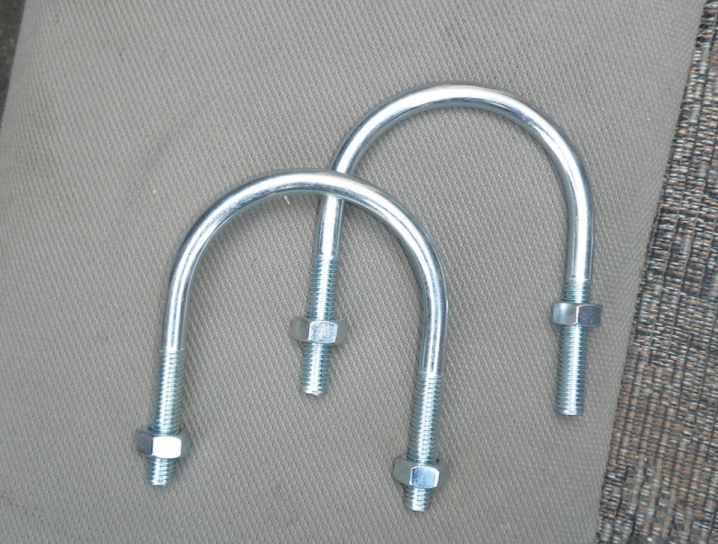

General characteristics

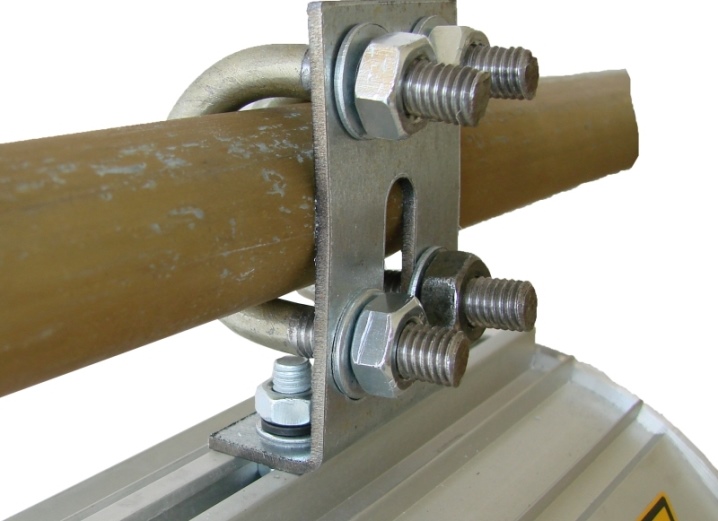

When describing U-clamps, it is imperative to take into account that their key characteristics are fixed in GOST 24137-80. The pipe or hose can be attached with similar fasteners to the surface of a metal sheet of any shape. These products are quite reliable. It should be noted that in terms of resistance to adverse factors, there is practically no real difference between U-brackets and rings equipped with bolts.

It is not simple, but necessarily microporous rubber. Such a substance perfectly dampens vibrational vibrations that can occur in pipelines.

Features of production

As already mentioned, in the production of clamps, domestic firms are guided by GOST 1980. Foreign companies are free from such a requirement, but it is necessary to find out which foreign standard a particular product meets and whether such characteristics meet. In Russian practice, the most widespread production of U-shaped hardware based on carbon steel. The dimensions are practically not limited, it is possible to apply a galvanic protective coating.

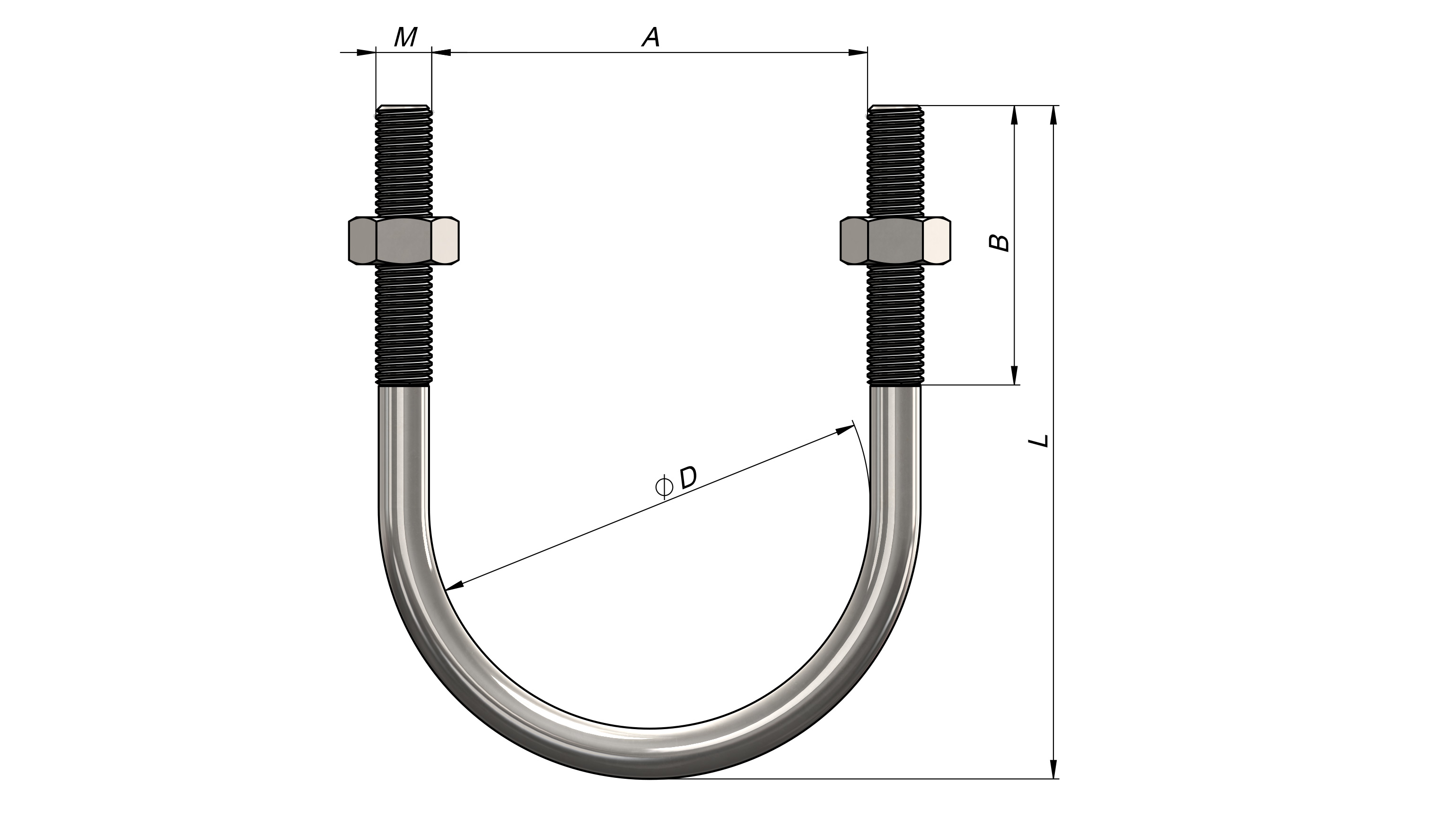

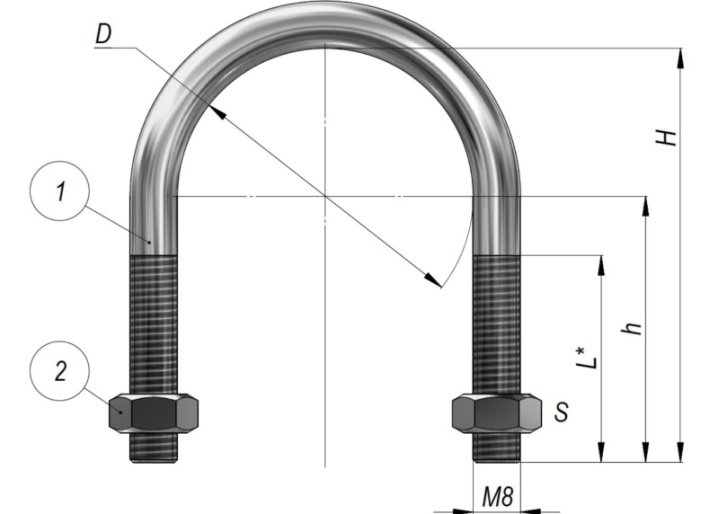

The upper "arc" in the shape of the letter U is the best guarantee of reliable retention of the pipe along the entire section. The nuts included in the kit must comply with GOST 5915-70. Experienced technologists always choose only solutions based on calibrated rolled products. Clamps made from it will have perfect curl. Scrupulously accurate geometry is also required.

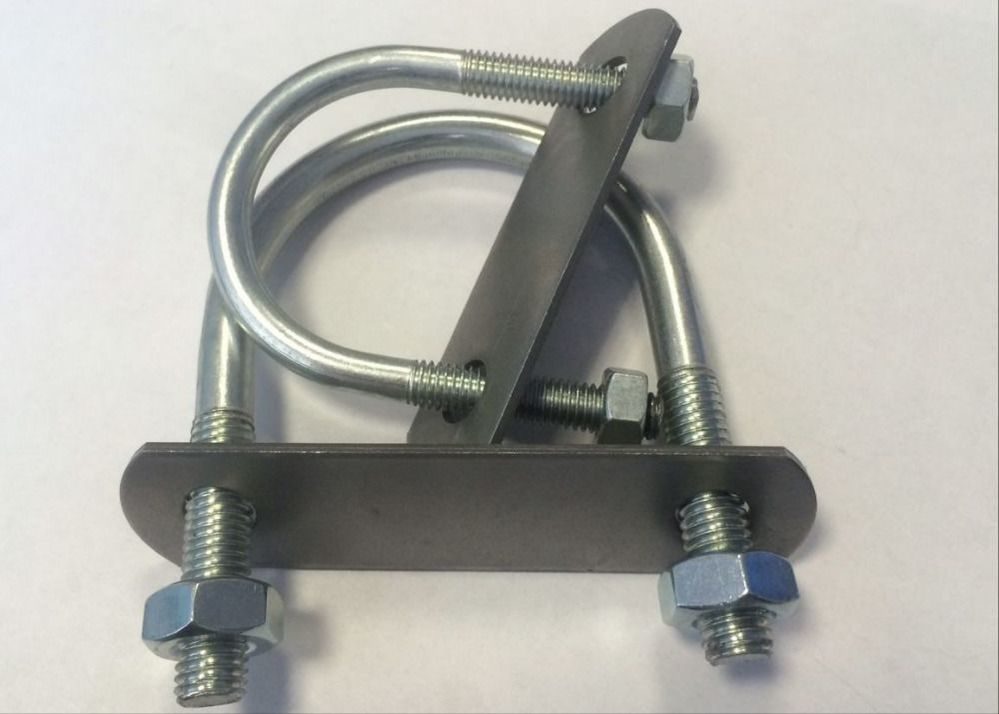

Of course, responsible manufacturers subject their products to multiple quality checks to ensure they meet official standards. It is often the practice to equip clamps with additional mounting plates. In addition to standard sizes, you can order products of original dimensions. Heat treatment of parts is carried out at the request of the customer.

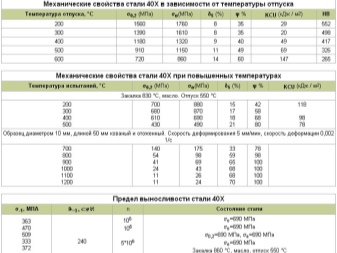

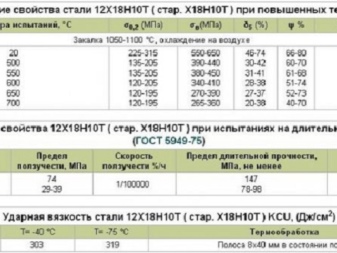

In order to produce clamps that differ from standard clamps, the client can provide his own design and technical documentation, especially drawings. High accuracy and excellent workmanship are guaranteed, final control is carried out according to a verified procedure. The technology as a whole is debugged, and therefore the production time of the clamps is minimal. Depending on the nuances of the technology, steel of the following categories can be used:

-

3;

-

20;

-

40X;

-

12X18H10T;

-

AISI 304/321;

-

AISI 316L and some other types.

Rubber porous gaskets. Technical conditions

This standard applies to rubber porous gaskets designed to seal the joints of prefabricated building envelope elements.

The gaskets must be manufactured in accordance with the requirements of this standard according to the recipe and technological regulations, approved in the prescribed manner.

The gaskets have a continuous surface film without cracks or breaks. Bloom of fading ingredients and products of their interaction, talcum powder, conveyor belt prints, waviness are allowed. Bumps or grooves are not allowed on the surface of the gaskets, vulcanized folds with a height (depth) of more than 3 mm, peeling of the surface film from the gasket with a length more than 50 mm more than 1 PC. per meter of length, bubbles larger than 1/4 of the smallest size of the gasket section.

The cross section of the gaskets should not have internal voids larger than 1/4 of the smallest size of the gasket section. For gaskets of the highest quality category, internal voids are not allowed.

Gaskets must be accepted in batches. A batch is considered to be gaskets of the same type, group and size in the amount of not more than a daily output, made on one technological line.The number of gaskets less than a daily output is also considered a batch. To check the appearance and dimensions, 5% of each batch of gaskets is taken, but not less than 3 coils or packs of gaskets.

To check the physical and mechanical properties of the gaskets that have been tested in appearance and size, at least 3 samples of 1 m length are taken from different coils or packs.

The appearance and dimensions of the gaskets, their density, resistance to compression at a temperature of (20 + - 5) ° C and permanent deformation are checked upon acceptance of each batch.

The consumer has the right to carry out a control check of the quality of the gaskets, observing the given sampling procedure and applying the test methods indicated below.

Gaskets must be supplied in coils or bundles. Coils or bundles should be tied with twine or other dressing material that ensures the quality of the package and the integrity of the surface film of the gasket.

The gaskets are transported by all means of transport in covered vehicles.

The gaskets should be stored in ventilated rooms or sheds at a temperature not exceeding 30 ° C in conditions excluding direct sunlight and substances that destroy rubber (oils, solvents, acids, alkalis).

The manufacturer guarantees that the gaskets comply with the requirements of this standard, subject to the conditions of transportation, storage and instructions for use.

Scope of operation

The bracket can be required, of course, for attaching pipes. But its area of use does not end there. You can use similar products to connect other important elements. It is allowed to work with pipes of various types. The U-clamp is acceptable for both vertical and horizontal pipe installation.

The main areas of application for the U-Clamp are:

-

fastening pipes and various beams;

-

placement of road signs and similar signs;

-

keeping television and other antennas in place;

-

ensuring the tightness of various technological systems without installation;

-

installation work on many types of surfaces and supports;

-

fastening of structural parts in exhaust systems of cars (according to the "pipe in pipe" principle).

The pipes to be installed will be fixed firmly and reliably, they can be operated for a long time. But clamps can be used not only during installation, but also when repairing the pipeline.

Installation of hardware on steel, plastic, cast iron and asbestos-cement pipes is allowed.

It will be possible to repair the pipeline if:

-

fractures;

-

fistula;

-

cracks;

-

mechanical defects;

-

other deviations from the norm.

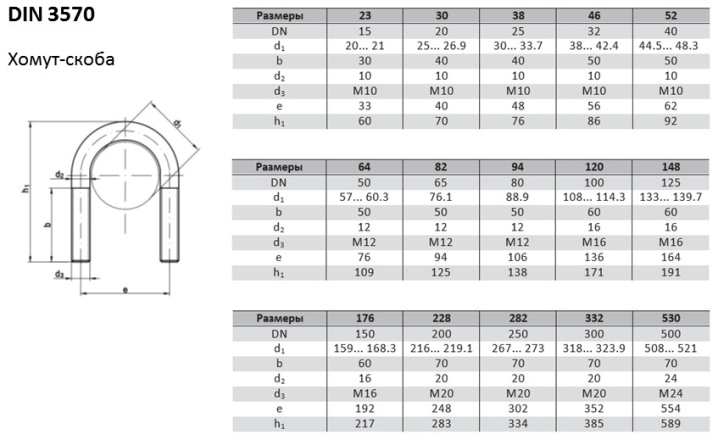

Types and sizes

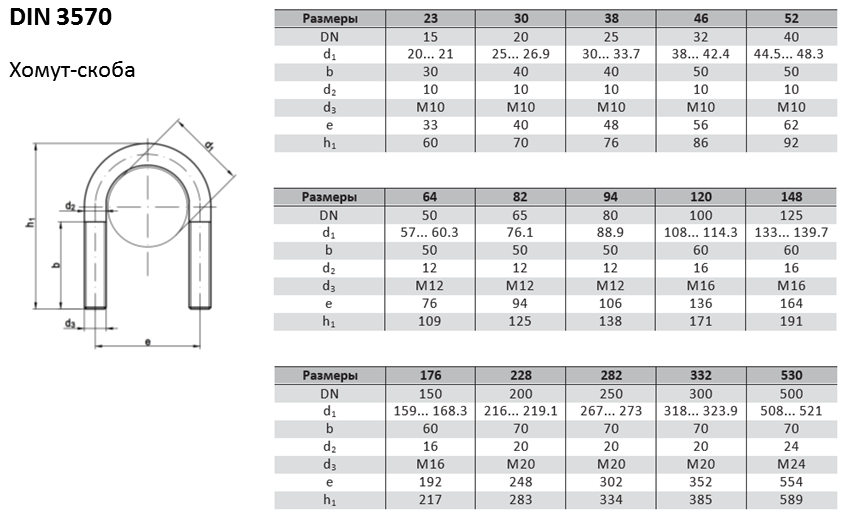

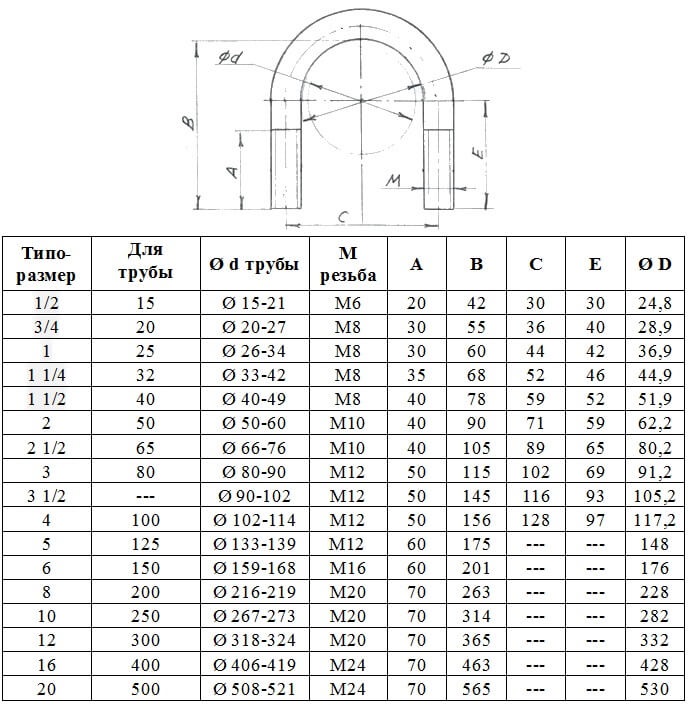

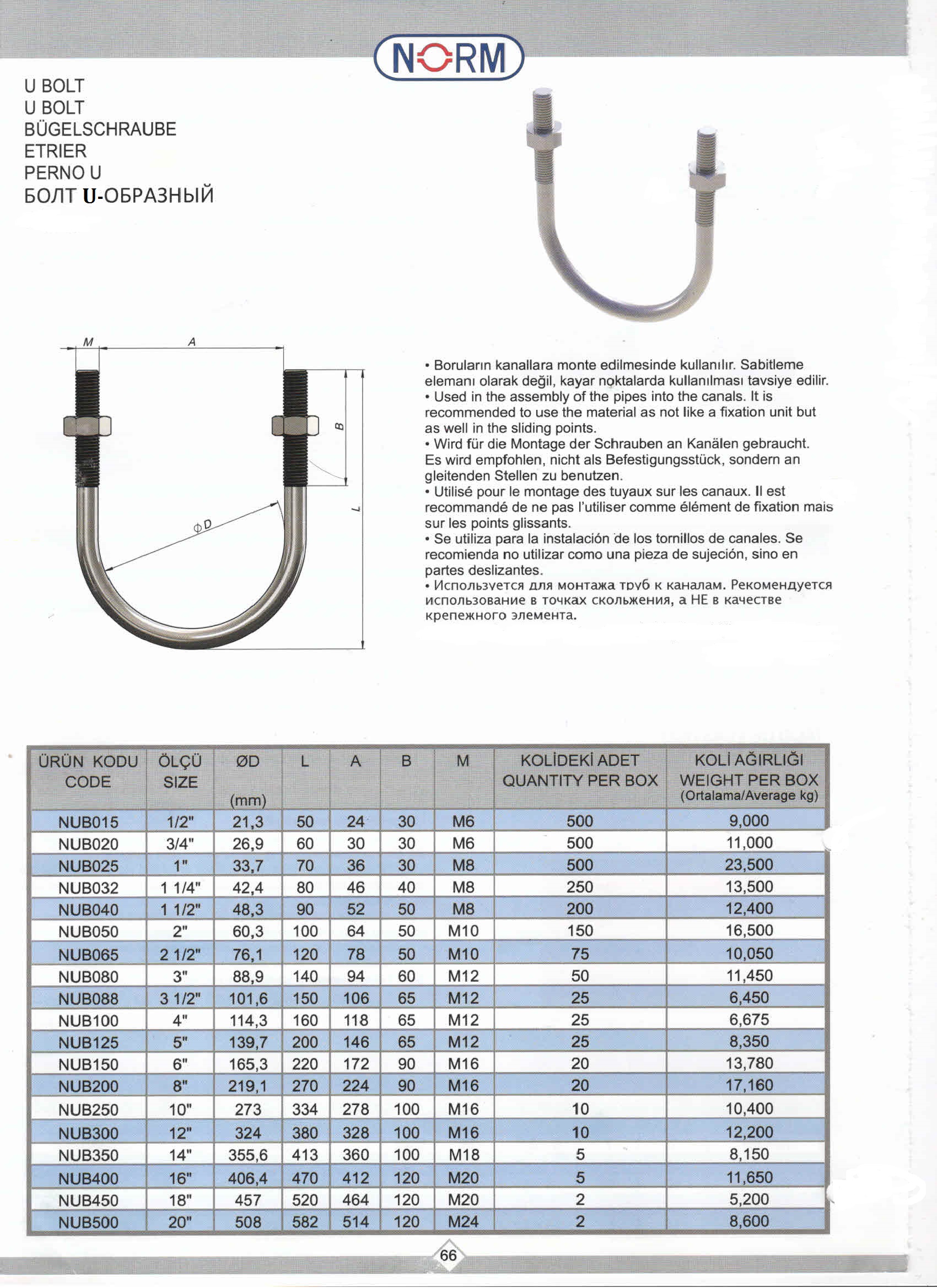

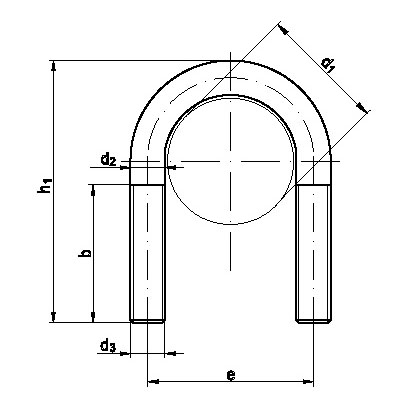

The main differences between the products are related to their cross-sections and to the main construction materials. Possible cross-sections for serial products are at least 16 and maximum 540 mm. Products conforming to the 1980 standard may have the following parameters:

-

cross section 54 cm and weight 5 kg 500 g;

-

section 38 cm and weight 2 kg 770 g;

-

diameter 30 cm and weight 2 kg 250 g;

-

diameter 18 cm and weight 910 g;

-

circumference 12 cm and weight 665 g;

-

circumference 7 cm and weight 235 g.

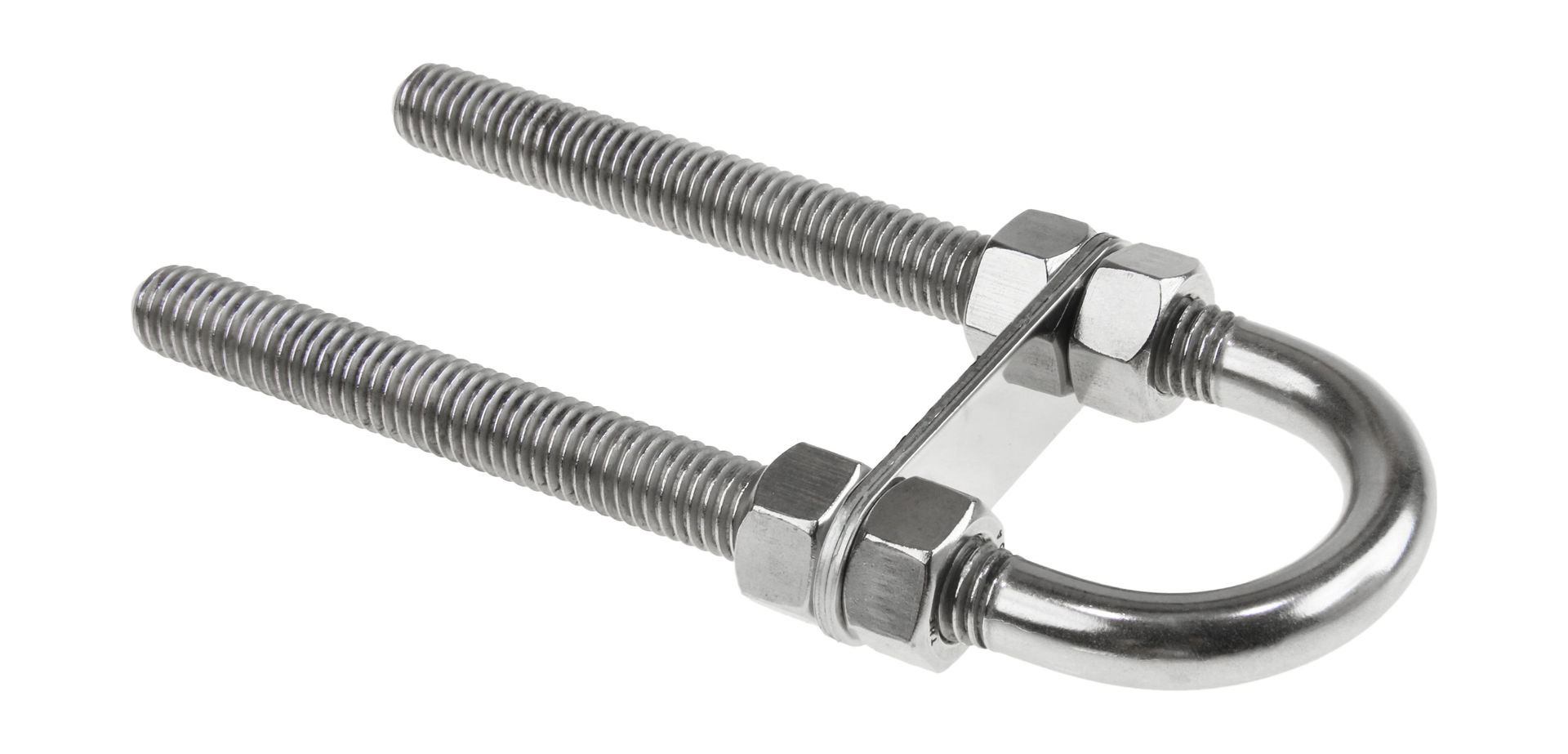

Various materials can be used for the manufacture of fastening clamps (staples). Most often, carbon steel is chosen. It is allowed to use both stainless alloys and galvanized metal; the thickness of the zinc layer varies from 3 to 8 microns. A wide variety of steel grades can be used.

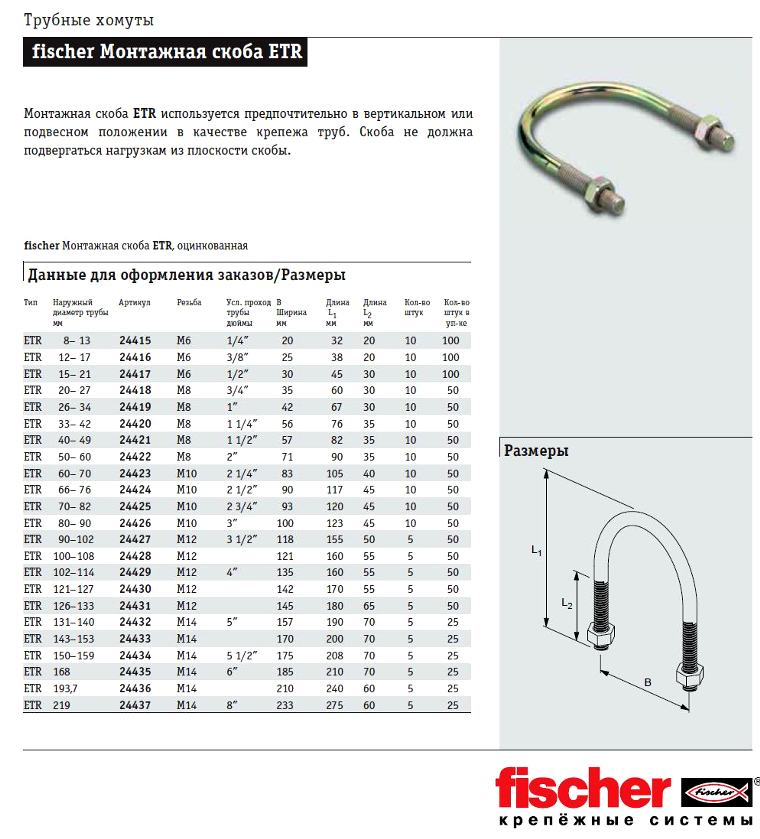

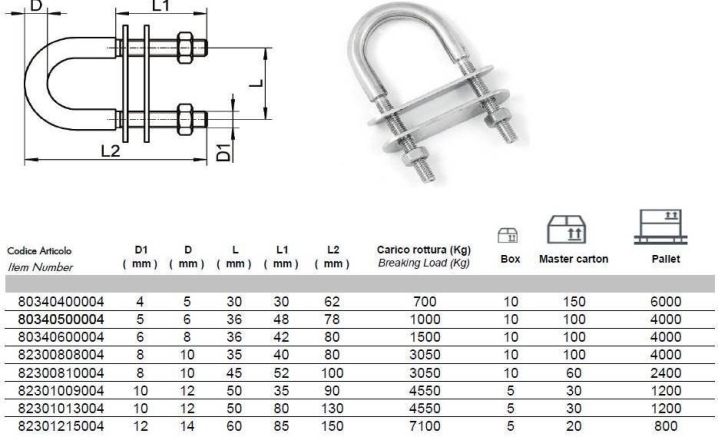

The delivery set usually contains, in addition to the bracket itself, a couple of nuts. The length of the bent rod can vary from 30 to 270 mm. The rod diameter can be 8-24mm. Shipment and daily storage of clamps is possible only in boxes. 1 box contains from 5 to 100 units of finished products.

Clamps are sold by the following leading manufacturers:

-

Fischer;

-

MKT;

-

Golz;

-

Rolltuff;

-

domestic "Energomash".

Differences can also relate to:

-

standard sizes;

-

thickness;

-

dimensions of the connecting nuts;

-

permissible workloads;

-

critical (destructive) load level.

What a U-clamp 115 GOST 24137 looks like, see below.

Steel version for fixing

A steel clamp for fastening pipes is an element of fastening the pipeline network to the foundation, to asbestos-cement pillars, and other structures that perform a load-bearing function. Their advantage is to ensure the immobility of the pipeline during operation.

For the long-term service of the highway, this aspect becomes very important. Plus, drainage networks, fastened with steel or metal elements, have the ability to expand, and this is the main condition for the operation of heating, gas supply and smoke exhaust communications.

Rubberized fasteners made of metal or steel are rigid structures. For these reasons, they are more priority for fastening a pipeline made of copper, cast iron, metal-plastic. The rubber gasket creates a soft and tight joint and protects the line from wear in the fastening areas.

The most popular type of metal for these locking mechanisms is steel. This was facilitated by its high wear-resistant characteristics, thanks to which the service life of the pipeline system is increased.

Products made of galvanized and galvanized steel have increased resistance. They are not afraid of the influence of external irritants and corrosion.

Professionals note that the highest quality in this range belongs to German goods. And the main advantages of metal and steel options for fixing are:

- High level of vibration and thermal insulation.

- Ability to withstand heavy loads.

- High impact resistance.

- Possibility to order a model of the required size at any time.

Fastener parts price

The steel clamp is widely used in the arrangement of pipelines, the price of these devices is affordable and looks like this:

| P / p No. | Product name pipe clamp with nut | Price (in rubles) |

| 1 | 1/4 (11-15) | 9 |

| 2 | 3/8 (16-20) | 10 |

| 3 | 1/2 (20-24) | 10,50 |

| 4 | 3/4 (25-28) | 11 |

| 5 | 1 (32-38) | 12 |

| 6 | 1 1/4 (39-46) | 13 |

| 7 | 1 1/2 (48-53) | 14 |

| 8 | 2 (59 -66) | 15 |

| 9 | At 3 (87-94) | 25 |

| 10 | 4 (107-115) | 30 |

| 11 | 5 (135-143) | 55 |

| 12 | At 6 (162-219) | 60 |

| 13 | At 8 (207-219) | 80 |

The table contained prices for galvanized types, and the cost of stainless steel products is at least twice as high. It should also be added here that the price of these goods is directly dependent on the manufacturer.