Basic properties

For non-aqueous compositions of the protective coating, increased moisture resistance is characteristic.

Like a water-soluble mixture, non-aqueous stain is used:

- to protect wood from decay;

- to resist mold;

- to protect wooden products from pests and microorganisms.

After drying, it forms a protective film on the surface, which is not washed off with water, and the surface itself, with the correct application of the mixture, does not require additional painting with varnish.

This stain must not be diluted with water. The pigment mixture penetrates deeply through the wood fibers and does not cause swelling.

The disadvantage of almost all non-aqueous wood stains is a pungent odor, therefore, the composition should be applied to a wooden base in a well-ventilated area, in a respirator.

Important! Work requires accuracy so that dust does not settle on the sticky surface, drops or smudges do not form

Peculiarities

Under the influence of aggressive environmental factors, including all sorts of bacteria, mold and insect pests, the tree can deform and start to rot

In order to minimize the risk of such problems, it is very important to take timely care of the wood. The most effective way to deal with such circumstances is wood stain.

The tool is a liquid composition that sets it the desired tone from a mass of options for colors and shades. This allows you to refine the natural color of wood or radically change it.

In addition to aesthetic functions, the main feature of the composition is antiseptic properties. Thanks to the use of the product, wood will be able to serve you twice as long.

Another feature of almost all types of wood stains is the ability to penetrate deeply into the wood without harm to the pattern and texture, unlike enamel or paint.

Wood staining has several advantages:

- the ability to combine different shades of color;

- strengthening and preserving the structure of the tree;

- the service life of products increases;

- the indicators of wood resistance to moisture increase.

Stain is not only a varnish for wood, thanks to its use, you can create a unique interior in a room or completely transform, at first glance, everyday interior items or furniture.

Advice

The method of application depends on the type of stain and the size of the product. For these purposes, use a swab, brush or paint spray. For processing a large surface, it is not recommended to use a brush, since there is a high probability that traces of its villi will remain, and it will also take a long time to process.

With a large area, it is more convenient to work with a spray. To do this, it is necessary to choose a lighter shade of impregnation, since the applied layer will be thicker than usual. At the beginning of work, do not forget to cover the untreated surfaces with a film.

If you still want to apply the composition with a brush, then for water-based and alcohol-based stains, you need to choose a brush with synthetic bristles. It is necessary to buy only a high-quality tool that will not leave fluff on the wood.

After choosing a suitable shade and tool, you need to make a test painting. This is done in order to find out the required number of layers of stain to obtain a specific shade. This requires:

- take a small sample of wood material of the same species as the product to be painted;

- grind the board in the same way as the main product;

- cover it with impregnation and leave to dry;

- apply the next layer on two thirds of the tree;

- when the last layer dries, apply the stain on the remaining one third of the board;

- compare the color saturation and choose the optimal shade.

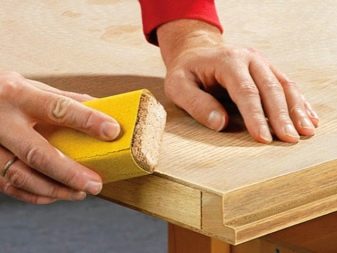

The stain is applied to an uncoated wooden surface: it can be a completely new product or a part from which the previous coating has been removed.

Dry wood needs to be sanded with sandpaper. During work, you must not press hard on the tree, you only need to move along the fibers. This will avoid the appearance of small defects on the surface. If before painting they will be almost invisible, then after treatment with impregnation, the defects will be strongly emphasized. The sanding process takes about 30 minutes, this is enough to obtain a smooth surface and open the pores for the stain to penetrate.

After sanding, it is necessary to remove fibers and dust from the product with a vacuum cleaner. Using white spirit or gasoline, degrease the surface of the part. At the end, you should spray the tree with water, so the impregnation will fit correctly. For even mixing of the contents, the jars are thoroughly shaken. Then you need to warm up the stain to an average body temperature, so the composition penetrates deeper into the structure of the wood, then moisten a brush or swab for staining in the impregnation. For the sprayer, pour the stain into a special container.

During the processing of vertical products, they move from bottom to top. If the composition runs off, the smudges will remain almost imperceptible. For processing horizontally, brush along the fibers, then across, and then again along

Before applying the second coat of stain, it is imperative that the initial coat is completely dry.

After the composition has completely dried, the final wood processing process is carried out on the surface. With the help of washing, excess impregnation is removed, which remained without being absorbed into the surface. After this process, the product looks different: shine, texture appears. Washing is carried out with acetone using a volumetric brush as follows:

- tilt the product slightly;

- an absorbent cloth is placed under it;

- dip the brush into liquid;

- brush from top to bottom to drain excess impregnation;

- continue actions until the appearance of surface homogeneity;

- leave the products to dry and then apply varnish.

Wood stain - classification by composition

Depending on the composition, the performance and application technology of the stain can vary significantly.

Water

The most common and affordable type of stain. Has a wide range of colors. It is produced both in the form of ready-made compositions and in the form of a water-soluble powder. In the second case, the intensity of the color depends on the amount of powder added to the water during the preparation of the composition.

Advantages: no pungent odor and toxic emissions, recommended for indoor use.

Disadvantages: when applied, slightly lifts the wood grain, which increases the material's susceptibility to moisture. Long complete drying time, which is about 12-14 hours.

Various shades of water-based stains

Alcohol and nitromorilac

It is an alcoholic solution of aniline dyes. Denatured alcohol is used as a solvent. Also produced as a ready-made solution or powder. A distinctive feature is a high drying speed - 20-30 minutes, which is both an advantage and a disadvantage.

To apply nitromorilac from alcohol-based formulations, it is recommended to use spray guns

High humidity and inaccurate brushing during application can lead to uneven pigmentation of the treated surface. Therefore, in order to obtain a uniform color, it is strongly recommended to use vacuum or pneumatic spray guns.

Advantages: fast drying, affordable cost;

Disadvantages: high likelihood of stains when applied manually, pungent and unpleasant odor, toxic discharge (especially nitromorilac).

Oil

It is one of the most convenient for manual application. Dissolving the different segments in oil results in a wide range of colors and a fade-resistant shade. White spirit is used as a solvent, the base is industrial linseed oil.

Applying oil stain with a brush

Advantages: does not form stains, does not raise fibers, provides a high degree of protection of wood from external factors, dries up in 2-3 hours;

Disadvantages: an unpleasant odor that disappears after a rather long time after application: from several days to several weeks.

Acrylic

It is produced in the form of aqueous dispersions of acrylic polymers with the addition of pigments. Such compositions have practically no drawbacks, except for the high cost.

Acrylic stain has vibrant colors

Advantages: dries up in 2-3 hours, has no odor, does not emit corrosive or toxic fumes during application and during further operation, forms a uniform coating without stains, provides reliable protection of wood.

Disadvantages: high price.

Wax

The composition is represented by an aqueous suspension of wax. It has a high density, it is applied with a cloth. Does not absorb into the material. Forms a relatively thick protective layer on the wood surface. It is used as a base "primer" for various paints and varnishes and for polishing the product with beeswax.

One-component stain based on wax "Borma wachs"

Advantages: Uniform pigmentation, reliable protection of the base, does not reduce moisture absorption.

Disadvantages: high cost, laboriousness of application.

Views

The composition of non-aqueous stains can include various components, which will affect the technical characteristics of the mixture.

There are several types of non-aqueous solutions.

- Alcohol-based. Such a solution is characterized by a high drying rate (thirty minutes). It is recommended to work with alcohol stain using a paint sprayer, as when applied with a paint brush or roller, streaks and stains may remain on the surface.

- Oil stain is ideal for decorative finishing of wood products. The mixture is available in a wide range of colors and is easy to apply to the surface without leaving stains and streaks.

- Wax stain perfectly masks minor defects in the form of uneven wood color. The disadvantage of this composition is the sensitivity of the applied layer of stain to scratches and other mechanical stress.

What is the difference and which is better?

In the modern building materials market, there are many types of wood stains, each of which has its own advantages and disadvantages. Varieties of tinting solutions primarily differ in composition.

Non-aqueous mixtures are made from polymers, coloring components and organic solvents. This solution forms a waterproof film on the surface. Unlike a water-based mixture, this type does not provoke swelling of the wood structure. It is not necessary to varnish the surface after applying a non-aqueous stain.

A non-aqueous solution has its own disadvantages:

- Strong unpleasant odor. Despite the fact that it quickly disappears, the room must be well ventilated during work.

- If dust gets on the solution or a wet treated surface, it will be quite problematic to remove it.

- Defects that may appear on the surface due to inaccurate application of the solution (drips, stains) are difficult to remove.

- The mixture dries for a long time. Drying time is on average twelve hours.

Alcoholic mixtures are a solution of dyes and alcohol.During finishing work, the coloring components penetrate into the structure of the tree, and the alcohol evaporates. This solution has a high drying speed, which ranges from fifteen to thirty minutes. It is necessary to apply such a composition quickly to avoid uneven coverage and the appearance of spots.

Alcohol based stain is moisture and UV resistant. The disadvantages of this solution include a bad smell.

Nitro-stains are made on the basis of solvents. They dry quickly and also require quick application to the material.

Oil mixtures are most often made on the basis of flax seed oil. This formulation forms a sun-resistant coating. The surface will not fade for a long time and will have a pristine appearance.

The oil-based stain adheres easily and evenly to the surface without lifting the wood grain. The drying time of the solution can be from two to four hours.

Acrylic compounds are environmentally friendly and odorless. In addition, such mixtures are fireproof. Acrylic stain adheres well to all tree species and dries quickly. Acrylic solutions are most often used for treating wooden floors.

Special care should be taken when applying multiple coats, as stains are likely to occur.

Previously painted surfaces can be treated with wax solutions. After drying, this mixture forms a protective waterproof layer on the product. The wax coating gives the wood its brightness, but does not penetrate into the structure of the material. It should be remembered that the surface should not be treated with a wax solution before applying the two-component varnish.

Whitening stains are made from acids. Such a solution is capable of making the surface several shades lighter. This composition is intended for the preparation of wood before further processing with paints and varnishes.

Water mixtures may be inferior in certain characteristics to other types of wood stains. However, water-soluble formulations are low cost and harmless to health. Such a solution is perfect for interior work, as it does not have an unpleasant odor.

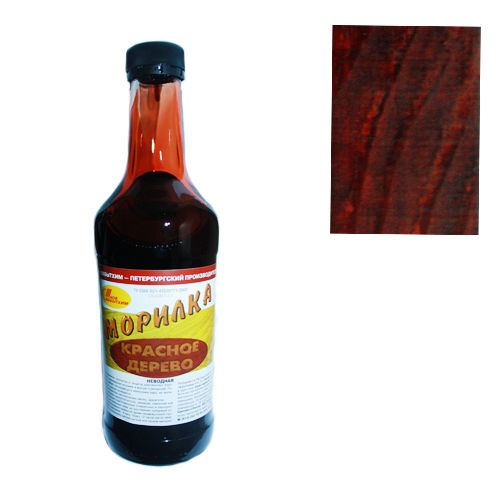

Colors

The water-based stain has an extensive color palette that imitates all types of wood: from light beige to black. If you need a different color, for example, green, then you need to look for it among the non-water stains. To create a rich shade, it is necessary to apply several layers or add more dry component when making a solution.

All manufacturers accompany their products with samples of wood stains. When buying, you can easily choose the right tone

However, it is important to know that the same color will look different on different types of wood. For example, the shade indicated on the sample, which is often pine, will turn out to be darker on oak or poplar furniture, and reddish on mahogany, but on maple it will hardly change, since the material is quite dense

The stains themselves can be mixed for a personalized finish. To obtain unusual effects, the basic tone is first applied, then with different strokes - a stain of a different color.

The red color of the stain will give a decoction of the following ingredients:

- larch bark;

- onion peel (shade closer to orange);

- crushed walnut shells with the addition of potassium dichromate solution.

Brown and mocha colors are obtained during the preparation process:

- Decoction of bark in equal proportions of willow and oak with the addition of alder earrings. The saturation of brown will give crushed walnut shells.

- Decoction of walnut shells and bark.

- Strongly brewed natural coffee.

- Brewed black tea, the strength of which affects the color.

Black and ebony can be obtained using:

- decoction of oak and alder bark;

- decoction of willow and alder bark.

The color of black ebony will give a solution of iron corrosion - for this, small glands need to be poured with vinegar and left to infuse in a dark place for two days. Black color can be obtained if they are infused much more, but not more than a week.

A gray color is obtained if, after staining with walnut broth, wipe the surface with vinegar essence. If you boil unripe buckthorn fruits, you get a yellow stain.

The color of the cherry will give a solution of potassium permanganate - this requires diluting 25 g of manganese in 0.5 liters of water. After processing, the surface must be immediately wiped with a soft absorbent cloth. To obtain a rich shade, several layers should be applied.

White wood furniture looks interesting. Instead of staining, it can be whitened with a stain, for which it is better to purchase a ready-made white composition from the manufacturer. Most often it is found in an oil base, but it can also be found on a water base. The stain clogs the pores, thereby lightening the wood, but does not color the pattern itself.

How to do it yourself

Stain made by yourself helps you experiment with shades and get the most unexpected results.

Plant-based

Methods for making wood impregnation:

- The bright red color is obtained from a strong decoction of onion skins.

- The brown color is made from dried walnut peel. The shell is crushed into powder, boiled for 10 minutes in water, filtered. Dissolve 1 tsp in the finished broth. soda. To get a red impregnation, instead of soda, potassium dichromate is used, gray - vinegar essence.

- Birch massifs are painted red with a decoction of larch bark.

- Light brown gives walnut shells and apple bark.

- Black stain is obtained from a boiled mixture of oak, willow and alder bark.

- Anthracite black is made from vinegar, oak or walnut bark.

- Golden yellow tone - from a decoction of unripe buckthorn fruits.

From coffee, tea and vinegar essence

Based on strong tea, coffee beans and vinegar, you can create wenge, oregon or pine stain:

- When mixing the same amount of ground coffee beans and soda, a rich brown color is obtained.

- Light wood can be processed with strong black tea leaves.

- You can make a black and gray stain using metal nails and acetic acid. Nails are placed in a container and filled with acid for 5-7 days. Insist in a dark place.

Based on chemical components

Impregnation preparation options:

- The brown board becomes after treatment with a solution of slaked lime.

- A dark cherry tone is given by a solution of potassium permanganate. It is necessary to dilute 50 g of potassium permanganate in 1 liter of warm water.

- A deep yellow hue is achieved by treating the material with a decoction of barberry roots with the addition of alum.

- Green wood is obtained by combining decoctions from poplar shoots and oak bark.

- The bars become dark brown from the juice of wolf berries and copper sulfate. Berries with Glauber's salt give a scarlet color, with potash - green, with soda - blue.

- Black stain for oak and mahogany is made from potassium dichromate (chromic). An orange powder is poured into a glass bottle, poured with hot water and shaken until completely dissolved.

- Herbal green color is obtained by adding 50 g of copperhead to vinegar essence. The mixture is boiled for 10 minutes.

Whitening effect

Stains are used as a base before painting wood. Whitening soaks can be prepared in the following ways:

The stain lay with a defect: ways to eliminate the consequences

Violation of the technology of work, the use of low-quality composition can cause defects, which sometimes can still be eliminated. If streaks have formed due to the large amount of stain applied and the excess removed in time, you will have to remove the impregnation layer.Subsequent application of the composition will soften the base coat. Remove excess stain with a rag.

Excess composition should be removed immediately.

If the coating turns out to be heterogeneous, for example, characteristic spots are visible, the composition from the painted area is removed mechanically, most often using a planer. All face veneer will have to be removed from the plywood. After that, the processing is repeated.

Advice

Stain is easier to work with than paint, but smudges and stains can occur. If the tree has any defects or plastered cracks, then such imperfections will become clearly visible.

Stain application algorithm:

- The surface must be clean. If there is exposed wood resin or oil stains, then they must be sanded and degreased.

- Some wood species absorb moisture well. To reduce the consumption of stain, you can pre-moisten the surface. This technique will also help to reduce hairiness after staining.

- The stain must be shaken or mixed thoroughly. If the diluted composition turns out to be cloudy, then it should be filtered through a dense cloth or cotton wool filter.

- You can apply the stain with a brush, foam rubber, roller, spray or cotton swab. It is necessary to stain along the fibers. If you "pour" a lot of liquid, then ugly smudges may remain. When painting a vertical surface, it should be applied from top to bottom.

- If there are several layers, then each subsequent layer should be applied after the previous one has dried (after 4-12 hours). The finishing layer dries up to a day.

When it is necessary to treat a large area, you can first use a cheaper composition, and for the finishing layer you can purchase a higher quality stain, thus saving on price.

If spots and smudges have formed, then they should be washed out with water or gently wiped off with acetone. In some cases, only grinding will help. After that, another 1-2 layers of stain should be applied.

When the product is assembled from different types of wood, then after staining the areas may differ in color, even if initially there were no differences in them. This must be taken into account, otherwise you can damage the product. In some cases, it is better to use paint or varnish instead of stain.

The acquired shade may differ from the sample upon application. To predict the result, you need to apply the stain on a block similar to wood, and at the same time choose the desired shade and determine the number of layers. If there is no bar, then it can be applied to an area where it will not be visible. For example, when working with a wooden chair, you can use the space under the seat or the inside of the leg. A poorly chosen color can always be corrected with a darker shade.

For more information on how to work with water stain, see below.