On reinforcement cage and cement

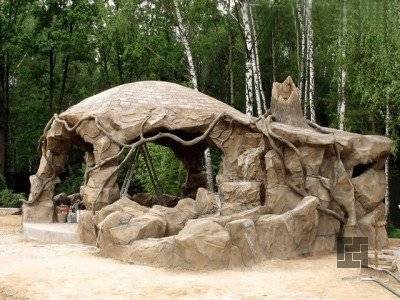

A garden gazebo can be built using ordinary cement mortar - this is also a non-standard solution. This option is complicated by the fact that it is necessary to create a rigid reinforcing cage for it, and a netting is also suitable. Reinforcement structures will have to be bent and welded together. But for the manufacture of the frame, you can invite a specialized specialist, and you can do the rest yourself. Make the solution thicker in consistency, spread it in parts, throw it over the reinforcement structure in small doses. When it dries up, you shape it into an interesting shape. It can resemble intertwined trees, vines, fantastic plant forms, exotic plants.

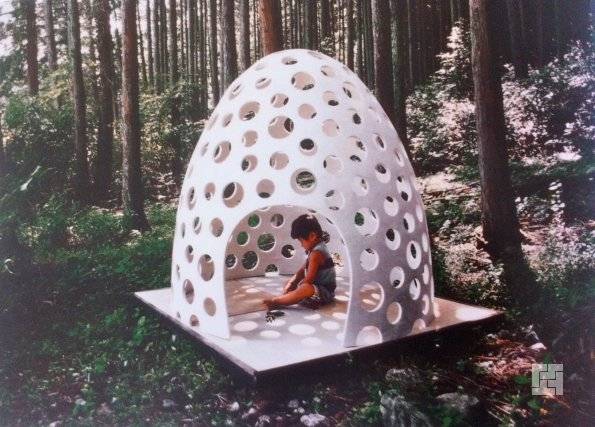

And, conversely, if you use a lot of metal parts and still decide to expose the reinforcement cage in some places, your gazebo will resemble the shape of a spaceship. Only the roof in this case must be made of metal, plastic or corrugated board, or maybe from transparent polycarbonate.

You can make an unusual tent gazebo using both cement and stone. It will resemble a part of a stone ridge and will organically fit into the plant landscape.

Gazebo pavilion for summer cottages

This, of course, is not the easiest project, but the pavilion gazebo for a summer residence is an ideal place for a summer dining room. You can always change the size and design of the pavilion to suit your needs and budget, but it is better to use the instructions and advice provided in the diagrams. A gable roof will improve the appearance of the structure, but it will require a large investment and a lot of materials. If you're looking to build a simple pavilion to enjoy with family and friends, there are several options you can choose from. On the one hand, you can build a gazebo or a simpler structure like this wooden pavilion. You can do it yourself, but you have to plan every step of the construction from the very beginning. It is recommended that you buy the very best materials you can afford. They should be weather resistant such as pressed wood, pine or cedar. Take accurate measurements carefully before adjusting sizes. Pre-drill holes in the parts before driving in the screws to prevent the wood from splitting. All stages of construction are shown in step-by-step diagrams, detailed instructions are on the site.

The foundation for the gazebo

Even the simplest gazebos for summer cottages require support - a foundation. This is due to the presence of groundwater, which, depending on its volume, can destroy the structure above the ground surface.

The construction of the pile-screw foundation is carried out in several stages:

- Marking the area for the foundation;

- Leveling the ground;

- Deepening of piles, depending on the type of soil (the flow of water at a low level gives a reason not to deepen the pillars much, but with a high flow, the piles must be screwed in deeper - by one and a half meters);

- Wrapping support piles with polyethylene;

- Filling the finished holes with rubble - the gaps between the piles and the walls of the soil.

- Pouring holes with concrete.

Further, pillars are built into the piles. The bottom must be supplemented with load-bearing elements for the flooring. Thick bars act as the first, and the process itself is called the lower strapping. Later, horizontal logs are attached to the bars, which can be sheathed with boards.

Erection of the frame

The next stage in the construction of the gazebo is the construction of the frame. To do this, use the main material - logs, beams or pipes according to the number of corners at the gazebo. The diameter of the base material should be approximately 14 cm, and if it is a square bar or pipe, then the approximate size should be 10 * 10 cm.A base, wooden or metal, is installed on the foundation, to which the frame is attached. After installing the main beams, they are altered together with the most suitable material. Rafters are attached to the upper part of the timber, on which the roof will be held. The rafters are also altered among themselves. Create a base for the roof. If the gazebo is erected from wood, then it is advisable to immediately open the frame with a special primer and paint, and if it is made of iron, then this cannot be done, since it is impossible to carry out welding work on the painted material.

Ergonomic gazebo made of natural material with decorative elements

How to make

It is not difficult to build a beautiful gazebo at the lowest cost with your own hands if you follow the recommendations of experienced builders and follow all stages of the work step by step. A simple summer gazebo will turn out for any summer resident and will allow you not to spend extra money on manufacturing. It is worth starting by looking at a standard work plan.

The base of the gazebo

Even the lightest arbor with the simplest design needs a fulcrum and must be anchored in the ground.

Let's take a closer look at the stages of building a foundation.

On the selected site, markings are made around the perimeter of the future building. This is usually a small area, so standard measuring instruments can be dispensed with.

- The best way to level the foundation surface is to dig the top layer of sod to a depth of 200 mm.

- Further, in the right places, you should dig holes with a depth of at least 50 cm and fill their bottom with gravel, which must be tamped.

- Log or concrete supports are placed in the pits, which are later leveled and concreted.

- After the concrete has completely dried, it is necessary to cover the supports with waterproofing and lay the bars on top, which can be connected using metal pins.

Floor laying

Laying wood flooring begins by attaching the beams to the bottom harness. To avoid sagging, concrete blocks or a cranial block should be placed under them. A floorboard is mounted on top of the bars.

Erection of the frame

When the foundation is completely dry, you can start building the frame.

- Vertical posts are placed in the corners, which can be secured with protruding metal pins.

- Supports should be carefully aligned vertically and secured with braces.

- Further, the upper parts of the racks are connected to each other by strapping. For greater stability, you can connect opposite corners crosswise with boards.

- Rafters are attached to the side harness at a distance of about 50-60 cm from each other. The attachment point can be made by cutting in both parts and fastening with nails and metal plates.

- The protrusion of the rafters beyond the bounds of the strapping should not exceed 40 cm. But it cannot be made too small either, because then the protection from precipitation will deteriorate.

Finishing

When the foundation and frame are ready, we can say that the main stages of work are behind. Finishing allows for more freedom and creativity, so installation is hardly time consuming.

The process of finishing the gazebo:

- vertical posts should be installed between the supports, to which the filling is attached;

- if the sheathing is made of lining, then fix it with carnations with small caps;

- the grille is mounted with self-tapping screws from the inside.

The roof installation process depends on the selected material:

- solid lathing is needed for tiles or wooden plates, that is, for piece roofing material (the best is a lattice made of moisture-resistant plywood with a thickness of at least 8 mm);

- for metal tiles, ondulin and polycarbonate, a sparse lathing of wooden beams will be required;

- the roof is fixed on the lathing according to the manufacturer's instructions, additional protection (drainage system) is mounted on request.

The final stage of the work will be the arrangement of furniture, the elimination of minor defects, the removal of construction waste and so on.

It is not so difficult to complete all the above points in stages, especially if you have at least some experience in construction. It is quite cheap compared to projects that are done by professional craftsmen. Moreover, a homemade gazebo is another reason to be proud of yourself. If, over time, the usual construction seems to be small, you can finish building the upper floor (near closed gazebos) or design the device of a full-fledged recreation area that can be attached to the house.

Manufacturing materials

Summerhouses are made from different materials. Depending on your plans, you can choose the option that suits you.

From planks

A wooden gazebo is the simplest and most comfortable model. To carry out the installation of such an object, you do not need to build a monolithic foundation, since it can be replaced with simple cinder blocks, concrete blocks, a wooden frame and old tires.

Wooden gazebos have numerous advantages:

- environmental friendliness of the material;

- ease of use: collapsible models can be carried;

- multifunctionality;

- the gazebo will fit into any interior;

- long service life.

There are also disadvantages for such objects:

- so that the material does not deteriorate, it should be treated with special means;

- wood is a fire hazardous raw material.

For work, you can use any material that is available. It is possible to make an object from oak, linden, pine. Many people choose blockhouse gazebos. Round timber is popular. Objects made from this material have different designs. The appearance depends on its size and type of wood.

Brick

It is a durable and reliable building material. With the help of these raw materials, you can create a gazebo for years to come. Such an object should be located on a solid foundation. Can be strip or monolithic base. Most use such gazebos as a summer kitchen, a place to relax with a barbecue.

Stone

Stone gazebos are also popular. Limestone and other natural materials are suitable for work. Stone buildings are reliable and solid. However, experts do not recommend making small gazebos from stone, as you will lose the effect of fundamentalness.

From foam blocks

To make a gazebo from foam blocks, several rules should be followed. This is due to the high absorbency of the blocks. To create a competent structure, you will need to equip internal waterproofing. Foam blocks are considered the best option for building a winter gazebo, since the material retains heat well.

Polycarbonate

Polycarbonate gazebos are lightweight and unpretentious structures that can be equipped on any foundation and frame.

The object has the following advantages:

- low cost;

- mobility;

- resistance to temperature changes;

- bright and colorful appearance;

- fire resistance;

- resistance to mechanical stress;

- flexibility and moisture resistance;

- good sound insulation of the material and heat retention.

The disadvantages include the following:

- low abrasion resistance;

- susceptibility to UV rays.

Metallic

Metal structures are the most durable gazebos. If you decide to create a metal structure, be sure that such a structure will serve you for many years.

Metal gazebos are a manufacturing method for a person who has a welding machine, an electric grinder and a perforator at hand. As a foundation, you can use bricks, monolithic fill, pipes and stones. With a well-designed drawing, you can quickly assemble your structure. There are lightweight options for your summer pastime. For winter events, you can insulate the structure.

Advantages of metal arbors:

- resistance to environmental influences;

- easy installation;

- fire safety of the material.

Negative qualities:

- heating in the sun;

- susceptible to corrosion;

- in winter, the metal freezes strongly.

From plastic pipes

Standard gazebos have capital construction. However, in addition to the usual brick and wood, many people began to use PVC pipes.

The advantages of this material include the following qualities:

- long term of use;

- resistance to aggressive environmental influences;

- easy installation;

- the possibility of modifying the building;

- mobility;

- affordable price.

Canopy designs depending on their area of application

First of all, a canopy is a means of protection that will protect a certain area from rain and snow, falling leaves and hot rays of the sun. Consequently, their location on the territory of a private house will be optimal where there are supposed to be recreation areas or areas of the greatest "passability" (where a person passes most often).

Canopy "visor"

This type of canopy is the most basic and probably the most important, because it serves as a means of protection from rain and snow near the front door. It is also very important due to the fact that it can protect the threshold or steps from the adhesion of wet snow and the formation of ice, which can lead to painful falls, bruises and injuries, and sometimes even fractures.

That is why you should pay special attention to it, carefully consider the length of its protrusion and width in such a way as to protect yourself from possible problems. A subtype of such a canopy is an extension above the terrace, which is fixed with one side to the wall of the building.

Under the canopy, you can arrange furniture, a table, a barbecue or a small recreation area for the comfort of residents of a private house.

Since this canopy is actually an additional part of the house, it is made from materials that correspond to the main building. If the house is wooden, then the canopy is made of timber, if it is brick, then a metal covering is suitable

In addition, it is important to take into account external harmony and color matching, so that at the end of the construction, the house and the shed look like a single whole.

Canopy extension

With the proper desire, you can create a canopy in the courtyard of a private house in such a way that it protects the entire territory from the gate to the threshold for entering the house or to any of the other buildings on the territory. This type of structure is quite massive and dimensional, it is a whole extension, one side of it is attached to the house, and the other is installed on supports. Their main advantage is that you can freely move along protected paths in any weather, and in winter these paths do not need to be cleared of snow. The canopy extension can also be of a stationary type (held on both sides by supports) or a mixed version.

A canopy over the pool of a private house

With this type of canopy, it would be best to construct the closures of the "greenhouse" type. If sliding elements are used in the structure, then they can be controlled by opening the sections in hot weather and closing them in wind or rain. The best option would be transparent coatings that will not interfere with the view and create a pleasant aesthetic impression.

Gazebo canopy

This is one of the most favorite types of canopy for all home owners, which can be made in any convenient form: a circle, square, polyhedron, etc. Such awnings are best placed in the most picturesque area of the site or on a small hill. Also, the gazebo can be of an open type, in which case there are enough supports and the roof itself, which will protect against bad weather.

Canopy over the play area or playground

This option is in demand among families with a child who like to play outdoors. Everyone knows that even in bad weather it is quite difficult to keep a child in the house, which means that a special canopy should be constructed, placed over a sandbox, swing or horizontal bars in order to protect the child from the "vagaries" of the weather. It is also worth noting that the canopy will extend the service life of the play area, protecting the wooden structures of the site from precipitation.

Car protection canopy

This is the best construction option for those who do not have enough free space on the territory of a private house and cannot afford to build a garage. Also, such awnings can serve as protection for the cars of guests who will be calm about their car, placing it under a special awning. The main advantage of this carport is the economic benefit, because building a garage is much more difficult and financially expensive.

Stages of building a canopy with your own hands

In order to start building a canopy on the territory of a private house with your own hands, you need to carefully prepare for this and follow the generally accepted sequence, which is as follows:

- creation of a project, drawing;

- preliminary preparation of materials that will be used;

- preparation of tools necessary for work;

- soil preparation, surface leveling;

- installation and concreting of canopy supports;

- installation of longitudinal beams between the supports;

- roof decking and fastening (profile or other material).

This type of extension is an attribute of comfort and coziness, which guarantees the holding of previously planned outdoor activities, regardless of the whims of the weather. Now on the market, many different quality materials are freely available, which means that they can be bought and used to create a building. By connecting a little imagination and realizing his desires, the owner of a private house is able not only to complete the planned construction, but also to make it original, stylish and sophisticated.

And what about polymer pipes such as PVC for the creation of this structure?

They are also good and can be applied. This is due to the fact that polymers do not need additional protection in the form of various coatings. This material is not susceptible to the appearance of fungi, decay processes.

But in order for PVC gazebos in the country to turn out to be strong enough, it is necessary to use a thick version of pipes based on a large diameter. Let's consider some of the features of this material:

- You cannot rely on the walls of the gazebo, since the strength of such a structure is not its main advantage;

- You will have to use furniture that will not put pressure on the plastic;

- And it is advisable to place the brazier as far as possible from the walls of the gazebo.

Making a brick gazebo on your own

Next, we will deal in all the details with the technology of making a gazebo with our own hands from bricks.

It is quite difficult to make a brick courtyard building on your own, but it is quite possible

Drafting a project

Before proceeding with the manufacture of a courtyard "house", you should draw up its project. It will be easier to make a gazebo with your own hands according to the drawings. The project must include drawings in frontal and profile projections, as well as a sketch or 3D model.It is also advisable to make a plan of the yard itself and mark the location of the gazebo on it. This will make it possible to determine the methods of supplying communications. Next, you need to calculate all the building materials necessary for the manufacture of the building.

The set of drawings should include, among other things, a construction plan

Foundation making

Making garden gazebos from bricks is a procedure that involves the construction of a reliable foundation. For a simple construction of four pillars and a roof, you can make a columnar one. In the event that it is planned to manufacture a structure with massive parapets, tape should be poured.

How to make a gazebo with your own hands. Photo of the manufacturing process of the strip foundation

The foundation of both the first type and the second is being built from a cement-sand mixture with the addition of crushed stone. The markings are preliminarily done, then a trench is dug, the formwork is installed, a sand cushion is poured, reinforcement is installed and everything is poured with concrete.

Wall masonry

Solid walls and parapets are usually laid out using the half-brick method. However, if it is planned to manufacture a winter structure, it is better to lay the brickwork in a brick manner.

Sometimes the brick is placed not parallel to the plane of the wall, but at an angle of 45g. In this way, a very original corrugated surface can be made.

Making walls using the half-brick method

Column pillars can be made using the same method by which the supports of brick fences are erected. That is, before pouring the foundation column into the pit, you need to insert a pipe up to the very future roof. Next, the column is poured and the laying around it is carried out using the method of one and a half bricks. The space between the pipe and the brick is laid with concrete.

Column post manufacturing process

It will not be too difficult to make a gazebo with your own hands using the video below. This video will surely help you visualize the manufacturing process.

Roof installation

In order to make the roof, floor beams are pre-laid on the walls, and then Mauerlat.

Next, the rafters are cut out and the columns are installed on the floor beams in the middle of the span, on which the girder is mounted. The rafter legs are knocked down in the form of the letter A, installed above the girder and attached to the Mauerlat with corners.

How to make a gazebo roof. The scheme of manufacturing a rafter system

At the next stage, the crate is stuffed across the rafters. Next, a waterproofing carpet is laid and the selected material is fixed. As the latter, metal or bituminous tiles are usually used. On this, the device of a brick building can basically be considered complete.

At the last stage, a metal tile is mounted on the roof

Below we suggest you see how to make a gazebo. The video clearly demonstrates the process of laying brick pillars-columns:

Do-it-yourself gazebo from scrap materials - photo instruction

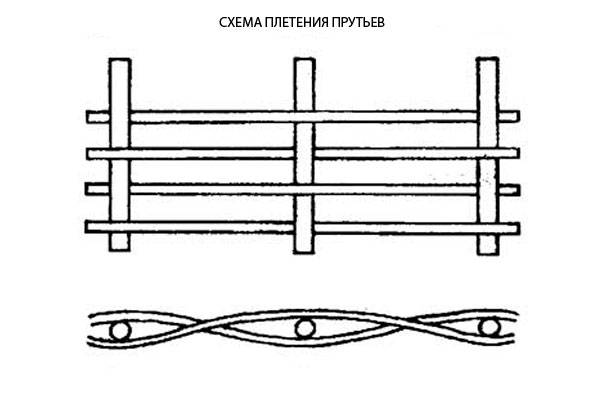

We invite you to consider an example of how to make a gazebo with your own hands from scrap materials. A photo of the finished structure from braided rods at the end of the section. The first step is to start designing.

Project and drawing

For design, decide on your own preferences - whether you want an open gazebo or a closed one. Would you like to install a canopy adjacent to the fence? How many windows? Where is the door located? Once you have made your choice, sketch it out.

If you are not a very good artist, there are plenty of programs out there to help you create a decent drawing. When drawing into details, it makes no sense to go into details - the main thing is not to forget to indicate the dimensions of the gazebo and its components.

We select a place

Your simple and original gazebo made of scrap materials has already taken shape on paper - it's time to bring the project to life. Examine the area carefully.A level place devoid of mounds and holes is great for installation. It is advised to choose places with a minimum presence of clay soil, but the wicker structure is light, and the likelihood that it will fall into loose soil is small.

Such structures look especially beautiful in the shady corners of the garden.

To quickly build a wicker gazebo from scrap materials, prepare the tools:

Materials:

Foundation

Having chosen a place, we move on to the foundation. You will need to level the ground around the building and remove excess debris and grass from it. You will not need a solid strip or monolithic foundation, but to strengthen the structure it is recommended to dig in several pegs around the perimeter.

Decide on the boundaries of the gazebo and dig into the ground around the perimeter of the rack. If you want to add stability, concrete the resulting pits (fill with concrete and fill them with rubble on top), and then proceed to the construction.

Walls

The earth has been cleared of unnecessary litter, it's time to start weaving. To do this, take a rod, fix its end with a wire and intertwine the stakes. You should have a basket. The ends of the woven rods are attached to the post with wire.

The size of the building is any - it depends on your needs and imagination.

The size of the building is any - it depends on your needs and imagination.

Roof

Since the structure is light, do not overload it with heavy materials such as tiles or slate. In addition to physical simplicity, it will not look so beautiful. Look much more impressive roofs made of natural materials - reeds, reed, straw. Remember that these materials are not durable.

To lay the roof, use metal rods or wooden beams (equally effective, we suggest choosing from what is at hand). After fixing the rods or beams to the uprights, install the roofing material.

Decorating

Such natural naturalness will serve as a decoration better than other decorative things, but you can always add a little coziness - weave a couple of chairs from a vine, throwing several multi-colored pillows on them.

Place a stone or wooden path next to it. Dig in the floor lamps around the edges - such a landscape will look fabulous at night.

Exploitation

Operate the structure, woven with your own hands, only in the summer. For the winter, we recommend that you remove it to a secluded place so that in spring and summer it will again please the eye on the site.

Shape and size

Modern technologies make it possible to create comfortable and beautiful gazebos of various sizes and shapes. It all depends only on your personal preferences, and, of course, financial capabilities.

- Rectangular. Such designs are most in demand. They have quite a decent appearance and are erected very quickly. Most often these are canopies on a metal frame or on a wooden or brick base.

- Round. Another name for such a design is the altanka. This is the second most popular type of arbors. Usually they are held on the pillars of the base.

- Corner. This design is chosen for its location. Its characteristic feature is considered to be two long sides forming an angle. Otherwise, the shape may vary.

- Multifaceted. These gazebos look very original and unusual. Most often, models with six or eight faces are chosen. The only drawback is that multifaceted gazebos require a lot of free space.

- Combined. This model includes several structures and often consists of several floors.

The dimensions of the gazebo are selected depending on its immediate purpose. If you are planning regular gatherings with friends, and you have a lot of friends, then the design should be of the appropriate size.

Structures that can accommodate up to 8 people are considered small.These include gazebos of 2x2, 2x2.5, as well as 3x3 or 3x3.5 m. But, on the other hand, a gazebo with such dimensions can easily fit even in a small area.

When it comes to a small architectural object, most people mean exactly the presence of gazebos on the site.

Models with dimensions of 4x4 or 5x5 meters are recognized as average. Gazebos with a wall length of 6 meters or more are considered large. For example, a 6x6-meter structure can easily accommodate 10 people.

If we talk about the height of the gazebo, then the minimum value from the overhang of the roof to the floor is taken as a basis, and it should be from 2.2 m.

Outdoor recreational facilities have been considered an expressive component of garden design for centuries.