general description

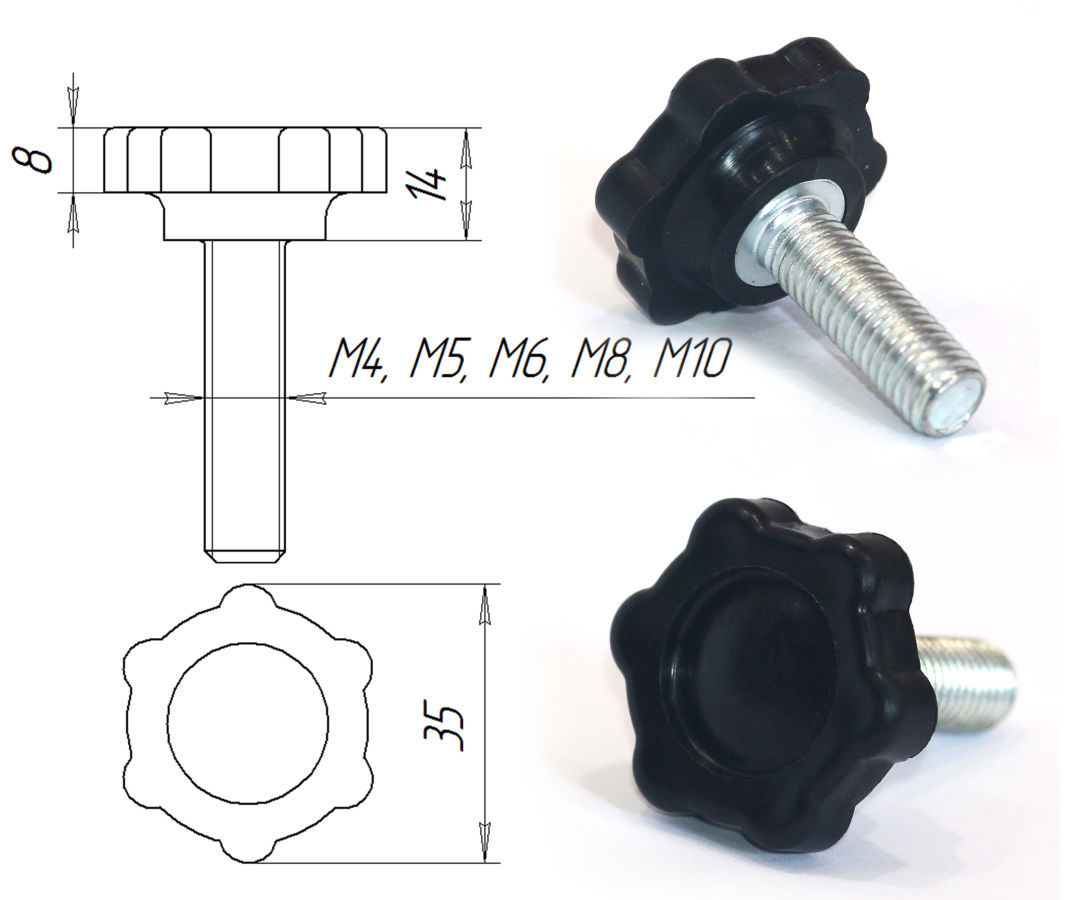

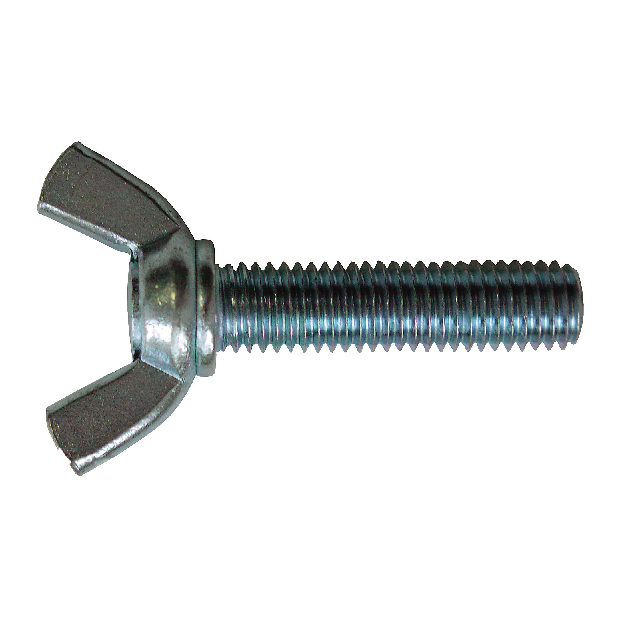

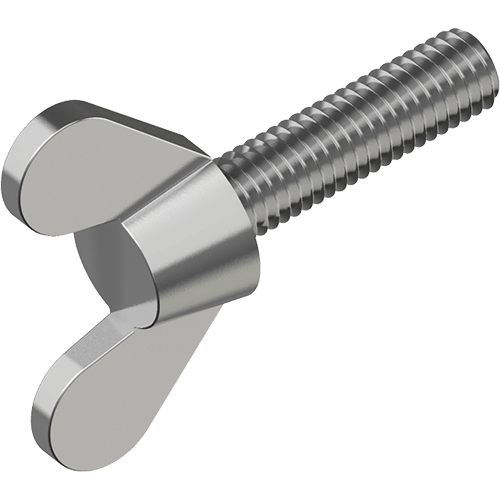

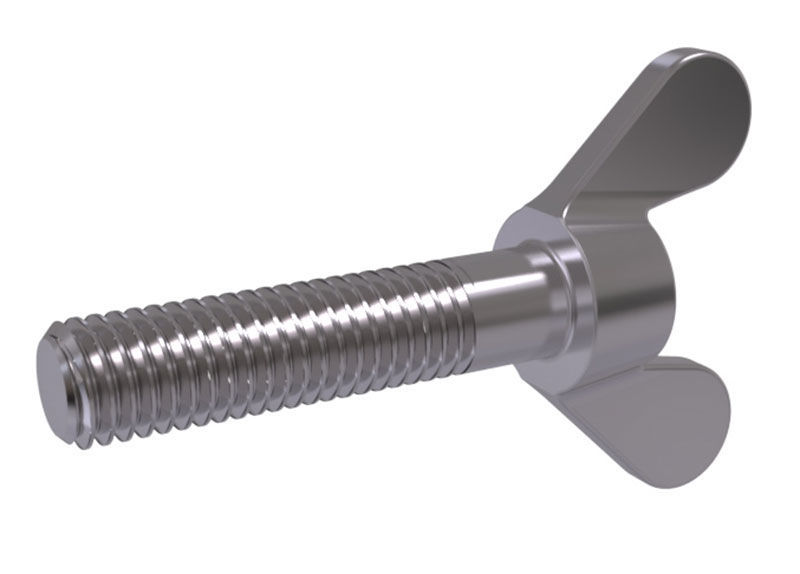

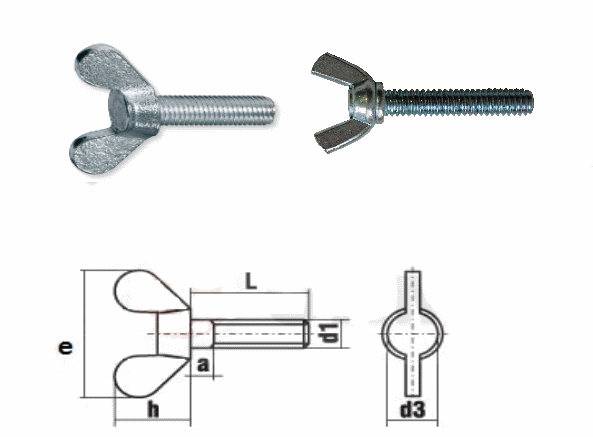

It is useful to start the conversation about the thumbscrew with the fact that the production of hardware in this category has been completely transferred to DIN 316. Other standards do not apply to this fastener. There is no specialized GOST either, so the maximum can be guided by the general GOST for screws, tool and structural steels. The screw shaft has a metric thread. It got its name for the characteristic geometry of the head, reminiscent of really small horns.

The petals of the head part can be rounded (then they speak of the German version). In the American version, rectangular geometry is more characteristic. The nominal diameter can range from M4 to M24. The basic norms for fasteners are fixed in DIN ISO 8992.

Peculiarities

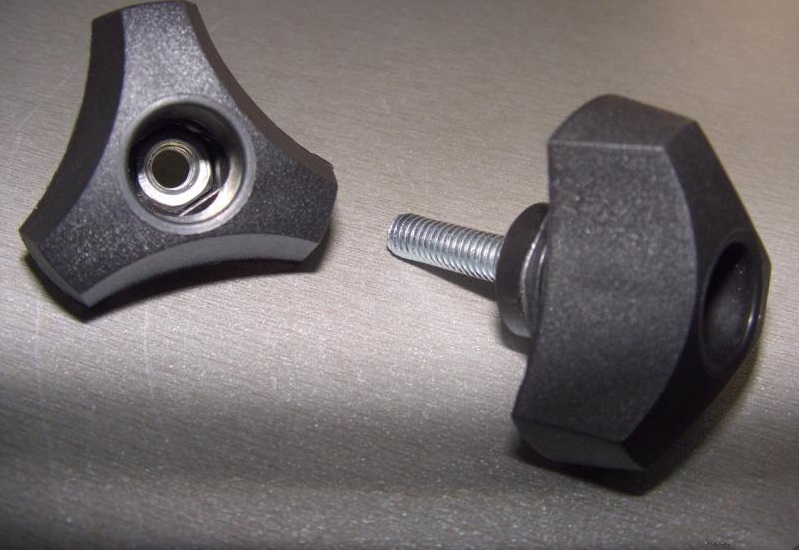

Both of these variants of wing nuts are now equally widespread. But the evolution of such manual fasteners did not stop there: new modifications appear, but now from other materials.

The main technical feature of the wing nut is its self-sufficiency. Of course, using it without a bolt or stud is impossible, but even these hardware are selected so as not to use a key or screwdriver to hold them. For example, a hairpin can be welded or have a loop instead of a head, with which it is movably attached to an object or part. The bolt should also not have a wrench head or screwdriver. For example, bolts used when installing wood products may have a rounded head and special stops that, when cutting into the wood, prevent rotation when tightening the fasteners.

The wing nut combines both fastening hardware and a tool for its installation. The need for such a fastener arises in cases where it is necessary to quickly tighten or loosen the thread of the fastener of a removable part, which is not a member of the supporting structures. Finding a wrench or screwdriver would take an unreasonable amount of time. At the same time, the effort of one hand is sufficient for functional fastening without additional devices.

Application

As already mentioned, wing nuts can be found wherever a lot of effort is not required, but often lightweight structures have to be mounted and dismantled.

Thus, steel products are used to install fuel filters on some engines. This structural element has to be changed quite often.

In addition, they can be seen on the lids of sealed thermos tanks. The covers have to be opened and closed several times a day, and it is unacceptable to damage the sealing gasket, which ensures tightness, by overtightening the nuts.

The use of such products for fixing hatch covers, sealed doors or windows is also based on this.

In some cases, closed-type fasteners are used (when the ears of the nuts are connected in the form of a metal loop). Such hardware has a higher decorative component, therefore, it can be used to fix some household appliances.

Galvanized and stainless steel lambs can be seen in demountable timber structures. For example, sketchbooks or easels, which are attributes of artists, have a number of adjustable and folding parts. It is impossible to imagine them without shiny lamb nuts.

Wing nuts are widely used in photography tripods, stage lighting and sound amplifiers. Installing and adjusting such equipment is required very often, and it would be very inconvenient to carry keys and screwdrivers for this.

Plastic wing nuts with steel cores closed type are used for the installation of some measuring electrical devices and radio equipment. Here they make it possible to reliably isolate the fastening elements, preventing the possibility of short circuits.

How soft plastic fasteners are used when installing plumbing and other plumbing equipment has already been mentioned. But it should be clarified that any tool cannot be used with such material, since the force created when tightening by hand is quite enough in this case.

The next video shows you how to make a wing nut with your own hands.