Species overview

Screw nails are available in a wide range of types. They can be knurled or not. In addition, consumers can choose drum, four-way, and other types of such hardware.

- Black. This product is made from low carbon steel. It is customary to make fasteners with such nails under conditions of short-term use or in cases of low humidity in the place of operation of the fastened structure. Black nails are often used for interior decoration and flooring. And also this hardware can be found on boxes, euro pallets, pallets with a short period of operation.

- Galvanized. After the stamping process, these hardware are coated with a layer of zinc, 6 microns thick. Galvanized hardware has a long service life, therefore, they have found their application during the decoration not only inside, but also outside the premises. Often they are used when assembling roofs, constructing small architectural structures.

Among other things, screw-type nails have differences in the shape of the heads. According to this characteristic, two types can be distinguished.

- With ordinary caps, which have a standard flat head, proportional to the bar.

- With frustoconical countersunk heads. Thanks to this structural feature, the hardware sinks into the surface and becomes almost invisible.

Screw nails test drive

To test our nails in the case, we will go out into nature and arrange a series of different tests. These will be:

- classic hammering,

- nail pulling

- "Wrong" clogging

- straightening bent nails with re-hammering.

As a testing ground, we found an excellent dead pine in a forest clearing.

Classic nailing

We start with the most basic thing - hammering. We put 10 nails in a row (we will literally make a couple of millimeters) and arm ourselves with a hammer.

Each nail is hammered in literally 3 strokes. Very easy and hassle-free.

We do not finish the last three nails by 3-4 mm. We will pull them out.

Pulling out nails with a nailer

Well, you understand, while testing nails, we could not pass by the symbol of our Instrumental laboratory - the nail puller.

Setting up the tool. The head of the screw nail is wide, the grip of the nail-driver is deep and tight.

Subjectively, no significant pulling force was required. But it is worth noting that the nails practically did not bend when pulled out, retaining their original shape. And by the way, the hats did not bend either.

We hammer them again. No problem again. The conclusion is that screw nails are quite suitable for repeated use.

"Incorrect" driving of screw nails

And how resistant the screw nails are to crooked hands. Let's see if it is possible to bend the nails if you deliberately hit them not vertically. Let's imitate the work of an inexperienced carpenter and hit at an arbitrary angle.

To do this, drive 5 nails to different depths. So as in life, when a hand with a hammer can tremble both at the first blow and at the last.

We begin to hit “wrong” at an arbitrary angle. As a result, only 1 nail was able to bend. of 5. The rest, even with curved hammer blows, still entered the wood completely.

Straightening bent nails with re-hammering

How will a screw nail behave if you turn a number with it - "economical builder"? We take out the bent nail, straighten it with the available means and hammer it in again.

We take out with a nail puller

Straighten it with a hammer right on the log.It was not possible to return to the previous form. But that's what we need.

We hammer again, already with the correct hammer blows. The nail went in great.

Hardware for a pneumatic pistol

As a rule, nails are hammered into the roofing by hand, but it is much easier and faster to do this with special equipment, or rather, with an air gun. Fasteners for the pneumatic unit should be short - no more than 4 cm, but at the same time have a wide hat. Quality elements of this type of fasteners are made of stainless steel or galvanized. Steel roofing hardware must be manufactured in accordance with GOST 4030-63.

The fasteners in the pistol are located in the chamber. At the same time, several dozen nails can be loaded into the pistol, fastened together with a wire. In appearance, they resemble a machine-gun belt. When the "trigger" is touched, a large air stream passes through the chamber, under the influence of which the hardware nails the roof covering to the crate.

Rusty nails

The ruffled fastening nail got its name from the notches evenly applied to the rod and resembling the needles of a household bottle brush. When installed, "brushes" are embedded in the wood and "tightly" fixed in it. Thus, a high-quality installation of the roofing material is ensured - all the elements of the roof will not move or fall out.

Brushed nails are made for fixing soft and hard surfaces (for example, slate). Fasteners of an asbestos-cement surface differ from ordinary nails in their size and appearance, since they have a rubberized cap that does not allow moisture to enter the mounting recess.

It is necessary to use finished nails in the installation of roofing materials in full confidence in their abilities or the skill of roofers, because if you have to dismantle the structure, then the fastening element can be damaged by itself, as well as nail the cladding.

For information on what nails are needed for roofing work, see the next video.

Nails for soft roofs

The list of soft roofing coatings includes roofing material and roofing felt. A feature of hardware for such flooring is their appearance - a large-diameter hat. Thanks to this design feature, the fasteners prevent the soft coating from breaking under the influence of gusty wind and other negative mechanical influences. The roofing material is pressed as close as possible by the hat to the crate and remains in the same position for many years.

For attaching the roofing paper, short nails are used that look like pushpins. The diameter of the hats of such hardware can range from 3 to 7 mm.

Since the roofing felt and roofing felt belong to the number of soft flooring, you do not need to apply increased physical effort to install them. Fasteners in this case are used from metal alloys and they do not differ in high strength, since they are intended for fixing soft materials. However, in order for the hardware not to be destroyed by corrosion during operation, which will negatively affect the condition of the entire roofing, you should buy only galvanized or copper nails that do not rust even in high humidity conditions.

Another soft roof covering is shingles. And although it is very similar in structure to roofing material, the nails for fixing it differ from the above options - the difference concerns size. For laying bitumen tiles, fastening hardware is used with a length of at least 2.5 cm and a head width of 8 mm.

Fasteners for shingles can be made from any metal, however, so that nails do not succumb to moisture for a long time, they must be galvanized with zinc. Such hardware is distinguished by excellent anti-corrosion properties.

1 Main advantages

Screw nails, once undeservedly forgotten, are again widely used in construction for a reliable and durable connection of wooden structures. They are used in individual construction for screed floor boards, upholstery of external walls of buildings, during roofing work. In industrial construction, they are used in the assembly of containers, pallets, boxes, floating equipment.

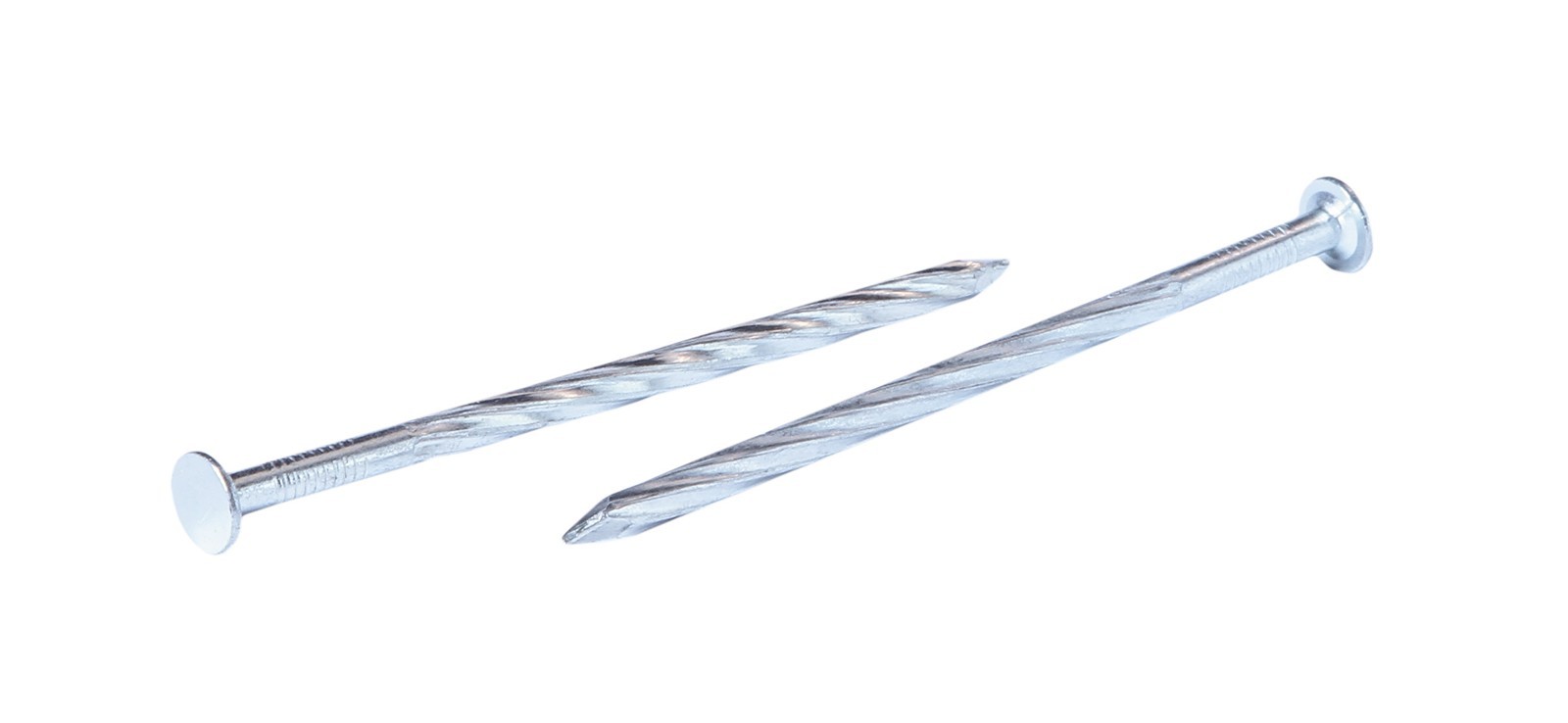

Screw nails are made from wire of round, square, pentagonal cross-section, and screw threads are applied to them. The wire is made of low-carbon steel, for particularly demanding work - from hardened. This ensures the preservation of its mechanical properties for a long time, it is less susceptible to corrosion. The most durable are zinc-plated or phosphated screw nails, but they are more expensive than black ones. The latter are used for the construction of temporary structures operated at low humidity.

The process of driving screw nails does not differ from driving smooth nails. But when struck, the nail moves not only progressively, but is also screwed into the wood, while it does not split.

Screw nail driving process

Screw nail driving process

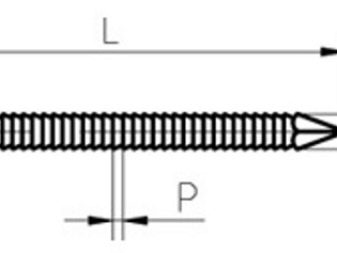

The hat is made smooth or corrugated, it can be hidden. There are also combination nails, consisting of a rod with a smooth surface and a surface with a screw thread 2/3 of the length (full and incomplete screw).

Diameter of nails from 2.5 to 3.5 mm, length from 60 to 120 mm. They can be made to order. Such nails are indispensable for fastening flexible structures and structures experiencing high dynamic and vibration loads, used in high humidity conditions.

Their main advantage is that over time they do not spontaneously leave their nests, they do not need to be periodically finished off. At the same time, they easily enter the wood and do not spoil or split it, unlike smooth ones. Nails of this type, like screws, provide up to 4 times more secure attachment than regular smooth nails.

Hardware for secure fastening

Hardware for secure fastening

In order for a smooth nail to provide a secure attachment, it has to be driven in at a certain angle, and this is not always possible. This can lead to misalignment of parts. The screw is enough to hammer perpendicular to the surface. A smooth nail will not be able to create a reliable connection between wood and some materials, such as chipboard. The screw copes with this task.

Many builders have recently preferred to use self-tapping screws for fastening. But they are more expensive; installation requires a screwdriver and a set of bits. Often, when screwing in, the splines are cut off, and the long screws break. Hardened screws do not withstand heavy loads when the fastened parts shift and break. Nails are free from this drawback.

Finished products. Screw nails. Ring-threaded nails

Nails for a pneumatic gun from the manufacturer.

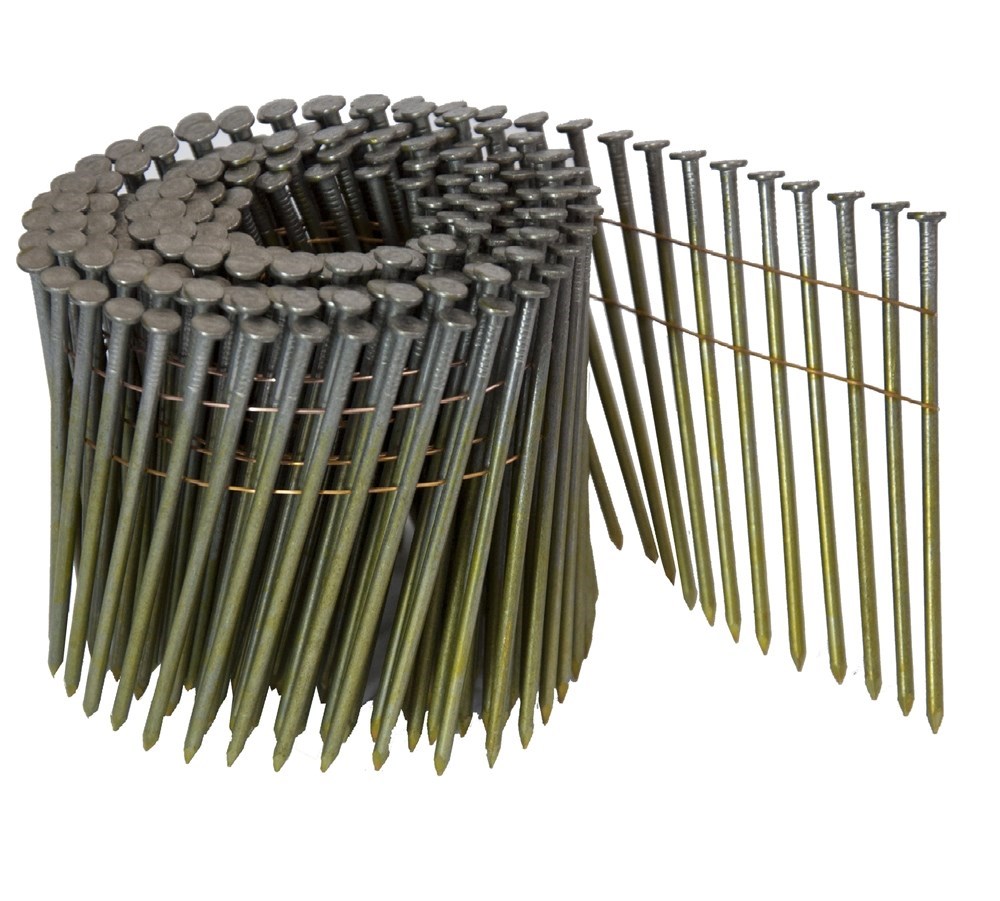

Nails for a pneumatic gun, nailer are a set of several dozen metal nails, connected in special bobbins or cassettes for placing in a gun magazine. Serve for fixing parts or materials to the base. Provides a strong connection between the elements. Various bundles of nails in a cassette are used. Wiring, for example, is common when joining smooth, screw and ring nails into a drum cage. And rack nails are tied with a tape of plastic or paper. For pallets (they are also wooden pallets), drum nails up to 400 pieces in one reel are used. For stronger fastening, ring knurled nails are used, and screw knurled nails enter frozen wood much more easily. For work with metal or concrete, dowel-nails in a plastic clip are used. And for those parts in which the attachment point is subsequently processed with a milling cutter on a machine, aluminum nails are used.

2 Disadvantages of screw nails

Wooden structures mounted with screw nails are very problematic to disassemble. They will either have to be sawed or broken. Therefore, at industrial enterprises, whole mountains of discarded pallets are collected, which are very problematic to dispose of.

Some owners, in order to use the material of pallets or other structures, cut off the nail heads with a grinder or drill them, but this is a very laborious process. If a subsequent analysis of the structure is expected, it must be mounted with screws.

Installation of the pallet with screws

Installation of the pallet with screws

Over time, black nails corrode, the wood rots at the point of contact with them and the fastening weakens. But this disadvantage is typical for other types of fasteners.

Ordinary smooth nails, screws and self-tapping screws can be reused; it is problematic or impossible to remove screw nails.

Types of screw nails

Screw nails are usually divided into two types:

- Black. Manufacturing material - low-carbon steel. Purpose - use with low air humidity or short service life of the item (interior finishing work, production of containers).

- Galvanized. Galvanized screw nails are distinguished by a zinc coating with a thickness of 6 microns. They are corrosion resistant and more durable than black ones. They can be used for work both indoors and outdoors.

Where to buy screw nails? You can buy fasteners in any construction market or in any specialized store. It is also possible to order products via the Internet.

Views

The construction market is rich in different models of roofing nails. They differ in properties and parameters, which affects their scope and purpose.

- Ruffled nails. Indispensable during installation of soft roofs, they are distinguished by the presence of a conical headrest. After hammering, the headrest is securely fixed in the previously made hole, which results in a very tight fit of the fastening hardware in the perforated ceiling.

- Screw nails (self-tapping screws). A popular type of bonded fastener used in construction work. The base material is steel wire. The main feature of screw nails lies in their appearance: the hardware leg is twisted along its entire length, due to which the fixing part does not fall out of the base of the structure and is securely fixed in it.

- Galvanized nails. They are used for fastening different types of roofing materials to wooden structures.

- Head hardware is a special type of galvanized nails with a length of 2.5 to 3.5 cm and a wide head, used for fastening shingles. The length of the nails allows them to easily penetrate the roof structure through the flooring, and the wide head prevents them from falling through the surface of the working material.

- Drum nails. They are recognizable by their ring knurling and are specially designed for use in air guns. The length of the products is 1.9-4.5 cm, which allows them to easily attach various roofing materials. Sold in rolls. As a rule, one such roll contains 100 pieces. hardware.

Subtleties you need to know for installation

A regular hammer is required to mount a screw nail. No special equipment is required. Also, you do not need to have any special skills and experience. Professional craftsmen give the following tips:

- when connected, a less thick object is attached to a more massive one;

- the diameter of the nail used must be no more than 1/4 of the thickness of the products to be joined;

- the length of the fastener should be two to three times the thickness of the element to be fastened;

- to prevent damage to the wood, the nail must be driven in at a certain distance from the edge of the board;

- it is possible to facilitate the process of hammering by pricking the planned attachment points with an awl.

In conclusion, we note that the choice of screw or conventional nails depends on the expected operating conditions of the structure. It is also influenced by financial wealth.

If you are going to do something capital, designed for a long service, then, if the budget allows, it is better to opt for screw fasteners, as they provide the most durable connection. Otherwise, you can get by with cheaper round nails or self-tapping screws.

What is it and what is it for?

Screw nails are called universal hardware, with the help of which craftsmen fasten wooden surfaces together. And also they find application during the construction of a residential or utility room, any structure. Externally, screw products are very similar to round ones - they also consist of a rod-cylinder, a head and a standard sharp end. And they are distinguished from ordinary nails only by the presence of a thread on the rod.

Practice has shown that screw hardware provides fastening, which is many times better than when using a construction nail. While driving a screw nail into a tree, the product rotates around its own axis. Thanks to this feature, the wood fibers are not damaged and adhere well to the surface.

The main purpose of a screw product is to fasten flexible surfaces and materials, for example, wood, wooden plates, structures that bend under the influence of moisture. This type of hardware has found its application in interior and exterior finishing works, manipulations with the roof, the manufacture of containers, furniture array, as well as in other types of work.

The production of wire screw nails is strictly regulated by the standards of GOST 283-75. This document contains information about the accuracy of the parameters and characteristics of the product that can affect the quality of the product. According to GOST, this hardware is made from low-carbon raw materials with a square section.

Advantages of screw nails:

- strength;

- endurance of heavy loads;

- durability of use.

According to consumer reviews, screw nails have some drawbacks. It:

- the impossibility of dismantling the connection due to the strong adhesion strength;

- susceptibility to corrosion;

- one-time use;

- high price.

Component 1. Equipment for automatic cold heading of nails, high-speed, up to 800 pcs / min

Model RG810

| Performance | 800 pcs / min |

| Nail diameter | 2.50 mm - 4.10 mm |

| Nail length | 50 - 100 mm |

| Equipment dimensions, LxWxH | 1800х2900х1250 mm |

| Equipment weight, kg | 3,100 |

| Power | 10 kW |

| Mains voltage | 3 phase / AC 380V / 50 ~ 60Hz |

Detailed specification of equipment

- Equipment for cold heading nails

- Wire unwinder

- Wire guide mechanism

- Container for collecting nail tips waste

- Electrical control panel

- Spare parts: cutting die x 3 pairs, cutting knife x 2 pairs, upsetting matrix x 2 pcs., Wire feeder x 2 pcs., Wire guide x 3 pcs., Synchronizer belt (AT5-2365) x 1 pair.

| Performance | 700 pcs / min |

| Nail diameter | 1.60 mm - 2.30 mm |

| Nail length | 25 - 64 mm |

| Equipment dimensions, LxWxH | 1000x3000x800 mm |

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

Photo of screw nails

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Wood grouse wood screw

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- Expansion dowel

- What are wood screws

- How to choose a wall mount for your TV

Ondulin nails

Ondulin is a roofing material that combines the characteristics of soft roofing material and hard slate at the same time. According to building codes and regulations, the fastening of the ondulin to the crate should be as strong as possible, but at the same time the wave that is inherent in this product should not be damaged. Hardware for ondulin also have their own characteristics. First of all, they differ from other nails in their appearance, or rather, in the ability to be painted. For this reason, such products can be red, green, there are also brown specimens.

In the process of laying ondulin, both ordinary nails and self-tapping screws with a plastic gasket under the cap can be used. After the hardware is screwed in or driven in, the lid closes tightly, preventing the penetration of liquid under the cap. Craftsmen with extensive experience, in order to facilitate the installation process, snap the covers long before the fastener is fixed in place.

Due to the irregular shape of the gasket under the cap, the fastener is securely and very tightly pressed against the ondulin. As a result, the coating is protected from the negative effects of environmental factors.

Manufacturers often make fasteners for ondulin from alloy steel and make notches on the rod that prevent the nail from falling out of the wooden crate.