What is biofuel and how to make it at home

Currently, a house, greenhouse or farmland can be heated not only with gas or wood, but also with biofuel. It is especially relevant for farms and greenhouses, where the issue of energy saving is acute. After all, the cost of heating the premises sometimes cost a pretty penny. This is where biofuels come to the rescue. Vegetable and organic raw materials are capable of heating quite large areas, you just need to competently approach the issue of processing.

Content:

- What is biofuel, its benefits

- What type of biofuel is prepared independently

- Biogas - fuel production plant

- Charcoal - Manufacturing Plant

What is biofuel, its benefits

Biofuels were invented long before the discovery of natural oil deposits. Since its use made it possible to obtain energy much faster, biofuels were quickly forgotten. However, along with oil, environmental pollution problems have appeared, the cost of fuel is inexorably creeping upward from year to year. Countries with no oil reserves have to invent alternative energy sources such as biofuels. Energy can be obtained by processing biomass in a thermochemical or biological way.

There are many advantages to biofuels. First of all, the processed plant or organic raw materials are inexhaustible, they are constantly renewed, which, for example, cannot be said about oil. The flammability of biofuels is much higher. The amount of carbon dioxide that is emitted into the atmosphere is much lower when compared with the emissions after using the same diesel fuel.

Biofuels can be made at home, especially if you have your own farm.

Along with the advantages of alternative fuels, there is also a disadvantage - diesel production is much cheaper than biofuel production. For this reason, the latter energy source is unlikely to take a leading position in the fuel market. Only those who have nowhere to go but to produce an alternative source of energy are interested in it.

If you have a winter greenhouse and your own farm, it is very profitable to be engaged in the production of biofuel - the greenhouse and the farm will be heated at their own expense. You just need to supply special equipment for the processing of biomass, you can do it yourself without any special costs.

What type of biofuel is prepared independently

Biogas is considered to be one of the most common fuels. It is produced during the fermentation of organic and plant waste. If you place manure and plant mass in a container without access to air, fermentation will begin, as a result of which it will be released:

- Up to 70% methane

- Hydrogen sulfide

- Nitrogen

- Hydrogen

- Carbon dioxide

Biogas can be used to heat rooms, heat water and use it as an energy source to generate electricity. The principle of biogas production is quite simple, it is often used by farmers to heat their livestock lands. The second most popular place after biogas is occupied by biobriquettes. They can also be prepared at home. Briquettes are used for space heating and other needs.There are also biopellets, but they are not very popular, since they require special incinerators, which is not very convenient and very expensive.

Charcoal is distinguished separately, which is also considered a biofuel.

It is manufactured on an industrial scale. Skillful owners of private houses have long mastered the technology of producing charcoal and successfully produce this type of fuel on their own. After all, the purchase of finished fuel is much more expensive than the independent production of coal. The decision in favor of a particular type of fuel is made based on the availability of raw materials for manufacturing. For biogas production you will need organic and plant waste - manure, plants. Horse manure or a mixture with cattle manure is best suited. Briquettes, pellets are made from vegetable waste, sawdust, bark, wood chips, paper.

Charcoal is burnt logs of different tree species. Usually, deadwood is spent on this, which is still in shape and has not turned into dust. If you want to stock up on fuel for things like barbecuing or barbecuing, you'll need charcoal. If you need to heat the premises - biogas or briquettes. If you have your own farm and greenhouse facilities, you can safely install installations and produce biogas.

Biogas - fuel production plant

In order to generate biogas, you will have to either purchase a ready-made installation, or make it yourself. The device consists of a container or reactor in which fermentation takes place, pipes for gas removal, a gas collector. If it is still planned to use fuel to generate electricity, a generator is built into the system. But usually such complex installations are used on huge farms where there are no problems with raw materials. If it is not possible to buy the installation, you can assemble it yourself.

The main point in this design is the reactor, the role of which can be played by an ordinary large metal container. It is better to dig it into the ground and concrete it. This is done so that the raw material is always warm, without heating the biomass at least to 30 °, fermentation will not occur and all attempts to obtain gas will go to waste. The metal container is closed so that there is no access to air. Pipes leave the reactor, through which gas enters the gas collector. From the latter, the fuel goes directly into the combustion chamber - heating takes place. When choosing a reactor, its size must be taken into account. This should be a container that should contain at least 700 liters of raw materials. If the volume is less, so little gas will be released that any labor costs will not pay for itself.

It is very important to prepare raw materials before they enter the container:

- First, it must be free of chemical impurities.

- Secondly, manure and plant waste must be chopped finely. Approximate fraction - no more than 2 cm.

- Thirdly, it is necessary to correctly compose the proportions of raw materials if it is planned to mix the ingredients.

For example, horse and cow dung mix 1: 1. It is imperative to add water to the raw materials - about 700-800 grams of water will be needed for 1 kg of manure. The biomass must be well hydrated. It is advisable to put a device in the fermentation container, which from time to time mixes the mass. This is necessary for a faster fermentation process. Many craftsmen, to constantly maintain the temperature in the reactor, 30 ° -40 °, surround the container with a water bath. As a result, fermentation will be guaranteed. However, this method is very costly, it takes a lot of electricity to heat the water. If the reactor is underground, there is no need for a water bath automatically.

Before you start building a gas production plant at home, carefully study the various design schemes.

Even the simplest model requires basic knowledge and skills in working with mechanisms.So, for example, for good fermentation of biomass, the reactor and the sleeve through which the container is filled must be well sealed. Also, as the reactor is filled with decay products, it is necessary to pump out biogas. For this, a compressor and a cylinder are usually used; you can use the same domestic gas cylinder (Propane). It must of course be empty and safe to use.

Also, do not forget about the climatic conditions in which biofuel production takes place. The colder the region, the more heat will be required to heat the reactor. It is for the northern regions that it is recommended to submerge the reactor underground. Only the sleeve for filling the reactor and the lid remain on top. In winter, the container with raw materials must be insulated, that is, the lid that is on top is insulated in all possible ways. In the southern regions, this can be avoided.

Charcoal - Manufacturing Plant

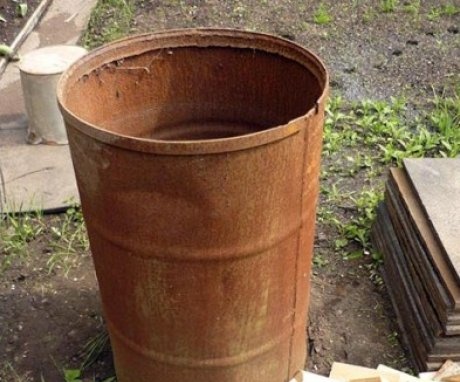

Anyone can master the manufacture of charcoal. To do this, you need a metal barrel and a place to burn logs. At the bottom of the barrel, you need to adapt a device for air injection. The incineration process boils down to the following:

- At the bottom of the barrel, a fire is made from dry thin twigs and other wood waste.

- Then the logs are stacked. Each layer is laid as the previous one burns out.

- When the barrel is half full, air can be blown in for better combustion. Otherwise, the logs will start to smoke and not burn.

- After that, we fill the barrel almost to the top.

- After all the logs are burned, the barrel is covered with a metal sheet. The coal must cool down.

Instead of a barrel, you can use an ordinary hole in the ground with a depth of about 50-60 cm (this is for two bags of coal). The pit walls should be slightly chamfered - trapezoidal shape. The principle of filling and combustion is the same, only there is no need to pump air - everything happens naturally. After the logs are burned, the hole is covered with leaves and earth, tamped and left for about a couple of days. After that, the coal is dug up, sifted and packed in bags.

The place for burning firewood must meet all fire safety standards.

There should be no vegetation or wooden buildings nearby. It is not advisable to do this in the forest, since the flammability of the forest cushion is lightning fast. Treat nature with care.

Making biogas and charcoal at home is more than possible. The main thing is to carefully plan everything, develop schemes and calculate the consumption of raw materials and the amount of the resulting fuel. With the right calculations, biofuel production will turn into a profitable undertaking.

More information can be found in the video: