Ladders are lightweight portable ladders that consist of support beams and steps. Depending on the type, the staircase can be additionally equipped with a platform, handrails, and also have structural features that allow it to fold.

All about ladder structures

In terms of material of construction, the most commonly used are:

- Wood, especially in the manufacture of simple attached wooden ladders.

- Iron, for the manufacture of heavy and durable structures.

- Aluminum... A material widely used in the manufacture of ladders and folding ladders.

Important! In the manufacture of a ladder, in addition to strength, weight must be taken into account. It is important that the product is easy to carry.

Types of stairs

Attached structures can be divided into several types, each of which has its own characteristics:

- Straight-line simple stairs.

- Folding option.

- Ladder.

- Ladders with a platform.

- With railings.

- Sliding.

To evaluate the features of the structure and use, a few words can be said about each of the types.

Simple stairs consist of two straight support beams to which the steps are attached. Fastening can be done either by winding the steps into the grooves on the sides of the support beams, or on the edge of the beam.

This is one of the simplest options for a staircase, and the scope of use of the structure is very extensive.

Folding ladders are interesting in that they can be used in small spaces, in the sense that they do not require a lot of space to store them, and the structure is fully unfoldable only for use.

But stepladders are truly universal staircases, and this is proven by the increased popularity and demand for this type, and its widespread use in completely different areas of human activity.

The stepladder can be used both in an apartment, with limited space, and in a garden. Just a step-ladder with a platform is the most demanded option due to its versatility.

The platform helps to install objects and containers necessary for work on a horizontal area.

More complex structures are equipped with handrails, but the fence here is designed to ensure the safety of movement along the flight of stairs, even if we are talking about an attached version.

By the way, a folding version of a ladder design is not necessarily only a portable folding ladder. For the most part, the structural features of such a staircase have found their application in the manufacture of attic staircases.

The main advantages here include:

- Functionality.

- Strength.

- Ease of work, use.

- Easy assembly when it comes to your own assembly.

- Small dimensions even when unfolded.

At the same time, there is always access to the attic space, but there is no need to keep the ladder leaning against the wall, or bring it from the back room each time, for example. In this case, the load that the product can withstand can reach 200 kilograms.

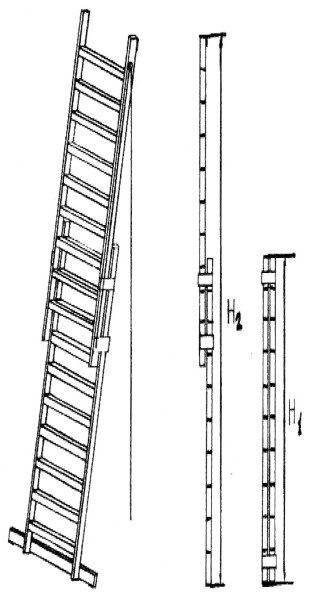

As for the sliding version, first of all, ergonomics can be noted. The structure consists of two parts, which are equipped with special guides, and it is they who ensure the normal sliding of the sections.

The advantage of this option is functionality and compactness, the sliding ladder is easy to assemble and easily transported, as well as it can be stored in the assembled state, without taking up the useful space of the room.

As a rule, aluminum is used in the manufacture, which makes the structure lightweight and allows the use of guides for sliding and collecting sections.

The pull-out sections are always securely fixed and the ladder is capable of supporting a weight of up to 200 kilograms. In addition, there are profiled steps that prevent slipping.

Another interesting option is attached and leaning ladders with railings. Made of metal, these structures can be fixed into the wall and serve not only as an entrance to the building, as an additional black exit, but also to carry out communication between floors.

With certain interior styles, such stairs can also be used indoors on a permanent basis.

This option is especially convenient when it comes to modular assembly, where there is no need to use welding, for example. Installation is quick and easy, and due to the fact that the weight of the parts of the stairs is also not large, all elements are easily transported and assembled at the installation site, both outside and inside the premises.

Additional elements

By taking some elements outside the general staircase structure, you can select them into a separate component, which is not always directly related to the staircase. First of all, these are wall handrails for stairs.

It is in this example that you can see that the handrails are not associated with the march and are not part of it. Accordingly, they can be made from other materials. For example, the staircase is concrete, and the railings are stainless steel or wood.

Moreover, such elements are made for external and internal flights of stairs.

Ladder requirements

Each design has its own specific requirements that it must meet. The severity of regulation depends on the degree of safety requirements, and with regard to stairs, strict adherence to the basic rules and regulations is always necessary.

They are based on the requirements for ladders:

- The total length should provide a person with the ability to work while standing at a distance of at least one meter from the upper edge of the structure. The total height is recommended up to 5 meters.

- Depending on which surface the ladder rests on, the lower ends should be either pointed or "dressed" in rubber shoes.

- The distance between the steps must be strictly within the range from 1500 mm to 250 mm. The cross-sectional dimension of the step is at least 40 x 20 mm. It is also important for making with your own hands to know all the subtleties of the dimensional grid.

- In a wooden structure, the steps should fit perfectly and tightly into specially prepared grooves and nests. The bowstrings must be tightened with special tie bolts with a step of two meters.

- The size of the working platform of the step-ladder must correspond to the minimum dimensions of 320 x 320 mm, pedestals - 300 x 220 mm.

- Metal parts should be free from cracks, burrs and sharp edges, edges. Cracks are allowed in the wooden bowstring, but only of the longitudinal type and no more than 100 mm in length and 5 mm in depth. Filling cracks with putty is not allowed.

- The instructions for the use of cracked ladders do not allow loosening of the bowstring or fastening of the steps.

- The sliding structure must be equipped with a special lock, a device that will prevent the spontaneous opening of a ladder or step-ladder during work on them.

- If the ladder is equipped with wheels, there must be a locking device that will exclude the movement of the ladders while working on them.

- Portable side ramps and ladders should be checked at least once every 6 months, even if they were not used in the work within the specified period. With frequent use, the frequency of checks increases.

Important! In addition, it can be noted that attached ladders in accordance with GOST also have a number of requirements that must be observed:

- Standard surface load up to 200 kg per square meter.

- Height up to 5 meters.

- Structures are installed at an angle of more than 75 degrees to the wall.

- If the staircase is planned for more than 5 meters, then an arc fence must be present starting from a height of 2 meters.

- If the ladder is installed at an angle of 70 to 75 degrees, it must be equipped with a handrail on both sides.

- The attached structure, no more than 5 meters, can be used without arc and railings.

Design test

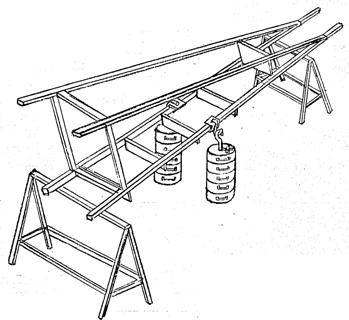

All ladder structures of the attached and portable type must undergo a static load test after manufacture and after repair. In addition, testing of ladders and ladders is recommended as a preventive measure to ensure safety during the operation of staircases.

Depending on the material of construction, the test is carried out:

- Metal stepladder - once every 12 months.

- Wooden structure - every 6 months.

In the static test, attachment and sliding structures of any type shall be placed on a solid surface. Next, you need to attach the ladder to the vertical plane at an angle of 75 degrees.

The test is carried out by suspending a static load from the steps and bowstrings of a flight of stairs. The average test time for an individual element is 2 minutes. During the test, a load weighing 120 kgf is attached to the step. After 2 minutes, the place of loading is examined. There should be no deformations or cracks on the step and bowstring.

Before starting the test, the stepladder is installed in a working position on a flat horizontal surface. A load of 120 kgf is suspended from an unreinforced step in the middle of the structure. If there are steps in both adjacent knees of the ladder, then the test of the second knee takes place in exactly the same way.

If the knee does not seem to be working, but only serves as a stop, then a weight of 100 kgf is hung on it, and the weight is installed in the middle of the knee to each bowstring.

An interesting nuance

Speaking about the choice of materials in the production of a ladder structure of an attached type, we must not forget that there is also an attached plastic ladder. It is a special design that is used in the chemical or pharmaceutical industry, power plants, and gas factories.

Steps and bowstrings here are made of plastic, which is additionally reinforced with fiberglass. This gives the structure additional strength and chemical resistance.

Plastic allows you to work in electrical hazard conditions under voltages of 1000 V AC, 1500 V DC!

Self-practice

It is very easy to make a simple ladder structure of the attached type.

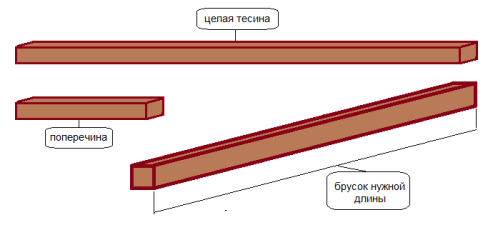

If a sliding element, sliding guides are not supposed, but the main material is wood, then before you make a ladder on your own, you only need to:

- Determine the size.

- Purchase two support beams with a section of 25x100 mm, for example.

- Prepare the steps.

Of the tools you need only a tape measure, a saw, a hammer. The ladder can be assembled with nails or screws.

And as can be seen from all of the above, attached structures will always have a lot of options for use in a large number of areas and in carrying out many works.There is no doubt about the importance of ensuring complete safety when using the ladder, therefore, such importance is assigned to prevention and verification, as well as product testing (also find out what makes up the cost of a wooden ladder).

In the video presented in this article, you will find additional information on this topic.