How much does a silicate brick weigh?

Silicate brick belongs to the category of artificial building materials for the construction of vertical enclosing structures. The characteristics are excellent, the scope of application is wide, but do not forget that the type of foundation or supporting elements depends on such a parameter as the mass of white brick. Therefore, even for the simplest calculations, you need to know the weight.

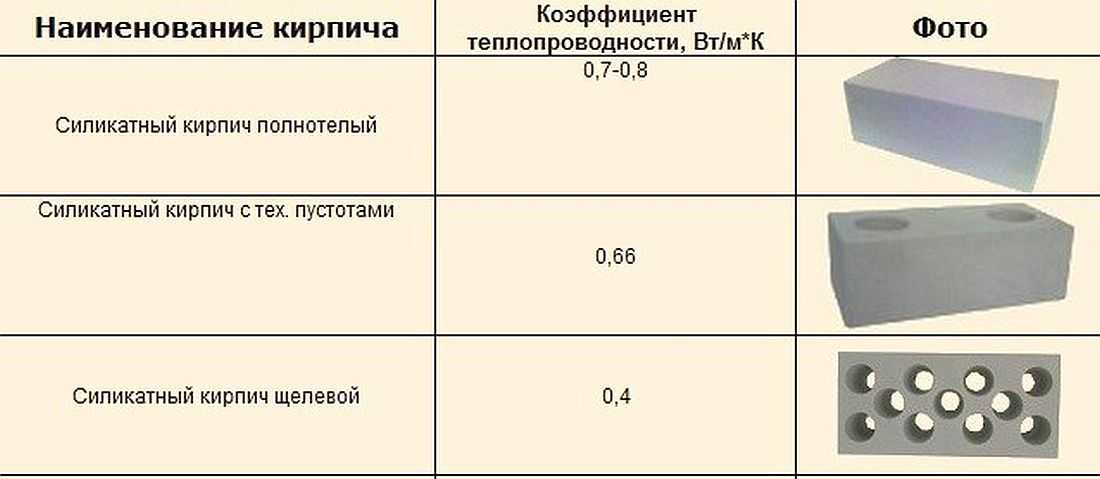

Types and characteristics

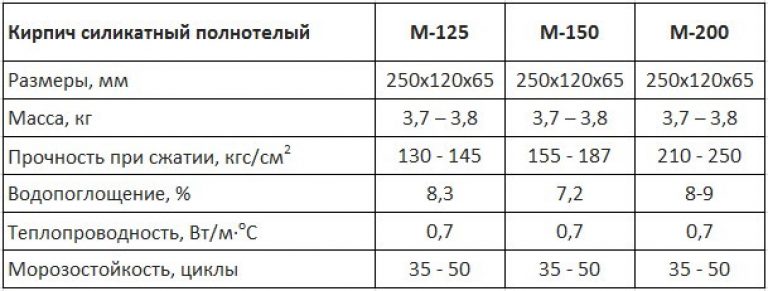

White brick is produced by a non-fired method from a mixture of lime binder, silica filler (quartz sand, fly ash, sludge, etc.) and a small amount of water to moisten the mixture. In production conditions, raw materials are pressed and autoclaved. Due to this, the finished block gains the required parameters:

1. The compressive strength is marked with the M75-M300 brand.

2. Thermal conductivity - up to 0.87 W / m * K.

3. Frost resistance: withstands from 15 to 50 complete freeze-thaw cycles when fully immersed in water.

4. Density: porous or lightweight up to 1500 kg / m³. Products with an index exceeding this indicator are called dense.

5. Water absorption - 6-16%.

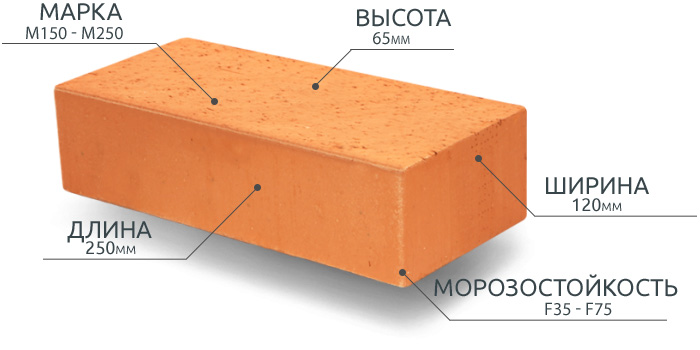

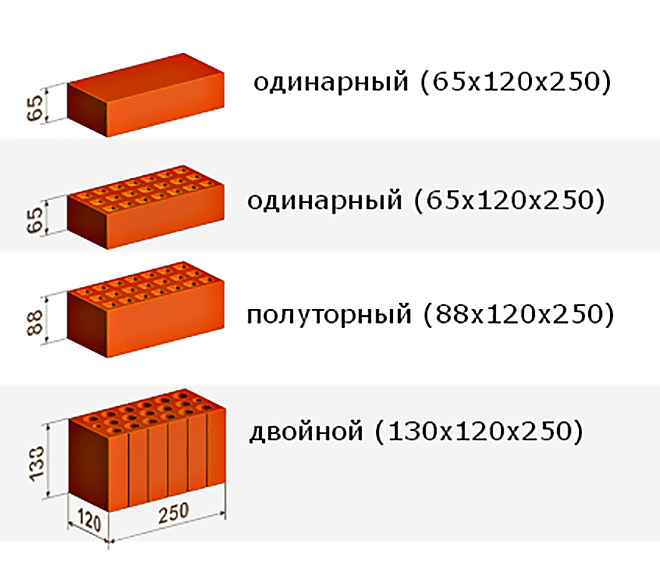

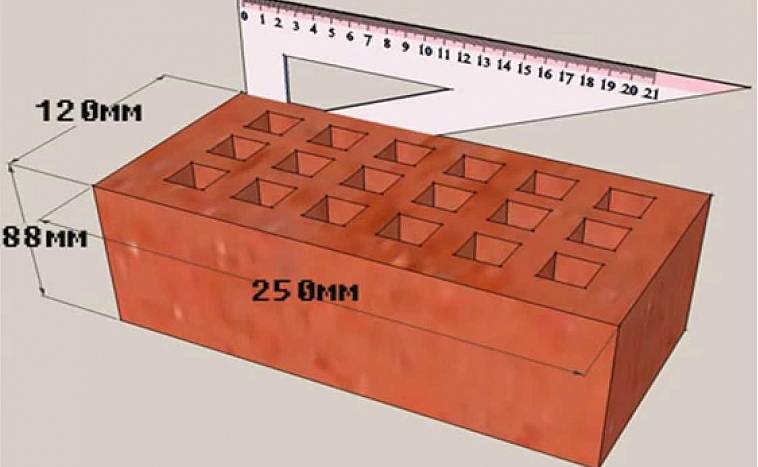

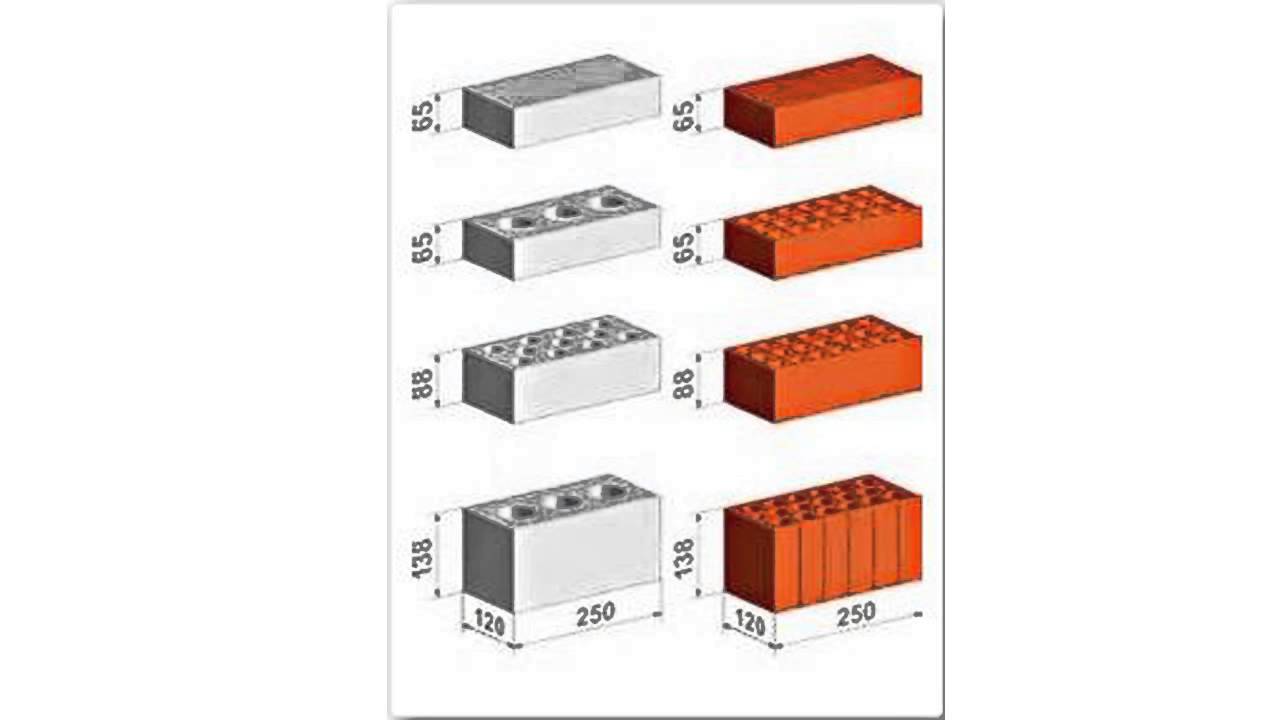

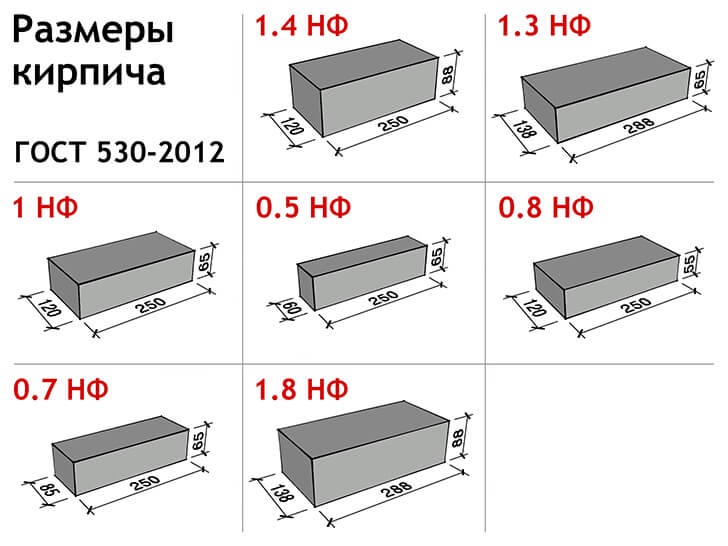

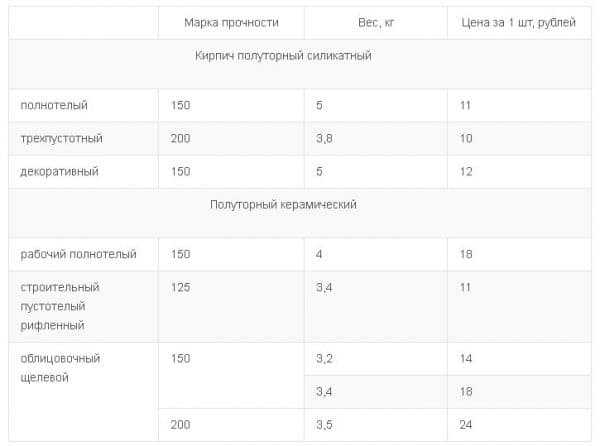

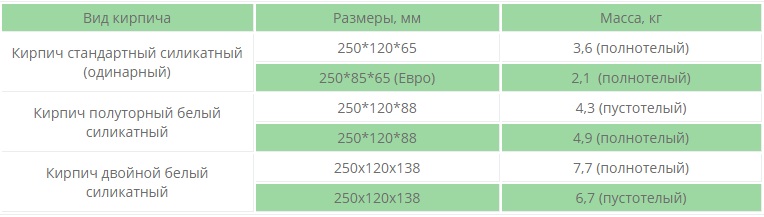

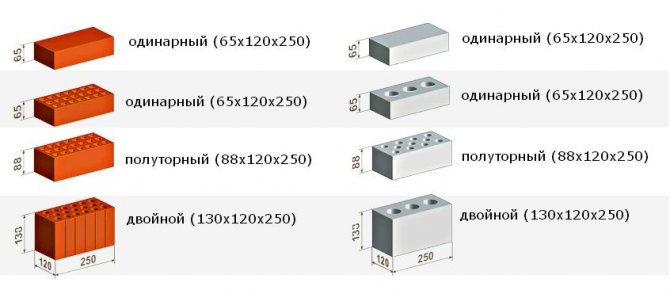

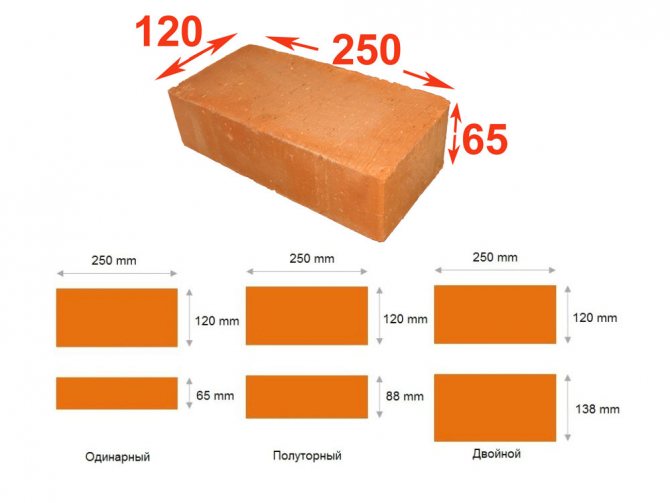

Plants produce a silicate block of the following dimensions:

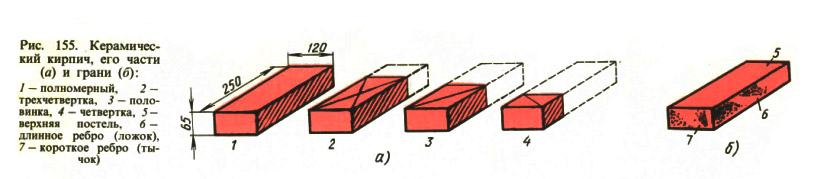

- Single: 250x120x65 mm.

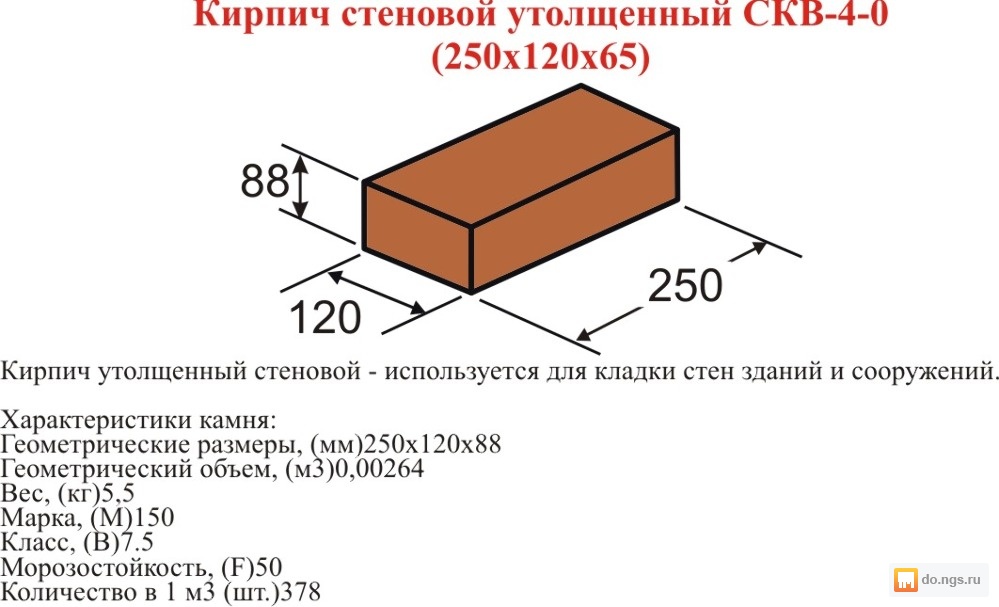

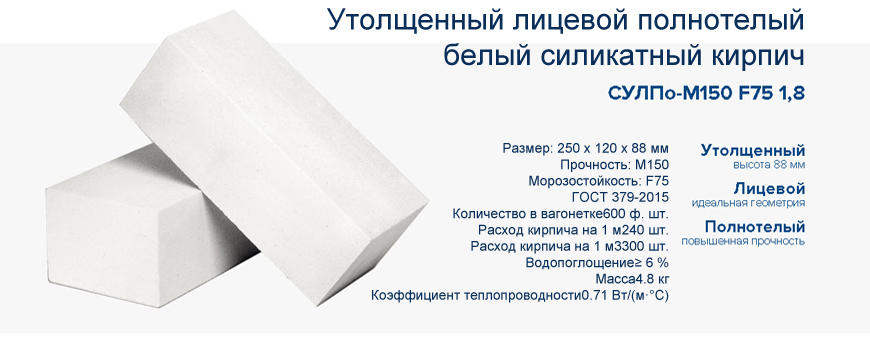

- One and a half or thickened: 250x12x88.

- Double: 250x120x103.

- Embossed: 250x90x65.

By the field of application, a distinction is made between working or ordinary brick and facing. The latter is used for finishing facades, foundations, basements, fences.

The structure for all sizes is typical:

- full-bodied or monolithic product;

- hollow products, with a void content of up to 15% (3-void), 25% (11-void) and 31% (14-void).

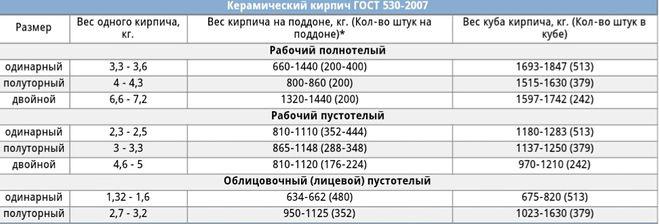

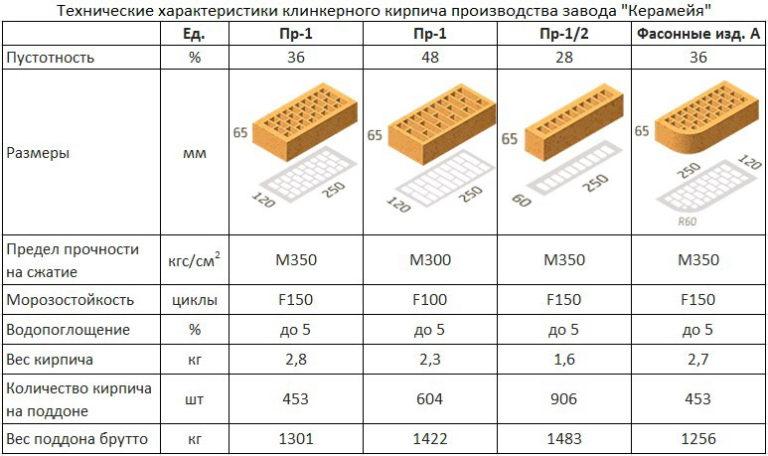

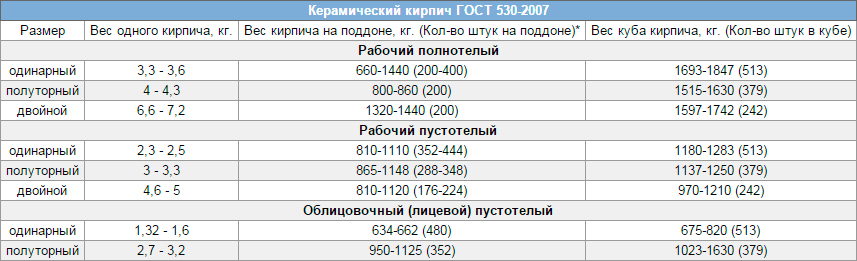

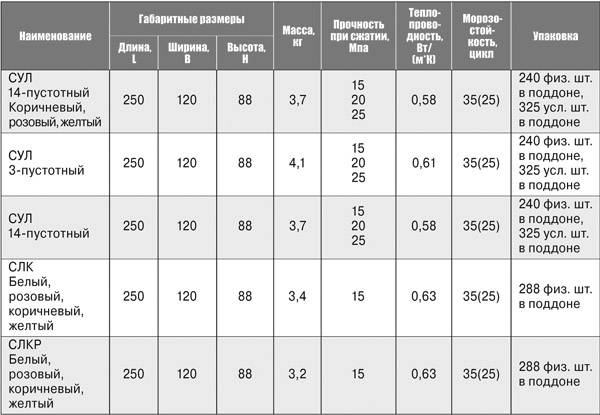

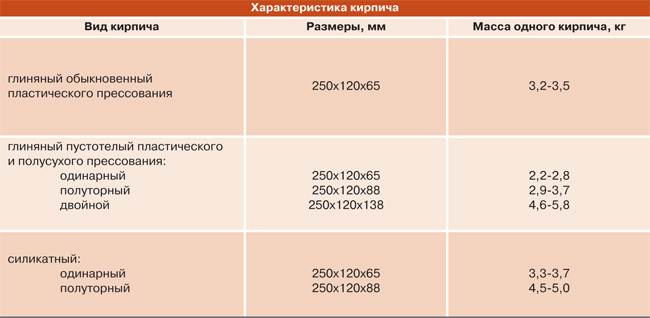

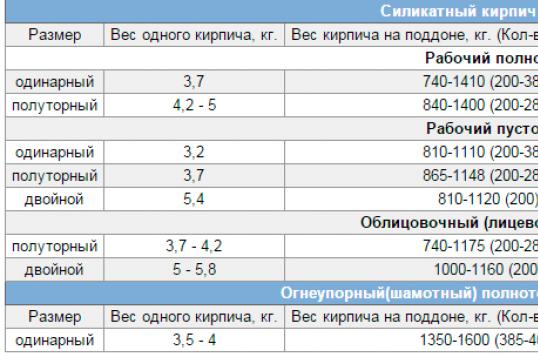

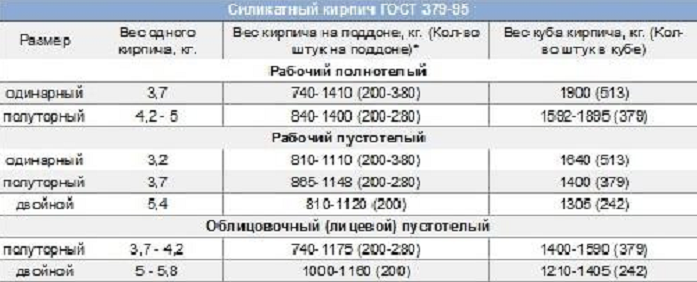

White brick produced in accordance with GOST 379-95 "Bricks and silicate stones" must have a standard weight according to the table below.

The data from the table are corrected for the weight of auxiliary materials. That is, for example, the weight of one one-and-a-half solid silicate brick made according to the basic recipe from lime and sand is 4.2 kg / pc. The total weight of the building material laid on the Euro pallet is 840 kg, but the pallet itself, protective film and fixing straps are added to this. Accordingly, the cargo prepared for transportation will weigh approximately 846 kg.

The weight of a hollow silicate block 250x120x88 is less than a solid analogue precisely due to the cracks, but during the construction process they will be filled with mortar, so the total mass of the masonry will increase significantly. This must also be taken into account when calculating the project plan.

Before buying, you need to carefully inspect the proposed product. The surface must be firm, even, free of chips, chamfered corners, cracks and cavities. If the product crumbles in the hand, slightly crumbles, it means that it was overdried or underdried, therefore it is not suitable for the construction of walls - it will quickly collapse.

White silicate bricks, along with red ceramic bricks, occupy a worthy place in the category of building materials for fencing.

Before starting any type of construction, you need to accurately calculate how much consumable material, including.

With the advent of new building materials, which significantly speed up and reduce the cost of construction of buildings, but do not have.

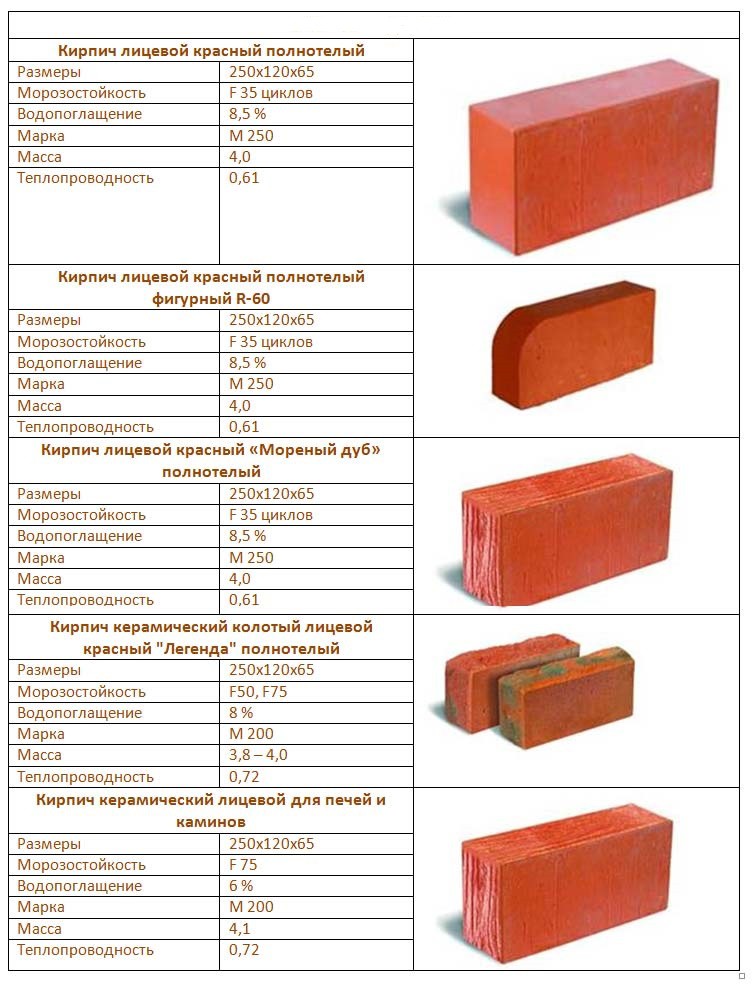

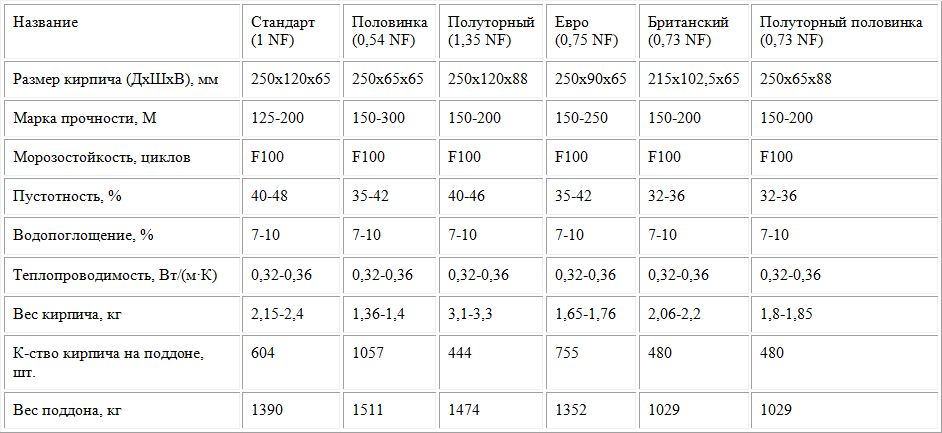

Classification of facing bricks

The gradation of the facade cladding is determined by the technology of its manufacture.

There are four categories of facing bricks:

- Ceramic.

- Clinker.

- Hyper-pressed (concrete).

- Silicate.

Brick in each of the listed categories is available in two versions: solid and hollow. The weight of hollow bricks is on average 25-35% less, and its resistance to heat loss is about 10-15% higher.

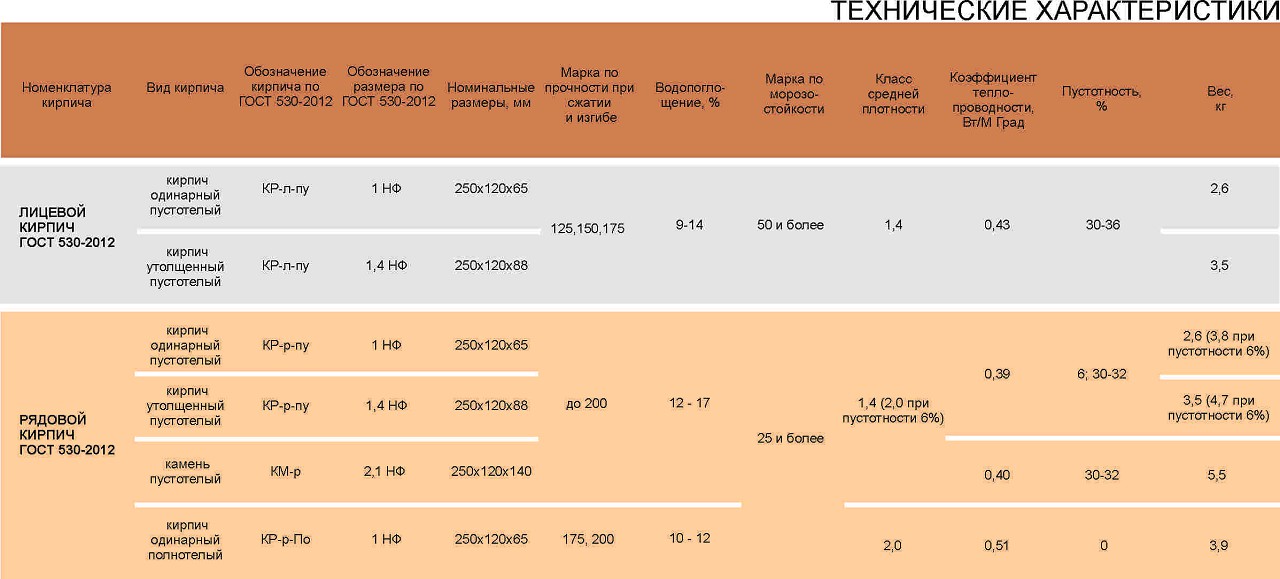

Ceramic facing brick

It is produced by firing a raw mixture consisting of red low-melting clay, organic and mineral additives that regulate plasticity. In this capacity, coal dust, slag, chamotte, sawdust, ash and quartz sand are used. The initial mixture successively goes through the processes of forming, drying and firing.The main difference between facing ceramic bricks and ordinary ones is the thorough preparation of the components before molding. Therefore, there are no foreign inclusions and cracks in it.

The material obtained at the exit from the firing chamber is characterized by resistance to moisture, high strength and good energy-saving qualities. Types and colors of ceramic facing bricks are varied.

On sale you can find not only ordinary, but also shaped material (for laying complex architectural elements). To expand the color gamut, manufacturers use mineral dyes (chromium oxide, finely ground iron or manganese ore), adding them to the composition of the feedstock.

Decorating the surface of ceramic bricks is performed in several ways. In addition to the smooth matte and glossy surface, there are available finishes that give this material a similarity to wild stone.

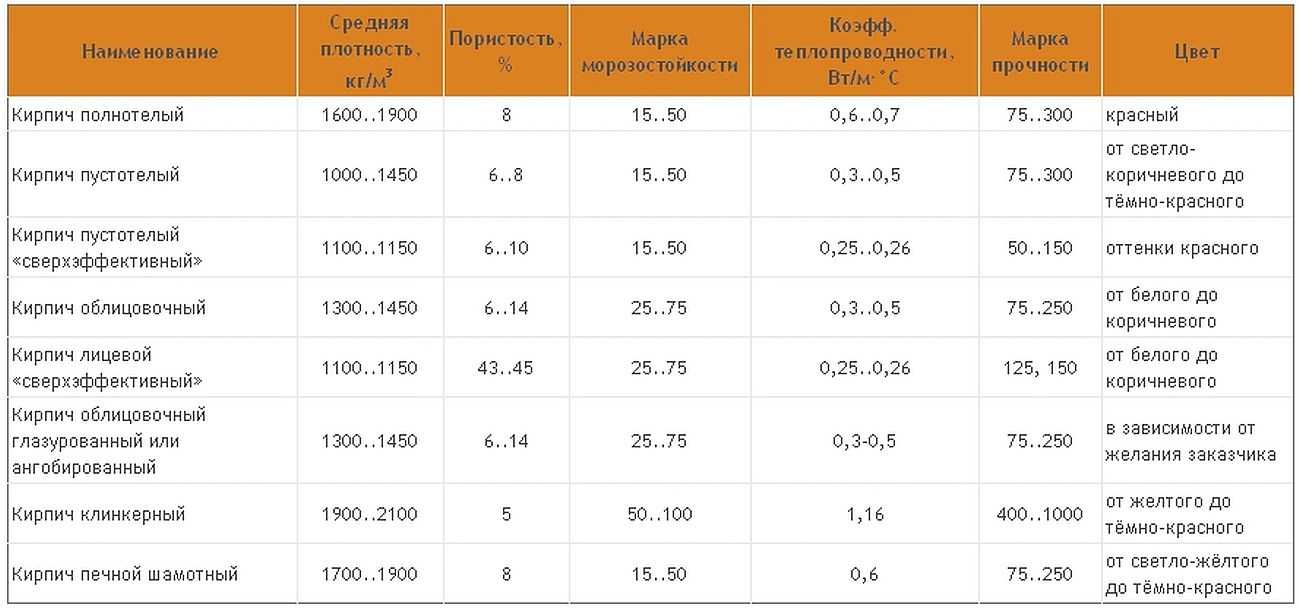

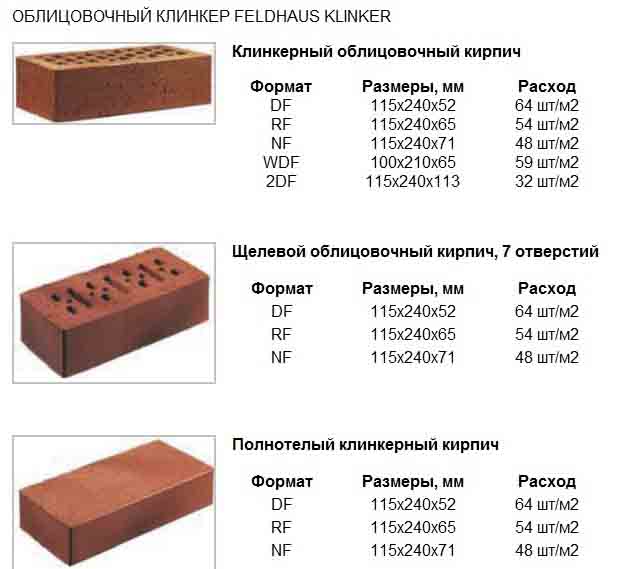

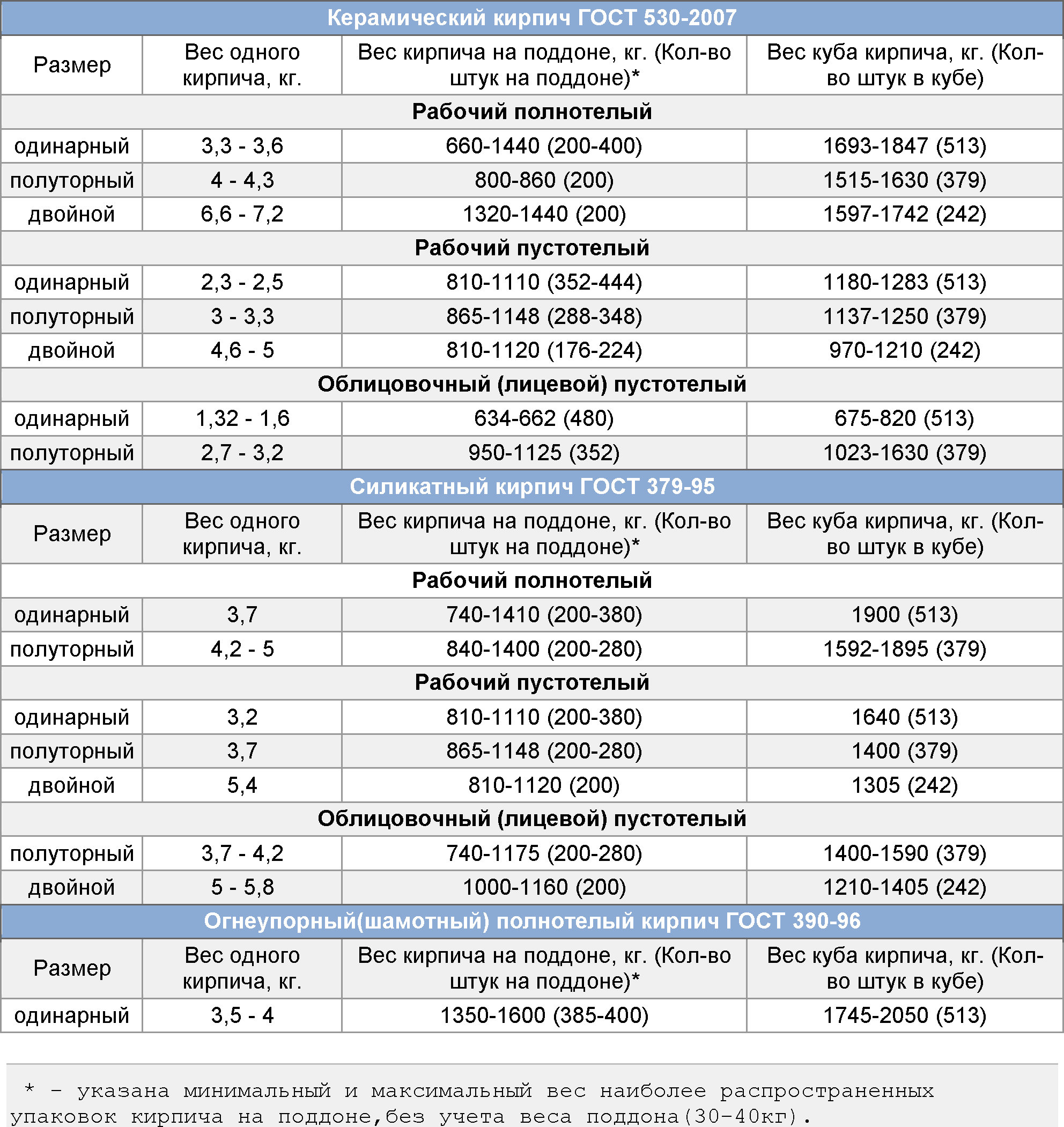

Clinker brick

The closest "relative" of ceramic bricks. The main difference between the two is the feedstock and the firing temperature. For the production of clinker, medium and refractory clays are used. Accordingly, they are fired at a higher temperature. The result is a very dense and durable facing brick with minimal water absorption. These qualities make it possible to use it not only in the decoration of the facade, but also for the cladding of the basement of the foundation, the construction of fences and the paving of paths.

The thermal conductivity of clinker stone is higher than that of ceramic. This disadvantage is compensated for by its high resistance to cracking at low temperatures.

The color palette and texture of clinker stone are extremely diverse, since each manufacturer offers its customers its own collections. The size range of this cladding is also not boring. In addition to the standard single version 250x120x65 mm, you can buy bricks of reduced thickness and height, as well as long clinker (528x108x37 mm).

Hyper pressed brick

Firing clay is an energy-intensive and not very cost-effective process. Therefore, many manufacturers are switching to pressed fired bricks. Its basis is granite screening, water and cement. At its core, it is an ultra-dense concrete that has been shaped into masonry bricks.

The main requirement for facade finishing is weather resistance. According to this indicator, hyper-pressed brick is perfect for finishing external walls.

In terms of strength and other quality characteristics, it is practically not inferior to clinker. Due to the texture of the surface (like a rock, torn stone) and the use of persistent dyes, this material looks great in masonry.

Facade decoration with hyper-pressed bricks looks elegant, solid and reliable

Silicate brick

Belongs to the category of non-firing materials. It differs from hyper-pressed brick in its raw material composition. There is no cement in it. High mechanical strength is achieved here due to the hardening of a mixture of silicate sand and hydrated lime in an autoclave installation (elevated temperature and pressure).

Nowadays, silicate facade brick as a facing material is losing its former popularity. In the struggle for a buyer, manufacturers have developed several color options for the silicate mixture. Unfortunately, they all look rather pale and cannot compete with the rich colors of ceramics and clinker.

In the cladding of the building, this material behaves well. Compared to clinker bricks, it absorbs moisture more strongly, but at the same time better than ceramics withstands repeated soaking, freezing and thawing.

Figured (shaped) brick

Today, no one is satisfied with the straight lines of the facade, therefore, each type of facing brick is complemented by a wide range of shaped elements. Using them, you can lay out complex architectural elements without time-consuming heaving and cutting, dressing up the house in a beautiful "stone lace".

Main types of products

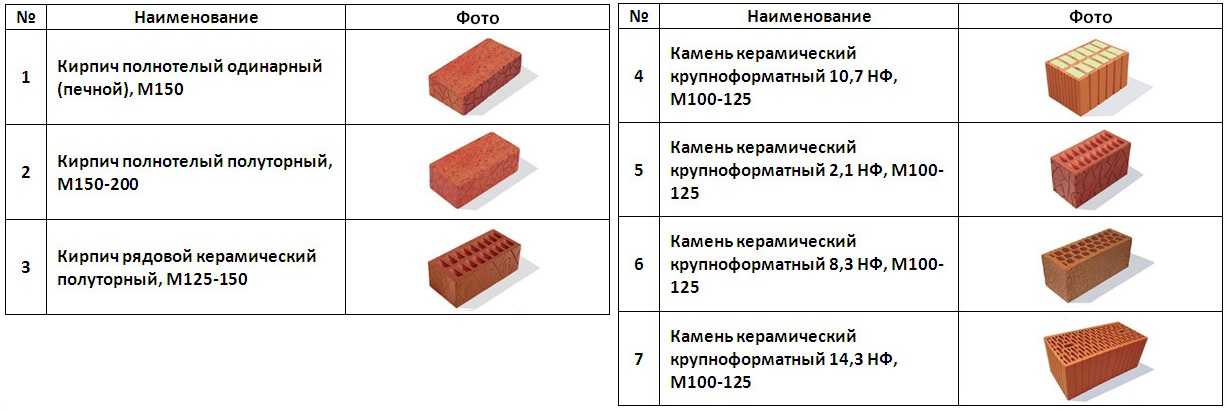

Most of the blocks have unified dimensions - 250x120x65 mm. This is the size of a single brick. By manufacturing methods, the following types of products can be distinguished:

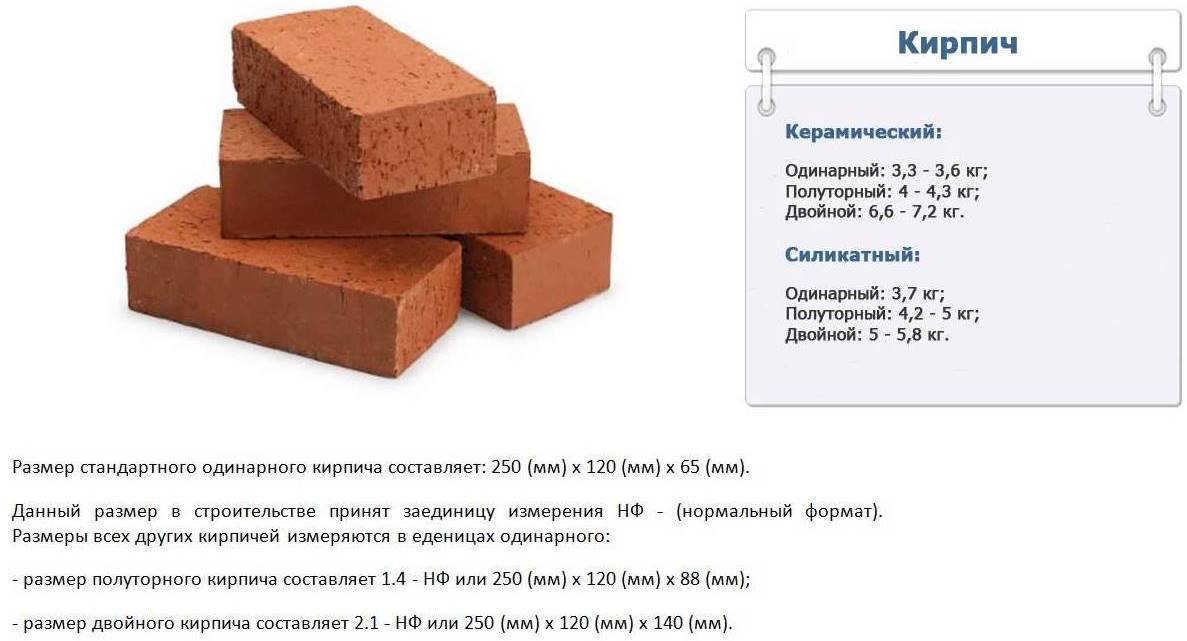

Image 1. The ceramic facing brick has a deep red color.

- ceramic;

- clinker;

- hyper-pressed;

- silicate.

Ceramic building materials are familiar to almost everyone. It is usually red in color. It can be full-bodied and with voids, which make the blocks lighter and increase the thermal properties of the material (image No. 1). In factories, surfaces are given various shapes and colors. The edges can be smooth or matte. Dyes are applied to the entire surface or only to the front sides of the product. To create a mosaic surface, a glazed version is available.

Image 2. Hyper-pressed facing bricks can withstand severe stress.

Clinker brick is a version of the red facing sibling. It has a high degree of strength and wear resistance. It is used for cladding the basement of buildings, for paving sidewalks and paths, for framing door and window openings. Brick is made by firing special types of clay at a high temperature. The product has not only durability, but also high thermal conductivity. There are specimens measuring 528x108x37 mm. The cladding made with this material looks fresh and original.

Hyper-pressed bricks are made by a non-fired method (image No. 2). The mass without sand and clay is pressed under very high pressure. Cement and limestone are used as binders. A coloring pigment is added to add color. Outwardly, the product resembles a stone with its torn chips. The material is well processed, has high frost resistance and ideally correct geometry.

Image 3.4. Silicate and red bricks are also used for cladding buildings.

Silicate brick is used less and less today. Its decorative properties are highly controversial. It used to be widely used for decoration of buildings (image # 3). The size of 250x120x65 mm or 250x120x88 mm continues to be in some demand. Less often they buy a size of 250x120x138 mm.

The classic red brick is in the greatest demand. Although its color can vary from peach to chocolate (image # 4). This material is not afraid of any atmospheric whims. It protects and strengthens the building well. It has excellent heat and sound insulation properties. Its service life is several generations of residents. The brick is environmentally friendly and safe for human health.

Low-rise construction and corpulent pattern

The foundation is the first thing that needs to be built for the house. The most important thing in this stage of construction is that the influence of water must be taken into account. It has a destructive effect on bricks. To keep the foundation for a long time, you can buy an ordinary corpulent private.

Ventilated façade - keep in mind that this will serve as a support. That is, it has an important constructive function. The load from the cladding will be transferred to the frame. Therefore, it is worth choosing corpulent as the material for the frame.

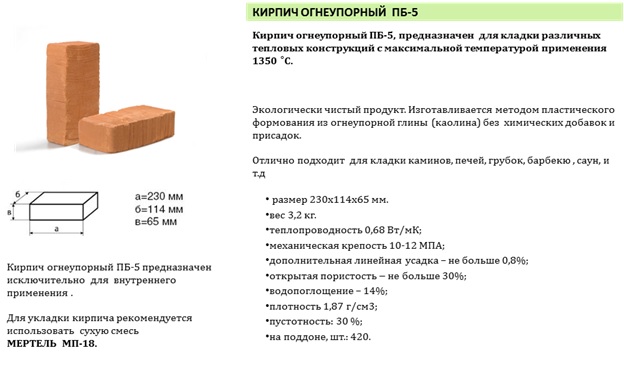

How to use bricks for laying stoves and fireplaces can be found in this article.

The video shows more information about the front red solid brick:

A very important property of a brick is its thermal conductivity. Heats up quickly in the sun, and cools down slowly enough

In this regard, in houses that are made of bricks, approximately one temperature is always maintained, it changes slightly. The wall, which will be located below the level of waterproofing, is built from burnt.

The partitions located in the house are also made of solid bricks. If you use dowels-nails, then you can hang the structures on the walls, they will be fixed well enough. Column and building vaults can be made from the red pattern.Not only is the strength high, but it will also help solve complex architectural decisions.

It is worth noting that even the buildings in which kings and kings lived have survived to this day. This once again emphasizes the strength and reliability of the material.

Many churches and temples have also survived to our times.

Having learned about the areas in which red solid brick can be used, you are convinced of its reliability and availability. It became widespread in the construction world.

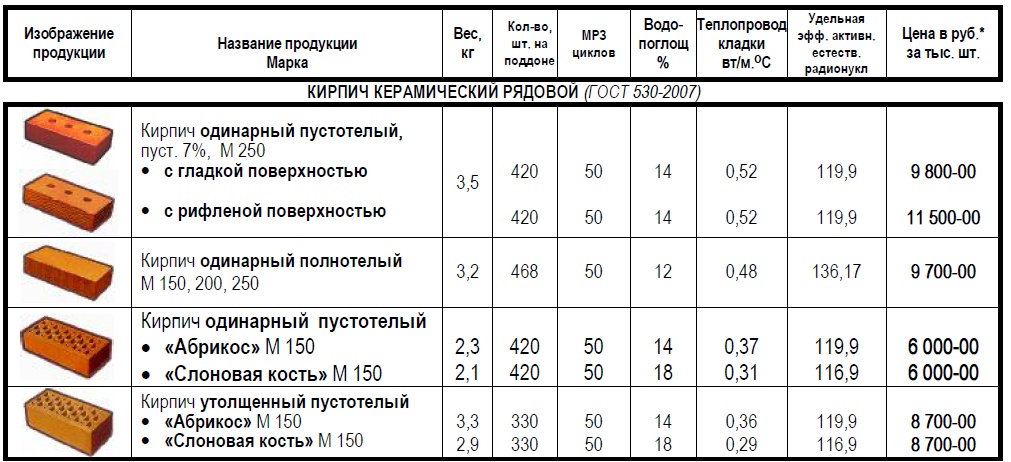

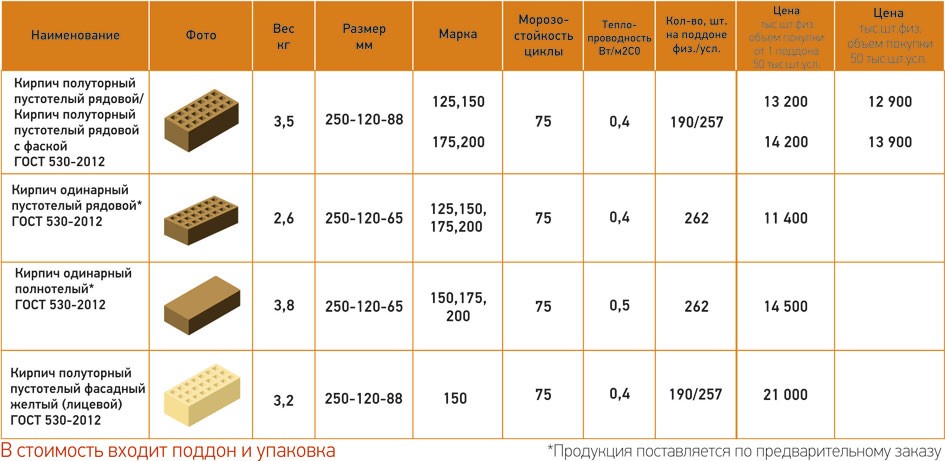

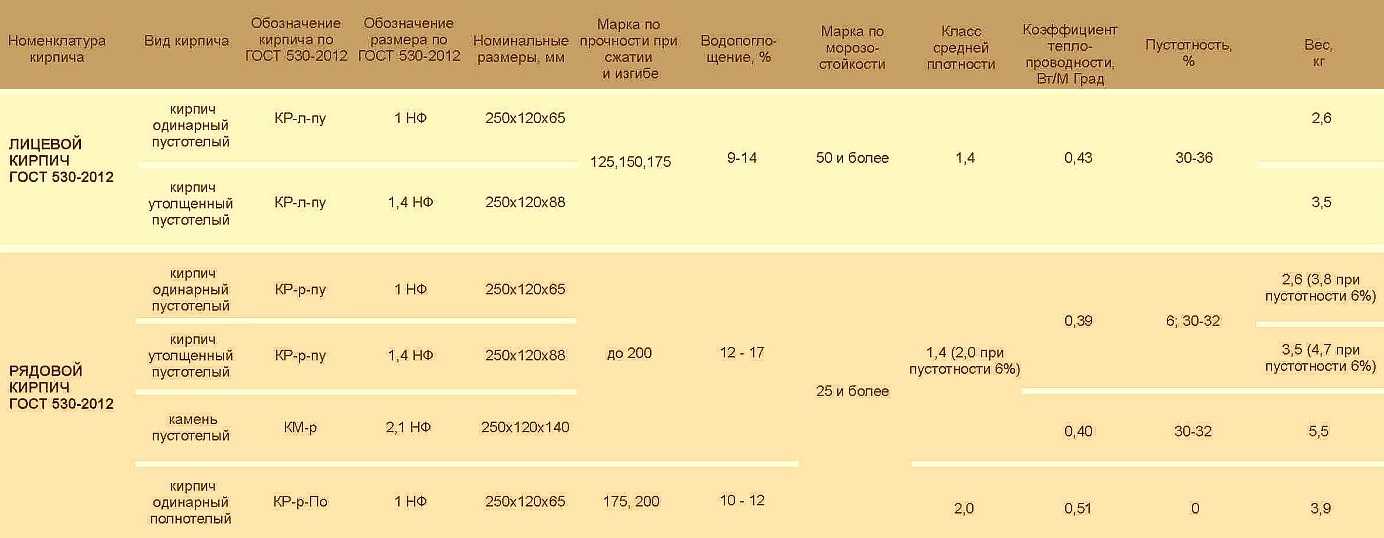

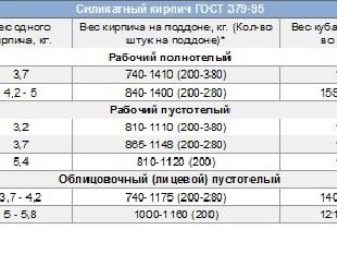

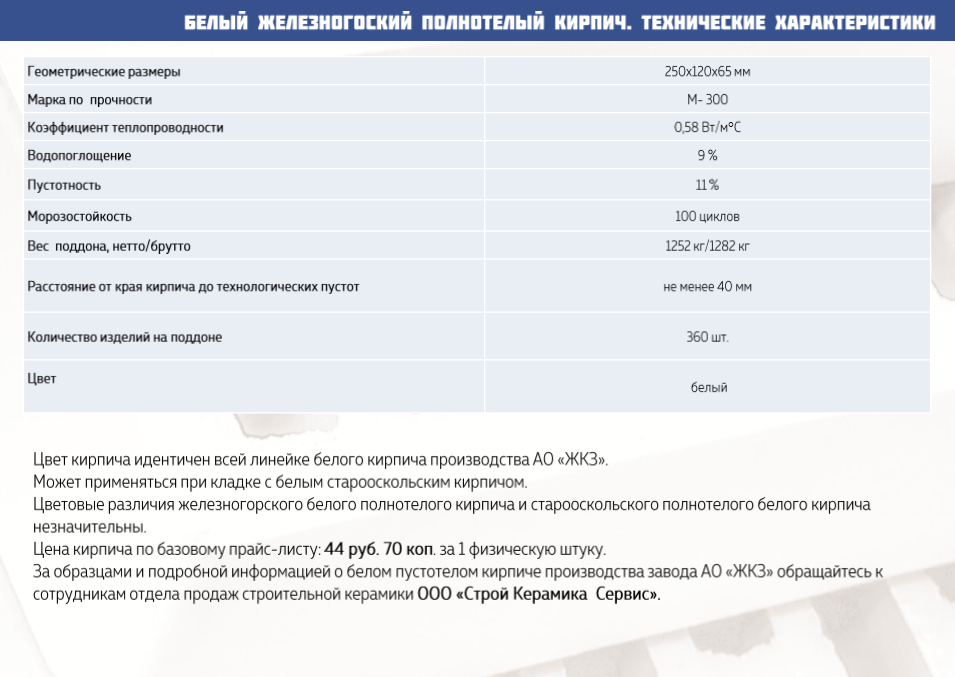

Consider what prices for bricks are offered by different manufacturers:

This form of brick is found according to descriptions in the Old Testament. Red brick was especially expensive. Previously, chopped straw was added to it to increase strength. He occupied a special place in pottery. In the 10th century, a fairly large number of builders arrived from Byzantium, who began to make bricks in Russia. Byzantine builders knew the secrets of brick making.

Until the 19th century, bricks were practically made by hand, that is, they were shaped by hand. And they dried it exclusively in the summer. And only after this stage did they move to a new level of production. Now, experts recommend solid red brick for the construction of their houses. This is a guarantee that the house will be preserved for years to come.

The age of the brick, isn't it time for him to retire?

Of the large assortment of building materials, only wood or stones compete with briquettes. The first records of the use of briquettes can be found in many ancient scriptures in Asia. Archaeologists also found briquettes during excavations in ancient Mesopotamia and China. Egyptian, Greek, Roman and Byzantine builders used this material extensively. So, according to the very minimum estimates, its age exceeds 10 thousand years.

The first attempts to establish a standard size for briquettes date back to ancient times by archaeologists. In Russia, this step was taken by the last Tsar of All Russia and the first Emperor of All Russia. With him, the briquette, the dimensions of which were 280 * 140 * 70 mm, became the most relevant. At that time, the process was controlled by special measures that each master had. This managed to achieve albeit minimal unification.

Some of the brick walls are thousands of years old!

Some of the brick walls are thousands of years old!

During the production of briquettes, a stamp was affixed as a certificate of full compliance with the established standards. This policy drew a flurry of criticism from the craftsmen, because the latter were eager to retail, trying to reduce the established sizes to save materials.

The tendencies for the installation of the specified sizes of briquettes were traced until the beginning of the 20th century, not only in the CIS countries, but also in all European countries. Manufacturers were eager to follow the established norms, because the contradictions not only made it difficult to install the minimum dimensions, but also stood out overweight, which negatively affected the sustainability of buildings. At the same time, European countries began to use briquettes of different sizes, which gave the structures a certain charm and originality. This can explain the diverse range of materials presented below.

Material parameters

The price of a material depends on its size and production. Of course, the more raw materials are spent on it, the higher the price will be. After all, the weight is greater. But sometimes what is more expensive is more profitable. Therefore, when choosing, there can be only one instruction, this is to make the correct calculations.

Attention: when calculating, it is imperative to take into account waste. They will be there anyway

Only unlike clay material, silicate waste can be used in few places.

Silicate brick weight:

Silicate brick

The production of silicate bricks is carried out in autoclaves under high pressure. This is one of the differences from the production of clay material.

- The composition of the brick includes sand, this is in the region of 92-94%. Lime is also used as an additive. Its volume fluctuates around 3-5%.Various additives are also used for the quality of products, which make up about 2%.

- This technology makes it possible to make high-quality and durable material. For example, hollow materials have increased sound insulation and heat insulation. Therefore, they can be perfectly used for the construction of partitions indoors.

- The frost resistance index ranges from 15 to 50 freeze and thaw cycles.

- This material can have almost any color. It all depends on the dye added.

Attention: This material has a significant drawback, it absorbs moisture strongly and therefore cannot be used for the manufacture of the foundation and basement of the room. The weight of the silicate brick depends on several parameters.

In the first place is the composition of the material, in the second place is the manufacturing technology. But the average weight of a brick is around 2.5 kilograms

The weight of a silicate brick depends on several parameters. In the first place is the composition of the material, in the second place is the manufacturing technology. But the average weight of a brick is around 2.5 kilograms.

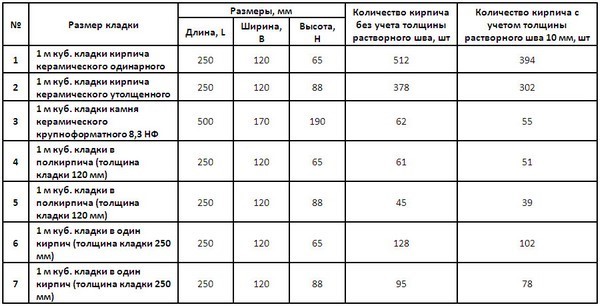

The volumetric weight of a silicate brick directly depends on its dimensions. They are quite different. There is one and a half material, there is also a single one.

Material selection rules

You make the choice yourself. Here you will need to look at the following components:

First of all, decide on the height of the wall. Here you will need to select a brick not only by weight, but also take into account its height. It will be possible to save on this;

Construction requires the use of quality materials. Therefore, do not take damp bricks on pallets. It dries very badly;

The price of color will be more expensive

Pay attention to this when choosing.

Be sure to take into account the weight, because for partitions it is better to take hollow material. True, here you will use up more solution.

But the wall will be lighter.

If you will be laying bearing surfaces, then it is better to use solid material here. It will withstand heavy loads.

When making a choice, you should never rush. There are always calculations before buying. Look at photos and videos, make an analysis. Construction does not tolerate errors. After purchasing the material you don't need, you will spend not just money, but you can make a poor-quality structure.

Silicate brick weight

Improving the surrounding space for humans has always been very important. Therefore, construction is still a thriving industry.

The question is, what material to use during the construction of the building? They are assigned to every builder planning a building.

It is necessary to select material based on the future operation of the facility. The choice of building material depends on the functional orientation of the building. The most popular building material is brick. Its positive qualities and a guarantee of environmental friendliness are not inferior even to wood.

Another main plus, the durability of the building, adds to the popularity of bricks. But in any case, it is necessary to decide which building material to use on the basis of financial security.

There are two main types of bricks: