Do-it-yourself brushed lining

If you wish, you can brush the finished board at home. This will reduce the cost of purchasing aged material, which always has a higher price in hardware stores.

Mechanical brushing

For work, you should choose boards with the desired pattern. The easiest way will be to brush spruce or pine lining, and cedar and larch, due to their high density, are quite difficult for manual processing. You also need to purchase a brush with metal hairs that can remove soft fibers and leave deep enough grooves. With a large amount of work, it is better to buy a sander with an appropriate brush attachment or a drill with a special abrasive ball.

You will also need:

- sandpaper;

- impregnation for wood protection;

- paint brush;

- rag.

After sweeping the dust from the lining, you need to lay the boards on a workbench or a regular table and fix them so that they are motionless. The lamellas are treated with a brush, evenly pressing on them and making grooves with a depth of 2-3 mm. The ends are worked out more carefully.

To obtain wide and deep stripes, a grinder with a stone disc is used. Then the sawdust is brushed off again and the wood is sanded with sandpaper to level and remove small fibers. Next, they are sanded with a nylon brush, and manual processing gives a more effective result.

At the end of the work, the lining is covered with a glazing impregnation, which gives decorative effect and protects the material from the influence of negative factors. To make the texture bright and attractive, you need to apply a transparent moisture-resistant varnish or wax-based stain to the material. If you want to provide a more interesting shade, oil for impregnation with the color dissolved in it is applied to the lining.

Technique with fire

Firing wood is considered a less time-consuming method of aging. It is a kind of brushing and involves the use of a gas torch or blowtorch. The disadvantages of the technique are the danger of implementation and the scarcity of the finished lining in terms of color.

The first method of brushing

From materials and devices you will need:

- board;

- wax;

- rags;

- fine grain sandpaper;

- gas-burner;

- gas cylinder.

Work is carried out outdoors or in a spacious utility room. The flame of the burner is led along the fibers, creating the pattern that is required. After that, the boards are polished, covered with a layer of wax and polished with a rag.

The second method of brushing

This technology will require a sander with a brush attachment for brushing, as well as a blowtorch. Fire burns wood to a depth of 1-2 mm, so that the surface becomes almost black. Then they remove the top layer with a machine, achieving the desired pattern of lines, grind the base with sandpaper and tint, varnish.

Oil lining processing technique

Oil is coated on a brushed board to enhance the contrast of the pattern. Choose special protective synthetic oils for outdoor use. The procedure will be as follows:

- open a can of oil, mix the liquid well with a narrow spatula (shaking is excluded, since many bubbles will appear in the oil);

- make dry strokes on wood, taking a minimum amount of oil on the brush;

- rub the liquid over the surface, achieving complete absorption;

- dry the lining for 5 hours;

- sand the material with sandpaper No. 150;

- dedust the base with a clean paint brush;

- cover the lining with a protective compound.

Technique for obtaining the "old paint" effect

To perform this technique, you need to buy black oil of the Lobasol brand, as well as any colored oil (you can use OSMO 2708). You will also need:

- paint brush;

- rags;

- rubber spatula.

Black oil is applied to the lining with a spatula in a thick layer, after 15 minutes, the excess is removed with a lint-free cloth. The base is polished with a similar rag. A day later, the colored oil is applied in a second layer. After 10 minutes, apply pressure on the wood with a rubber spatula, removing unabsorbed residues. In another day, the lining will be ready for applying a protective biocomposition.

General idea

The specific domestic name for timber planks has been preserved since the times when they were used for covering freight cars. For a long time, freight rail transport has been designed differently, and the name is firmly rooted in the spoken language.

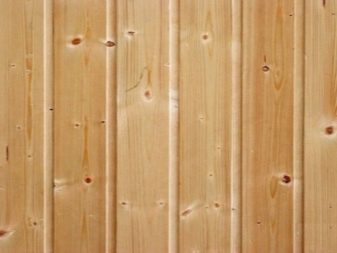

Now clapboard is called planks with grooves and spike-like protrusions, which allow you to make cladding quickly and efficiently. In Europe, there is no such term, the product is classified as a profiled board and is produced according to the relevant standards, which contain more stringent requirements than domestic GOST standards.

The lining made according to European standards has noticeable advantages:

- a varied pattern that allows you to choose products for any interior;

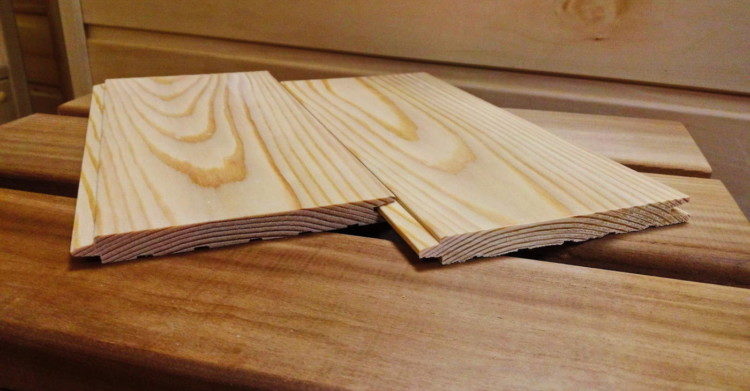

- wide, easy-to-connect spikes;

- a good ratio of the thickness and other dimensions of the strips;

- perfectly sanded surface;

- moisture indicators (no more than 15%), ensuring long-term preservation.

Products are classified depending on the quality of wood, the way it is processed, and consumer characteristics. The lining for exterior decoration of outbuildings, residential buildings is exposed to a high load of atmospheric factors, therefore it is additionally processed - primed, painted, varnish or other protective coating is applied. In this regard, the requirements for its appearance are less stringent than for the type of lining for interior decoration.

Scope of application

It is possible to use lining for interior cladding of buildings in different ways. For example, it is an excellent material for decorating the floors of baths and saunas. In this case, it is possible to cover both the walls and the ceiling of the structure with it. However, 1 nuance is important here: the types of lining for operation in high temperatures differ. Therefore, for the walls, you can use some rocks of the massif, for the ceiling - others.

This is due to the different ability of wood to release resin when heated, as well as different degrees of heating of the material itself. According to safety rules, it should not cause skin burns upon contact. It is laid one on top of the other more often horizontally, which is associated with imitation of a bar.

The lining is used to cover rooms inside a private house or apartment. It can decorate the walls or ceiling of a summer residence, it looks harmoniously in the decoration of the attic, attic space. In addition, it can be used to decorate the walls of a closed veranda, a gazebo and even a bay window; it is also used for the floor. If desired and creative approach to design, it can decorate the interior of a glazed balcony or loggia.

The material is so attractive that it is also used to decorate offices. In addition, it can be seen in the design of studios and some salons. It looks harmoniously in the interior of the cafe

However, it is important to take into account the fact that for aesthetic appeal, the amount of the profile, as well as its shape, must be dosed. If there are a lot of lining, it can create not only boring, but even depressing atmosphere.

This is an excellent material for partitions, with which you can zone the space of the room inside, thereby giving each part of the room its own functionality. At the same time, you can create a partition using a product on a double-sided basis. If you need slats for a closed gazebo, you can use coniferous boards.Spruce lining is better than other varieties to maintain heat.

The cedar profile is remarkable not only for its high quality and performance characteristics, but also for its pleasant shade. For interior decoration of private houses, it is better to use hardwood products, since their structure is more resistant to rodents and insects. Some varieties can be used for furniture elements in tune with the general idea of stylistics. For example, slats can form the basis of benches and gazebo seats.

Phenol

Phenol is a very simple aroma. In its pure form, it looks like crystals with a faint smell of gouache - or, to be precise, this gouache smells like phenol. Smoked products also smell like phenol and its derivatives, since smoking actually represents the saturation of the product with aromatic hydrocarbons. It is they who give the products a characteristic smell and they also have a detrimental effect on microorganisms. Unfortunately, not only on them.

Phenol is poisonous. When it comes into contact with the mucous membrane, it causes severe irritation, and when inhaled, it disrupts the work of nerve cells. In addition, it easily reacts with various substances that are present in our body. The resulting aromatic compounds can accumulate and cause various disturbances. There is evidence that at least some of them are carcinogenic, although there is no evidence that phenol itself is carcinogenic to humans.

The good news is that there is no phenol in today's chipboard. It is manufactured using urea-formaldehyde resins, which, in principle, do not contain phenolic compounds. Phenol-formaldehyde resins are used today only for the production of FSF plywood and film faced plywood based on FSF, but plywood of these grades is prohibited to be used indoors.

Which is better

The lining for interior decoration is presented in the construction market with a huge assortment, so each of its types differs not only in a unique design, but also in technical characteristics. To make the right choice and determine which of the materials is the best, you need to take into account many nuances.

Currently, manufacturers produce wall paneling from both deciduous and coniferous wood species. Pine and other coniferous planks contain a lot of essential oils and resins, which protect it from mold and mildew. In addition, such lining serves for a long time, is easily processed and has an unusual texture. Also, products made from coniferous trees have high thermal insulation and fill the space with a pleasant smell. Therefore, if you need to beautifully decorate the interior inside a house or apartment, then you cannot choose the best option.

If you plan to finish the sauna or bath, then you can give preference to the lining made of hardwood, you can also sheathe the toilet. After special processing, such a board does not emit resins, withstands high temperatures and is not afraid of moisture. Oak board is in great demand among craftsmen: although it is expensive, the price is justified by the quality. In a private house, such material is perfect for decorating slopes and the second attic floor.

For cladding the walls of a country house or summer cottage, you can also use birch or linden lining. A pleasant shade of these types of wood will not only make it possible to embody an interesting design of the room, but also create a special atmosphere of home warmth and comfort in the room. The decorative wall decoration with clapboard looks beautiful in the hallway, bedroom, bathroom, it is also suitable for the corridor, and the doors decorated in this way will become a real decoration.

Selection Tips

Before choosing a product, first of all, you should decide on the lining material. Wooden lining has long established itself on the market as an affordable and reliable material for interior decoration.Of the positive qualities of wood, it should be noted good sound and heat insulation, as well as the convenience of working with the product itself. Wooden lining has a wide range of applications: it is used for sheathing both baths and living rooms, both inside and outside.

Lining made of wood can be made from different types of wood, respectively, all of them are divided by properties

A thicker lock, high requirements for wood and its moisture content, as well as surface treatment make the Euro lining incomparable in quality with the usual version. However, if you need to save a budget, then the classic lining is also a good option. But you should closely monitor the quality when choosing a material, and also be prepared for difficulties in the form of a poorly connecting lock, a rough surface, falling out knots and possible cracks if the installation is carried out in a damp room.

Fasten the wooden lining with clamps. A kleimer is a bracket that is attached to the crate with nails or self-tapping screws and presses the lining lock to the base, but at the same time itself is not rigidly fixed to the board. This allows the lining to change its dimensions without problems due to thermal expansion and humidity and move vertically, which guarantees the reliability of the fastening and the absence of cracks or extraneous sounds in the future.

Separately, it is worth noting such a scope of lining, as finishing baths and saunas. Coniferous lining is rarely used in baths, as it can release resin, but this helps it to resist aggressive conditions, such as changes in temperature and humidity, as well as fungi and microorganisms. In saunas and baths, alder or linden lining is most often used - such wood, after processing, does not emit tar at all. Hardwood lining has a shorter service life due to the porous structure of the material, but thanks to the same porosity, this wood can withstand high temperatures.

Plastic panels appeared on the market not so long ago, however, they have gained a good reputation. They are not suitable for external decoration, but are great for cladding loggias and bathrooms or showers. Since plastic is insensitive to water, the panels can withstand any humidity and are also insensitive to sunlight. Unlike wood, plastic lining can have any pattern or pattern that repeats wood or stone. You just have to beware of low-quality panels, which, at the slightest drop in temperature, become extremely fragile due to the fact that the manufacturer saves on the quality of plastic.

MDF lining is laminated, veneered and painted. Laminated options are covered with PVC film, have a lower price and are more wear-resistant than veneered ones, which are covered with premium wood veneers. Painted panels, as the name implies, have a uniform color. Overall, this is a good alternative to the previous options. MDF lining has all the advantages of a wooden version and is produced in a wide range of colors. This alternative is suitable for the entire apartment - it can be used both in the kitchen and in the corridor, using it in the wall or ceiling cladding.

It is imperative to monitor the quality of the material when choosing it: the surface of the product should be even and smooth, uniform in color, without darkening and cracks. Do not trust the exhibition samples, as the sample may be from a different batch, or the lining could be stored in unheated and damp rooms. Unfortunately, it is impossible to know exactly the quality of storage of the material, therefore, as an option, you can buy one or two packs of material and see what will happen to it at the installation site.

Views

Wooden lining has two main classifications: according to the material from which it is made, and the shape that is given to it during processing.

By material of manufacture

The lining is made from various types of wood, it determines both the main operational and aesthetic features of the product. Also, the material determines the price category of the lining: the rarer the species of wood, the more expensive the lamellas. The main types are:

Deciduous

- Linden. High strength, pleasant texture and color that darkens over time. Needs impregnation treatment to improve durability and maintain appearance. Can be used in rooms with high humidity.

- Alder. It stands out for its excellent moisture resistance and a high content of tannins that evaporate into the air when heated. For its qualities it is widely used in the decoration of saunas and baths. Beautiful shade, high heat and sound insulation. Must be treated with impregnation to extend service life.

- Oak. An elite variety among hardwoods. High strength, excellent aesthetic and performance properties. Mainly used for interior cladding.

Exotic

A group of valuable red rocks, mainly growing in the tropics. Wood with excellent aesthetic properties is used for interior design finishes.

Conifers

A distinctive feature is the high moisture resistance of the entire group.

Spruce. It stands out for its softness and plasticity, it is easily processed, it can be bent into rounded shapes on a permanent basis. Very low surface roughness. Beautiful, but discreet texture. Weaknesses are: a large number of knots, a predisposition to fungal infection and the presence of bugs, one of the most non-moisture resistant of conifers. Often it undergoes additional processing during the production process. Spruce boards can be used for both interior and facade work.

- Larch. High strength, comparable to oak, increases over time from the resinization process, excellent performance in all parameters, exceeding the corresponding qualities of other conifers. Excellent thermal insulation, the breed contains phytoncides, natural antioxidants and substances that calm the nervous system. The resin of the tree is a natural remedy for parasites, which reduces the cost of additional processing. Excellent texture combined with a pleasant red shade that does not fade over time. The disadvantage of this breed is its high cost.

- Cedar. Differs in a pronounced characteristic odor due to the high resin content in the wood. The material is not subject to the warping process and has a high density. Good thermal insulation is combined with durability both for indoor use and for facade decoration, provided that it is impregnated with a hydrophobic mixture.

By the form of manufacture

In the process of processing, the lamellas are given a certain shape, which determines the specifics of the locking mechanism, and, accordingly, the installation of the product and its appearance.

Recently, brick products have become popular.

- "Standard" ("Calm"). It features a flat and very smooth surface, reminiscent of a timber.

- "Eurolining". It is similar to the standard shape, but leaves a small groove 15 mm wide at the joint. Higher quality standards are adhered to in the manufacture.

- Softline. It is similar to the standard look, but has more rounded corners, creating a specific relief of the finished surface.

- "Landhouse" ("Village House"). It is characterized by longitudinal grooves and slightly convex edges.

- "American". It is distinguished by a specific horizontal fastening method. Forms a characteristic coating with an overlapping arrangement of lamellas, which helps to protect the panels from the penetration of precipitation under the surface.

- "Blockhouse". The wall, trimmed with such clapboard, is similar to the wall of a house made of round timber.

- "Wooden wallpaper". A new type of lining for interior work, imitates the walls of a wooden house. It is subdivided into subspecies:

- "wave";

- "House";

- "Embossed";

- "With brushing";

- "threaded".

Classification

Lumber is produced in several varieties. The grade is determined by the quality of the processing of the front surface of the panels, the structure of the wood, the type of wood, the correct geometry of the profile.

The "Calm" lining is made of the following grades:

- Extra;

- Prima;

- A;

- AB, BC.

Extra

This class is assigned to panels without defects. HS of "Extra" class has no cracks, chips, distortions and rotten knots. The profile is made by splicing from several boards. Due to this, the front surface of the lining is smooth. The highest grade VS is considered elite, which is reflected in its high price. The products are delivered to the retail network in vacuum packaging.

Prima

The lining "Prima" is made of larch. Lumber is used for facing facades. The boards are durable, they tolerate sudden changes in temperature well. The facade clad with "Prima" creates an imitation of wall decoration with profiled timber. Larch panels are used to cover the interior surfaces of living quarters.

A

The lining of class "A" is a product of the 1st grade. From different manufacturers, VSh 1 grade is in no way inferior in quality characteristics to panels of the "Extra" class. The technical conditions of production allow subtle cracks no more than 90 mm long, light knots ø no more than 15 mm.

AB, BC

The lining of classes "AB", "BC" with reduced requirements for the quality of the material are rejected boards of the highest grades or products from low-quality wood. Usually, lumber is used for wall cladding, ceilings in utility rooms.

Wood used

In the manufacture of lining, all types of trees are used, and the difference depends on the characteristics of the tree itself. Color, quality, durability are determined by the breed, and areas of application are selected taking into account these data.

Conifers

Such a rock is impregnated with its own resins and essential oils, and this creates a protective barrier against the formation of fungi and mold, therefore, such lining is often used in facing external walls. They are widely used in dressing rooms, showers, swimming pools, loggias and living rooms. Conifers get very hot, for this reason it is not advised to use such wood in steam rooms, where the temperature is above 60 degrees. Such material accumulates heat and burns, creating inconvenience, as at high temperatures resin begins to release, which can drip.

Spruce is inferior in strength to pine, but surpasses it in flexibility; the material from such wood is knotty. Low roughness and attractive texture. Low resinousness and white color. Spruce boards must be additionally treated with special solutions to increase their service life.

Pine, has a lumpy red hue, it is one of the most budget options, as it is a fast growing tree, and is widely distributed in the market. Not bad looking and durable enough. Pine lining, emits a lot of resins, is vulnerable to scratches and mechanical damage, is not prone to warping during drying.

Larch, a very durable species, for example, its strength is 20-40% higher than that of pine, has a beautiful structure and retains its appearance for a long time. Larch lining has a natural natural protection against moisture, insects and early decay, thanks to its resinous nature. No shrinkage and warping, such wood is comparable in strength to oak. With a pleasant honey-golden color. Unlike other conifers, it has a high pricing policy, about a third more expensive.

Cedar, soft and at the same time dense, excellent heat insulator, average resistance to physical damage. The color is light, the external image is soft and pleasant, in warm shades.Euro-lining cedar exudes a pleasant aroma that has a beneficial effect on the human body and repels mosquitoes, a natural antiseptic sterilizes the air by killing bacteria in it. Durable and practical for any decoration.

Hardwood

These breeds have earned popularity in interior decoration, they do not have resins and other protective barriers like conifers. They have a shorter service life, low thermal conductivity, and are an excellent option for lining saunas. Lining made of such a breed does not heat up and does not burn in a sauna, it retains heat well in any space.

Linden, is in the middle price category. Low resistance to mechanical damage and deformation, but not prone to cracks and warpage. The color is white, knots are rare, does not change color over time, retaining the shade, is used in the manufacture of high-quality lining. Euro-lining linden, perfect for cladding balconies and saunas. Of the shortcomings, the softness of the rock can be distinguished, for this it is necessary to additionally process the material to increase the service life and protect against mechanical damage with varnish and similar solutions.

Alder has high sound insulation properties, low thermal conductivity, resistance to moisture and damage. The color ranges from light yellow to red. Compared to the hardness of oak, oak is 100% and alder is 50%. It also requires additional processing, since it has a short service life.

Oak, many have already heard about its increased strength and high price. Color palette from light shade to yellow and brown. Resistant to moisture and insects. Rich appearance. It has a lot of positive properties, it is durable, strong, and beautiful, no shortcomings have been identified in this breed. Suitable for all types of finishes. High price.

The presented canvases can be painted, varnished, stained, with the necessary decorative additions that do not have to be processed, and are a finished product for installation on walls.

Models are also sold without a decorative layer, which it is advisable to cover with protective solutions, varnish, paint, apply wax, etc.

Varieties

For the production of wood planks, different types of trees, types of raw materials, forms of surface treatment are used, which determines the existence of different types of products. It is much easier to choose a product, having an idea of the specific features of the material, its technical characteristics, and the expected operating conditions.

When determining the grade of products, foreign manufacturers rely on European standards, domestic - both on European and on their own standards, developed taking into account the requirements of GOST.

Extra

The best products are designated as extra. Old-school consumers call this category "top grade". The lining of the highest grade has practically no defects: worm or wane spots, blueness, sprouting, areas with rot. In most cases, spliced material belongs to this category, because in solid wood, be it linden, larch or other conifers, it is extremely difficult to find a large amount of ideal raw materials.

The lamellas of the highest grade have an absolutely smooth surface without knots, spots, chips, cracks; it is packed by vacuum sealing in a film to avoid damage during transportation and storage

The products should be fixed very carefully using special adhesives. Competently mounted cladding, covered with good varnish, has an elite look, is a worthy decoration of expensive interiors

3> A (first)

According to the long-familiar classification, the next group of products can be called 1st grade products. Now it is customary to designate it with the letter A. In a minimum amount, it can have microscopic cracks, resin inclusions that do not have a through character.

The sizes of knots are regulated, the diameter cannot exceed 15 mm, and the knots should not be germinated. The maximum permissible size of black knots is 7 mm. Products of this grade are most often used for cladding residential and administrative premises; the formation of a decent appearance of a high-quality surface can be completed by processing with wax, oil or just varnish.

In (second)

Lamellas of grade B are habitually called clapboard of the 2nd grade, which informs the buyer in advance about the possible presence of small defects. On each section with a length of up to 60 cm, small flaws may be present: cracks, dents, chips, with a total area of no more than 3 cm. The sizes of knots and bluish spots are also limited, should not occupy more than 10% of the plank area.

It is important to know that all the indicated defects in the 2nd grade products cannot have an end-to-end form.

This should be noted during inspection. For the installation of such a lining, experience is needed, because the ends can contain small areas with unplanned wood.

They do not interfere with the docking, do not spoil the appearance of the cladding when installed correctly. Small flaws of the front surface are masked with grouting, staining.

C (third)

Planks of grade C have the most loyal requirements for quality and low prices, they are mainly used for finishing technical premises. Installation of such products requires experience, great efforts; to some extent, the surface can be improved by additional work on finishing, painting.

The cladding usually has knots, cracks, chips, roughness in an amount that is noticeable to the naked eye even with a cursory examination. Unfortunately, some manufacturing plants in category C introduce completely defective material with an unlimited number of serious defects, although by standards the total area of stains should not exceed 20%. Regulatory documents do not contain any restrictions on the number and shape of knots in this type of product.

> When choosing a lining, the buyer should study not only the accompanying certificates, but also inspect the material on his own. Unfortunately, unscrupulous manufacturers and trade representatives tend to sell products of not the best quality at inflated prices. To make a purchase, it is advisable to contact reputable suppliers with a positive reputation. Good quality lining will make surfaces attractive for years to come.