Characteristics of moisture resistant MDF panels

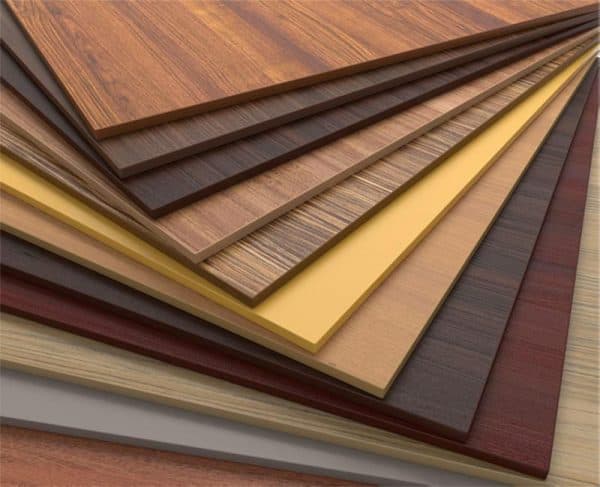

In fact, waterproof mdf panels are densely pressed sawdust. Due to the high pressing temperature, the product has excellent strength, while remaining flexible enough for installation work.

There are several types of decorative wall panels for interior decoration:

lining, the principle of installation, connecting them together. The final design resembles a crate. It is very aesthetically pleasing;

Lining

another kind of panels is the shape of the tiles;

Tiles

another type is mdf sheets. This type of panels is very convenient due to the ability to place any pattern on the surface.

Sheets

The uniqueness of mdf sheets is that they are cut according to the customer's measurements to fit perfectly into your decor. Moisture-resistant sheet mdf panels for walls are convenient in that they cover the entire wall entirely, and there is no need to additionally finish it with something.

As a result, you get a wonderful appearance without additional seams spoiling the appearance of the room. According to the standards, the produced mdf panel sheet has dimensions: 1200 mm by 2800 mm. After that, the sheet is cut according to the dimensions provided by the customer.

Also, the sheet goes through an additional stage of facing, it is covered with a special decorative film, chosen at the discretion of the customer, and a laminate.

Laminate

The sheet version of MDF is produced according to a specific order.

When choosing a mdf sheet for a bathroom or kitchen, you should not stop choosing a picture with imitation of wood, this type is suitable only for a dry room. Many people often compare mdf panels with chipboard, but professionals prefer to use moisture-resistant mdf panels for walls during repairs. Here you will find out what is best for furniture, mdf or chipboard.

Here are the main differences between the two materials:

- finishing material production technology. When creating mdf sheets, materials of higher quality are used, thereby increasing the operational life and improving the external design of the building material;

- environmental friendliness of MDF guarantees safety, because such dangerous resins as phenol-formaldehyde and urea-formaldehyde are not used in production;

- high resistance to moisture due to a good protective layer covering mdf panels;

- the ability to apply a finishing material, such as paint, without preliminary surface preparation of the sheets.

And this is not all the possible advantages of mdf panels.

What are the moisture-resistant wall panels for bathrooms?

There are quite a few options for finishing the bathroom, to determine the best material, it is important to analyze all the advantages and disadvantages of each of them. Finishing options can be divided into:

- rack and pinion;

- tile materials;

- sheet canvases - it is advisable to choose them for large rooms.

Characteristics of PVC wall panels for bathroom

PVC is the most inexpensive material for bathroom decoration. The technology for the production of polyvinyl chloride allows the production of panels with imitation of wood, natural stone or ceramic tiles in different colors. The main advantage of the material, in addition to moisture resistance, is that it is non-toxic even at high humidity. Interesting interior solutions using PVC panels for bathroom are presented in the photo gallery.

PVC in the interior is not inferior to tiles

Related article:

Characteristics of MDF panels for the bathroom

MDF bathroom panels are suitable only with a laminated coating, it prevents moisture from entering the chipboard. If we compare the characteristics with PVC, MDF has undoubted advantages:

- high strength;

- a large number of supports are not required, therefore, the structure is more durable;

- the finished product is painted;

- has heat and sound insulation.

The only drawback can completely negate all the advantages: hydrophilicity. Unfortunately, chipboard absorbs moisture, it will take a little time for the board to become unusable. To prevent this effect, it is necessary to apply additional coating and completely isolate unprotected areas.

The finished MDF sheet does not need additional decor

Characteristics of MDF bathroom panels

Fiberboard fibers have a low density, therefore they are afraid of moisture and can swell. To use fiberboard in conditions of high humidity, they must be treated with a composition with the effect of moisture resistance. For use in the bathroom, it is recommended to choose laminated hardboard - fiberboard sheets that are treated with bitumen impregnation, then covered with a film and a special compound with protective properties. As with MDF boards, it is necessary to control the integrity of the film coating, this is an additional protection against high humidity, it must be intact. During installation, all butt joints are treated with a sealant.

It is undesirable to use laminated fiberboard in the bathroom

Related article:

Characteristics of moisture-resistant chipboard-based panels

Chipboards are made of shavings and small chips. Ordinary boards, like fiberboard, are afraid of moisture, they swell and lose their shape, which does not recover even after drying. Manufacturers produce moisture-resistant boards, which include binding components, and the surfaces are additionally laminated. For bathrooms, you should choose a material with a waterproof effect. In terms of cost, it is equivalent to moisture-resistant MDF for a bathroom, however, MDF is much better in terms of characteristics.

Laminated chipboard is also not quite suitable for the bathroom.

Related article:

Characteristics of acrylic bathroom panels

Acrylic lamellas are innovative developments of manufacturers. The concentration of additives affects the color and structure of the material. The gloss on the surface is much higher than that of PVC and MDF. The main advantages of acrylic can be identified:

- high strength;

- resistance to mechanical damage;

- resistance to abrasion and light reflection;

- environmentally friendly product;

- absolutely waterproof.

The only drawback of acrylic does not overshadow the entire list of advantages - it's high price. Only water panels can be considered as its competitor.

Range of acrylic lamellas for the bathroom

Glass wall panels

Tempered glass lamellas are quite in demand for wall decoration in the bathroom. The smooth and shiny surface beautifully reflects the glare from the lighting, this effect will visually expand the space, the room will look radiant. The advantages of finishing include:

- not afraid of temperature changes;

- resistant to high humidity;

- easy care;

- durability.

Glass paneled bathroom interior

Other types of wall panels

When choosing a material for finishing a bathroom, one cannot but highlight the water panels, today this is the most ideal solution. They are a fiberglass mesh filled with weightless expanded clay. Of the positive qualities, it should be noted:

- resistance to high humidity and temperature extremes;

- easy care;

- beautiful appearance;

- the material can be bent.

During installation, the aquapanels are attached to the wall surface using special glue on a pre-assembled frame.

Aquapanel is the best solution for the bathroom

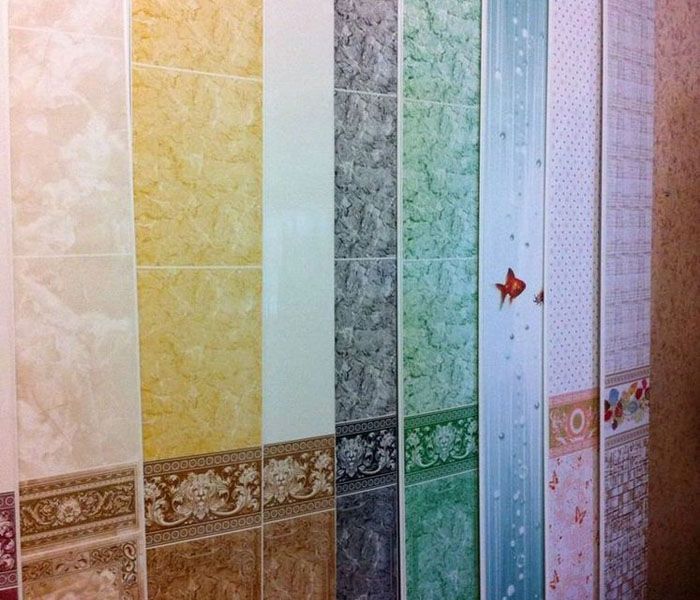

Imitation tiles in the bathroom

Plastic wall panels imitating traditional tiles are a great alternative to ceramic cladding in bathrooms and washrooms. The standard sizes of most waterproof decorative PVC wall panels are:

- length - 2.5-3.0 m;

- width - 25-30 cm;

- thickness - 0.5-1.0 mm.

Panels imitating tiles can be used for both wall and ceiling decoration. Elements are mounted using liquid nails or special plastic guides.

Finishing - imitation for tiles

The main advantages of modern cladding plastics for bathrooms are:

- high level of color rendering;

- the realism of the image applied to the surface of the panels;

- increased resistance to direct sunlight;

- a wide selection of colors, patterns and designs;

- visual expansion of a small space.

Bathroom interior - an interesting option for choosing panels

The level of practicality and high quality characteristics of modern finishing plastic panels are beyond doubt, and their use in cladding rooms with high humidity levels has the following positive aspects:

- the insignificant weight of PVC panels makes it easier and faster to carry out the installation with your own hands;

- installation of finishing elements is not accompanied by the accumulation of a large amount of construction debris or dirt;

- a protective outer layer protects the finished surface from scratches;

- care of decorative trim during operation is carried out using the simplest and most common detergents.

The cost of plastic finishing is available to a wide range of consumers. With the right choice of material and adherence to the installation technology, plastic panels that imitate tile coverage can last for an almost unlimited period, while maintaining their original visual appeal.

The nuances of installing MDF panels

Large-format MDF boards for bathroom walls, shower rooms, cafes, restaurants are not intended for frame installation. They should be glued with universal construction adhesives or specialized adhesives for wood surfaces.

The glue is applied pointwise, with an interval of 20-30 cm

The glue is applied pointwise, with an interval of 20-30 cm

The base for sheet products must be flat, clean, dry and smooth. Dust is removed with a vacuum cleaner, oil stains, soot and other things need to be cut, irregularities should be leveled with a putty or cement-sand mortar.

Installation starts from the inner corner. On the seamy side, you need to apply glue in zigzag movements, attach the panel to the wall, press and tap the entire surface with a fist or mallet. Remove excess adhesive with a damp cloth.

It is recommended to install the adjacent panel with a thermal expansion gap of 1-2 mm, which can then be filled with silicone colored or transparent wet room sealant.

Edges along the top and bottom edges, window and door openings, inner and outer corners can be finished with plastic profiles or decorative cornices made of polyurethane, PVC.

Installation features

In order to fix models of various sizes on the walls of the bathroom, no special skills and abilities are required. By and large, the installation of wall MDF is very simple, but it has its own nuances. Many panels are fastened to the lathing, which greatly simplifies the installation process. In addition, if the walls of the shower rooms are flat, then finishing can be carried out without preliminary preparation.

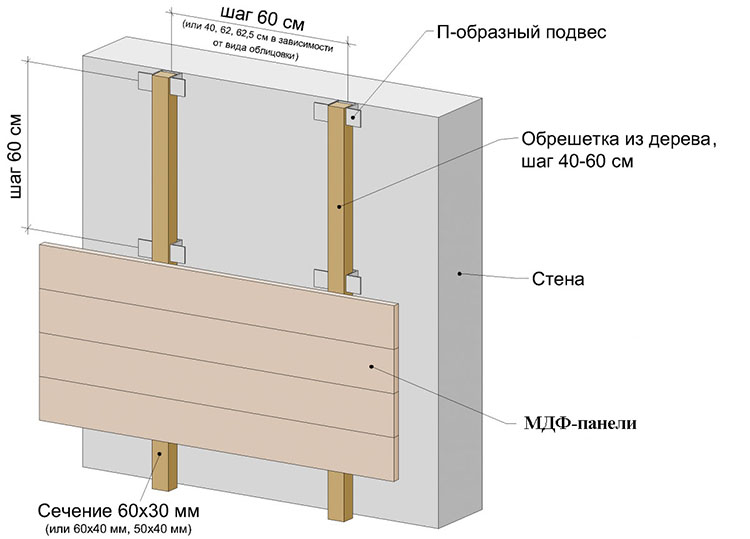

Installation on a crate

Installation on a crate

However, if there are flaws in the wall surface, they must be corrected. You should prime the wall, plaster it or use plasterboard blocks. The latter option allows you not only to level the surface, but also to create a new one. After carrying out the preparation, you need to measure the room. In addition, it is necessary to let the moisture-resistant panels stand for several days in the bathroom. This will allow them to acclimatize and get used to new conditions.

Plasterboard wall alignment

Plasterboard wall alignment

After that, they will acquire qualities that correspond to the temperature regime of the shower room, as well as the level of humidity. It is best to fasten sheet panels of various sizes to the wall using a special frame - lathing. This makes it possible to bring communications, for example, wiring for lighting. This method is suitable for coatings with small defects that need to be hidden. Wall MDF are mounted using self-tapping screws, special brackets, clips or nails.

Installation is carried out starting from the corner of the moisture-resistant product. It is worth knowing that a smaller hole will be better from the point of view of subsequent operation. In addition, if you get tired of the option with a crate, then after a while it can be removed without unnecessary problems. This is suitable for people who like frequent changes in the interior style in the bathroom. Separately, it should be noted that the installation of wall panels can be carried out both on a frame with a metal base, and on a structure with another material.

Peculiarities

Despite the fact that all manufactured wall moisture-resistant panels have the same name, the characteristics of such finishing materials have significant differences, including moisture resistance indicators:

- PVC panels are installed in places of direct contact with water;

- fibreboards and MDF panels need to be sealed for sections and have a solid laminating film to maintain moisture resistance.

Wall chipboard panels do not belong to the category of moisture-resistant materials, therefore, they are highly not recommended for use in rooms with high levels of humidity.

Moisture-resistant wall panels are a relatively new finishing material that has many advantages:

- simple installation, easy to perform even by non-professionals;

- absence of dirt and dust, as well as other construction debris during installation;

- quick installation due to convenient dimensions;

- joining of panels is effortless;

- there is no need to thoroughly prepare the surface in advance;

- high strength of the coating due to the large number of transverse partitions in the panels;

- the ability to hide any irregularities and communications under the surface decor.

The water-repellent coating of the wall panels allows for a durable, high quality finish that will not deteriorate when used in high humidity conditions.

The main features of moisture-resistant wall panels include resistance to temperature extremes, hygiene and ease of maintenance, a rich assortment of colors and shades, as well as the completeness and integrity of the finished decor.

Views

Today, the domestic market offers a wide variety of all kinds of plastic products. Wall panels come in several different variations for bathroom applications. In fact, in terms of performance, they are at the same level, however, in terms of functionality and appearance, they differ quite sharply.

Leafy

Sheet models are very large elements. They differ from other brethren, first of all, in their size, but at the same time they are very easy to install. They are usually used with a pattern or image already applied. Sheet products are high quality material that withstands high levels of humidity and temperature changes well.

Sheet panels

Sheet panels

Usually, sheet panels are used for installation in the most difficult, from an operational point of view, areas. Often it is either a kitchen area or a bathroom, which allows the data in the room to be reliably protected. The main material used for the production of sheet products is fiberboard raw material. Eucalyptus additives containing natural resins, essential oils and other natural ingredients are specially added to it.

This allows, together with protective impregnation, to impart high strength and fire resistance to sheet panels. In addition, the production of sheet products is allowed from PVC material. In this case, it is a special sheet of medium-sized plastic. The resulting model is very convenient for transportation and installation. During installation, a very small number of joints and seams are obtained. This has a positive effect not only on the appearance of the shower room, but also on its performance.

In addition, the wall panels are treated with protective impregnations, which protect them from the effects of an aggressive environment, which are formed when using cleaning agents. Separately, it should be noted that special impregnations protect the material from additional stress and scratches on the sheet surface. The service life of this product may vary from 10 to 15 years.

Rack

The next type of wall panels used in the room is rack and pinion. These products are distinguished by high moisture-resistant properties in comparison with wooden or plastic lining. The domestic market offers a fairly extensive range of rack and pinion models. A wide variety of panel colors and shades can be easily selected. This allows you to add a little originality and aesthetics even to a nondescript shower room.

Rack panels

Rack panels

Such material will perfectly fit into a room that is not distinguished by its large dimensions. Rack products will create a special coziness and a sense of comfort in the space, by the way, visually increasing it a little. Due to the visual effect, the height of the ceilings increases, and when choosing interesting patterns, an original shower room can be obtained. Installation of the structure is carried out using special glue, as well as staples and screws.

Tiled

Paneling is done differently depending on the model. For example, tile panels are staggered. These panels are made from the most modern materials. The most commonly used plastic raw materials, and also have a square shape. They fit onto the wall surface in the shower room. In addition, these products successfully replace mosaics, natural stone, wood, decorative plaster, and other materials.

Tiled panels

Tiled panels

Before laying the frame, it is necessary to carry out a thorough surface treatment. It should be well prepared for the installation of tile products, otherwise the fasteners will begin to dangle over time. This will lead to deformation of the structure, as well as the emergence of favorable conditions for the reproduction of microorganisms.

Mounting

There are several options for fixing mdf panels:

on a specially installed frame;

On the frame

on the glue.

On glue

It is the second method that is more popular, it is less time-consuming. The only important nuance is landing on a perfectly flat wall, so you have to prepare everything in advance.

The whole process of gluing panels is divided into several steps:

- accurate knowledge of meters in the room where the panels are planned to be glued. This will help minimize waste;

- preliminary adjustment of all parts of the decor. So it will be easier for you to decide and place all the pieces in the right places for subsequent gluing;

- the next step is to attach the starting molding in the right places;

- now you can glue the panels in sequence. Here's how to glue mdf on the wall. The adhesive layer must be thin and uniform to avoid defects. It is applied in thin strips evenly spaced from each other;

- all joints and abutments of MDF for the ceiling must be hidden behind the panels prepared in advance.

Another option is to use a crate, thereby leveling the walls for the subsequent fastening of the panels using self-tapping screws.

For more details on the installation of MDF panels, see the video:

Wall mounting methods

Moisture-resistant finishing panels can be mounted on the surface of the walls in different ways, which differ in the level of complexity and characteristics of the resulting cladding.

Moisture-resistant finishing panels can be mounted on the surface of the walls in different ways, which differ in the level of complexity and characteristics of the resulting cladding.

The planks can be fixed vertically or horizontally.

Installation of wall panels will require the purchase of accessories in the form of:

- connecting moldings to hide the joints of the elements;

- ceiling moldings installed in corners and at joints;

- end decorating moldings covering the edge of the finishing panels;

- external and internal corner decoration elements;

- starting moldings that are guides in the horizontal or vertical direction.

Wall panels for tiles

Moldings of the universal type are now finding wider application. All purchased accessories must be of high quality, without damage.

Installation on glue

Not a very popular method, characterized by low adhesion rates of the finishing material to the wall surface and the complexity of dismantling. Installation technology with moisture-resistant glue is as follows:

- measuring the walls in the bathroom;

- fitting panels and moldings with a hacksaw in accordance with the measurements obtained;

- installation of the first molding at the starting point;

- phased gluing of finishing panels on wall surfaces;

- sealing joints with baseboards and ceiling moldings.

Bathroom decoration with wall panels

The adhesive should be applied to the back of the finishing panels in fairly thin and zigzag lines.

It should be noted that the installation of panels on an adhesive composition requires a thorough leveling of the wall surface with the removal of all defects using cement mortars or putty.

Installation on wooden rails

The use of a wooden frame base for the installation of moisture-resistant wall panels in the bathroom is in demand in rooms where the surfaces are characterized by the presence of large flaws and irregularities.

The use of a wooden frame base for the installation of moisture-resistant wall panels in the bathroom is in demand in rooms where the surfaces are characterized by the presence of large flaws and irregularities.

The frame of such a lathing is made using wooden bars 40x40 mm. Screws are used to fix the frame to the wall surface.

The technology for self-installation of finishing panels is as follows:

- fix the corner rails vertically;

- fix horizontal bars end-to-end with vertically arranged elements, adhering to a step of 40-60 cm;

- installation of a starting molding;

- installation of finishing panels using tongue-and-groove joints;

- cladding with skirting boards, corners and moldings.

Fastening MDF to a wooden crate

The cladding panels are installed on wooden rails by fixing with staples from a special stapler.

It is important to remember that the use of guides in the form of wooden structures will require mandatory preliminary thorough treatment with special antifungal and antiseptic compounds.

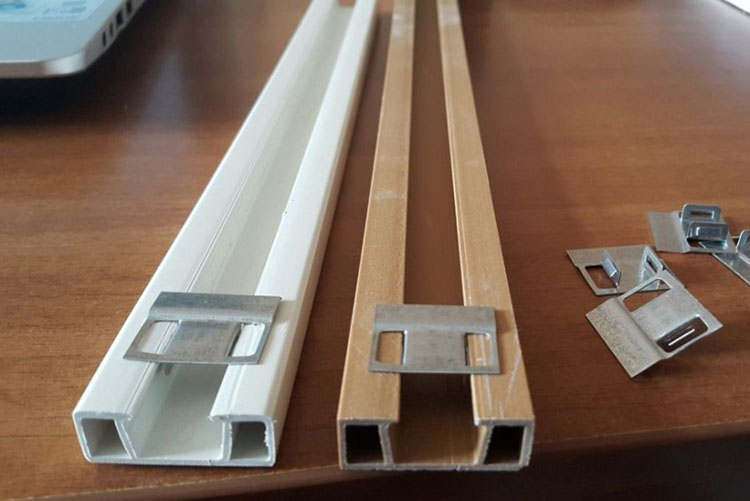

Installation on special plastic rails with fixings

One of the newest, most convenient and promising options for self-assembly of moisture-resistant wall panels, involving the use of special strips and clips. With this method of installation, a complete, ready-to-install set of moldings must be purchased.

Clips with a mustache must be prematurely installed in the strip grooves.

Plastic strips

All installed clips are hidden by the edges of each subsequent mounted finishing element, which allows you to get the most monolithic and aesthetic surface of the cladding in the bathroom. In this case, screws, staples and nails are often replaced with special clamps.

Improving the level of water resistance of the surface lined with moisture resistant panels is achieved by applying standard silicone sealant to the ridges and grooves during installation.

Advantages and disadvantages

The main disadvantage of high-quality materials for finishing shower cabins is their high cost. But, as mentioned earlier, a way out was found during the creation of MDF panels. The panels are really effective for bathrooms: they are affordable, strong, durable, practical, comfortable and easy to install.

The material is primarily processed in a special way to the formation of fine chips. Then it takes the desired shape by dry pressing under the influence of high temperature and pressure.

It should be noted that the domestic market is characterized by a stable demand for MDF panels.

They have a number of significant advantages:

- ease and simplicity of installation, which is quite possible to carry out with your own hands (removal of old coatings and leveling is not required, installation can be done using improvised means without the use of professional equipment, during operation there is practically no dirt, dust, waste);

- versatility (suitable for finishing not only walls, but also the ceiling);

- durability (with proper operation, the MDF finish will last more than 10 years);

- strength;

- resistance to moisture;

- antiseptic properties (panels are treated with substances that protect against mold and mildew);

- easy care (you can clean the dirt from the surface with a damp sponge);

- affordable price;

- ease of cutting;

- various options for attachment to the surface are possible;

- are excellent heat insulators;

- the raw materials from which the panels are made are environmentally friendly;

- represented by a fairly wide range.

In addition to all of the above, the finishing material in question can be combined with any other finishing materials. For example, many combine MDF panels with a stone or tile coating - this is one of the most attractive in appearance options. It is also possible to combine different finishes.

The resistance of MDF panels to high humidity allows them to be used also in bathrooms with a large area.

Despite the large number of positive aspects, negative aspects are also characteristic of MDF panels. However, you should not be afraid of this: this applies to all other finishing materials, it is just that each of them has its own disadvantages. The correct approach to the installation and operation of such panels will help to avoid negative manifestations.

The disadvantages of MDF panels are usually:

- low impact resistance;

- it is easy to cause damage to the surface, for example, scratches;

- unreliability in terms of fire safety.

So, MDF panels have high performance, despite the presence of certain drawbacks. But you need to keep them serious, because if they are not approached correctly, they can really cause some problems. At the same time, exaggerating the shortcomings is useless - the correct approach will ensure getting rid of them, moreover, they may not appear at all.

In general, all the indicators of the material do not require separate recommendations.

Advantages and disadvantages

The high consumer demand and the growing popularity of the panels are due to a number of important advantages of this material.

- Bathroom panels are available on the market in a wide range. This greatly facilitates the choice of the desired option and allows you to purchase a coating of any color and design. There is a large selection of panels on sale that very naturally imitate tiles, wood and natural stone. With the correct selection of shades and the correct combination of textures, it is very difficult to distinguish such surfaces from the original.

- Bathroom panels are waterproof and do not tend to accumulate and retain moisture. This completely eliminates the risk of mold and pathogens.

- Due to the flat and smooth surface, the panels fully meet the sanitary and hygienic requirements for the interior decoration of bathrooms and bathrooms. They are easy to clean, do not tend to build up static electricity and do not attract dust.

- Due to the fact that most of the models are mounted on a frame, there is no need to align walls and ceilings. This greatly simplifies the repair process, saving the owners from the complex preparation of work surfaces before applying a finishing finish to them.

- The installation of the frame and the installation of panels is a very simple process, which can be handled by a person who has no experience in finishing work.

- Due to the composite structure of panel surfaces, in case of damage or breakage of a separate element, it can be easily changed to a new one without dismantling the entire cladding.

- In comparison with tiles, wall panels are lightweight and do not create a significant load on the supporting structures.

- Due to its high wear resistance, the service life of such a coating is 10 years or more.

- During operation, the material is not subject to deformation and retains its original shape throughout its entire service life.

- The price range of wall panels is very wide. This allows you to choose and buy both very unpretentious monochromatic models, and a solid coating with imitation of expensive materials.

- Due to the presence of the lathing between the panels and the wall, a free space is formed, which allows placing electrical and water supply lines in it.

There are not many disadvantages to wall panels. These include the tendency to fade plastic models, a decrease in the usable area of the room due to the installation of the frame and low resistance to mechanical and shock loads of PVC products. Another disadvantage is the limitation of the use of chipboard panels in places of intense water ingress, for example, near a washbasin or shower.

Veneering process using guides

Installation of wall panels is considered a simple matter that does not require special skill.

Nevertheless, it is worth paying attention to its features, because only following all the rules can you make a quality finish. There are several ways, for example, it is advisable to install the panels on a metal profile crate, which is ideal for a humid environment.

Wooden beams can also be used, but they are not as practical.

The process consists of several stages:

- Preparation of the necessary tools and material. The calculation of the panels is carried out as follows: the width of the room is measured, after which, based on the known dimensions of the material, it is determined how many pieces need to be prepared.

In addition to mdf panels for walls, you will need corners, fastening clips, screws and dowels, an adhesive, as well as a profile or beams for the lathing. As for the tools, you need to prepare:

- level;

- roulette;

- plumb line;

- puncher;

- screwdriver.

- Surface preparation. Before fixing the crate and panels, you should remove the old coating, and if there are places affected by the fungus, treat them with an antiseptic. Further, the surface is primed, if necessary, a heater is mounted.

- Installation of the crate. First, the markup is made taking into account how the profile will be located: horizontally or vertically. Then the lathing is attached with a step of 40-50 cm, during which a level is used to check the evenness of the location. Fixation can be done with dowels or glue. Installation is carried out horizontally if vertical installation of panels is planned, and vice versa.

- Facing. You should start from the corner. The first panel is measured, cut in height with a 2mm gap and fixed to the wall. Each subsequent panel is inserted into the groove of the previous one, fastened with self-tapping screws to the profile of the crate. From the side of the groove, fixation is made using special clips.The last panel is cut to fit the width and is attached without clips, but only with self-tapping screws. The fixation points are closed with corners, which are also installed along the entire perimeter of the cladding using an adhesive.