From two to four is not the life of stairs, it is the number of sections, which allows you to solve many problems, both in everyday life and in professional activity, if, for example, this activity is related to construction, installation of electrical equipment and other high-altitude work.

Our article is devoted specifically to modern solutions to these problems, the main assistant in the solution of which is aluminum alloy.

What happened

More recently, a person knew two types of stairs: a side ladder and a stepladder. The first was quite actively made by craftsmen at home with their own hands (in garages or workshops), the second found wider application in office buildings, apartments with high ceilings, and among builders. And that would be fine, but here's the problem; at that time, the main materials from which such structures were made were metal and wood.

At the same time, the metal was taken more reliably, the wood was more massive, which had a number of disadvantages:

- The mass of the material reduced the possibility of increasing its length;

- Both wood and metal required appropriate processing and painting;

- There are difficulties in the installation and use of ladders more than 3 m in length in the places of passage of wires, dense building structures, densely located branches of trees;

- Long ladders are weakly stable due to the small support area;

- Wooden stairs can "lead" over time. This is due to the processes taking place in wood.

It was like this until aluminum appeared on the scene.

What is

The lightness and reliability of aluminum made it possible to actively use it in the military industry, however, the slogan "we will beat swords into plowshares" is still relevant, therefore aluminum, or rather its alloys, entered peaceful practice and made a real revolution in many areas of the national economy. This also affected the manufacture of stairs..

Thanks to him, not only lightweight products appeared, but also sliding ones, which make it possible to solve many problems and are devoid of the above disadvantages.

The modern market offers sliding aluminum ladders of the following types:

- Two-piece. By and large, these are the same ladders, however, with less weight and greater opportunities;

- Three-section aluminum ladders... An ideal option, including in terms of price-quality ratio. These products will be discussed in more detail in a separate chapter;

- Four-section. These are full-fledged transformers that allow you not only to assemble a ladder or step-ladder, but also a platform for comfortable working conditions for a builder, a bricklayer, a cladder or for other work.

Interesting to know!

Many models have additional bonuses.

So, in a three-section model, one section can be removed and used independently, in a two-section model - with a slight movement of the hand, the step-ladder turns into an attached, long ladder.

These are the features of transformers.

Modern stepladders

The purpose of these ladders does not need additional sound. But what's interesting is that the staircase itself has acquired a number of advantages that need to be voiced.

For your information!

The analysis of models with a mathematical calculation of the advantages will take place on the basis of the first professional 8-step model.

Models 6 and 7 are considered household, 8 and higher - professional.

So:

- The weight of the structure is only 7 kilograms;

- The height of the stepladder in working condition is slightly less than 2 meters;

- The height of the ladder is 3.1 meters.

In the piggy bank!

It is believed that the height at which an adult can safely work is calculated using the formula ladder length + 1 meter.

In the above case, the maximum working height will be 4.1 m.

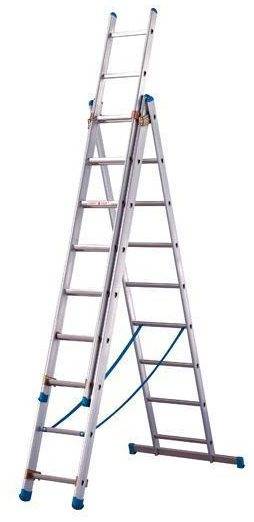

Three-section analogs

By and large, this is the same sliding step ladder, but with great possibilities.

Let's go through the digital indicators of the first professional model (as you remember, the 8-speed model), so:

- Weight as a basic characteristic - 12 kg;

- Height as a deployed step-ladder - slightly less than 3.2 m;

- Fully unfolded height - 4.5 m.

The three-section model is the most bought and it is on it that I want to make a general analysis of the entire aluminum family.

By tradition, let's start with the positives:

- All ladders have a good "carrying capacity", withstand 150 kg of weight;

- In all models, the problem of the ratio of the length and weight of the structure is ideally solved (data for comparison have already been given);

- All sliding metal ladders have increased stability, since the support area is increased due to the introduction of such an element as a traverse - a long transverse bar with stops shod in "non-slip" shoes;

- The section fastening system has increased reliability, and the sliding fire escape is equipped with a similar system;

- In all products, aluminum is presented in the form of an alloy, with a special anti-corrosion coating, which in turn does not require additional costs for processing or coating with special protective mixtures.

This applies to the achievements of all models of the series.

Now about the negative or conditionally negative points:

- Prepare for the fact that the price of household and professional models will differ sharply from each other, so if you do not plan to do high-rise work professionally, opt for household models. This is a conditional disadvantage, since the work will very quickly pay off this acquisition;

- The second drawback is inherent to a greater extent precisely in three-section models and therefore can also be called conditional. The fact is that a stepladder using all three sections has a fairly long boom. The support will, of course, withstand it, but under the weight of an adult, the ladder may bend slightly, this, in turn, creates the impression of weak reliability, although the structure itself is quite reliable and stable. (see also article Staircase-transformer 4х4 - convenient and versatile design)

Now let's digress from the general problems of the family and go through the capabilities of the three-section model:

- The first feature of the three-section is precisely the ability to make an ordinary step-ladder a hut. This is convenient enough for work on the ceiling, for example, changing the wiring, or fixing a chandelier.

A canopy visor is not a problem - The second proposed model is an extended ladder that allows access to both the top of the tree and the roof. This is the same option that we included in the list of conditionally negative ones, although we will repeat once again this position is quite stable, and the ladder is reliable;

- The third option is a single arrow. At the same time, the ladder is no different from the usual attached ladder, although there will still be differences. First, it is much easier to assemble, even in places with limited space. Secondly, the weight of a 4.5 meter aluminum ladder will still be less than that of a metal counterpart of the same length;

- The fourth option is a combination. One of the sections can be safely removed and used independently by the second worker, as a ladder. In addition, the remaining structure can be used both as a stepladder and as a deployed extension ladder.

Three to four

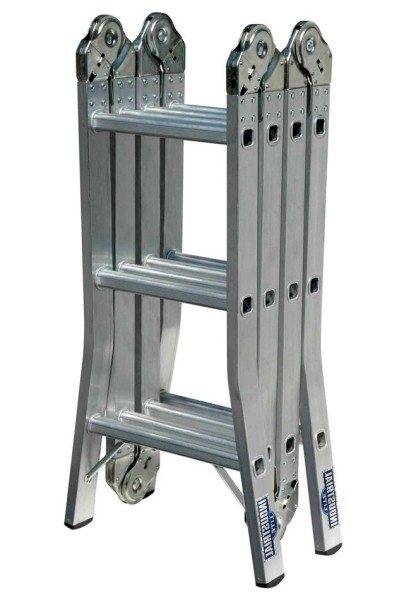

The complete transformer consists of four sections and initially has its own characteristics:

- The number of steps in a section is from 2 to 5;

- Due to the additional section, it is possible to set the stairs U-shaped and L-shaped, which is not in other models;

- The design allows you to install a platform like a platform for work on the ceiling.

And a few digital data for clarity:

- The weight of the product 4 by 4 (4 sections of 4 steps) will be 13.5 kg;

- The maximum height of the disassembled ladder is slightly less than 4 m.

Safety first

As much as we want, work at heights is always associated with increased danger and risk of injury. Even despite the fact that the stairs are quite stable, reliable and comfortable, the instructions below can help you avoid many problems.

Let's go through the points:

- You should not take professional staircase options for household needs. Although they have a longer arrow length, do you need it?

- Since working at height is a risky category, it will not be superfluous to check the fasteners before each assembly, especially since it will take you a few seconds of time.

- There is no ideally level ground on the ground, therefore, the safety of work depends on the correct choice and stable position, if you put a ladder and see that it is shaking, then it is better to find a more stable position for it.

- Professionals advise not to abuse the slopes of the product. Moreover, the option is a transformer, it is quite possible to do this.

Advice!

With the maximum vertical position, the ladder may fold, and with a very shallow angle, they will tip over.

- Each step of the ladder is equipped with a special relief pattern that prevents the foot from slipping. However, it is desirable that the soles of the shoes are not slippery, if this happens (for example, an employee stepped into spilled oil or other composition), then the shoes must be replaced or cleaned of residues of oils and other liquids or compounds.

- Although aluminum is a fairly strong material, and the products can withstand a significant load of 150 kg, you should not overload the ladder with various objects and tools. (see also article Features of two-piece aluminum ladder: design features and scope)

Finally

Nowadays, aluminum stairs are the most demanded and practically out of competition. The video in this article is also ready to demonstrate the presented topic in all its glory.