A feature of transforming stairs is the ability to install from several sections of the required design. They usually consist of several standardized parts, from which a variety of options can be assembled, from a regular step ladder to a traditional staircase with cantilever ends.

Main functions

Due to the wide variety of options, these types of structures can be used as:

- ladder ladders;

- ordinary ladder;

- as a retractable ladder;

- attic fixed stairs;

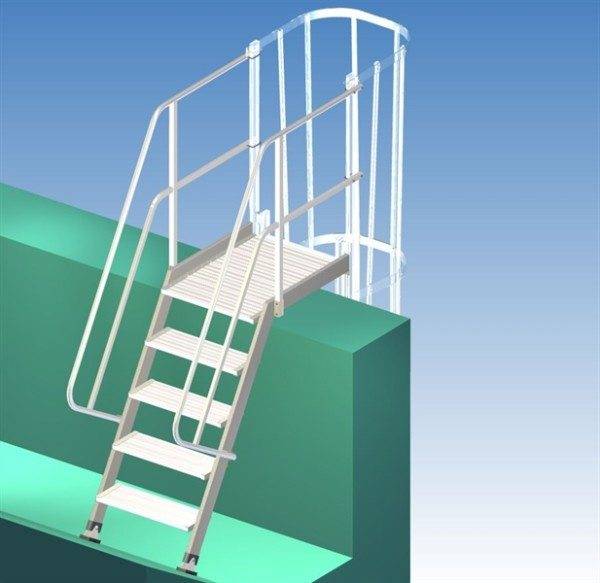

- as a working platform for construction work.

This device is indispensable for work that needs to be done at height.

The main areas of application include the following:

- harvesting and pruning fruit trees;

- external window washing;

- repair and decoration of facades;

- maintenance of drainage systems;

- inspection of roofing and their repair.

The most functional option is a structure that consists of four or more sections. Such models can be transformed into complex temporary structures, from which it is convenient to carry out the necessary work.

There are household and professional options for such stairs.

Professional types differ:

- lifting height,

- maximum permissible stage load,

- higher quality materials that are used for manufacturing.

Household species, as a rule, can be used at a height of up to 3m. The professional design, thanks to a more stable base, has a wider range of applications.

Basic constructions of stairs of transformers

Folding transformer ladders are used to climb the attic space.

By design features, they are classified into the following types:

- folding or lever;

- scissor;

- sliding and telescopic;

- folding.

They are made from metal, wood and a combination of these materials. Combinations of metal and wood are the most common.

As a rule, steps are made of hardwood. Parts of fasteners, mechanisms, with the help of which sections and various springs are transformed, are made of metal.

Wooden parts significantly reduce weight, and metal products provide strength. To prevent friction that may arise between the elements of the section, fittings made of polymer materials are used.

Design features

A characteristic feature of the design is the presence of unified sections that can be fixed in the desired position.

Thanks to this, the following types of auxiliary equipment can be obtained:

- Ladder;

- L-shaped stepladder;

- Console ladder;

- U-shaped platform;

- Retractable ladder.

An important point that affects the mechanical strength of the structure is the method of fastening the steps to the racks. The most reliable method is rolling or pressing the step into a metal rack. The standard tread width is equal to the rack width.

However, there are many models that have wider steps. They are usually used for painting and other works that require a long stay on the steps. The increased width of the steps, in this case, plays an important role for comfortable work.

Scissor ladders

Metal folding scissor ladders can be folded in the form of an accordion. The mechanism that allows them to fold is made in the form of a parallelogram or an oval.

Such options are made, most often, of metal. They have a multi-link mechanism, in which there is a spring device that helps to control the process of unfolding and folding the sections. There are types equipped with an automatic drive, which is independently capable of expanding or folding them.

Advice. When buying, pay special attention to the latches, which are used for safe use in the spring mechanism, which do not allow spontaneous folding. Safety of work depends on them.

Telescopic

Telescopic metal folding ladder is able to fold by entering sections one into another. The material for production is aluminum alloys, which provide, along with mechanical strength, a low specific gravity.

They have the ability to both increase the length to a certain size, and the ability to completely fold. This folding aluminum transformer ladder is easy to transport. When used as a stationary option, it can significantly save space.

Folding ladders

A folding wooden folding ladder is most often used for easy access to the attic. Most of the time, this structure is assembled and attached to the wall, thereby not taking up much space. If necessary, the structure unfolds.

These wooden folding ladders are the most popular. It is associated with simplicity of design, ease of use and the ability to do everything yourself.

The main elements of a folding ladder are three or more sections, which are interconnected by means of metal shoes equipped with hinges. If the staircase is retracted into the ceiling opening, it should be remembered that the length of the sections should not exceed the width of the staircase opening.

Auxiliary elements of transformers

- elements for securing loads.

Stand extensions are used when working on uneven ground. The extension cord is fastened using threaded connections. For this, there are special holes on the main racks.

Additional supports are intended to increase the area on which the structure rests. Thus, its greater stability is achieved. Additional elements for the legs contribute to the convenience of moving the structure.

Advice. Pay attention that the feet do not slide on the floor. It is fraught with accidents.

The elements for securing loads are made of hardened steel and are used to place equipment and materials in the immediate vicinity of the work site. Additional elements significantly expand the operational capabilities of the structure.

Safety Requirements

Due to the fact that transformers are used at height, they must have an increased level of safety. For this, a test procedure is carried out. It can be produced both under laboratory conditions and under construction site conditions.

The main tests consist of:

- confirmation of the composition and grade of the material from which the structure is made;

- determination of nominal deviations from the information declared in the passport data;

- determination of the strength and reliability of a structure by analyzing general and permanent deformations that occur under the action of loads.

In the domestic production of this type of stairs, there are no standards. Therefore, domestic manufacturers arrange tests according to their own specifications.

In the European Union, there is a single standard for these products - EN131.This standard regulates the basic technical requirements and test methods for similar structures. They include labeling requirements and contain such a regulatory document as instructions for operating rules.

Manufacturers overview

There are products of the following manufacturers on the domestic market:

- KRAUSE,

- Elkop,

- Portuleiter,

- VIRA,

- SSS "LUCH".

The main criteria from which the price is formed include the following:

- material of manufacture;

- design features;

- functionality of the design;

- dimensions.

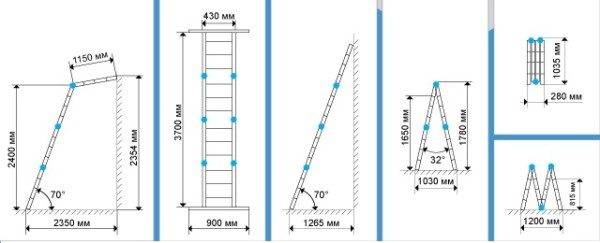

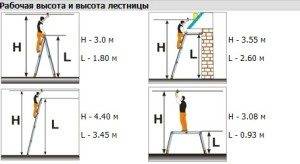

Situations often arise when a non-standard solution is needed to work at a certain height. It is these options that can help in such situations. The determination of the working height is calculated from the last step or the working platform.

If household options have a height of up to 3 m, then professional types can be more than 20 m.Taking into account the danger of high-rise work, stairs transformers without fail must be supplied with safety ties, metal braces or belts that prevent spontaneous folding.

Conclusion

Such folding aluminum ladders are quite often used by professional builders as scaffolds, ladders, etc. Functional features allow them to be used in a fairly wide range.

In addition to construction, these are fire escapes, etc. In addition, they are often used in everyday life. For the types of transforming stairs and how to use them, see the video in this article.