Advantages and disadvantages

Metal profile gazebos have a whole list of undeniable advantages:

- Reliability. The finished structure is resistant to physical and mechanical influences, as well as to weather conditions, does not lose its shape in the event of soil subsidence.

- Easy to operate. Redecorating the frame can be done on your own, without involving outside specialists.

- Visual appeal. The appearance of arbors made of iron and other metals inspires respect: they look very expensive and respectable.

- Durability. Welded metal structures can stand for several decades, remaining safe and sound.

- Versatility. Ironwork will look great in any setting, be it a public park or private property.

- Fire resistance. Iron and other metals are absolutely not afraid of fire, so there is no need to fear that a spark from a fire or other source of fire can destroy a welded structure.

- Large price range. If you want to have a metal gazebo on your garden plot, you can choose a more economical or more refined option.

- Resistant to weather conditions: the metal does not fade in the sun and is not afraid of moisture, unlike other materials.

- Garden gazebos made of various types of metal are not afraid of insects and small rodents.

- Variety of designs. Metal gazebos can be either solid-welded or collapsible. Prefabricated models are also good in that, if necessary, they can simply be disassembled and moved to another place.

There are very few disadvantages of such buildings. The downside is their higher cost compared to plastic and wood products. However, the difference in price is not as great as the number of undeniable advantages.

Another disadvantage of metal is that it is prone to corrosion, and you will have to regularly update the protective layer to keep the building in good shape.

Technology for assembling a gazebo from a profile pipe

So, the project has been drawn up. Now you can start actually assembling. A gazebo is assembled with your own hands from metal in several stages:

- Filling the floor.

- Erection of the foundation.

- Assembling the frame and painting it.

- Parapet and roof sheathing.

Structurally, a metal gazebo is a simple construction

What materials will be needed

Metal gazebos are being erected using the following materials:

- Profiled pipe. Its section and wall thickness depend on the size of the gazebo.

- Polycarbonate. This material is the easiest to use. If desired, the cladding can be done by any other. It is very easy, for example, to assemble a gazebo from a metal profile with your own hands.

- Metal paint. Acrylic enamel may work well.

- Cement, sand and crushed stone for pouring pillars and floors.

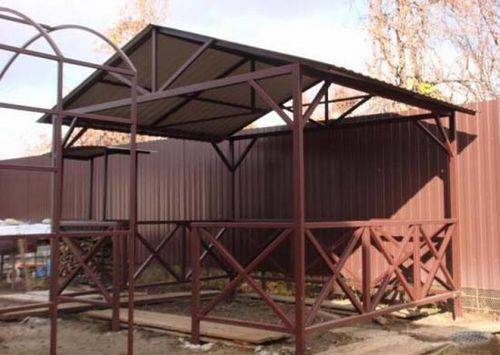

Photo gazebos from profile pipes

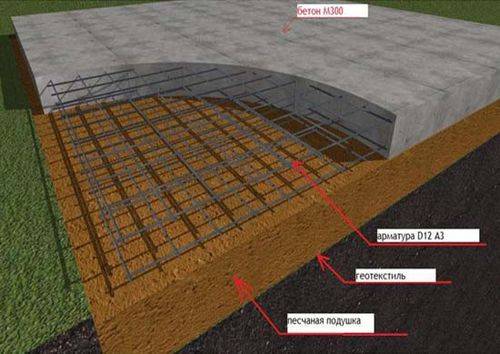

Steel rods 12mm for welding the reinforcing cage of the floor.

In addition, you will also need the following tools:

- Welding machine.

- Pipe bender. It is necessary if there are curved elements in the design of the gazebo.

Curved elements of metal arbors are made using a pipe bender

- Shovel.

- Screw gun, drill.

Pouring the floor of the gazebo

The floor under the gazebos from the professional pipe is usually poured as follows:

- The site is marked using the "two curves" or "Egyptian triangle" method.

- On the marked site, a layer of earth with a depth of 15-20 cm is removed.

- A 5 cm layer of sand is poured into the resulting shallow pit and compacted with water.

Pouring the concrete floor of the gazebo

- Then the timber formwork is installed.

- Next, the reinforcing mesh is laid.

Important: The mesh should not be welded, but tied with wire. Otherwise, in the attachment points, it will begin to rust very quickly.

At the final stage, the foundation pit is filled with concrete. The surface of the resulting site must be carefully leveled.

Sometimes, instead of pouring concrete, the floor of the structure is laid out with paving stones with their own hands.

The floor of a metal gazebo can be faced with paving stones or tiles

The foundation of the gazebo

Further, along the edges of the resulting platform, pits are dug (according to the number of support pillars of the frame) with a depth of 80-100 cm. Then, in their center, pillars from a profiled pipe are installed. At the next stage, the pits are filled with concrete.

The supporting pillars of the frame of the metal gazebo are poured with concrete

Assembling the frame

After the installation of the pillars is completed, they are scalded with two rows of veins. One is located at a height of 2 cm from the previously poured floor, the second - at a height of 90-150 cm from the first. Of course, the cross pipes are not fitted between the pillars of the door opening. In the next step, the upper harness frame is welded on.

The process of welding the metal frame of the gazebo

Roof truss welding

The rafter system is assembled according to the project. The easiest way is to weld a gable roof. To do this, pieces of a profile pipe are connected in pairs on the ground, and then lifted up.

Tip: Welding a gazebo from a profile or a professional pipe is best done with an assistant. In this case, one person can level the elements of the structure, and the other one can perform the actual welding.

At the next stage, to the section of the frame of the upper trim from the side of the facade and the future rear wall, they are welded along the rack (in the center). Their height should be equal to the height of the roof. Next, a run from a professional pipe is welded between them. The fastened rafter legs are lifted up above the girder and welded to it and to the frame of the upper harness.

The frame of the gable roof of the metal gazebo

Gazebo sheathing

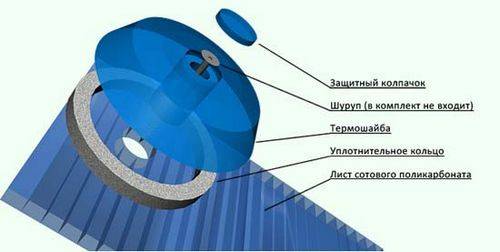

As soon as the welding of the metal frame is completed, it is primed and painted. After the paint is dry, you can start the cladding. To do this, pre-drilled holes in the frame railings, lower strapping and roof rafters. Next, the polycarbonate is cut out. At the next stage, you will need to drill holes in the sheets, having previously made the markup. Through them, the polycarbonate is screwed to the frame.

Scheme of fixing cellular polycarbonate to the frame on a self-tapping screw with a thermal washer

Important: You need to work with polycarbonate correctly. Since this material is capable of expanding with increasing air temperature, it is not allowed to tighten the fasteners too much.

A gap of about 1mm should be left between the sheet and the head of the fastener. It is best to use special self-tapping screws with a thermal washer.

At this point, the installation can be considered complete. Below we suggest you watch a video on how such a simple metal structure is assembled.

As you can see, assembling a metal gazebo is not a particularly difficult process. The main thing is to draw up the correct project, having calculated everything exactly. The rest is a matter of technology.

Types of polycarbonate gazebos

Before decorating a summer cottage with light architecture, you need to decide on the models and functional load of the building.

And the building itself can be varied and is classified according to the following criteria:

- Construction type. There are sheltered and open buildings. Any kind will decorate a private home. Open ones are erected for recreation only in the warm season. If you plan to rest in bad weather, then choose a closed option.

- By type of installation. Separate mobile and fixed. The last option is being built on a foundation, so it will be possible to move it. The portable version is suitable for those who prefer constant changes on the site.

- By complexity. There is a simple, lightweight and composite canopy. When building a simple version, special efforts are not required. When building a complex gazebo, you will have to spend a lot of effort, time and money. But on the other hand, such models are durable and can perfectly complement the overall design (house, garden, alpine slides).

- By the degree of equipment.Can be equipped with a fireplace or barbecue. An uncomplicated option is suitable for regular tea drinking. If it is planned to gather guests at the dacha, then it is better to build a canopy with a barbecue.

- According to the degree of operational load. There are models with additional and artistic features.

- By the shape of the structure. The garden house can be round, square, oval, rectangular or polygonal.

Stages of building a gazebo

According to statistics, most often gazebos are built of wood, because you can handle it without experience and special tools. Working with metal requires skills, and bricks are long and difficult. Therefore, we will take a closer look at a wooden structure from a bar.

Drawing

Before starting work, be sure to make at least a schematic drawing with all dimensions. Choose a suitable plan on the Internet, order it from professionals or draw it yourself - it's not difficult.

Site preparation

Choose the area on which the gazebo will stand and mark it with pegs and string. Remove the top fertile soil layer, because organic matter will cause the tree to rot. Fill loose loose soil with broken brick or rubble, and sand on top. It is better to cover clay soil with clay and tamp it.

Foundation construction

Once again tamp the pillow and place the concrete foundation blocks on top of it. You can make brick posts, but it will take much longer, because they still need to be strengthened. The step between the blocks is up to 2 meters, depending on the thickness of the material for the frame. With each step, check the level so that all the support columns are in the same plane. Lay a waterproofing layer on top and install the bars for the lower strapping. Reinforce the frame with metal corners to make the structure more stable during bad weather.

Installing the frame

First you need to install vertical support posts - strictly perpendicular to the foundation. They must be in the corners, on both sides of the entrance and above the foundation posts. When installing, use oblique strips and reinforce all joints with metal corners. The next step is strapping on top, which completely repeats the bottom one and is attached according to the same principle. Then check again all levels, distances and right angles. Place the harness in the middle at the level to which the lower skin will go.

Roof arrangement

You will have to assemble the rafter system, depending on the type of roof you choose. In fact, these are triangles reinforced with a horizontal crossbar, which are attached to the upper harness with nails. To make a roof with an overhang, a small recess is cut in the rafters, which will stand on the support. After installation, again check the levels, angles and reliability of the fastening. Under the corrugated board or slate, the usual lathing is enough, and under the soft roof you need a continuous sheathing so that it does not sag.

Decorating and decorating

Planks are best for sheathing the bottom of a wooden gazebo. Together with the outdoor ones, treat them with an antiseptic and cover them with a stain or special paint. It must be for the tree and the street in order to protect the structure from precipitation.

Decorating the gazebo

At this stage, all parts are installed and the interior space is designed. Inside, the building can be equipped with a table, benches, flowerpots, shelves, a bar counter, a hammock, a suspended chair and other attributes. The main condition is good quality materials.

Textile products will add comfort to the gazebo. Solid or multi-colored curtains in each individual section will create a different atmosphere.

Exterior decoration consists of:

- painting and varnishing wooden wall parts;

- equipment for flower beds;

- construction of garden paths;

- installation of lanterns.

Everyone can show imagination in decorating the gazebo. For example, an open structure can be drowned in curly flowers (hops, grapes, honeysuckle). Containers with petunias on the railing or pots with annual flowers, hung around the perimeter, look good.

Important! Since the summer version of the canopy is not heated, fluctuations in temperature and high humidity can damage the furniture.

Whatever frame is planned for a polycarbonate gazebo, it will undoubtedly decorate the garden plot. And if space permits, you can show your imagination and create a real architectural masterpiece.

Calculation of material and size of the gazebo

First of all, you need to purchase the material. For the posts of the gazebo, the following profile pipes are needed:

- 50 × 50 mm if slate, bituminous tiles, metal tiles or profiled sheets will be laid on the roof;

- 75 × 75 mm if tiles or slate will be installed on the roof.

For lintels, a thinner profile is possible: 50 × 50 mm - maximum, minimum - 20 × 30 mm. If you plan to build a large gazebo, then, accordingly, it is better to take a large section of the profile and vice versa. Also take into account the weight of the material with which the frame of the gazebo will be sheathed.

To make a square metal gazebo with a size of 3000 × 3000 mm with a rack height of 2200 mm, you will need the following set of material:

- pipes for strapping 12 m - 50 × 50 × 2 mm;

- profile pipe for lintels in this name: 30 m - 40 × 20 × 2 mm, 6 m - 20 × 20 × 2 mm and 14 m - 40 × 40 × 2 mm.

- metal strips 2 m 20 × 4 mm.

Supplements for comfort and aesthetics

Items that can complement your gazebo will be listed below. For the most part, this is just a decor, but a barbecue or furniture can really help you with comfort.

Installation of a barbecue or barbecue

Rest without cooking on coals has become a rarity. It is already difficult to surprise guests with a barbecue, but no one is going to refuse it. Therefore, it makes sense to think about installing a barbecue or barbecue.

The profile design allows, in some cases, to place the brazier inside the gazebo. Usually, either very large rooms are adapted for this, or they have a platform for frying meat directly.

Decorative forged elements

If you want to add some extra touch to your gazebo, then forged metal will do the best. Complex architectural elements such as flowers, animals or abstract patterns are considered expensive. A simpler option is curved metal pipes that emphasize the iron frame of the building.

Excellent forging for metal

Excellent forging for metal

Greening with plants

Since the metal does not have the property of rotting or seriously deforming (without extreme loads), the profile pipe can serve as the basis for climbing plants... If you do not plan to sheathe the gazebo, then you can make full-fledged protection from fresh flowers and plants from light and wind.

Lathing

A wooden lattice will almost always be appropriate. I have not yet seen a single gazebo where inclined slats would not look aesthetically pleasing (provided that they are fixed evenly and securely).

In addition to the decor, the crate has another interesting property: people sitting inside the gazebo will calmly see everything that happens around the building. But the space inside will be hidden from prying eyes.

Furniture

Since the furniture is difficult to "sew" into the frame of the gazebo, since it consists of steel, the owners begin to think about purchasing it after construction. I would like to offer you several options that will help you decorate your country house.

Construction of a gazebo from a profile pipe step by step

The first step towards building a metal structure is choosing its type. It can be open, semi-closed or completely closed, with or without lighting. For this, a construction project is drawn up.

Design

The sketch can be sketched by hand, or entrusted with the development of a professional designer. At this stage, you should decide on the dimensions of the structure. The height of the structure should slightly exceed the average height of a person (180-200 cm), the width of the entrance opening should be no less than the width of the entrance door (about 1 m).

a drawing indicating the actual dimensions of the building is needed in order to calculate the number of pipes for installing the frame, as well as other necessary building materials.

Detailed drawing of a metal gazebo

For the installation of an iron structure you will need:

- profile pipes with a cross section of 50x50mm and a wall thickness of 2-4 mm for the frame;

- iron rods or pipes with a section of 20x40 mm for the transverse elements of the sheathing;

- roof covering;

- electrodes, welding;

- grinder, drills for metal;

- screwdriver, self-tapping screws.

Preparatory work

Next, they begin to prepare a place for installing a metal gazebo. It can be a site near a reservoir, in the shade of trees, or near a house - the main thing is that it is picturesque and comfortable for relaxation. In the selected area, remove the top layer of soil (15-20 cm) and level the base. Since the metal gazebo is lightweight, a columnar foundation will be enough for it.

Preparation of the site for the gazebo

Next, they begin to install the columnar foundation - the base of the gazebo. To do this, holes are dug at the corners of the site with a depth of 50-70 cm, into which a layer of crushed stone (20 cm) is poured and the supporting profile pipes are poured with concrete.

Preparation of the site for the gazebo

Attention: the evenness of the installation of the pillars must be checked with a level.

Formation of a metal frame

After installing the vertical metal racks, proceed to fastening the horizontal crossbars. To do this, you can use iron rods, or pipes of a smaller section. Metal elements can be connected to each other by welding, or using bolts and self-tapping screws. Transverse pipes for fencing the structure are installed at a height of 1-1.2 m. And the top of the support pillars is fastened using the upper strapping.

Please note: piping should be welded to each upright to ensure structural reliability.

Methods for fastening elements of a gazebo made of metal, photo drawings

Next, proceed to the installation of the frame under the roof. So that precipitation does not linger on it, the transverse logs are fixed at an angle (30-45 degrees). For a gable roof, several support triangles are made, which are connected with a common profile along the upper point, and their bases are connected to the main frame of the gazebo.

Construction of the frame of a metal gazebo for a summer residence, photo

Advice: before installing the roofing, the metal frame should be primed and painted, since after the overlap it will be problematic to do this.

Roof

One of the simplest and most economical roofing options for a gazebo is polycarbonate. Cellular polycarbonate 8 mm thick is suitable for the roof of the gazebo. It is attached to special bolts with thermal washers. For this, polycarbonate sheets are cut to the required dimensions, and holes are drilled in the pipes for fasteners. The ends of the polycarbonate sheets can be closed with special strips - this will provide them with additional protection and give a more neat look. As a result, we get a rather cozy and inexpensive gazebo, which only remains to be equipped with benches or other furniture for a good rest.

Attention: when installing roofing, install it with a slight overhang. This will protect all structural elements from atmospheric influences. ... Do-it-yourself ready-made gazebo from a metal profile

Do-it-yourself ready-made gazebo from a metal profile

Metal gazebos in the country are a sign of the good taste of the owners of the site. They will be a harmonious addition to landscape design, a reliable and cozy place for outdoor recreation. These structures can be of different shapes and sizes. Metal combines well with other building materials, which allows even the most daring design ideas to be realized.

Gazebo roof

The choice of roof depends on the complexity and shape of the structure. For example, for the simplest open gazebo, a classic gable roof is suitable. Square structures with a hipped roof look interesting

And if the gazebo is adjacent to the wall of the house, pay attention to the lean-to solutions. For pentagonal, hexagonal and octagonal buildings, a hipped roof is best suited. It is more difficult to make, but it looks very neat.

Basically, you need to calculate the slope and carefully connect the rafters at the center point. To make the roof round, concave or curved, use sheets of polycarbonate. They can be shaped and bent without edges, experimenting with colors and transparency. For such a roof, a welded frame made of bent metal pipes is needed.

Options for giving with barbecue

The market offers the following format: a forged structure with a barbecue located inside for frying meat and a barbecue bench, but there is no table for guests.

As a result, we get an ordinary grill, which is simply aesthetically decorated under a gazebo, in which it is pleasant to be a person roasting meat.

If you are looking for some kind of summer cottage option, then it is better to consider something similar to a classic wrought-iron gazebo, and install the brazier somewhere next to it. Standard forged buildings with barbecue did not impress me at all (photo below).

An option is possible when the barbecue is inside the gazebo. However, there is an obvious drawback: the design is too large and expensive.

Its implementation is possible only on a large area where there is free space. It is not always expedient, however, everything is under one roof, and this can justify itself.

Types and technological features of metal arbors

Garden houses can be built from various materials - brick, stone, wood, metal. Each of these materials has its own advantages and disadvantages.

Let's consider in more detail the technological features of metal arbors. The main advantages of metal structures over products from other materials:

- high strength (the strong frame of the metal arbor can withstand mechanical loads, does not deform when the soil subsides);

- durability (metal structures can last for several decades);

- fire safety;

- combination with other materials: profiled sheet, slate, polycarbonate can be used as a roof for a metal frame.

The combination of iron with polycarbonate - metal gazebos, photo

Unlike wood, the metal does not burn, it will last much longer, does not fade in the sun and does not crack. It will not be damaged by insects and it will not collapse under the influence of weather factors. The only drawback of metal is a higher price compared to wood (by about 15%), as well as certain difficulties in assembly (welding).

Tip: you can extend the life of a metal product with regular maintenance - timely detection and elimination of corrosion traces.

Varieties of metal structures

Metal garden buildings can be divided into two groups:

- stationary - capital buildings built on a permanent basis on a strip or columnar foundation;

- temporary - collapsible structures installed directly on the ground so that, if necessary, they can be easily removed or moved to another place.

Photo of metal arbors - stationary and portable

If you decide to build a metal gazebo for a summer residence with your own hands, you need to start by choosing a project and determining the method of manufacturing the structure.

when choosing a technology for constructing a metal structure with your own hands, be guided by your own construction skills, as well as the availability of tools and special equipment.

The simplest option is a profile gazebo. It can be built from a corner, round or shaped (rectangular) pipes, channels (metal beams). You can assemble such a structure using bolts, or welding.

Tip: if you cannot weld a gazebo from a profile, you have no experience with a welding machine, choose a prefabricated bolted connection.

Welded and bolted connection of elements - photo of gazebos from a metal profile

The gazebos from the professional pipe are mobile, resistant to the influences of the external environment, and reliable. This material is used as a supporting element to form the frame of the structure, since it can withstand heavy loads and does not lend itself to deformation.

Photo of a gazebo from a profile pipe using forged elements

Profile pipes are often used for the construction of garden houses. And, if the iron pipes are quite heavy, then you can use an aluminum profile pipe, which is lightweight and cheaper.

Gazebo on a metal aluminum frame

If the structures from the professional pipe look simple, then forged gazebos are more elegant. Ornate patterns, curls, openwork inserts made by artistic forging will give the building originality and a beautiful appearance. But to create a forged structure, you must have blacksmithing skills, and have special equipment. An alternative would be to buy a ready-made forged gazebo, which you can assemble yourself.

Please note: Since the forged steel structure is laborious to perform, it is quite expensive.

Forging products - summer cottages made of metal, photo

Do-it-yourself metal gazebos are always prestigious. Iron construction can have various configurations. The most common are rectangular and square structures, a little less often - eight- and hexagonal garden buildings.

Complex design projects can only be realized by experienced craftsmen - original iron gazebos, photo

Considering the constructive solution and functional purpose of the garden metal gazebo, it can be equipped with various attributes for relaxation - furniture, barbecue table, barbecue. In some gazebos for summer cottages, special brackets are provided on which you can install seats around the perimeter. This greatly improves the comfort of the building.

Summer building with barbecue - a cozy place for outdoor recreation

Work on the bottom rail and supports

Once the blocks are in place, the pipe sections can be laid on top of them. When forming the lower trim, a square section pipe with a side of 50 mm is used. You can take more powerful products. After laying the pipes, their position is checked horizontally using a level.

From a pipe of a smaller section, two jumpers should be made, on which the floor boards will rest. Pipes are painted with a primer

Particular attention must be paid to those places where you passed welding. The height of the racks should be 220 cm

The racks will turn out to be quite massive, and in order to secure them securely, it is necessary to weld the mounting jibs using a strip of metal.

When building a metal gazebo, the dimensions of which were mentioned above, you must install the post correctly by checking its position with a plumb line. The jibs are clamped with clamps. First, a pipe is welded along the perimeter, and after that it will be possible to remove clamps and jibs one by one. The door posts should be finished at the level of the railing.

Beautiful examples

There are a huge number of examples of metal gazebos. It can be either an independent detached building or a building adjacent to the house. The simplest version of the gazebo is a pipe frame with a canopy, an uncomplicated table and two benches on either side of it.

If the area of the site allows, you can make a more original design - combine under one roof and a place for gatherings, and a brazier or barbecue. The roof will reliably shelter the coals from precipitation, and it is much more convenient to watch the kebabs without interrupting the general fun.

Wicker rattan furniture looks very nice in the gazebo. In the rocking chair, you can take a nap in the fresh air.An alternative to a rocking chair is a hammock or garden swing next to the table.

The shape of the canopy plays an important role in the perception of the appearance of the gazebos. The roof covered with colored slate looks interesting. If you like complex shapes, you can build an arched wrought-iron canopy with a glass ceiling. It will protect against possible precipitation, but will let the sun's rays through.

Various non-standard forms of arbors with curved lines look very unusual - for example, in the shape of a ball. As a rule, this is a closed type of structure in which the frame is made of metal. Polycarbonate can be used as the outer sheathing material.

Beautiful lighting will decorate any building. This will allow friendly gatherings to continue even after sunset. There can also be a lot of lighting options - from a central lamp in the center of the curtain to an LED strip around the perimeter of the gazebo. Moreover, lighting can be started up not only at the top, but also duplicated at the bottom.

The most exotic option for the location of the gazebo is the creation of a bridge across an artificial reservoir as its logical continuation.

How to make a gazebo with your own hands, see the next video.

Made of metal

A more expensive and sophisticated option is a gazebo made of metal. Most often, such a structure is a welded frame made of pipes with decorative forging elements.

Decorative forging is considered a special chic, about which you can read in more detail here - Forged gazebos: photos, options, beautiful, welded, for summer cottages.

If you can pick up an interesting and original drawing, then your gazebo, not only will be unique, but also beautiful. The pleasure is expensive, but such a design is well worth the money.

The advantage of metal gazebos for summer cottages is reliability, which is demonstrated by a properly welded structure. Unlike wood and brick, it is not subject to any kind of atmospheric influences (except perhaps rust, which is periodically tinted).

Types of structures

A metal gazebo made of plastic and versatile material, in terms of plan, can have the form:

- square;

- rectangle;

- polygon;

- circle.

The roof structure is a spatial system in the form of:

- arches;

- one, two or four rays;

- tent;

- domes;

- cone;

- a cascade of arches or waves.

Interesting are the spherical arbors, where the walls and the roof are made as a single rounded structure.

Spherical metal gazebo

The frame is mounted from a circular or square profile, angle, reinforcement. Forged twisted pillars, openwork metal details decorate the building at the same time.

The traditional frame consists of supports, horizontal braces, and a roof. But options are possible when benches, a table and a barbecue are connected into one structure.

For covering, roofing materials are used:

- metal or soft tiles;

- asbestos or plastic slate;

- professional sheet;

- ondulin;

- waterproof textiles.

Wall openings can be open, half-filled or completely filled. In this case, a door leads to the gazebo. Fencing materials - wood, polycarbonate, glass, composites, metal.

The resting place is decorated with wrought-iron openwork lattices, climbing plants, flowers, lighting. Wicker furniture, textiles, decorative details create coziness. For the installation of the floor, paving or ceramic tiles, terrace or ordinary boards, concrete are used.

Tips & Tricks

If you certainly want to have a beautiful summer gazebo in your yard, but you do not want to bother with its construction, you can order an individual design project and its subsequent execution in a special manufacturer. With the help of a computer program, a 3D model will be drawn for you in various projections, and you can make your adjustments and wishes.

If this option seems too complicated or expensive for you, you can make a gazebo from scrap materials yourself.Sometimes some of the materials for such construction are in many in the country, for example, round or rectangular pipes left over from previous construction, metal beams, corners and other consumables. It is enough to drive 4 support pillars into the ground, fix them in the ground, and you can attach the roof to them using bolts or by welding.

Well, a very simple option is to buy a collapsible model in the store and assemble it yourself. There are a lot of options for such awnings now.