically for cladding rooms. Thanks to this connection, the boards fit snugly together.

Of the advantages of the lining, the following points should be highlighted:

- Low material cost;

- Ease of installation;

- Good sound and heat insulation properties;

- Attractive appearance of a natural board;

- Lining is a natural natural material that creates a pleasant microclimate, which is important for indoor spaces;

- Clapboard can be used for interior decoration of arbors, as well as exterior.

Pine lining

Types of lining

Interior decoration can be made of material of various types of wood, however, pine is the cheapest and at the same time a fairly high-quality option. In addition, it has a very beautiful texture.

There are also more expensive types of lining from:

- Lindens;

- Alder;

- Oak;

- Cedar;

- Larch;

- Aspen.

On the market, the lining is presented in different shades, ranging from the lightest to dark. In addition, all kinds of tinting allow you to give the tree any color.

Installation features

The lining can be mounted in several ways:

- Vertically;

- Horizontally;

- Diagonally.

In addition, a combination of these variations is allowed, it looks very interesting. However, if the gazebo is small, then it is better to use a horizontal arrangement, as it expands the space. For a low gazebo, you can arrange the material vertically, which will visually increase its height.

Instruments

In addition to the finishing material itself, you will need the following tools to complete the cladding:

- Level;

- Roulette;

- Small-headed nails;

- Transparent mounting brackets;

- Screwdriver;

- Screws;

- Drill;

- Hacksaw;

- Wooden hammer;

- Perforator.

Laying lining

In most cases, for finishing gazebos with clapboard, it is required to lathing with a wooden lath with a step of about 0.5 m.It should be borne in mind that the facing boards are mounted across the lathing.

Laying should start from one of the corners of the gazebo. This must be done very carefully, since the further laying of the cladding will depend on the installation of the first boards.

The installation instructions for the lining are as follows:

- Fixing the boards is carried out using self-tapping screws or nails.

- After laying the first boards, the remaining parts should be mounted as evenly as possible, but not very tightly. The gap between the panels is not more than 2 mm.

- The evenness and evenness of the laid boards must be checked with a building level.

- After completing the work, the lining must be varnished.

Siding of different colors

Beautiful examples of cladding

- A variety of types of siding in terms of material, shape, color and texture makes it possible to implement design solutions in the design of the facade. For example, installing single matte siding in light shades has already become a classic solution. Installation of a colored "Christmas tree" in a double or triple version will make the facade laconic, but bright, as is typical of modern design trends.

- Houses and cottages, sheathed with basement siding from foundation to roof, look beautiful, soundly and expensive. Modern fiber cement siding most accurately reproduces the relief and texture of natural stone and brick, so from the outside it will be difficult to distinguish such stylization from a real stone.

- Wood trim is always relevant for a private house. Light siding will perfectly fit into the Provence style, darker shades and imitation of untreated wood will be appropriate in the country style. "Ship's beam" with a pronounced texture and siding imitating expensive wood species will recreate the elite design of the classics in a modern interpretation.

How to mount siding with your own hands, see the video below.