Types of outbuildings

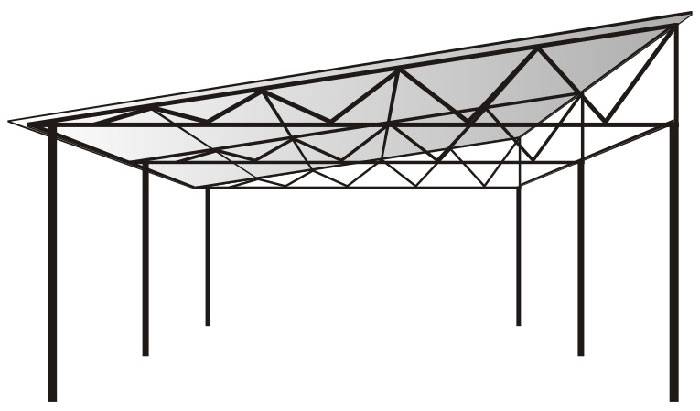

Sheds from a professional pipe are classified according to the type of support and rafter systems.

The type of support system depends on the location of the canopy relative to other buildings. Separate attached, console and freestanding structures.

| Canopy type | Scope of application | Design features |

attached |

terraces, verandas, outdoor cafes, attached parking lots, canopies above the entrance groups | attached to one or more walls of an existing building, have additional supports |

cantilevered |

small canopies over entrance groups, windows, balconies | has no supports, is attached directly to the wall of the building, additional fixation is provided by a suspension system, also fixed to the wall |

standing separately |

outbuildings, sheds over playgrounds, sports grounds or individual equipment, private and public parking lots, summer cafes, bus stops, and so on | rests on one support (umbrella canopy) or a support system of several racks |

Since the roof is the main part of the hinged structure, the complexity of erecting a canopy depends precisely on the shape of the roof.

By the type of rafter system, one- and two-pitch, arched and hipped roofs are distinguished.

| Canopy type | Design features | Installation features |

lean-to |

one side of the support system is higher than the other, if the canopy is free-standing, for cantilever and attached canopies, the upper ends of the rafter legs are attached to the wall, the lower ends are supported by a suspension or support | the simplest type of canopy in execution, which does not require complex calculations and the presence of special equipment, any roofing material is suitable, for installing a canopy over a large area, the rafter system is assembled on the basis of trusses in the form of a right-angled triangle |

gable |

the upper ends of the rafter legs rest on each other or on the ridge, additional vertical and inclined elements are required for the stability of the system | if there are correct calculations and a drawing, the installation is not much more complicated than a shed awning, the installation of roofing material is complicated only by the need to install a ridge, the trusses for installing the rafter system of a large canopy are in the shape of an equilateral triangle |

hipped |

rafter legs meet at one point - the top of the tent | the calculation of the rafter system becomes more complicated with the increase in the number of roof slopes; to make the roof, precise cutting of the roofing material is required, special roofing elements are required to protect the joints and the tops of the roof |

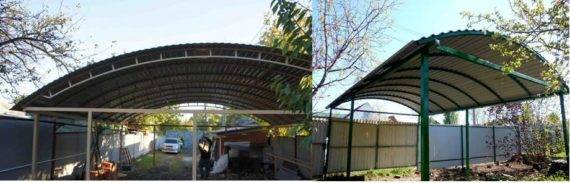

arched |

the roof has the shape of a wave, arch or semi-arch, the rafter system is assembled on the basis of arched rafter legs or trusses | independent production of rafters or trusses is possible only if there is a pipe bender and the skill of forming equally bent pipes, the roofing material for such a canopy should be flexible, curvilinear canopies are rarely mounted with their own hands |

Manufacturing of lathing

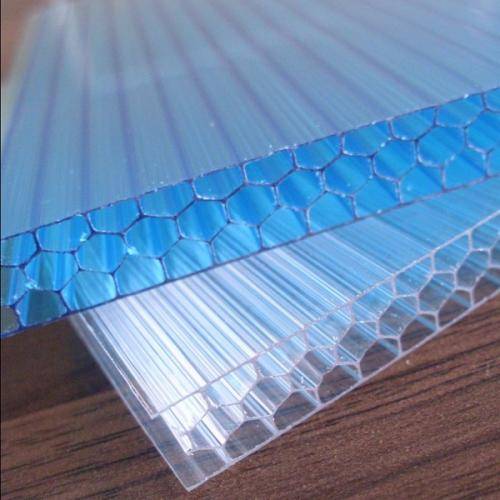

A wooden crate is placed on the trusses, on which a roof covering is installed. The easiest and most reliable way is to put a simple flooring from a metal profile. It is reliable, quite durable, and relatively inexpensive. The use of polycarbonate sheets for the manufacture of canopy roofs is also widespread today. In addition, no one has canceled the slate, and you can also use polymer sheets.

In order for the lathing made of wood to serve longer, wooden structures should be treated with antiseptic preparations. The polycarbonate roof is laid directly along the girders of the truss.

Do-it-yourself canopy to the house from a metal profile. Step-by-step instruction

When all the materials are ready for work, you can start installing the canopy. Assembly technology consists of several stages:

- Preparations.

- Frame assemblies.

- Roof overlaps.

- Structural strength checks.

Before starting the installation, preparatory work should be done.

Preparatory work

At the initial stage, you should prepare a place for construction. For this, the territory is cleared of debris and vegetation. The site must be leveled and compacted. Then the marking is done: using a tape measure, marks are made of the location of the pillars. Places should be marked with pegs, between which to pull the rope. Then, holes are dug 1 m deep (for a large structure, 1.5 m).

The next stage of preparation is pipe cutting. If round pipes are used as supports, then the diameter must be at least 80 mm. The optimal length is 3000 mm. It is also necessary to prepare pieces of pipes with a diameter of 83 mm.

Cut-off parts of pipes of 83 mm are laid in the prepared holes. 80 mm pipes are inserted into them

It is necessary to pay attention to the fact that the support should not be visible from the cut short pipe. Then the support with the cut pipe must be bolted

The finished structure must be inserted into the pit, covered with sand and poured with concrete. Leave to dry for 1 week.

Frame installation

When the concrete mixture is dry, you can start assembling the frame. To do this, each row of pillars is tied with profile pipes. These beams are bolted together. The evenness of the installation must be constantly checked by the building level. If the pillars are of different sizes, then they should be sawed off, and then continue to work.

Then the strength of the structure should be increased. For this, jibs are installed - metal profiles that connect the support posts and beams.

Then the stage of installing the supporting truss begins. It is mounted on beams. This design will strengthen the canopy, due to which it will withstand a heavy load.

The truss is a triangle, in the center of which profiles are installed in a zigzag direction. To make a farm correctly, you need to carry it out according to the drawings. The trusses are installed every meter.

On top of the truss, logs (rectangular pipes) are mounted perpendicularly. All elements are bolted together. After assembling the structure, it is necessary to check the strength of all joints. More reliable protection needs to be provided if necessary.

The finished structure must be covered with a layer of primer and then painted. This will extend its service life. When the paint is completely dry, you can install metal profile sheets. Installation starts from the bottom up.

You need to fix the sheets with self-tapping screws. It is necessary to perform at least 8 fasteners for one sheet. The first row of metal profile sheets is overlapped. The second row is installed end-to-end to the first row. But all sheets of the second row are overlapped relative to each other.

Shed carport. Project preparation

The construction of the canopy begins with the preparation of the project. It includes a drawing with basic dimensions and a description of the parameters of the future design. The design takes into account the optimal operating conditions, the composition of the coating, the characteristics of the base and the coating.

- Choosing the best winter option.

All the benefits of a carport are fully revealed in winter.

When developing a project, the climatic features of the area must be considered.

It has been proven that it is better to store a car under a canopy in winter.

The structure of support pillars and roof reliably protects from precipitation, and also does not create its own microclimate. Having driven under a canopy in winter, the car gradually cools down, which means it is not covered with dew. In the garage, due to temperature changes, dew falls out, which gradually destroys the metal of the body.

In areas with cold and long winters, a more durable structure is chosen to withstand a thick layer of snow. The frame made of wood or metal is additionally reinforced to withstand a load of up to 150 kg per sq. m roof.

Among roofing materials, only polycarbonate does not change its qualities in a harsh winter.

- The choice of site coverage.

An inexpensive and simple method of covering is backfilling with gravel. In order not to make a descent, the cover must be at ground level.The stiffness of the crushed stone is achieved by high-quality compaction.

More costly methods are laying concrete or paving slabs. In any case, before laying, the site is prepared: they remove the soil layer, do the filling with crushed stone and sand, tamp it.

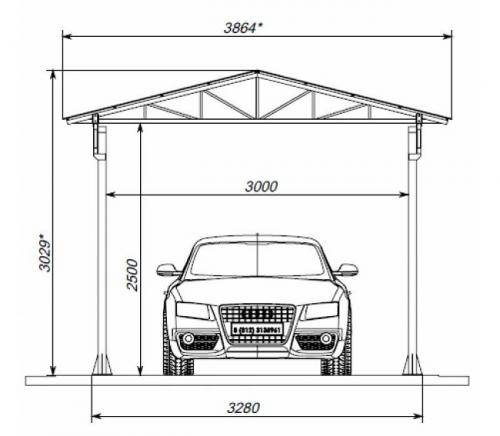

- The choice of the size of the structure.

Sizes are chosen depending on the number of machines.

The standards establish that for one car, the canopy should be one meter longer than the car, and up to two meters wide.

For two cars, the width of the canopy is calculated by the formula: W = W1 + W2 + 2 m + 0.8 m, where:

- Ш1 and Ш2 - machine width;

- 2 m - a stock of 1 m from the outer sides of the cars;

- 0.8 m - distance between cars.

The height is chosen taking into account the dimensions of the car with a load on the trunk. With a very high canopy, slanting precipitation falls into the interior of the structure. The optimum height is 2.3 meters.

The following sizes are considered universal:

- Medium car with a small area - 6.0 x 3.0 m;

- Minibus, SUV - 6.5 x 3.5 m;

- Two cars - 6.5 x 6.0 m.

- Selection of support materials.

Suitable building materials for racks are: metal, wood, concrete, brick, stone.

Supports are usually built from metal or wood. They are easy to install, and most importantly, they are cheaper than other building materials.

Metal racks.

The main requirement for prefabricated metal poles is strength. To withstand the load of a snow-covered roof, 100 mm metal pipes are required. The diameter depends on the pitch of the installation. The minimum pipe size is allowed if there are many racks. But for a single-pitched roof with four pillars, pipes of the maximum diameter will be required.

Wooden racks.

Special requirements are imposed on wooden supports. First of all, this is due to possible rotting due to moisture. Supports made of quality wood, treated before installation, will last up to 15 years.

Sufficient reliability is provided by 200 mm rounded logs and a bar of 150 mm in size.

Before buying material, you need to count the number of racks. Depending on the step, a different number of them is required. Each rack must be able to withstand pressures of up to 250 kg.

It is estimated that 6 racks would be required for an average car with a small footprint. A distance of up to 3 m is selected between the supports. Racks are necessarily placed at the corners of the structure.

- The choice of materials for the coating.

As a covering for a freestanding building, corrugated board or ondulin is best suited. They have high reliability and durability, therefore they serve for more than 20 years. Only metal roofing lasts longer, but it is more expensive, and most importantly, it delays the snow melting. These coatings do not transmit light, so there is always a shadow under them.

Canopies are best suited to polycarbonate

The main attention is paid to the choice of the quality of the material. In hot weather, a three-layer polycarbonate with a high absorption of sunlight creates good shade

At the shed attached to the house, it is logical to make a roofing of the same type as the house.

The main parameters of the roofs are established by the “Building codes and regulations”. They are used in the design of roofs with any coating. The slope in degrees or percentage is determined by the level of the horizon. The type of roofing material is of great importance for the choice of slope.

For all roofs on pillars, the slope of the slope is considered optimal from 15 to 25 degrees.

Basic rules for drawing canopies

Carrying out the drawing of the canopy, it should be taken into account that the minimum structure height (from the ground to the lower edge of the roof slope) is 2000-2400 mm, the maximum depends on the type of roofing system.

Roof - what to consider in the drawings

Above, we discussed in detail how to calculate a gable roof for a canopy, a gable roof is calculated according to the same principle. The angle of inclination depends on the choice of roofing material and the climate in the region:

- 45-60o - snowy areas;

- 9-20o - windy areas;

- 15-30o - universal slope of slopes, almost all types of roofing materials are suitable: corrugated board, roofing material, soft tiles, slate, polycarbonate, galvanized iron, metal tiles, ondulin, etc.

One- and two-pitched roofs are optimal for all types of awnings made of wood, brick, concrete, stone, forged items. For welded metal structures, more and more, they arrange an arched roof. In order to correctly calculate a canopy from a metal profile with your own hands, the drawings should reflect, in addition to the size of the building, the radius of the roof arc.

In fairness, let's say that welded and prefabricated metal structures are crowned not only by an arched roof, but also by other types of trusses. The calculation of the truss for the shed, the calculation of the structure of the shed depend on the overall dimensions of the building. It is very difficult to calculate the rafter system on your own, so it is better to use an online calculator, contact a specialist, or take a ready-made project of a standard farm as a basis, as in the photo below.

An example of how to weld a shed truss, drawings of typical structures

Materials (edit)

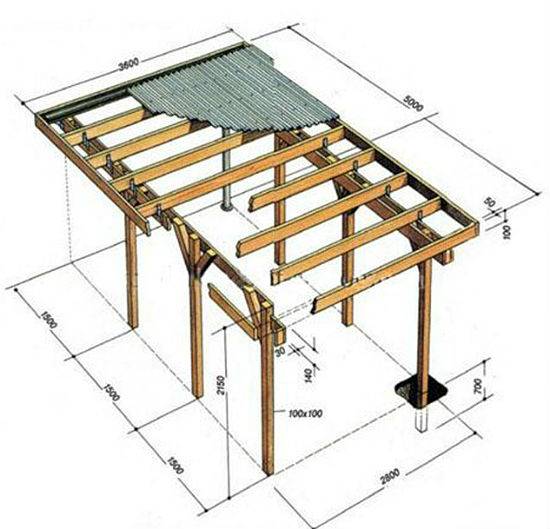

Here are the standard materials that are suitable for all typical drawings. For wooden awnings:

- Supports, strapping around the perimeter - profiled or glued timber, 100 * 100, 150-150 mm, rounded log with a diameter of 200 mm. The distance between the posts is 1.5-2.0 m.

- Rafters - edged board 150 * 40 mm.

- Lathing - rail 15-20 * 40, unedged board, moisture-resistant plywood, OSB.

Drawing of a wooden canopy with the estimated dimensions of the main structural units

Metal awnings:

- Vertical racks - round pipe with a diameter of 100-150 mm, profiled pipe 50 * 50, 80 * 80 - for small structures up to 6 m, 100 * 100, 150 * 150 * - for large buildings.

- A farm for a canopy, a frame (upper and lower belt) - a professional pipe 40 * 40, 40 * 60, 30 * 60 mm - depending on the size of the structure, the wall thickness is 2-3 mm.

- Slopes and stiffening ribs of the truss - metal profile 50 * 25, 40 * 20, 25 * 25 mm, thickness - 2 mm.

- Lathing - professional pipe 20 * 25, 20 * 40 mm.

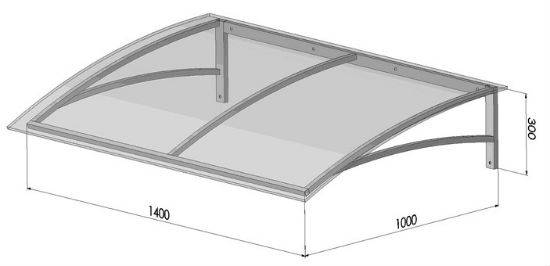

Drawing of a standard visor

How to cook and assemble a canopy

How to assemble a canopy

If you do not own this craft at all, then it is better to entrust welding to a specialist. But if you have a welding machine and skill, then you will be able to make welding with a tubular section. First, the splicing is carried out along the edges. Then continue towards the center. Spot baiting, leveling, straightening with a sledgehammer, welding of all elements - these are the stages of welding. As a rule, the side parts and the rafters are assembled alternately and separately, and then they are also put in turn on the supports - the side ones and then on them and the rafters. If there is a lift, the frame can be completely assembled directly on the ground and lifted into place as an assembly.

The finished frame is placed on supports, this will require help, since one pair of hands is not enough. Next, the same spot welding is carried out, the accuracy is checked using a level, and finally, constant welding is carried out. When the frame is assembled, the joints should be cleaned to remove the scale, and then the metal frame is treated with an anti-corrosion coating. Often, the metal profile already has such a coating. If it is not processed, the processing must be done independently.

Application of a metal profile

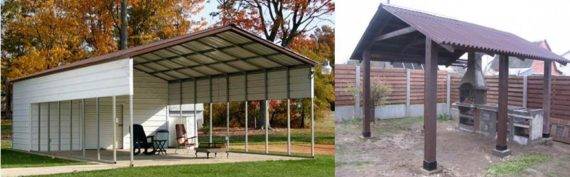

The metal profile is well suited for the construction of canopies for both household and recreational purposes. Recreational are used as protection from the sun and wind over swimming pools, playgrounds.

The utility shed is erected in the place where the summer kitchen is arranged, storage of household equipment or in the parking lot of the car. The structure of the canopy can be free-standing or be an extension of the house. In the first case, the canopy is erected on separate supports, and in the second, one or two sides rests on the wall of the house.

Shed canopy

The easiest to install is a lean-to shed. When erecting it, one row of supports is lower than the second, which is why the metal profile sheet is mounted at an angle. Due to this roof structure, the snow flows down unhindered.

There are other types of metal profile structures: gable, arched. In the first case, it will be more difficult to complete the frame and select more metal profile sheets to overlap the roof. A gable canopy is often used to protect a large area from wind and rain. It is more resistant to adverse weather conditions.

To make an arched canopy, you will need to use the services of professionals. It is quite difficult to make an arched structure yourself. Therefore, lean-to sheds are often installed.

Decking as a roofing material is often chosen due to its advantages:

- Environmental friendliness.

- Longevity.

- UV resistance.

- Resistance to low temperatures.

- Longevity.

- Strength.

- Acceptable cost.

- Easy to care for.

- Fire safety.

In addition to all the advantages, corrugated board can be easily assembled with your own hands. You can build a structure without outside help, but on condition that the canopy is small. A canopy made of metal profiles can transform the exterior of a house, if the work on its installation is carried out competently.

Most manufacturers offer a ready-made canopy assembly kit. It is enough to understand the finished drawings and assemble the frame using them. But this option will cost more than assembling the frame from separate shaped pipes. In the case of the latter option, you will have to spend time selecting and trimming the supports.

A canopy made of corrugated board adjacent to the house. How to make a canopy of corrugated board adjacent to the house with your own hands

Owners of private houses are trying to make special sheds in their yard, adjacent to the house, which serve as protection in the summer from the hot sun, and in the fall from heavy rain. In addition, such covered spaces are used as temporary parking spaces. Since such awnings are not the main architectural object, with the right design that will fit the overall concept of the house, they can not only perform protective functions, but also become an excellent addition to the yard as a whole.

Owners of private houses are trying to make special sheds in their yard, adjacent to the house, which serve as protection in the summer from the hot sun, and in the fall from heavy rain. In addition, such covered spaces are used as temporary parking spaces. Since such awnings are not the main architectural object, with the right design that will fit the overall concept of the house, they can not only perform protective functions, but also become an excellent addition to the yard as a whole.

It is worth noting that the construction of such a canopy does not require any special building skills. This work can be done with your own hands, since the structure of the canopy is simple and uncomplicated.

Most often, a canopy made of corrugated board adjacent to the house is made single-pitched, since this option is the simplest and does not require a large amount of material, costs and efforts for its installation.

Preparatory work

Any construction work begins with preparation for them: a place is chosen, a project is made, a material, a design is selected, and the purpose of the future structure is determined.

In order to make the right project, you should consider the following factors:

- climatic features of the region of residence;

- wind indicators;

- the construction of the house, to which the canopy will adjoin.

Design documentation is done in two stages: at the first stage, they make an approximate sketch of the future structure, at the second - the final drawing, with a drawing of all the details. The location of the shed directly depends on its purpose - if the shed is to be used as a resting place, it is better to place it on the inner side of the yard, if as a parking place, then on the front side.

When it comes to the choice of material, many have their eyes scattered, because you can use wood, slate, plastic, etc., however, practice shows that the most optimal and practical material for a canopy will be corrugated board. This material has the most suitable price / quality ratio, besides, this material is easy to work with and does not require special skills and abilities.

During the installation process, you will need a tool such as welding, a grinder, a screwdriver, and you will also need support pillars, which will bear all the load.

Installation work

Arrangement of a canopy made of corrugated board is a complex work, therefore the installation procedure must be consistent. In the process of assembling the structure, the following steps are followed:

- Markup.

- Laying the foundation.

- Assembling the frame.

- Laying of corrugated board.

If each stage of work is performed according to the technology, the frame made of the profiled sheet will be strong and will last for a long time.

Laying the foundation

Starting the construction of a frame adjacent to a residential building, it is necessary to make markings and strictly follow the design drawings. It is better to make the foundation for the canopy from a metal profile, measuring 20 × 20. To do this, according to the marking, holes are dug up to a depth of 60 cm, and pillars are laid in them (the future basis of the structure)

In the process of laying the foundation, it is very important to observe strict verticality (for this you can use the building level). After the pillars are dug in, they are poured with concrete mortar and given time to stand well.

Structure frame

The frame of such a structure as a canopy is most often made of a metal profile. If the canopy is attached to the house, then two metal pillars are attached to its wall, located parallel to the metal supports located on the opposite side of the site. The main lathing of the entire roof will be attached to these 4 pillars. To provide the necessary slope, the posts adjacent to the house should be higher than the posts on the opposite side.

A crate is mounted on the main pillars, on which the roof is subsequently laid.

Roof installation

A canopy roof is most often made of a metal profile, since this material is very practical, reliable, has a large selection of colors, which allows it to harmoniously fit into any design. In some cases, the roof is made of polycarbonate, but it is less durable and also transmits sunlight.

Sheets of corrugated board are laid with an overlap on the crate of the structure and fixed with screws

During the installation process, care should be taken, since the protective layer of the material can actually be damaged and thereby reduce its service life.

Roofing methods may differ in some points, but the general principle of work will be the same.

Opening hours will directly depend on organizational issues. If all the material is purchased in advance, the drawing is completed, and the tool is prepared, the work will not take much time and will be done quickly and efficiently.

Views

By its design, the building has various ways of execution. It all depends on the purpose of the canopy, material and personal preferences of the owner. Today, an extension can be built in various ways, taking into account the chosen material. For the construction of supports, metal or wood can be used. The roof frame is made in the same way. And here is how metal siding looks like wood, you can see here.

The versatility of the corrugated board is that there is no need to adjust the floor under the fasteners

(It is also worth paying attention to how the gable is covered with corrugated board). And this is due to the fact that the edges of the sheet are concentrated very close and this is quite enough to fix the iron sheet

The perimeter cladding can also vary. The attached structure is open, finished with boards with windows, and is presented in the form of a terrace.

But what are the canopies and awnings above the entrance, you can see here.

On the video canopy made of corrugated board adjacent to the house:

Canopies made of polycarbonate can have different designs. The most common ones are:

- arched;

- single-slope;

- gable.

The difference between them lies in the complexity of the installation and the amount of material spent.

But what are the carports made of polycarbonate, and how they can be made, this information will help to understand.

Arch

This version of the polycarbonate canopy has a rather attractive appearance. To attach it to the house, you need to have significant construction experience, because this structure is distinguished by its complexity.

Canopy arch from corrugated board adjacent to the house

They arise for the reason that the shoulder straps of the roof, to which the corrugated board is to be fixed, must be presented in a curved shape. And to obtain such a bend, special equipment is used.

Shed canopy

This type of corrugated board extension does not require special experience and the use of special equipment.

But at the same time, increased attention will be required here when choosing the correct angle of inclination of the roof.

Shed canopy

Thanks to him, the canopy will not be exposed to the constant accumulation of snow in winter, and the crate is freed from unnecessary pressure. You can also look like a canopy over the porch made of polycarbonate.

Gable canopy

This structure is a complete roof. To obtain such a canopy, one corrugated board will not be enough. The gable roof can be used when a spacious open-type summer kitchen is required. There is also another version of the roof - this is a multi-slope roof. This kind of structure is the most difficult to implement. Only professional builders can make it.

Gable canopy

If we talk about the dimensions of the canopy, then their choice should take place taking into account the load and the purpose of the structure. The canopy adjacent to the house should not be large, otherwise the wall will not be able to withstand the load being carried out. If this canopy is over the porch, then it should not be very small. But the carport is calculated taking into account its size. And here is what the texture of the wall looks like under the plaster, you can see here.

If the car is small, then it can fit under the structure of at least 2.3x5.5 m.For an SUV or a truck, you will have to find a load with dimensions of 3.5 x 6.6 m.It is also worth considering the height of the canopy. The optimal parameter is 2.3 m.But for a gazelle, this will not be enough. As the height of the canopy increases, the likelihood of rain and snow falling under the extension increases.

You may also be interested in learning more about what a curtain wall facade looks like.

Determine the type and size of the canopy

Having set yourself the task of building a canopy from corrugated board with your own hands, you need to clearly determine how it will look and what you plan to hide under the canopy. By their design, canopies made of corrugated board can be adjacent to the house and freestanding. An adjoining carport to the house is usually erected over a terrace or porch, adjoining carports are possible.

The canopy to the house is made of corrugated board even if the roof of the house is made of the same material. In this case, the canopy and the house look like a single whole.

In shape, the canopies are single-pitched, gable and arched. A lean-to canopy is the easiest to implement with your own hands. The roof is tilted to one side so that rainwater flows to the ground, and there is less snow on the roof. However, the angle of inclination should not be too large. This will lead to the fact that slanting rain drops will fall under the canopy, unless of course the canopy is not adjacent to the house.

In regions with snowy winters, it is wiser to make a gable canopy, since its angle of inclination may be greater than that of a lean-to. A gable canopy can cover a much larger area. Such a canopy design assumes the presence of trusses, since the holding force of the beams will not be enough. It is easier to buy metal trusses ready-made than to make them with your own hands, especially since they come in different sizes.

An arched canopy made of corrugated board will look most attractive, but it is also the most difficult to build with your own hands. In order to bend a sheet of metal into an arc, you need special equipment, it is almost impossible to do it yourself. The awnings above the porch have the largest bending arc, so they are rarely made from corrugated board.

As for the size of the canopy, they should be selected taking into account the load and the purpose of the structure.The canopy adjacent to the house or building should not be too large, the load on the wall should not be the maximum permissible. If this is a canopy over the porch, then it should not be too small. The carport is calculated based on the size of the car.

For a small car 4.3 m long and 1.6 m wide, the area under the canopy will be at least 2.3x5.5 m.For an SUV or truck, you need to look for a platform measuring 3.5x6.6 m.At the same time, do not forget about the height of the canopy ... The optimal height is 2.3 m, but this may not be enough for a gazelle. By increasing the height of the canopy, you will increase the likelihood of rain and snow falling under the canopy.

We draw up a drawing and an estimate

Before building any shed, you must first draw up a drawing and an estimate. It is not at all necessary to make a drawing in accordance with all GOST standards, it is enough to indicate all the necessary dimensions of the canopy, and reflect its structure. Consider how to make a canopy with your own hands, using the example of an arched structure for a car that is not adjacent to the house.

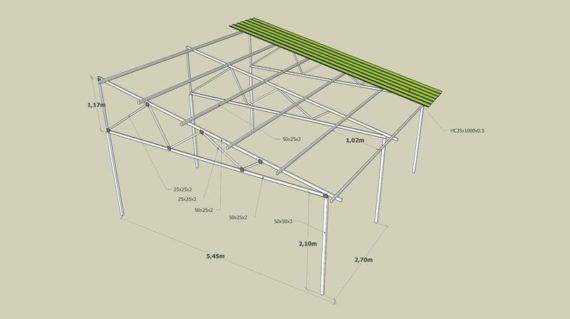

The area of the plot under the canopy is 5.45x5.4 m, the height is 2.1 m. For individual sizes, you can independently calculate what material is required for construction, all the formulas for this are in the article How to calculate a canopy and make a drawing. For the design we have chosen, you will need:

- profile pipe 80x80 mm in size and 3 m long - 6 pieces;

- profile pipe for a run measuring 50x25x2 mm, length 6 m - 6 pieces;

- corrugated board NS 35 x 1000 x 05 - 7 sheets 6 m long. It will provide a good drainage of water and withstand the load of snow;

- galvanized self-tapping screws;

- ready-mixed concrete or cement, sand and crushed stone;

- single-slope ready-made trusses with a length of 5.45 and a height of 1.17 m, made of a profile pipe 50x25x2 mm and 25x25x2 mm - 3 pieces.

And, of course, you cannot do without tools: tape measure, grinder, marker, drill, screwdriver.

Manufacturing and installation of a canopy

Consider the step-by-step manufacture of a canopy with your own hands with a metal profile coating.

Marking and pouring the foundation

First you need to prepare the tools:

- wooden blocks;

- cord;

- roulette;

- square.

The foundation marking begins from either side according to the dimensions indicated in the drawing. Pegs are hammered along the edges and the cord is pulled, while with the help of a square, the right angle is controlled. Then the twine is pulled on the other sides.

To assess the correctness of the markings, measure the diagonals between opposite corners: the distance should be the same.

For a canopy from a profiled sheet, a too strong foundation is not needed. This is due to the fact that only two factors will affect the structure:

- snow load;

- wind load.

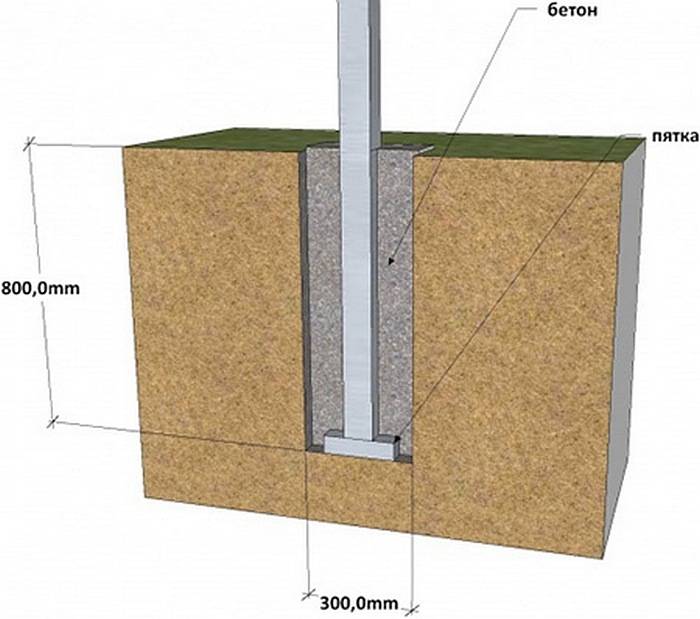

The simplest option for arranging the foundation is to drill a hole 80 cm deep, fill the bottom with sand with a layer of 20 cm, put a support stand from a profile pipe, leveling it with a plumb line. The space between the rack is filled with concrete. So that the forces of frost heaving do not squeeze the support outward, a metal plate is usually welded to the lower part. To level the rack, before concreting, it is fixed with temporary struts made of metal or wooden supports.

Farms construction

Truss designs are different, but they are all designed for heavy loads.

The most popular are the following designs:

- rectangular;

- triangular;

- arched.

For farms, a square metal profile, a round pipe, a corner or a channel is most often used.

Mounting

If the distance between the support posts is no more than 5 m, then for the upper horizontal strapping, you can use square pipes of the same dimension as for the posts themselves, for example, 40x40x2 mm.

Diagonal braces may be required depending on the specific situation. If the distance between the supports exceeds 5 m, it is necessary to use rectangular trusses, which are characterized by greater reliability and the ability to withstand high loads.

In the process of carrying out work at a height, the use of ladders is prohibited: for safety reasons, scaffolding is used.

Lathing

The lathing structure is fixed by welding perpendicular to the trusses from a metal profile of a square or rectangular cross-section. The step between the elements of the lathing is chosen in the range of 300-700 mm, which depends on the thickness of the profiled sheet and its configuration.

During the installation of the battens, the plane is leveled and checked using a cord that is pulled from the bottom of the roof to the ridge, while deviations of more than 2 mm should be avoided. In order to protect the elements of the truss structure, they should be coated with a metal coloring material before installation.

Installation of a profiled sheet

For the construction of a canopy, it is recommended to use a load-bearing corrugated board, denoted by the index H.

To fix the roofing material, special fasteners are used, consisting of self-tapping screws in the form of a drill, which are screwed in with a screwdriver.

Such fasteners are mounted using a rubberized washer to ensure tightness. The self-tapping screw is installed in the lower groove. Thus, a tight fit of the corrugated board to the crate is ensured.

If the roof structure is made of two slopes, the joining point on the ridge is covered with a ridge element. One can be purchased or made independently from a galvanized sheet. Installation of this part is carried out with self-tapping screws to the upper groove of the profiled sheet. To make the roof structure as rigid as possible, it is recommended to use solid sheets of roofing material. This will allow it to withstand high snow and wind loads.

Since the corrugated board is made by rolling metal sheets, material of different shape, profile and length can be made to order.