Types of foundations for gazebos

The foundations of these summer cottages can differ both in design and in the type of material used. The main thing is to ensure that the foundation is solid, reliable and durable.

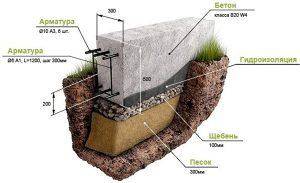

Strip foundation

This type is usually poured under rather heavy brick and concrete structures. Sometimes a similar foundation is erected under chopped and cobbled pavilions. It is advisable to use a strip foundation for light shield buildings only if the soil on the site is very weak.

A strip base is usually poured under brick arbors.

It is not necessary to make a filler strip foundation. For a gazebo, such a base can also be assembled from ready-made narrow concrete blocks. When using them, the foundation will be erected much faster.

Video on how to fill the tape support under the gazebo:

Column foundation

Such a base is usually erected under light wooden panel or metal arbors. On stable semi-rocky or sandy soils, this type of foundation can also be used for log or cobbled structures. Sometimes small brick arbors are also placed on the pillars. In this case, a solid concrete tape is poured over them - a grillage.

It is easiest to fill in an inexpensive columnar foundation with your own hands.

The material for the construction of such a base can be used in different ways. Columnar foundations are usually made of concrete. Brick is often used for their construction.

Important: You can not assemble the foundation for the gazebo from white bricks (silicate), foam or aerated concrete blocks. These materials do not tolerate high humidity very well.

Within a few years, such columns will crack and warp.

Pillars are most often erected by the "brick" method. Concrete supports are poured into the formwork.

Brick pillar supports will be quite reliable

Sometimes they also arrange a foundation for a gazebo made of timber. It is also quite reliable, but not very durable option. It is suitable only for a wooden gazebo. Before installation, that part of the pillars that will be in the ground must be treated with bituminous mastic or drying oil. For greater reliability, a cross is nailed to the wooden supports at the bottom.

Simple columnar foundation from a bar

Pergola on screw piles

Such supports are one of the most reliable and at the same time inexpensive types of foundations. Screw piles are screwed into the ground at the corners of the building and along its walls using a lever. Of course, they can be installed only if the land on the site is not rocky. The gazebo will stand on piles even on unreliable ground for a very long time.

The base on piles is very good to use when erecting a street "house" for recreation, for example, on the side of a mountain.

At the final stage, the piles are tied from above with a rigid wooden or metal horizontal frame.

A gazebo on screw piles will stand for a very long time

Slab base

The slab foundation is placed under structures made of wood, brick and concrete on very unstable soils. When moving, the site moves as a single monolith, and with it the structure itself.

The filling of the structure in this case is usually carried out with the involvement of special equipment. However, for a very small gazebo, you can also make a stove manually, calling for help, for example, neighbors or relatives.

Slab foundation is the most reliable foundation

Screw piles

This option is universal.It is suitable for all types of gazebos with barbecue, with the exception of stone or brick. With a light open structure, screw piles can also be used for brick, stone structures. This option has its own characteristics and advantages.

The principle of the pile foundation is to screw them into the soil until a solid layer is reached. The advantages of this method include:

They are suitable for difficult and mobile soil types, including heaving, clay and all others. Therefore, the type of soil is not critical.

Only the bedding of the solid layer is important. Based on its depth, you need to purchase piles of the appropriate length;

No need to level the area under the gazebo

If there are natural irregularities, they do not need to be leveled. It is easy enough to use piles of different lengths. Relative to the horizon level, they will create a completely flat base for the installation of the building frame;

The installation of piles is done manually. It will be enough for two people and a gate as which you can use ordinary scrap metal. To speed up and facilitate the process, you can involve a technique. But in any case, there will be no need to use bulldozers, tractors and other heavy equipment.

At the same time, the piles are durable and can withstand 70 or more years of operation. They do not rust thanks to a special coating. Products are not exposed to mildly corrosive environments.

Moreover, the pile option will be the best if the gazebo is erected in a reservoir.

Columnar base

This option will also be a good solution for light arbors. This is a great way to create a foundation for an open gazebo made of wood, metal or polycarbonate.

The basis of this foundation is brick posts. They burrow into the ground by 70 cm and rise above the soil level by 30 - 40 cm. The use of bricks is the most convenient. It is an affordable and inexpensive material. Moreover, you can use halves of used bricks.

Such posts should be placed at a distance of no more than 50 cm from each other. In this case, this distance should be observed not only with the perimeter arrangement of the columns. They should be arranged throughout the entire inner area of the gazebo.

In general, the type of foundation depends on the plans of the owner of the site. And in each case, you can create a foundation with minimal cost, doing the work yourself. The main thing is not to overestimate your strengths and skills. If the work is difficult, but you need to contact the specialists, and not count on luck.

With the help of professionals, it will be possible to create a durable and very solid foundation.

Design selection and sizing

All types of strip base are built for lightweight frame buildings. The differences between them are in the method of installation, materials and depth of installation.

Foundations also differ in depth, which depends on the type of soil. Shallow ones are built on slightly weeping and dry soils. If the swelling is strong, they are satisfied with the deepened ones. A minimum of equipment will make it possible to make a tape-type foundation of any kind. Each of them requires drainage, insulation, waterproofing, sand cushion installation. These measures increase the lifetime of the foundation.

On slopes, the structure is subjected to high shear forces; therefore, it is not recommended to arrange belts there. On fine sandy soils, embankments, the sole is expanded with a concrete slab.

Belt depth

depends on the region where the structure is being erected, as well as the total weight of the structure.

The weight of frame buildings is small, so the foundation for them is laid to a depth of 0.4 to 0.7 m.If construction is carried out in the northern region, where the soil is very frozen, a different approach is required.The formula is applied: the depth of the foundation sole is 30 cm more than the seasonal freezing of the soil.

Shallow foundations are built for lightweight structures. Recessed bases are more durable, less deformed from heaving of the soil. They are mainly used if they plan to arrange a basement under the house. Then the concrete base serves as its walls.

It is not recommended to lay a foundation deeper than 2.5 m. If the bearing layers are lower, instead of building a strip base, another version of the foundation is used - the installation of supports from pillars.

Width, height of the structure

Frame buildings are fixed on a strapping laid on top of the foundation. It is made of either a wooden bar of a standard width of 15 cm.For the strength of the structure, the width of the concrete base itself should be 30-40 cm.If the frame is to be lined with bricks, increase to 50 cm.

The height of the tape should exceed the width by 2-4 times, which under standard conditions is 0.6-1.2 m.

Pile

At the heart of the pile foundation are small-section supports that go deep into the ground and are well fixed. Metal or asbestos-cement pipes are used as piles. Wooden beams are used extremely rarely, as they need additional preparation. To increase the reliability of the structure, improve adhesion to the soil, you can purchase factory screw piles.

So what are the advantages of a pile foundation? First of all, it is stability even on unreliable soils, small financial investments. The piles have worked well when installing a gazebo on a slope. However, you should be extremely careful when strengthening the piles. They must be very secure.

Construction of a strip foundation for a gazebo

In most cases, the strip base is a reinforced concrete strip, erected under the load-bearing walls of the building. To make such a foundation with your own hands, it is enough to follow certain instructions.

Site preparation

Like all foundations, the concrete tape is erected on a flat, pre-cleaned area. To do this, it is necessary to remove excess vegetation, large debris and level the site well.

Next, the site is marked according to a previously drawn up drawing. Pegs are placed in the corners of the future foundation and a construction cord or ordinary rope is pulled between them.

Excavation

A trench 30-35 cm wide is dug along the stretched cord. The depth of the trench is determined by the occurrence of sandy soil, and in its absence by the level of freezing.

A sand cushion is arranged along the bottom of the trench, which will act as a shock absorber during vertical movement of the ground. To equip the pillow, it is necessary to pour a layer of sand 10-15 cm thick, pour it over with water and tamp it thoroughly.

On top of the sand, crushed stone of a fine or medium fraction is poured, the thickness of this layer is also equal to 10-15 cm. The crushed stone is leveled, tamped and poured with lean concrete.

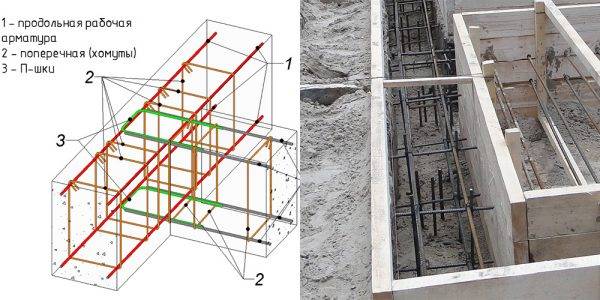

Reinforcement

We reinforce the formwork

Any foundation must have a reinforcing frame, the base for the gazebo in this case is no exception. To create a frame, you can take building reinforcement with a diameter of 8-10 mm and a soft knitting wire. The reinforcement rods are laid horizontally at the bottom of the trench and tied together. Next, vertical rods are exposed, the height of which should slightly exceed the height of the trench. These elements are also tied to horizontal bars. You can use welding equipment to connect the reinforcing rods.

However, it should be remembered that the welded connection may not be able to withstand the stress. This will cause deformation not only of the foundation, but also of the gazebo.

Formwork

The formwork structure is erected if the foundation has an elevation above the ground. For construction, you will need planed boards, plywood sheets or other flat materials. For fixing the formwork, wooden bars are used, which are used to make supports. Between the walls of the formwork, bars are also installed, cut into segments along the width of the foundation.

Pouring concrete

The entire structure is poured with concrete, preferably in one go. The poured mixture is pierced with a bayonet or metal bar to remove air from the concrete.

Determination of the place for the construction of the foundation

If your suburban area has a magnificent garden or an artificially created reservoir, then it is better to build a gazebo with a barbecue there. In addition to the magnificent view from it, coolness will blow from the reservoir on a sultry day. When planning a place for a gazebo, consider how the benches or benches will be located. Do not place it in the open sun. It is better when all or at least half of it will be located in a shaded place.

Although there are temporary (collapsible) options for gazebos, it is better to take care of the construction of a stationary version of it. The main advantage of such awnings is all-season, that is, they are used all year round, while the first have to be removed with the onset of cold weather. In addition, on stationary options, you can build a brazier, barbecue or grill, but temporary ones are not designed for this. They are often made from awning material and metal structures, which absorb soot and smoke, and can also cause a fire.

Did you know? The largest foundation slab in the world was poured into the foundation of the largest European skyscraper in St. Petersburg "Lakhta-Centre". It was poured for 49 hours and twenty thousand cubic meters of concrete solution was spent. This is a new world record.

A structure with a foundation is erected according to the following restrictions:

- the minimum distance from the pressure sewerage and water supply system is maintained at least 5 m;

- the distance from the low pressure gas pipes is not less than 2 m and 4 m from the average;

- any power cables should be 60 cm away from the gazebo;

- if there are stationary fire hazardous facilities, then observe a distance from the fence of at least 5 m.

Important! If it is planned to install a stove or barbecue in the gazebo, then the foundation for them is made of separate slabs. The base for the stove should rise 10-15 cm above the floor of the gazebo

For the correct measurement of these distances, keep in mind that the protruding roof is also taken into account. In the case when it does not protrude much (up to half a meter), measurements are taken from basement to basement, if more, then measure from the place where the roof is projected onto the ground .. Worry about your neighbors, make the canopy so that the smoke from the barbecue or grill does not go to a courtyard or house adjacent to you

In addition, according to all the requirements, any structure must withstand a distance from the border with neighbors of at least a meter. Make the gazebo away from other people's structures, especially the toilet and chicken coop. In this case, you will not hear the neighbors' noise, foreign smells, and you, while resting, will not annoy neighbors with noise or music. Choose a place with the least drafts and unpleasant odors.

Take care of your neighbors, make the shed so that the smoke from the barbecue or grill does not go to the courtyard or house adjacent to you. In addition, according to all the requirements, any structure must withstand a distance from the border with neighbors of at least a meter. Make the gazebo away from other people's structures, especially the toilet and chicken coop. In this case, you will not hear the neighbors' noise, foreign smells, and you, while resting, will not annoy neighbors with noise or music. Choose a place with the least drafts and unpleasant odors.

Learn also about landscaping for the recreation area.

Please note that when laying electrical wiring, the cable is buried at least 0.6 m in depth. The trench should be at least 0.4 m wide. If garden paths are laid on the site, this can cause difficulties.Here the method of "hanging" electric cable will come to the rescue.

It is very important that the gazebo fits into the surrounding flora, therefore green spaces should be combined with the delivered structure. You can hide it in bushes or trees from prying eyes, or, on the contrary, make the main emphasis on it

If you place a gazebo close to home, then it should fit into the design and, as it were, complement or complete a certain style. In the case when it stands alone, style compositions are not limited.

Important! It is not worth placing a gazebo base close to the house base, since the load on the foundation of the house and the gazebo is different, and their influence on each other is negative

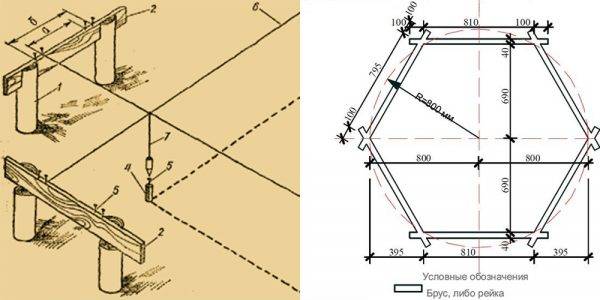

Erection of a columnar foundation

The base in the form of columnar supports is erected for buildings with low weight, it can be a wooden or forged gazebo. The work is carried out in the following order.

Site preparation and marking

The area set aside for the construction of the gazebo is cleared of large vegetation and large debris.

You will need wooden pegs and a rope to make the markings. For a rectangular structure, the angles are determined by the method of the "Egyptian" triangle. To do this, put a peg in one of the corners, measure the distance of 3 meters and put the second peg, then measure 4 meters in the other direction and put the peg again. If the distance between the marks is 5 meters, then the angle corresponds to 900. The rest of the corners are checked in the same way.

Layout and preparation for a columnar foundation

To mark for a hexagon-shaped gazebo, you need to take two pegs and connect them with a rope. One peg is stuck into the ground approximately in the center of the site, with the other a circle is drawn, slightly pulling the cord. Then a line is drawn through the center of the circle and in those places where the circle and the line intersect, additional marks are put.

Further, other angles are determined, for which a peg with a rope is placed in one of the marks and a semicircle is drawn, which should have intersection points with the main circle. They also put marks here. Similar actions are performed on the other side of the circle. As a result, you should get six pegs, they are connected with a rope.

Excavation

At this stage, it is necessary to make pits for the pillars, which must necessarily be located at the corners of the gazebo and along the line of long walls. Most often, the distance between the posts is 1.2-1.5 meters. The pits can be about 0.7 meters deep. The bottom of the finished recesses is covered with sand, moistened and compacted well. The height of the sand cushion should be at least 20 cm. Its main purpose is to reduce the impact of heaving forces during seasonal soil movement.

Formwork construction

If loose soils prevail on the site, then it is necessary to assemble the formwork using boards or thick plywood for this. You can use strips of roofing material by rolling them into rolls of the required diameter. Quite often you can find asbestos-cement pipe formwork. If the soil is dense and the walls will not shatter, then you can simply fill the sand with a layer of lean concrete and proceed to reinforcement.

Reinforcement

Three or four rods are installed in each hole and tied together, forming a kind of frame. The bars of the reinforcing frame should protrude 0.2 meters above the ground.

Pouring concrete

The structure of the formwork and the reinforcing frame is poured with concrete mortar, which is prepared from cement grade M400 and sand in the ratio 1: 3. The poured mixture must be compacted to remove air bubbles.

The operation of the columnar base and further construction work can begin only after a month.

Construction of a frame gazebo with a pitched roof

To avoid serious mistakes and minimize construction costs, you need to start with the simplest. For example, a rectangular gazebo with a pitched roof and on a slab foundation is taken.

Construction of a frame gazebo with a pitched roof

Necessary materials:

- large stone or rubble;

- sand;

- concrete solution;

- formwork boards;

- timber 100x100 mm and 50x50 mm;

- boards with a section of 30x150 mm;

- primer for wood;

- dye;

- slate or corrugated board for the roof;

- screws and bolts;

- reinforcing bars.

You will also need tools:

- shovel;

- building level;

- rule;

- hacksaw;

- jigsaw or circular;

- screwdriver;

- hammer;

- paint brushes;

-

Bulgarian.

Marking the base of the gazebo

Marking the future gazebo

Choose a flat, open area of the garden and make markings. To do this, determine the location of one of the corners of the gazebo and mark it with a peg. They measure the distance to the remaining corners, put beacons, pull a string between them. The diagonals are measured in the resulting rectangle: if they are of the same length, the markings are made correctly.

Pit preparation

Sand filling and ramming

The soil is selected with a shovel to a depth of about 25-30 cm, the bottom is leveled, it is carefully tamped. The pit walls must be strictly vertical. Then coarse sand is poured with a layer of 10 cm, it is well leveled and abundantly moistened for compaction. Formwork from boards up to 10 cm high is placed along the perimeter, reinforced with a bar.

Pouring the foundation

The pit is laid out with large flat stones or covered almost to the top with large rubble. At the corners of the perimeter between the stones, pieces of reinforcing rods are driven in; the rods should rise above the finished foundation by at least 10 cm. A concrete solution is prepared and the foundation pit is poured. The surface is leveled with a rule or smoothed with a trowel.

Foundation

Installing the frame

For the frame, 4 beams of 100x100 mm are taken and cut to the height of the arbor. The front beams are left 15-20 cm longer than the rear ones to make the roof slope. After that, the supports are well treated with a primer and dried. In the lower end of each support, a small hole is drilled along the diameter of the reinforcing rods, which protrude from the concrete at the corners of the base. They put the bars on the rods, set them vertically using a level and additionally strengthen them with metal plates and anchor bolts.

Frame made of timber

After installation, the side supports are interconnected with boards of 50x150 mm, and then the braces for the rafters are mounted. At a height of 10 cm and 0.5 m from the floor, the racks are connected with horizontal jumpers from a bar of 50x50 mm. Vertical bars are fixed between the lintels with a pitch of 40 cm. The doorway is left free. All fastenings are carried out using bolts and steel corners, which are screwed to the tree with self-tapping screws.

All fastenings are carried out using bolts and steel corners, which are screwed to the tree with self-tapping screws.

Prices for various types of timber

Beams

Roof installation

Roof layout

On the boards connecting the support beams, logs are stuffed with a step of 30 cm. From above, the logs are sheathed with an edged board of 30x150 mm. Gaps with a width of 5 to 15 cm are left between the boards. Of course, all roof elements must be treated with an antiseptic primer and well dried. You can cover the top of the board with glassine and fix it with staple staples. Thin strips are stuffed over the film so that there is a ventilation gap between the roofing and the film. Slate is laid on the slats and fixed with 120 mm nails with galvanized heads.

Arrangement of the gazebo

Painting the gazebo

After installing the frame and roof, all wooden surfaces must be painted. When the paint dries, a wooden table and benches along the walls are placed inside the gazebo. Electricity is connected from the house to the gazebo, they hang a light bulb or lamp. To add coziness to the room, you can hang the walls with a dense light-colored fabric. The interior decoration completely depends on the taste and capabilities of the home owners.

This version of the gazebo is basic. If you wish, you can improve the design: install wooden gratings between the supporting beams, sheathe the walls with clapboard or waterproof plywood, lay logs on the concrete base and make a wooden floor. Instead of beams for the frame, you can take metal pipes, and replace the slate with polycarbonate or soft tiles.

Soil types and construction features

To select a foundation, an analysis of the state of soils and their properties is required. The most convenient and desirable are sandy and rocky soils. They are the least troublesome for builders. The depth of the foundation in these cases is permissible 0.5 m and the mainland soil will be a good support.

The most insidious are clay soils. Wet clay swells when frozen, and not evenly. This immediately affects the foundation, it begins to lift and warp. The building will deform. This is especially noticeable on glazed pavilions. Doors and frames stop opening and cracks may appear on the glass.

Foundations for gazebos can be solid, tape and columnar. The simplest and most affordable, as well as the most stable on clay soils, in swampy areas, soils with a high moisture content and quicksand will be a columnar foundation.