Many home craftsmen know firsthand that a handcart in the house is an irreplaceable thing. The need for the transportation of goods arises both during minor construction work and in everyday life. Therefore, it is advisable to always have a small trolley on hand that can facilitate the lifting of various types of loads. And the topic of this article will be the HT 1310 stair trolley.

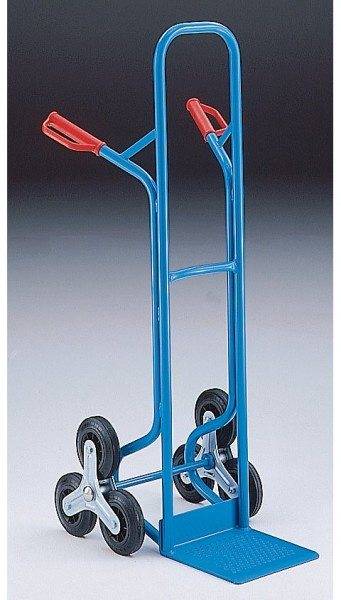

This design allows you to transport goods not only on a flat horizontal plane, but also to transport them along reinforced concrete stairs. This is made possible by a special design that allows the trolley "step" on the steps.

Trolley designed for stairs

Residents of high-rise buildings in which there is no elevator, in particular, Khrushchev buildings, know firsthand about the difficulty of transporting goods up the stairs. Even if the load is not heavy, it is sometimes very problematic to drag it to the fifth floor along reinforced concrete staircases, especially for the elderly.

It is to facilitate such work that special ladder trolleys are used, which allow you to effortlessly transport loads of any weight along the steps.

Advice! When using such carts, the slightest shaking of the transported cargo occurs, which is especially important when transporting fragile luggage.

The declared carrying capacity of such trolleys is from 50 to 150 kg, that is, even the most fragile structure will allow you to easily transport bags of sugar or cement.

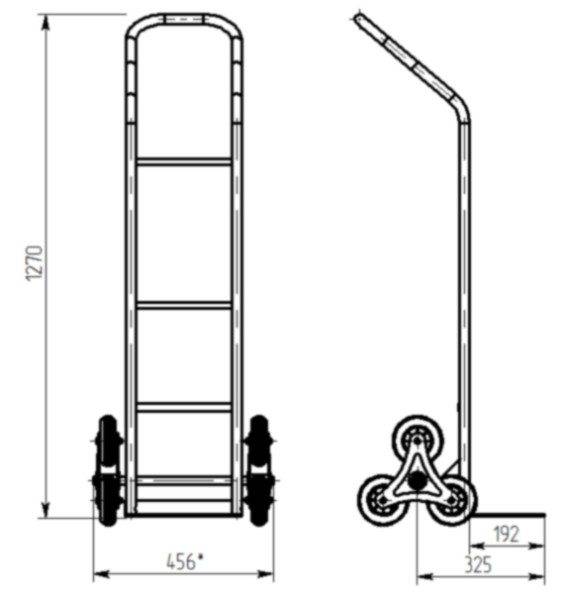

Cart design

The trolley for stairs consists of the following parts and assemblies:

- The frame, which is the basis of the structure.

- Retractable handle.

- Frame crossbars, which are stiffeners.

- Three-beam sprocket, which ensures the structure is passable along the steps.

- Wheels. Such a cart has 6 wheels, 3 pieces on each side.

- Cargo area.

- Load platform support, which can be either retractable (most often) or static.

- Retainer chain or elastic band for securing the load on the cargo area.

The secret of the stair trolley lies in the special arrangement of the wheels. So, instead of the usual pair, there are as many as six of them. Such wheels are "mounted" on minor axles at the ends of three-pointed stars. Thus, when transporting on a flat surface, the wheelbarrow travels on four wheels.

However, in the event that both front wheels hit an obstacle, be it a threshold or a step, then the three-pointed sprocket starts to turn, and the cart seems to step over the obstacle. At the same time, moving down the stairs will not require any effort from you, since the structure will "step" under its own weight, you will only need to support and guide it.

The advantages of this design

Due to its design features, the stair trolley is not highly specialized and does not have any disadvantages over the "traditional" two-wheeled designs. As mentioned above, it can be used for horizontal movement of loads, but at the same time, this design significantly expands the range of use of trolleys.

Advantages over two-wheeled cars:

- Possibility to move freely up the steps, while ordinary carts move up the stairs with difficulty and jerks.

- High cross-country ability on roads with small obstacles (stones, rapids, etc.).

- Can be used as a normal trolley.

- High lifting capacity.

- Compactness.

- Acceptable price.

- Free access to all structural units, including three-beam sprockets with wheels. In the event of a breakdown, you can easily repair the wheelbarrow with your own hands.

We make by ourselves

Due to the simplicity of the design, the trolley for climbing the stairs can be made by you yourself. In practice, this is much easier than it might seem at first glance.

Advice! If you have an old two-wheeled cart, the easiest way is to get ready-made sprockets with wheels and attach them to the axles.

So, the manufacturing instructions:

- We make the frame. To carry out these works, you will need electric welding skills. For the manufacture of the frame, you will need a steel pipe with a cross section of 15 mm and a length of 220 cm.

- We measure 80 cm from one end of the pipe and clamp it at this point in a vice.

- Using a hammer, bend the pipe at right angles.

- We do the same from the other side. As a result, you should have a pipe in the shape of the letter "P", the long strips of which are equal to 80 cm, and the middle one - 40 cm.

- We take a pipe with a section of 10 mm and a length of 40 cm and weld it to the edges of the U-shaped workpiece. This tube will house the axle for installing the wheels.

- Now you need to weld stiffeners to the frame. For this, three metal rods are enough, which are welded to the frame horizontally at regular intervals.

Advice! If the wheelbarrow will be used to transport heavy loads, then the number of stiffeners can be increased to 5-7.

- We take a pipe with a cross section of 15 mm and a length of 120 cm for the manufacture of a cargo area.

- Similar to the frame, we clamp the workpiece in a vice, stepping back 40 cm from the edge.

- Using a hammer, bend the pipe.

- The same must be done on the other side to get a square U-shaped platform.

- We weld the platform to the axle.

Advice! For additional rigidity, it is advisable to weld metal corners on the sides of the structure.

- For the cargo area, it is also necessary to provide 2-3 stiffening ribs made of steel rods.

- For the axle, you can use both a factory part and a metal rod that is inserted into the lower tube of the structure.

- Now let's move on to the most important structural elements - the three-pointed asterisks. They are also available for free sale, but you can make them yourself. They can be cut from steel sheets, the thickness of which is determined depending on the expected load capacity of the structure. Sprockets can also be welded, in which case steel tees, quatavras, channels, corners, squares, etc. are used as beams.

After the sprockets are ready, holes are made in them to install the wheels.

- We attach the sprockets to the axis.

- The wheelbarrow is ready for use.

What you need to know when purchasing a cart

If you need a trolley for transporting goods along the stairs, then the easiest way is to purchase it at a building store, especially since not everyone can make such a structure on their own. Since today there is no separate industry in the industry that would be engaged in the production of carts, then there are no brands at all.

And in such circumstances, the choice between a new and a repaired wheelbarrow is largely indistinguishable. Moreover, the old Soviet design, due to the capture of the modern market by Chinese goods, will be much better than the new one.

Let's take a look at what you should pay attention to in order to make the right choice:

- Enjoy the comfort of the handrail or handles.

- Measure the dimensions of the product. The overall width is a very important parameter, since an excessively wide product may simply not enter the door or the elevator. That is, you need to purchase the largest model possible.

- Design features largely determine reliability. Check the quality of the welds on the frames, paying particular attention to the presence of distortions or any distortion of the geometry. Inspect the body for rust and dents.

- Carry out a thorough inspection of the wheels. Depending on the manufacturer, they may differ in price and quality. Make sure the wheels are suitable for the load that you plan to transport on the wheelbarrow.

Conclusion

Such a simple design as a trolley is an indispensable assistant in everyday life, therefore every self-respecting home craftsman should have it in his arsenal. In the video presented in this article, you will find additional information on this topic (also find out what ladder tray).