Characteristics of polyester resin

- Mechanical properties. In this parameter, polyester resins are significantly inferior to epoxies. Therefore, mechanical stress and deformation often lead to cracks and delamination in products.

- Adhesive properties. Polyesters have poor adhesion, so they do not work well as an adhesive.

- Shrinkage. Polyester can shrink in volume up to 7-10%. However, the shrinkage process may take time and delamination will not be immediately apparent.

- Water resistance. After curing, the surface has poor waterproofing properties and is permeable to water.

- Shelf life. Polyester has a short shelf life: on average 6 months - 1 year.

- Polymerization. The curing rate of polyesters is significantly faster than epoxies, and usually takes several hours. The drying process can be accelerated using the MEKP catalyst.

- Smell. During curing, the polymer components give off a strong odor.

- Boiling. Polyester polymers are not prone to boiling.

- Durability. Polyesters form a durable coating, but are prone to microcracking, less resistant to impact, less durable than epoxy coatings.

- UV resistant. Polyester surfaces are UV resistant and do not need a topcoat to prevent yellowing or deterioration from sunlight.

- The complexity of the application. The material is quite simple to use and does not require special knowledge and experience.

- Spheres of application. Polyesters are used in cases where low cost and ease of use are more important than strength and durability. For example, in landscape design, plumbing, auto tuning, etc.

- Price. Polyester resin is 2-3 times cheaper than epoxy.

- Environmental friendliness and safety. Polyesters contain carcinogenic styrene, which gives off a strong unpleasant odor. The resin components are flammable liquids, catalysts are flammable and explosive. But there are resins on the market without styrene and with its reduced content.

Peculiarities

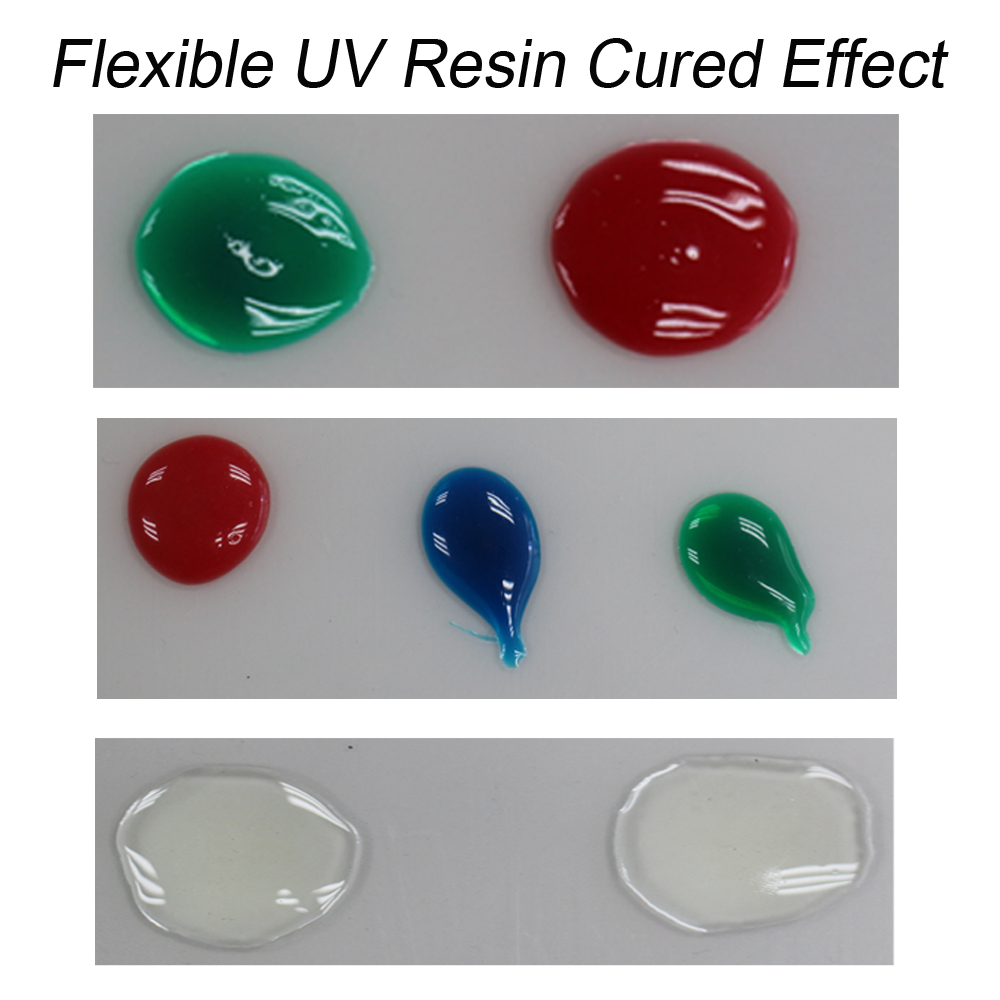

UV resin is a colorless gel that hardens under the influence of ultraviolet radiation. It contains only one component, so it does not need to be mixed with a catalyst. The resin can be painted with powder paints and with a paste. In this way, the desired color is obtained. It takes 1-10 minutes to cure, the curing speed depends on the density of the layer and the amount of pigment used. The material remains liquid before exposure to ultraviolet rays. UV resin resembles gel polish, they have an identical curing process. Follow the rules for creating a gel polish manicure when working with resin.

The main advantages of UV resin:

- fast solidification;

- the possibility of applying thin layers;

- transparency;

- high strength of the created coating.

Ultraviolet resin saves time, allowing multiple coats to be cast in minutes. The composition does not need to be diluted, it is completely ready for use, there is no probability of making a mistake with the proportions.

What harm does epoxy do

The toxicity of epoxy before it cures is a proven fact. The greatest danger posed by a resinous substance is severe skin lesions. Severe skin irritation, allergic manifestations occur when the liquid mass comes into direct contact with unprotected skin. Dermatitis is also accompanied by severe irritation of the membranes of the respiratory tract, damage to the mucous membranes.

Occupational diseases

Working with epoxy requires the presence of personal protective equipment. In their absence, as a result of long-term contact with the constituents of the liquid substance, workers note in themselves:

- severe, prolonged migraines;

- burning and pain in the eyes;

- decreased appetite and nausea;

- eczema and the appearance of itchy spots, rashes;

- swelling of the skin of the face, eyelids.

Resin can cause discomfort if violated safety rules

Resin can cause discomfort if violated safety rules

One third of all employees have rhinitis, pharyngitis, and lesions of the bronchopulmonary system of various levels. Cases of development of bronchial asthma, bronchitis and lesions of the pulmonary tract were noted. And in 2-3% of workers, physicians revealed the development of conjunctivitis and serious allergic manifestations.

Disorders of pigment, protein and carbohydrate metabolism are frequent results of long-term and close contact with epoxy. Epoxy is toxic until fully polymerized. The harm of this substance is manifested in the following:

- lesions and development of pathologies of the heart muscle (myocardium);

- liver and kidney disease;

- problems in the work of the digestive tract.

Episodic illnesses

It is necessary to immediately say when studying the question whether epoxy is harmful to a person after hardening, that any allergic manifestations in this case occur extremely rarely. The coincidence of very many and different factors is necessary for the development of allergies from contact and contact with cured epoxy.

But in the presence of a predisposition, extremely low immunity and ongoing chronic diseases, even odorless resin can be harmful. In this case, the following manifestations are noted:

- dizziness;

- headache, pain and itching in the eyes;

- hoarseness (rare);

- profuse rhinitis.

If such manifestations have been noted, and the person continues to be in close contact with epoxy resin, this condition worsens. And when exposed to toxic vapors (in contact with a liquid substance) for a long time, health is in danger of many troubles. Damage to the liver, myocardium, and the digestive system occurs. In severe cases, ulcers appear on the mucous membrane of the gastrointestinal tract.

Resin can be harmful before it cures

Resin can be harmful before it cures

How to use

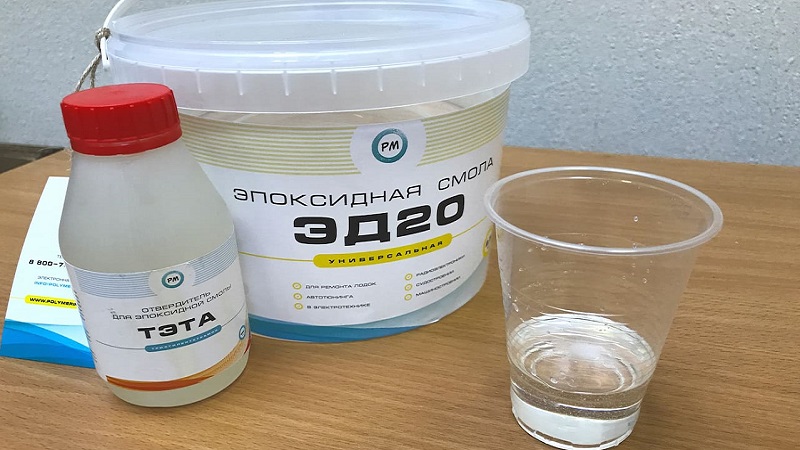

During use epoxy resin Artline it is worth remembering that this product is two-component. In other words, it comes in two separate bottles. The first contains the resin itself, and the second contains the hardener.

The required amount of resin is taken from the bottle, then calculations are made and a certain amount of hardener is added. The label always states in what proportion you need to knead. You always need to follow the standards specified by the manufacturer, otherwise you can completely render the mixture unusable, and its further use will be impossible.

After studying the proportion and determining the optimal value, you can proceed to the kneading process. This should be done clockwise and counterclockwise, alternating directions. This is necessary in order to achieve maximum uniformity. Stir for at least 3 minutes, otherwise the molecules will float separately, which will not lead to solidification, or the mixture will turn into a gel.

The curing process can vary depending on the temperature of the catalysis. You can understand that everything is ready by its appearance: the hardened resin is quite similar to hard plastic. Even after complete hardening, it is worth waiting for several days, since the resin has not yet hardened and is not able to cope with mechanical stress.

An illustrative use of Artline epoxy resin on the example of creating a serving board from wood is presented in the following video.

Please tell us how the Epoxicon-400 bleach works. Does it make the white parts whiter or increase the transparency of the resin?

Concentrate

dyes EPOXICON-400 (110A) is added

in optical (jewelry) epoxy resins for

improving aesthetic perception. He uses

property of the human eye. When we

we say "crystal clear" we mean

necessarily with blueness. As before to improve the appearance when

washing clothes

or whitewashing of ceilings was used

bluish, so now, for the same purposes,

bleach (turn blue) jewelry resins

Especially

this is important when making "thick"

products with a thickness of more than 3-5 cm. Many foreign

compositions of Crystal resin, ICE resin, Luxe resin, Table Top

Crystal Clear EE-116, etc.

use this technique. V

unlike them we provide

choice: can be purchased standard bleached

compound (PEO-510KEF-20/0), compound without

whitening effect (PEO-510KE-20/0) or

create a compound with the selected

whitening concentration to your liking

additives, i.e. use a pair of PEO-510KE-20/0

plus EPOXICON-400 (110A). In the same way you can

compose the other six marks

jewelry compounds PEO: PEO-10KF-20/0, PEO-610KEF-20/0,

PEO-10KEF-20/0, PEO-210KEF-20/0, PEO-310KEF-20/0

and PEO-710KEF-20/0.

How to use?

The consistency of the UV resin resembles a thick gel. If there is a need to obtain a more liquid substance, it is heated with a hair dryer. The resin pack can also be microwaved for a few seconds or placed on a battery.

Before using the composition, you need to prepare all the necessary equipment and consumables: an ultraviolet lamp, paints, decorative elements.

At the first stage, the surface is cleaned with alcohol, degreasing it and removing dust.

A small amount of dye is mixed with a colorless resin. You can use a metal or plastic stick to mix.

After that, paint is added to obtain the desired color.

It is important not to overdo it with the amount of dye - this can negatively affect the hardening of the resin.

Much depends on the chosen design - in some cases, there is a need for temporary "edges" to contain the composition and prevent its spread beyond the boundaries of the product (you can use narrow tape).

The first resin layer is applied to the base (it should be thin) and wait for it to harden. Subsequent coats may also contain dye, but if multiple shades are used, each coat must be poured and dried separately.

It is necessary to work carefully and unhurriedly

Haste is fraught with the appearance of bubbles. Heating the resin surface to contact with ultraviolet light can cause bubbles to rise to the surface.

After fulfilling all the instructions, the product is placed under an ultraviolet lamp for a couple of minutes. If the colorant has already been added to the resin, the time interval must be increased.

It is important to remember that the darker the shade, the longer the substance needs to be irradiated with ultraviolet light.

New layers are added on top of the hardened ones until the required height and thickness is reached.

For what UV resin is and how to use it, see the next video.

I have a surplus of component A of transparent epoxy resin PEO-10KE-20/0 (component B was spilled). Is it possible to harden it with some other substance?

If

you have a surplus of component A,

then it is most correct to acquire the missing

the amount of "native" component B,

for example, in the Nestandart store (St. Petersburg). The same applies to

procurement of missing component A. Important

remark - component B for the whole line

jewelry resins PEO-10K-20/0, PEO-610KE-20/0, PEO-510KE-20/0,

PEO-10KE-20/0, PEO-210KE-20/0, PEO-310KE-20/0 and PEO-710KE-20/0

same. 4

Epoxy

froze, but the upper

part of the lens was covered with oil

film. I rubbed the lens with acetone, resulting in the lower part

smooth and transparent, and the top has become

rough. Why so

happens and how to avoid it in the future?

4. Epoxy

froze, but the upper

part of the lens was covered with oil

film. I rubbed the lens with acetone, resulting in the lower part

smooth and transparent, and the top has become

rough. Why so

happens and how to avoid it in the future?

Reasons

the appearance of an oil film may be

several: low temperature, high

humidity, wrong ratio

components and poor mixing. Sorry, you don't write

what kind of hardener were used. When used in

as a hardener TETA essential

have the first two factors. Even with

correct weights and careful

stirring curing at room

temperature with high

likely to be accompanied by

the appearance of an amine film. Prevent

its appearance can be increased by increasing the temperature

curing up to Т = 30 ºС and above.

Epoxy resins for

creativity PEO and Crystal resin are not so critical to

curing temperature. For them the most

a common reason for the formation of a film is not taking into account the fact that

density

components A and V different and therefore

ratio of components A: B differently

"By mass" and "by volume". Second most common

the error is due

common misconception that if you take

the hardener is more than the norm, then the curing

will happen faster. In fact, for

significant excess of hardener

will remain unresponsive between nodes

mesh, and on

the surface of the product will be observed

gradual "sweating" (film). By the way,

simultaneously

decrease in strength and chemical resistance

cured epoxy resin,

moisture absorption, on the contrary, will increase.

If

the film has appeared, then remove it from

the surface does not need acetone, but warm

water and a sponge or diluted ethyl alcohol.

5.

I am out of proportion

(6.6ml: 1.5ml) and PEO-510KE-20/0 glue is not completely frozen.

Can I pour a new one on top of this incompletely frozen layer with the correct

proportion?

If you made a mistake and poured

A= 6.6ml,

V= 1.5 ml, and the mixture has not yet been poured onto the product,

then add more hardener V= 0.5ml and again

stir. As a result, it will turn out A: B=6,6:(1,5+0,5)=6,6:2=3,3:1

and you can continue to work.

If the product has been poured, then decide whether to wash off the polymer layer or

leave him - you will have to yourself, given

many factors: appearance, degree of crosslinking

polymer, product "liability" and

etc. If

the product is custom-made, then I would not risk it,

making a second fill. Strong house

you can't build on a bad foundation. I remind you

just in case that the permissible error of the sample

components 5%.

1. What is the pot life of epoxy jewelry? When does the rubber-like phase occur, in which the epoxy is plastic and can be bent, molded?

Different brands

jewelry resins, these parameters are different.

Let's consider them on the example of three popular

brands: Crystal resin (PEBEO S.A., France), EpoxAcast 690 (Smooth-On,

Inc., USA) and PEO-610KE-20/0 (SPbGTI (TU), Russia).

Viability

is the period of time during which

epoxy composition after mixing

components are still in sufficient

liquid and usable

condition. For the above resins

viability at room

temperature is approximately 115, 195 and 250

min., respectively. This time is enough

so that air bubbles come out of the mass

naturally as from volumetric

coatings, as well as from small in volume

mold-cured castings. Next

stage - gelation - occupies the inflection area

curves. At its final stage, a gel-like

the consistency becomes elastic ("rubbery"),

her

an external sign may be a dent,

which remains on the surface of the casting

when you press. If refilling is required

epoxy, it is recommended

to produce during this period, because

chemical processes have not yet ended and in

the result of co-curing

the interface will be invisible. In the "rubber"

epoxy phase

the composition is still plastic and at this time its

can be modified to give the desired shape. Obviously,

jewelry resins Crystal resin, EpoxAcast 690, PEO-610KE-20/0

compared to short-lived

formulations of the CHS-Epoxy 520 / 921ОП type, having 3-4

times less vitality, have advantages in terms of lightness

removal of air bubbles, as well as

refill and geometric correction

product shape.

How do your compounds relate to freezing during transportation? I have the very case when you can buy PEO anywhere except Moscow ... and it's not May in the yard

For 8 years as a jeweler

PEO epoxy compounds were

offered to members of the crystalresin community in

Learn as an alternative to foreign

materials Crystal resin, Luxe resin, Ice resin, and then

jewelry was launched on the market, there was no

one case with a claim to their frost resistance. I quote "St. Petersburg epoxy rode

week: in St. Petersburg it was -20, we have in Novosibirsk

-32 during the day, -40 at night ... no changes at all. "

Geography of jewelry supplies

PEO resins and accessories for them in Russia is extensive:

Barnaul, Yekaterinburg, Irkutsk, Kazan,

Krasnoyarsk, Perm, Tomsk and many others

cities. In Moscow, I recommend an excellent

Jubiju shop.

Characteristics of epoxy resin

- Mechanical properties. The tensile strength of epoxies is 20-30% higher than that of polyesters. The ability to withstand stress and deformation without damage is much stronger. The flexural strength and resistance to stress are extremely high.

- Adhesive properties. When cured, the epoxy acts as a powerful adhesive with high adhesion.

- Shrinkage. Epoxies exhibit slight shrinkage when cured.

- Water resistance. Cured epoxy resins are water resistant.

- Shelf life. If stored properly, the resin will not lose its properties for several years.

- Polymerization. Curing of epoxy is influenced only by the curing agent and temperature. On average, at room temperature 22-25 ° C, the resin hardens in 24 hours. It is not worth adding more hardener to speed up the cure, the liquid may not harden at all. You can shorten the drying time by increasing the room temperature. When the temperature is increased by 10 degrees, the polymerization rate doubles. But do not set the temperature above 40 degrees.

- Smell. The resin does not emit a pronounced odor when cured.

- Boiling. Epoxy can boil and become unusable if heated too much.

- Durability. Cured epoxy resins resist wear, cracking, flaking, corrosion, micro cracking and mold.

- UV resistant. The polymer itself is not UV resistant. Although some brands contain additives that increase UV resistance. However, the best way to protect the surface from yellowing and deterioration is to apply a UV-resistant polyurethane varnish.

- The complexity of the application. Working with epoxy requires application experience and certain skills, since viscosity is lost during curing and it becomes difficult to work with the material on vertical and inclined surfaces.

- Spheres of application. Epoxies are used for the production of products with increased wear resistance, waterproofing, adhesion strength. For example, in the rocket and aircraft industry, shipbuilding, the production of racing cars, etc.

- Price. Epoxy is much more expensive than polyester.

- Environmental friendliness and safety. Epoxies do not contain carcinogenic components, volatile organic compounds, and are not flammable. The resin components are safe and easy to transport and store.

Can I pour jewelry resin over a pastel (watercolor) drawing?

At first

for pastel drawing. Yes, you can. But

keep in mind that pastel crayons are made up of small free-flowing particles that

can be mixed with resin. If you are pouring large volumes, distribute

resin over the surface using inclined manipulations (like dough on a pancake

skillet).This will reduce the mixing of the particles with the resin. Moreover, not

forget to run a little test on a piece of pastel paper to make sure

that it does not absorb resin.

Regarding the watercolor painting, such a fill

is also possible, but only after the image has completely dried and if the picture

created on special watercolor paper. Such paper is thick, high

quality, good water repellency and does not allow the epoxy to be absorbed. V

anyway, before pouring, test on a small piece of paper and

test it for durability.

Out of inexperience, I left my "fingers" on the master model. I’m thinking: redo the shape or polish the product. Tell us more about polishing cured epoxy. There are no complaints about gloss and transparency.

Optics good

know: the higher the hardness of the material, the higher

polishing quality. For example,

inorganic glass having hardness

6.5 on the scale

Mohs (scratched with a file) polished significantly

better than organic glass or

cured epoxy resin having

hardness 3.5 on the Mohs scale (scratched

window glass, copper coin, knife). To compound

PEO-510KE-20/0

was harder, you need to dry it well:

about 8-10 hours at T = 60 ºС. Second way

- use slightly harder instead of PEO-510KE-20/0

compounds PEO-10K-20/0

or PEO-610-KE-20/0.

For polishing

cured epoxy compounds can be

use a few simple

ways. We

used a steel circle on top of which felt was fixed or

Peko-rosin resin was poured. At first

grinding was carried out with abrasive

micropowders 28 and 7 microns, then polishing with

diamond powder with a grain of 1 micron, as a lubricant

soapy water was used.

What to choose: polyester or epoxy?

Answering the question which is better, epoxy or polyester, first of all, it is necessary to take into account the requirements for the future product.

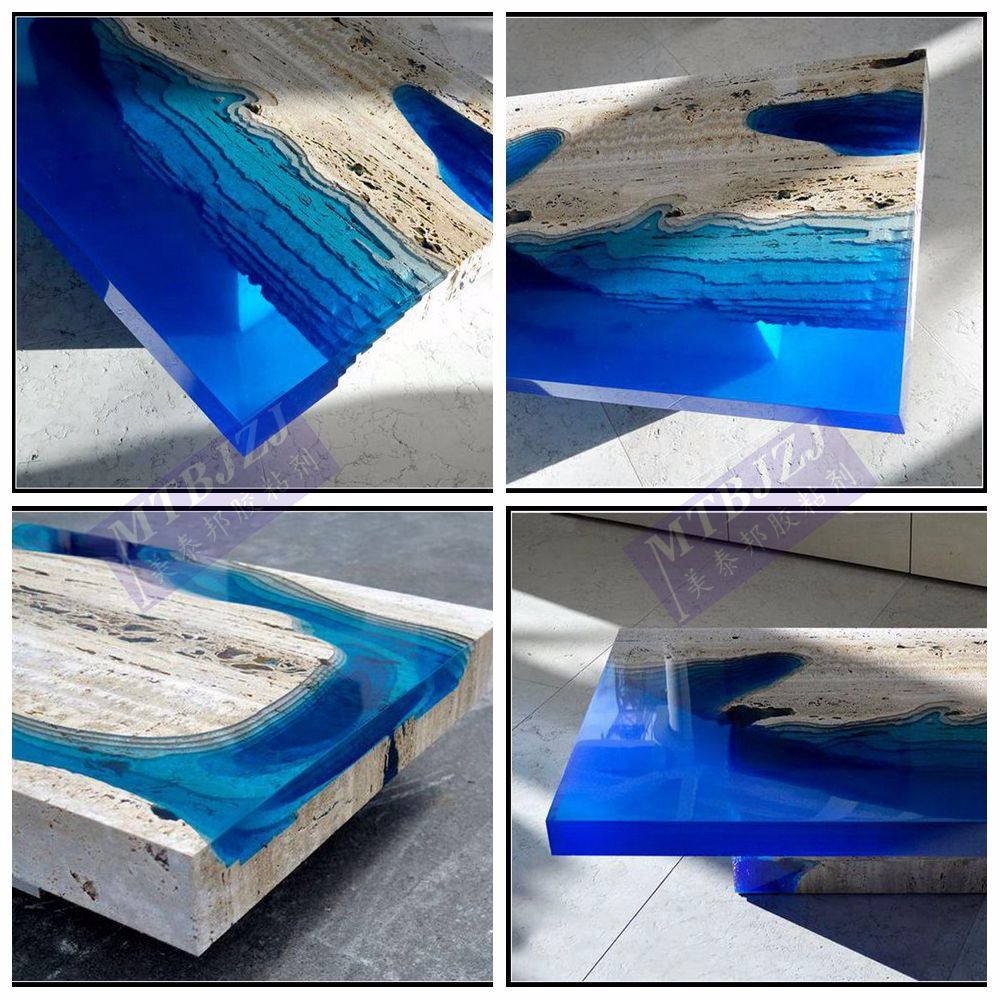

Epoxy resin, due to its strength, glossy finish and durability, is ideal for the manufacture of bar counters, tables, countertops, cabinet fronts, home decor and ornaments. Due to its low cost and ease of use, polyester resin is suitable, for example, for the production of artificial stone, sanitary fittings, motherboards, window sills, car bumpers.

Overall, the bottom line is that if durability, strength, and a glossy finish are important, go for epoxy. And if you do not plan to subject the product to high loads, and the price is of great importance, make a choice in favor of polyester resin.

Subscribe to the channel, leave comments, like, share the article with your friends. This motivates you to continue to issue articles! Thanks!

- I recommend looking at the article about

Is it true that jewelry epoxy is harmless compared to technical resin? Or ALL epoxy resins are equally toxic, there is such an opinion?

All epoxy

resins are toxic, but jewelry is toxic

smaller. V

quality "construction and technical"

resins use epoxy resins of the 1st grade,

as cheaper, but for "jewelry"

applications - premium epoxy resins,

more expensive. Why? Because

volatile content (epichlorohydrin

and toluene) according to GOST 10587-84 y

the first is allowed no more than 0.4-0.8%, and for

the second - no more than 0.1-0.2%, i.e. 4 times less! In epoxy resins

foreign manufacturers - mainly raw materials

jewelry compounds - content

volatiles less than 0.1%. So

there is a difference. Another thing is that

the seller can position his product

as jewelry, but actually use

1 grade epoxy or use

cheaper but higher hazard class

hardener. So is it possible

for any product: alcohol,

cosmetics and stuff. Conclusion - you need to buy from

a trusted manufacturer.

According to

expert

the conclusion of the FGUZ "Center for Hygiene and

epidemiology in the city of St. Petersburg "

No. 78.01.09.025.П.345 dated 14.02.2011 optically transparent

epoxy compounds PEO "allowed

apply in the jewelry industry,

production of jewelry and souvenirs, including

number, in everyday life. " In the hardened state

PEO compounds are harmless. So much so that their

even used in

as filling materials for

root canals of teeth and for sealing pacemakers,

implanted into the human body.

Safety standards adopted in the European Union

Transparent resinous substances produced by leading manufacturers in Europe and intended for the production of jewelry and designer furniture meet all standards. They fully comply with the requirements and are safe for humans even with prolonged use of such products. But according to EU standards, all potentially dangerous epoxy resins that can provoke various health problems are necessarily labeled:

- H319: There is a risk of irritation if the substance gets into the eyes;

- H315: the appearance of allergies when the resin comes into contact with the unprotected skin of the body;

- H317: with prolonged contact with the skin, there is a risk of dermatitis;

- H314: high risk of toxic damage to the epidermis with close and prolonged contact with the resin;

- H312 and H302: toxic substances that cause serious poisoning and intoxication of the body if swallowed or prolonged skin contact.

Such jewelry resins are safe even at the stage of dilution and pouring of the mass. In other cases, epoxy products can be safely used after the mass has completely hardened. This requires 2-3 days.

How can you avoid that the jewelry compound does not drip from the edges of the product and “bald spots” do not form on the surface. Only the second fill layer helps, but I want to ensure that everything is normal the first time.

Completeness

compound wetting depends on three

main factors: 1) ratios

surface tensions on three interfacial

boundaries: substrate-compound-air-substrate,

2) the initial viscosity of the compound and 3) the state

surface.

Obviously in your case 1) and 3) factors

unfavorable - the substrate is bad

wettable with epoxy composition. The backing material needs to be changed

or introduce special

additives, which is not always possible due to

deterioration of transparency. Change

surface condition by grinding also

hardly

whether it will be possible, tk. the poured will deteriorate

picture, and degreasing, I hope you

do. It remains to use 2) factor -

viscosity. To prevent the compound from dripping, do not

pour it freshly prepared immediately,

let stand for a couple of hours (this

depends on the brand of compound and temperature

environment and is determined by experienced

way), then fill in.