Steam room sheathing. Peculiarities

Planks and lining (linden or aspen) are well suited for finishing the "insides" of baths and saunas.

What is good lining (aspen) for finishing steam rooms and dressing rooms:

- Does not emit resin, which distinguishes it from coniferous lining;

- Does not burn the body due to low thermal conductivity;

- Very moisture resistant material.

After processing, it is not afraid of any damage by fungus or bacteria, it does not rot.

Some varieties may turn slightly black over time from exposure to moisture.

Features when lining baths and saunas: it is recommended to place the slats horizontally - with a spike towards the top (that is, the lathing bars should stand vertically). This is necessary so that condensation does not accumulate at the joints, and air circulates freely between the frame elements, the outer walls will become less damp. In addition, if there is a deformation of the log house, it will be enough to remove the extra panel or add a new one - with the horizontal arrangement of the lamellas - this will not be difficult.

One of the disadvantages of the vertical arrangement is that if the central board (boards) are damaged, you will have to disassemble the entire wall, and the advantage is the speed and ease of assembly, even alone.

When installing the frame, it is recommended to use stainless steel screws; at high humidity, the metal quickly rots. To lower the ceiling, special galvanized suspensions are used, the crate is attached to them. The crate is treated with an antiseptic before assembly.

You can completely assemble the frames of the walls and ceiling, and then finish everything together with clapboard. Or, first completely make the ceiling, and then move on to the walls.

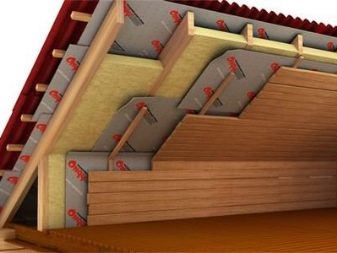

It is better to use mineral wool to insulate the steam room. For the outer layer, it is advised to use a thin foil vapor barrier, it is desirable that the foil is on both sides.

To fix the lamellas, it is imperative to use clamps (special brackets for fastening). It is more difficult and longer to work with them, but their presence will make it very easy to disassemble the wall, if required. It is not recommended to hammer in nails and screw self-tapping screws into the lining. It is advisable to use carnations and self-tapping screws with small caps.

When the lining is not enough in length, it is increased. The lamella is mounted on the crate, it is measured how long an additional piece is required, it is cut off (you can pick it up from other scraps) and attached end-to-end to the already fixed panel.

When you set the wall, you should check the parallelism of the boards of the already assembled side, for self-checking, so as not to redo all the work later.

A gap of 2 cm should be left between the floor and wall panels (as well as between the ceiling and walls). Some craftsmen also install expansion gaps in the corners, covering them with decorative slats or skirting boards.

For vertical installation, start from the corner, for horizontal installation - from the top.

Features of aspen lining

Aspen lining - almost without eyes and knots. No resinous discharge, noble light smooth surface, high strength.

All these properties make it possible to use the lining not only for finishing walls and ceilings, but also for making furniture: benches, tables, cabinets.

According to the structure of the outer edge, the lining (aspen) is:

- With a semicircular edge;

- Flat edge;

- Profile edge (wavy, tapered).

All these types can be used both individually and in combination of different types, for example, in the manufacture of furniture, arrangement of a bath.

The standard of board sizes differs in that there is a lot of waste during cutting and drying of wood, therefore boards longer than 4 m are extremely rare.

Norms:

- in thickness - 12-15 mm;

- in width - 87-88 mm;

- in width with a thorn - 95-96 mm;

- in length - from 1.0 to 3.0 meters (rarely 4 m).

Separately, it should be said about the euro-type aspen lining. Firstly, its cost is quite high. It features high-quality surface treatment and a special type of connecting lock.

The standardization of manufacturing quality in Russia is regulated by GOST 8242-88, and if the country of origin is a European state, then there must be compliance with DIN 68126. According to humidity, quality of planed surfaces, the lining is divided into grades:

- "Extra" is the highest grade. No defects or knots. Smooth white and even surface;

- "A" - there are deviations, a small number of knots, uneven color;

- "B" - knots, the color is not even, there may be defects: scratches, etc.;

- "C" - poor quality of the board, a lot of dry knots, cracks and chips, rotten parts at the end. Used for rough work or finishing of utility rooms.

Euro lining belongs to the "extra" class.

The deeper the lock on the lamellas, the more durable the connection will be. The lock groove must not be less than 8 mm.

If lining (aspen) with some minor defects is used, then with the help of dark varnishes it is possible to hide defects, and with putty - even small cracks.

Aspen lining

Aspen is a tree unjustly forgotten by wood-growers and builders. The density of aspen raw materials is about 490 kg / m3, the resistance to abrasion is practically equal to that of oak wood. In addition, the material has a number of wonderful qualities, for example, lumber is somewhat whiter than many tree species, it lends itself well to processing on a lathe and is quite easy to cut. The aspen raw material is so homogeneous that it allows you to cut and process the workpiece in any direction without fear of chopping and crushing it.

Aspen is a tree unjustly forgotten by wood-growers and builders. The density of aspen raw materials is about 490 kg / m3, the resistance to abrasion is practically equal to that of oak wood. In addition, the material has a number of wonderful qualities, for example, lumber is somewhat whiter than many tree species, it lends itself well to processing on a lathe and is quite easy to cut. The aspen raw material is so homogeneous that it allows you to cut and process the workpiece in any direction without fear of chopping and crushing it.

Apparently, aspen has peculiar substances that kill putrefactive bacteria, since it is known that pickles do not sour in aspen dishes. In the old days, cuttings and handles for implements were made of aspen, which combined lightness and strength. For such a purpose, a young aspen was chopped in the spring, when it was filled with juices, and they were given the opportunity to wither in the shade, while drying out. Then she became strong, like bone and light. Obviously, when withering, not just shrinkage occurs, but some kind of polymerization process under the influence of the components of its juices.

The material is also good because it is perfectly preserved in the aquatic environment, and after drying it does not warp and does not crack, maybe that is why our ancestors knitted well logs from aspen logs. You cannot find a better product for the construction of baths: it is durable, strong, perfectly retains heat, does not burn the skin upon contact, so there is no need to lay rugs on the shelves. With an increased temperature index, aspen raw materials do not have resins, which can not be praised for conifers, and does not rot at high constant humidity.

In regions rich in construction timber, they preferred to cut the bathhouses from aspen, but such an arrangement for the breed, however, was given away where aspen forests with a healthy core and straight trunks grew. The problem of choosing the right aspen tree lies not only in the straight trunk, but also in the defects of the wood, which are unacceptable for the production of lining. If it is possible to make a four-meter rail with a vengeance from a coniferous tree, then you rarely find an aspen tree without defects of more than three meters. Accordingly, the product is cut into short lengths. Many experts argue that if the aspen material after the production process lies for some time without fixing, then the strips will lead, and even at the same time in several planes. After that, the slats will begin to resemble a propeller, so it is better to immediately fix the lumber in its place, this is better for both you and the profiles.

When installing aspen trim, it is recommended to rally the slats as closely as possible, avoiding left, even small, slots on the plane. It is not necessary to make the facing at a high temperature, because after a while the raw material may begin to dry out and form gaps between the plates on the plane.

There is no fundamental difference between aspen lining and an identical product, but from conifers or from linden. The material in question is produced on an identical woodworking device, and a board is produced with a similar profile. The average price category of the finished product ranges from 250 rubles / sq.m and up to 900 rubles / sq.m, the pricing policy depends on the class of purchased plates. In the retail offer, aspen raw materials can be bought not only by measuring square meters, but also by linear meters, for example, the average price of a linear meter of aspen lath is about 35 rubles.

The aspen tree is a rather controversial breed, for example, sorcerers and magicians recommend using it as needed. If you have nightmares, it is advised to put a peg or an aspen board under your pillow at night and everything goes away. It is best, under similar circumstances, to hang an aspen twig over the headboard. The Slavs previously used aspen bark to remove bad energy, and in case of wounds and cuts, they were advised to apply it to the site of injury in order to heal faster. In addition, when using aspen raw materials in bath decoration, you should not combine it with linden, so that the materials do not suppress each other.

Mounting

It is quite simple to sheathe a steam room with your own hands, if you do everything according to the rules and do not deviate from the installation instructions for this particular finishing material. Do not violate the installation technology, since the profile, if installed incorrectly, will quickly become unusable.

Although the aspen profile has a high level of moisture resistance and has a considerable margin of safety, this will not save the panels, in case of poor-quality installation, from the imminent wear of the material. In order to avoid negative consequences, it is required to comply with a number of necessary requirements:

- Mandatory gap between the profile and the wall to ensure ventilation;

- If the wall is subject to moisture or is itself wet, then it is necessary to treat such a wall with a moisture-proof solution;

- Soak the wooden planks of the crate abundantly with a primer to avoid the appearance of decay and bark beetles. Also, the crate should be impregnated with a fire retardant;

- The profile is also treated with protective solutions, after which it must be dried in the yard or on the balcony, and then the panels are brought in the steam room - a day before the start of work. During this time, the lining adapts to the room temperature and, in general, to the atmosphere of the steam room. This condition must be met in order to avoid deformation of the panels after installation due to significant temperature differences.

The lining can be installed in three ways: horizontally, vertically and diagonally. The preparation of the walls will depend on which installation method you choose.

The slats for the lathing are chosen based on the quality of the walls, as a rule, a 40x20 mm cross-section or specialized metal profiles are used. If it makes sense to increase the insulation by adding a layer of insulation, the slats can be thicker. A distance of at least 400-500 mm must be maintained between the guides. The length of the rail should correspond to the height or width of the walls, it depends on the installation method (horizontal or vertical). If the guide is shorter, then the length is increased by an additional bar, the main thing is that the bar is in line with the butt-to-edge rail.

The cladding is fixed to the wooden wall with self-tapping screws, but if you have a brick or stone wall, then you need to use dowels. Additional bars are attached around the window and door openings, to which platbands and wooden panels are mounted.Holes for sockets and other decorative inserts, as well as for various fasteners, are drilled with a drill bit - a crown.

After installing the cladding in your steam room, it is highly recommended to paint the decorative surface areas with wood varnish. Such a procedure will not only significantly improve the appearance of your steam room, but also significantly increase the service life of the material you have chosen.

Some people use paint instead of varnish, but in this case, the unique texture of the wood itself is hidden. It is worth varnishing the panels every year, at least once every three years. In this case, your profile will be in excellent condition for a long time.

The initial and final aspen panel is fixed at a distance of about 5 mm from the ceiling and walls. This is done to increase ventilation between the panels and the wall. After the installation of the initial and final panels, minor flaws may be revealed, including not hidden heads of nails or screws, such flaws are remarkably masked by baseboards or decorative inserts.

Such a sheathing will serve you faithfully for more than a dozen years, aspen reacts remarkably to aggressive influences, and will not crack, especially with proper operation and proper care. Aspen lining for a bath leaves only positive reviews from the masters who dealt with this material, and this material is also widely in demand among the modern consumer.

The undeniable benefits of aspen

This type of wood is deciduous, has a rather high density, about 490 kg per cubic meter. Aspen is a worthy competitor to conifers, has unique characteristics, and, of course, a reasonable price is an indisputable advantage. Thanks to all these qualities and many others, lining made of such material is in demand among consumers and is the favorite material of craftsmen.

Aspen has unique advantages, first of all, it is the smell, the aroma of this wood species fills the bathhouse with a fresh-bitter spirit of health. Well, and secondly, but not least - high sensitivity to air humidity - such a material remarkably absorbs moisture, which creates in the steam room the effect of moisture formation not only from the surface of the stove, which has been doused with liquid, but also from the entire wall area in general.

Of course, quality should be the top priority when choosing a cladding material. It is much better to purchase high-quality lining made of inexpensive wood than to buy more expensive linden, but of lower quality. Poor quality and insufficiently dried material will lead to the fact that in a couple of years some elements of the cladding will have to be changed, well, all panels will have to be replaced.

MAIN PROPERTIES OF WOOD

Aspen is a deciduous tree species with a density of approximately 490 kg / m3. It easily replaces coniferous trees - it has excellent characteristics and low cost, due to which it has gained high popularity when choosing a finishing material.

The structure of the tree is inexpressive, weak and does not have a pronounced and bright odor. The wood is soft, homogeneous and in terms of strength is very close to the properties of linden.

Aspen dries out moderately, cracks a little, lends itself to bending and various types of processing, splits well and is fairly easy to polish and paint.

Due to the low thermal conductivity of aspen, you will not burn yourself against the wall, even if there is a very high temperature in the steam room.

The wood is light, has a pleasant white color, and the fiber structure is fine. And, most importantly, it is quite heat and moisture resistant.

Aspen has few knots, so it is easy to process, moreover, it does not crack and retains its aesthetic appearance for a long time.

Correctly processed aspen products become very durable and resistant to decay.The only drawback of the tree is the rottenness of the core, which appears at a fairly mature age, therefore, 35-40-year-old trunks are usually used.

Direction

When buying an aspen, and it does not matter, from a photo from an electronic catalog or in a shopping center, in the market, it is very important to understand for what purposes the wood and already have an idea whether it can be used for them. To do this, let's look at the features of the application

Application area

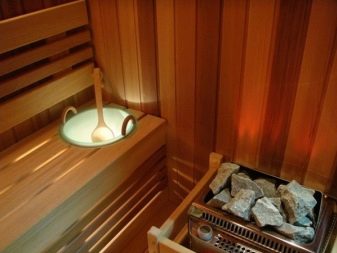

We decided that aspen is a completely versatile material that can look amazing in baths, saunas and simple living rooms. Everything largely depends on the desire of the one who is going to decorate the room.

For a bath or sauna, aspen is ideal. It is delightful and beautiful, the tree keeps its shape perfectly, will not get damp, will not dry out

This is very important in the organization of saunas, steam rooms, baths. Therefore, aspen can be safely entrusted with a room with special conditions, such as, for example, high-grade humidity - 100%, as well as temperature drops, which can sometimes be from 60 to 0 degrees, for example, in winter, when the bath was not heated

Surface finishing

Varnishing will help extend the life of wood surfaces and change their appearance at the discretion of the owner. Regular paints are not recommended, they will cover the texture of the wood. Before varnishing, you need to treat the surfaces with a fine sandpaper, and then remove the dust.

Varnishes are applied to the surface with a roller or a soft brush in several layers. The coating should be renewed every few years, this will prolong the life of aspen lining panels. In the steam room, you do not need to apply synthetic varnish, when heated and temperature changes, it will most likely fall off, in addition, the fresh smell of wood is very pleasantly felt in the bath.

One of the old ways to protect the walls in a bath is to impregnate with vegetable oil in two layers. Now there are special impregnations of European and Russian firms. You need to focus on the purpose of the composition: for baths or saunas.

Euro lining and the stages of its manufacture

Euro-lining is a cladding panel used for facing surfaces, or rather lumber with a moisture content of 10-12%, which has an identical profile, groove and tongue for joining the molded product in the plane.

Euro-lining is a cladding panel used for facing surfaces, or rather lumber with a moisture content of 10-12%, which has an identical profile, groove and tongue for joining the molded product in the plane.

The product in question is a classic lining board, only produced according to European quality standards, but not in Europe, as many think. Treated strips have a slightly different profile, dimensions and are made from a different (higher) type of wood, which makes it look more attractive. The main feature of Euro-plates is the presence of longitudinal ventilation recesses for the purpose of protection against condensing moisture. The profile has connecting grooves that are slightly deep in depth, which serves as an auxiliary way to prevent the appearance of gaps.

The product is made according to Euro standards from edged boards, which can be dried in special dryers. The drying process continues until the elimination of deformation moments during further processing stages. Next, the front surface is cut off with chamfering. On the reverse side, the material is sampled, designed for air circulation after mounting the strip on a blank surface, this protects the raw material from decay.

After completely passing through the production stages, the plates are sorted by quality, and they receive a category or grade, who is used to calling it. The strips are packed in polyethylene shrink wrap so that the product retains the proper moisture content and appearance after transportation.

It is impossible to check the percentage of moisture, but if you examine the sealed material to identify drops of moisture (condensation) on the inner surface, then when the film is dry, the moisture content of the boards is about 10-15%.

Plates, produced according to European standards, can be packed either in two strips, or in five and ten strips, depending on the packer and manufacturer. The length of the strip in the package can be from 0.5 m to 6 meters. The width of the plate is about 80-120 mm, while there is more than one concept of width. It is worth distinguishing between working and full width. The first may be 0.5-1.2 cm smaller. The thickness of the finished product ranges from 10 millimeters to 25 mm.

Wood species used in the production of Euro lining

Euro lining is made of many types of wood, the quality and texture of which depends on the wood, climate and its age, growing conditions, soil composition.

Raw materials of conifers (pine, larch and cedar), from which the facing slats are made, are used in the decoration of any rooms, except for areas where there is a high level of moisture, such as a steam room, a sauna. For outdoor decoration and for "wet" rooms, beech, oak, linden, ash, alder and other red species are suitable.

Most often they prefer linden lining. The mentioned tree not only possesses an elegant texture of raw materials, but also ease of installation, and not great weight. Linden molded panels are extremely durable, do not react to fluctuating temperatures and high humidity coefficient.

Most of all, the market is saturated with Euro lining made of pine, which is oversaturated with resin and therefore appreciated for its resistance to manifestations of an aggressive atmosphere. Pine panel is easy to process, has a moderate density and properties that absorb sound waves and thermostabilize temperature changes.

Larch stripes are good in rooms where humidity is high, not only because of the absence of large quantities of emitted resins, but also because they did not acquire a blue tint, which is inherent in pine and spruce.

The panels produced from have a pleasant pinkish-brown color and structure, with an inherent odor. The raw materials are valued for their durability, and besides, they do not give in to decay. Inhomogeneity of color and pattern gives a unique appearance to the surface. Phytoncides present in cedar raw materials kill pathogenic bacteria in the lined room and disinfect the air as a whole.

The properties of black alder, from which cladding panels are also made, are amazing. It has the ability to absorb excess moisture, and in dry air, give it back to the environment.

When facing with clapboard made according to European standards, external surfaces, additional processing of raw materials by impregnation or painting is required. When using slats for interior work, such processing and a protective coating are not necessary.

Installation rules

In the process of finishing saunas and baths, the lining is placed either horizontally or vertically. In the second case, inexpensive shortened boards are often used, the joints of which are hidden under shelves or a decorative element. You can also save money by using material of a lower grade in inconspicuous places than that used in areas that are conspicuous.

The first step in finishing is to create a heat-insulating layer on the ceiling and walls - for this purpose, basalt wool with a layer of 50-100 mm is used. By varying the thickness of the thermal protection, you can change the thermal properties of the room as a whole. It is necessary to put cotton wool in the intervals of a bar, the cross-section of which is 50x50 or 100x50 mm, a foil is placed above it to reflect heat, and the joints are treated with self-adhesive tape.

Then work begins with a frame of well-planed slats, placed on gaskets 10-20 mm thick. It is most convenient to put the lining on the clamps, fixed with nails or screws. After completing the preparatory work, in the corners and at the intersection of walls and ceilings, they put internal corners and fillets. If necessary, cover strips and external corners are used.

The technology allows you to mount lining panels from any angle, but professionals believe that it is best to start from the left slopes. For the decoration of large rooms, it is advisable to take a spliced lining, which, in terms of technical parameters, does not differ from the usual one, but is noticeably wider than it. There is no need to paint the aspen blocks. Natural varnishes help to give an elegant appearance to these structures, which additionally protect the material from moisture and steam.

In wooden buildings, the cladding must be mounted directly to the ceiling or walls. It is possible to cover the internal volume of brick structures only with a slatted crate, the same applies to cases when a hidden vapor barrier, waterproofing, thermal insulation is being prepared. Vertical and diagonal fastening is better than horizontal, because the water then drains faster and does not stagnate in the grooves.

The use of aspen lining does not negate the obligation to impregnate facing parts and sheathing structures with antiseptic compounds and hydrophobic preparations. This must be done not only before installation, but also after its completion, as well as during the subsequent time - at least once every 6 months. It is advisable to use special gels or liquids that do not give off extraneous odors at significant temperatures and increased humidity.

The cost of aspen is determined by its grade and length, and when calculating the need for material, it is necessary to take into account that the area given on the packages will exceed the actually useful cover by 9%. That is, to decorate a wall of 5 square meters. m, you need to use a material designed for 5.5 m2. The rest of the volume will be wasted when cutting, as well as due to possible defects in the lining.

Do-it-yourself installation of aspen lining is relatively easy, but if you turn to professionals for help, the work will be done faster and better. Compared to this benefit, the increased cost will not be that great.

Before installing the euro lining, you need to store it strictly in its original packaging in a dry and clean room. In this case, it is necessary to prevent sudden changes in temperature and contact with sunlight. The preliminary "habituation" of the material to the environment is achieved by exposure for 48 hours without packaging. It is necessary to remove dust particles and dirt from the lining using a completely dry cloth, only occasionally a damp cloth can be used. Before starting work, you need to make sure that the air in the room is not colder than +5 degrees, and its humidity is maximum 60%.

For aspen lining, see the next video.