Device selection criteria

Several conditions affect the quality of work. To obtain an excellent result, it is necessary to take into account all the properties of the model and select a platform rammer, focusing on the tasks facing the unit.

Mass characteristic

This is the main quality of the vibrator for compacting any surface, which affects the effectiveness of the task.

It is necessary to pay special attention to this when buying or making a homemade vibrating plate. The assembled device with your own hands is often skewed towards one feature, therefore it is necessary to understand all the characteristics of the mechanism

By weight, vibratory rammers are distributed as follows:

- Lightweight models weighing up to 75 kilograms are suitable for working on surfaces with a small (up to 15 centimeters) soil layer thickness: paths in the garden, adjacent territory for laying tiles or rugs.

- Medium with a draft of up to 25 cm is quite versatile. They will cope with light work with equal efficiency, will help when laying asphalt and paving slabs. Their weight is in the range of 75-90 kg.

- At a construction site, when pouring the foundation and strengthening the bottom of the communication ditches, as well as laying several layers of asphalt pavement, medium-heavy vibrators weighing up to 140 kilograms and a compaction depth of up to 60 centimeters are useful.

- Heavy slabs do the same work as the previous ones and weigh over 140 kg.

The balance between the mass of the sole and the power of the power plant is the main thing that affects the performance of the device. The skew towards the gravity of the slab will drown the installation in the ground, the low weight with excessive pressure on the base will not reach the required surface density. The optimal ratio is the ratio of the mass of the plate of 100 kilograms to the drive power of 5 horsepower.

Additional criteria

In addition to the main ones, there are also characteristics that you need to pay attention to. They have no less influence on the efficiency of the work and the control of the mechanism:

- The strength of the vibration.

- Sole dimensions.

- Engine power.

- Type of fuel.

The pressure of the slab per unit area to be treated depends on the size of the base.

The traditional fuel used by vibratory rammers is gasoline, diesel and electricity. All professionals recognize the benefits of a gasoline powered stove. They are unpretentious to working conditions, their cost is in the middle when compared with analogues. Diesel units are the most expensive and noisiest of all. The only advantage is the economical engine. An electric tool is the cheapest, it does not lag behind gasoline tools in performance, but it is tied to the power grid.

The traditional fuel used by vibratory rammers is gasoline, diesel and electricity. All professionals recognize the benefits of a gasoline powered stove. They are unpretentious to working conditions, their cost is in the middle when compared with analogues. Diesel units are the most expensive and noisiest of all. The only advantage is the economical engine. An electric tool is the cheapest, it does not lag behind gasoline tools in performance, but it is tied to the power grid.

Lightweight vibrators have the most balanced power. The range of works performed by them does not imply serious characteristics for technology. The motor with the power to match the type of work and the weight of the sole will drive by itself, and the operator will only have to set the direction.

Useful functions

All vibration installations have additional devices that facilitate work or provide additional protection. In order to move the machine to a new place of work, the presence of wheels and a foldable handle will make this task easy to do.

Various covers will protect the machine from the ingress of particles of the compacted surface. The plate wetting system is effective when rolling hot asphalt. Without it, it will stick to the top layer.

Strengthening the bottom in trenches or compacting the soil in narrow places is almost impossible without providing reverse motion.

Appointment of vibrating plates

A similar mechanism is used for compaction of crumbly land and building materials, as well as non-hardened asphalt and concrete surfaces. It is especially effective on small areas and sidewalks, as well as where the entry of heavy equipment is inaccessible.

The use of this device will greatly facilitate manual labor in household or suburban landscape construction. It is easiest to compact the soil on a garden path or a small car park near the house using a mechanized method.

The ramming vibrodynamic will also help out during excavation work on the laying of underground utilities, when you need to ram the soil at the bottom of the trench.

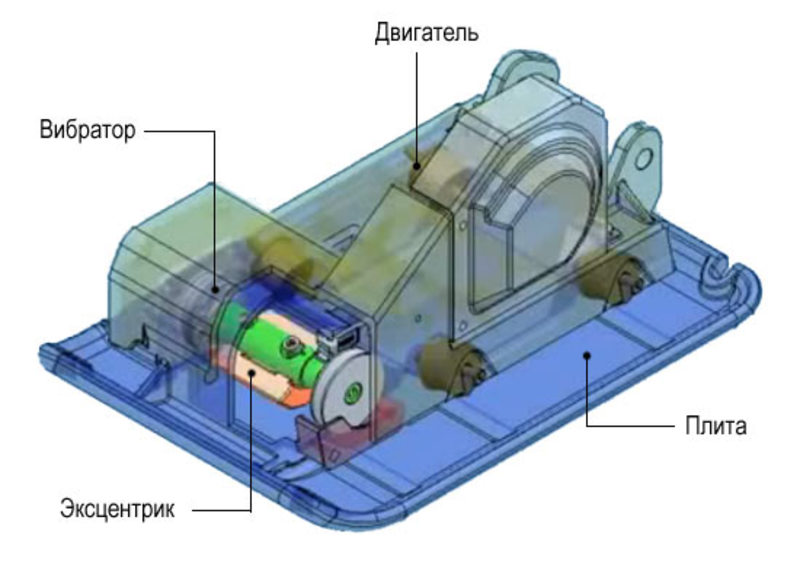

This device functions due to vibrations arising from the rotation of the flywheel fixed on the eccentrics:

- The vibration generated by the displaced ballast is transmitted through the drive to the iron base - the sole.

- The heavier it is, the stronger the oscillatory process and the denser the rammer.

Benefits of Sand Cushion Buildings

Among the many advantages that are worth noting when using sand cushion technology, it is almost impossible to distinguish major and minor ones. Each feature taken separately makes its own unique contribution to the strength and reliability of the entire structure. The first and obvious advantage of the sand cushion is its cheapness and simplicity of all work on the device, which will take a minimum amount of time.

A house with such a foundation can be built on almost any soil - weak, watery or heaving. At the same time, the service life of the building can be significantly increased if high-quality geotextiles are located under the pillow, and a high-quality drainage system is provided on the very site where construction is underway. As a result of this, such frequent problems with a new home will be excluded, such as:

- the formation of cracks in the walls and the foundation itself, caused by uneven shrinkage of the building;

- freezing of the foundation and, as a result, an increase in the cost of heating the house;

- accumulation of water in the basement, often observed in houses that are located in areas with high groundwater levels, especially in the spring;

- constantly high humidity, which is noted throughout the house, and not only in the basement, which leads to the formation of mold, damage to furniture, the appearance of various allergic reactions in residents;

- the need to install a serious supply and exhaust ventilation system, the costs of the device and the operation of which can be quite decent amounts.

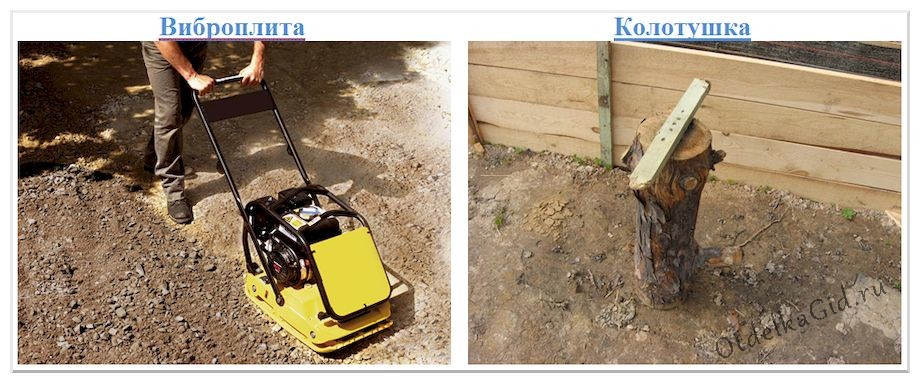

Tamping accessories

Made of metal, it weighs from 5 to 10 kg. It consists of a handle and a base ("paw") - a plate approximately 20 x 25 cm in size or a channel (the smaller the dimensions of this part of the device, the greater the impact force). The handle of the tool is straight (in the form of a tube) or T-shaped, with two handles on the sides. If necessary, the manual rammer with a channel can be made heavier by filling it with cement.

If there is a need to save money, then it is easy to make the device yourself. Two manufacturing options:

- Make a handle from a heavy wooden bar about 1 m long and nail a "paw" from a solid board to it from below.

- Buy a separate ready-made plate (it costs about 1000 rubles) and put it on a shovel handle or a metal stick.

For compaction of soil and bulk materials, including sand, in a confined space, use a "vibro-leg". The engine of this device runs on gasoline or diesel fuel. At the base of the apparatus there is a “heel” plate with a width of 15 to 30 cm and a length of about 33 cm. Vibratory rammers also differ in power.The principle of operation is based on vertically directed force, like a hand-held device, but the efficiency is much greater. This type of equipment is used on sites where operation of large-sized equipment is impossible: vibratory plates and vibratory rollers.

For work on a large area, subject to the possibility of free movement, a rammer using a vibrating plate is suitable. This apparatus consists of a motor, a basket with a central shaft, a "heel" or "shoe" and a guide handle. The unit moves back and forth, transmitting strong mechanical vibration (vibration) to the sand particles, due to which compaction occurs.

Types of equipment for soil and bulk materials with a slab base:

- gasoline;

- diesel;

- hydraulic;

- electrical;

- with remote control.

Vibratory plates vary in weight. The lightest are suitable for sand.

For the largest volumes of work, vibratory rollers are used. Their types:

- with manual control due to the guiding handle;

- self-propelled with a cab for the operator single-drum (rear wheel-mounted);

- with two-drum cab;

- trench with remote control.

The device of a high-quality vibratory roller allows compaction along the edges of the site, that is, the use of additional equipment (manual or vibratory ramming) is not required.

The price of the services of professional builders for compaction of sandy soil or sand bedding is from 90 to 600 rubles per m2. If the area that needs to be tamped is large, or we are talking about permanent work, then you need to compare these prices with the cost of equipment. In many cases, it is advisable to purchase a device or rent it and do it yourself.

| Type of device | Price, rubles |

| Manual rammer with straight handle and base plate | 1800 |

| Manual with T-handle and channel base | 2800 |

| Vibrating rammer | 27 500 |

| Vibrating plate | 21 000 |

| Vibratory roller manual | 270 000 |

| Vibratory roller with control cabin | 2 000 000 |

Depending on the type of equipment, either a vertically directed force of impacts or vibration transmitted from the roller shaft or the base of the plate acts. In any case, the technology does not include any secrets and complexities.

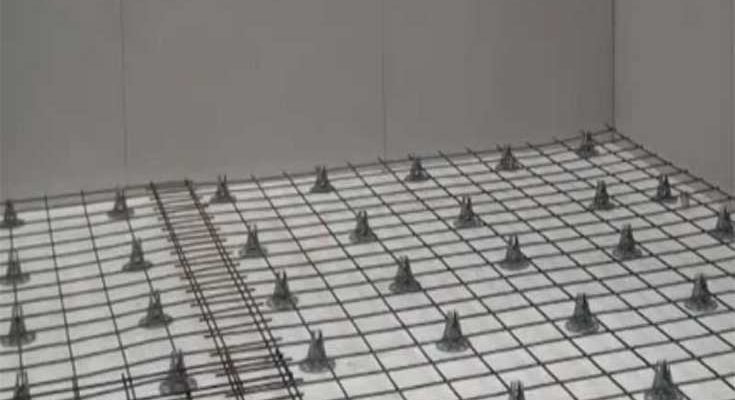

In the first part I talked about the construction of floors on the ground, now I will move on to the practical part of the implementation of floors on the ground in a private house.

Features of an independent device of a sand cushion

Before starting work, it is necessary to determine several points on which the quality of the resulting base directly depends:

- the thickness of the pillow must be at least 200 mm;

- the most successful option is the trapezoidal shape of the pillow;

- the optimal base thickness is considered to be a value that does not exceed the width of the foundation by more than 3 times.

Installation of a pillow under the foundation

All work on the installation of a sand cushion can be divided into several main stages.

- Careful marking of the site, carried out in accordance with the selected parameters of the foundation. All measurements and marks should be verified as accurately as possible, using a tape measure and a building level.

- In exact accordance with the outlined lines, a foundation pit or trench is dug to a depth slightly exceeding the freezing point of the soil.

- It is imperative to level the bottom of the trench or foundation pit and compact it as much as possible.

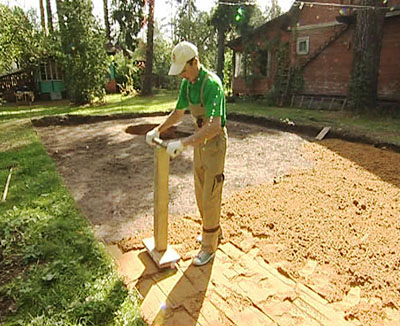

- Sand is poured in "thin" layers, while the width of each of them should not be more than 20 cm in width.

- Before tamping the sand, it must be moistened with water, however, avoiding excessive moisture. You can check the "readiness" in a simple way - it will not be possible to blind a lump from the optimally moistened sand.

-

Each layer is compacted separately. When performing work in the summer at high ambient temperatures, it is necessary to constantly moisten the layers of sand, since moisture evaporates from it quickly enough.

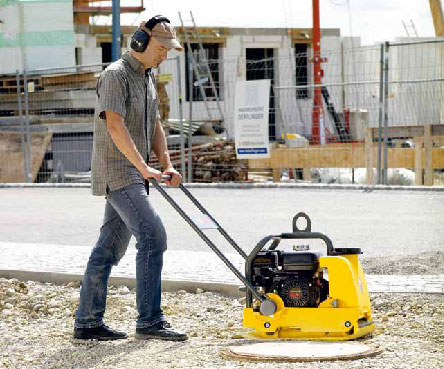

- In order for the tamping of sand for the foundation to be of high quality, it is best to use a special vibrating plate. Since its cost is quite high, and its scope is limited, it will be most convenient to rent it.

- In the event that the use of such a tool for some reason is difficult or impossible (lack of power supply, for example), manual ramming with your own hands can also be carried out using homemade devices. For example, you can attach side handles to a round bar (log), and roll each layer of poured sand.

It should be borne in mind that if you provide for the presence of special drainage in heaving soil, this will exclude the possibility of flooding the sand cushion with water in the off-season, which directly affects the durability of the foundation and the entire structure as a whole.

Sand cushion under the foundation - when you need it

Before starting construction, it is necessary to assess not only the condition of the soil in the area of \ u200b \ u200bthe construction of the house (bearing capacity, proximity of underwater waters), but also the climate conditions, as well as the total weight of the structure. Heaving soil is compulsorily rammed, which is significantly deformed during freezing and thawing. If you make a mistake with the choice of material for installing a slab under the foundation, most likely the building will shrink heavily, which will entail the formation of cracks in the walls and the foundation itself. In addition, if the soil in the construction area has a high bearing capacity, and the water table is extremely low, you can do without creating a sand cushion.

Of all the materials that are used to create a pillow, it is sand that is most acceptable. It not only allows you to save a decent amount, compared to a slab of crushed stone or concrete, in addition, it is quite acceptable to tamp sand with your own hands - for example, it is much more difficult to work with crushed stone. There is only one limitation on the construction of a sand cushion - heavy buildings (apartment buildings, shopping centers) cannot be built on it, but for private low-rise construction, it is almost an ideal material.

Sand pillow

A properly designed sand cushion has many benefits:

The base created with sand fully complies with all standards used in low-rise construction.

Complete protection of the entire building from the negative effects of groundwater.

Creation of a perfectly flat construction site without the use of complex and expensive technologies.

The ability to carry out all work on your own.

Quite affordable cost of this important stage of work.

Safety at work

The compaction of the soil with a vibrating plate must be carried out in compliance with safety precautions. Among the many recommendations, the following basic rules can be distinguished.

- During work, it is necessary to apply individual protection means

: Appropriate clothing and footwear, glasses, headphones, headwear. - Before starting operation, you need to check the used equipment for external damage: if any, then they must first be repaired.

- It is forbidden to leave the operating equipment unattended, while the operator must be located behind him and move behind the machine in a timely manner.

- A break of about 10 minutes should be organized every 40 minutes to prevent operator fatigue.

- It is impossible to further accelerate the mechanism by applying additional efforts.

- If you need to work on an inclined surface

(when the angle does not exceed the norm), the maintenance personnel must stand above the unit, moving from top to bottom. - It is forbidden to operate the technical device near sources of explosive or flammable materials.

- At overturning vibratory plate

, it should be turned off first, and only then put into working position. - It is worth deploying the unit with one hand.

- To prevent injury, keep your feet and hands away from the working sole of the plate.

- In the event of a collision with any obstacle, you need to stop the unit, and then remove the obstacle and possible breakdowns caused by it.

- From the edges of trenches, pits, ravines and other recesses, it is required to be no closer than at the minimum permissible distance, but better - further away.

- It is strictly forbidden to allow people under the influence of drugs, alcohol, psychotropic drugs to work.

It should be borne in mind that the higher the center of gravity of the vibration equipment (and the smaller the support area), the easier it can turn over.

It is very dangerous for the operator.

Also, be very careful when turning on appliances that are not equipped with a soft start function.

The use of a vibrating plate is required when carrying out all construction activities that are associated with the compaction of loose soils. It is imperative to take into account the features of the rammed materials in order to achieve a quality result. It is necessary that the maximum depth of the poured layer corresponds to the thickness that the operating unit is capable of tamping. In any case, safety must come first. Failure to follow simple rules, coupled with carelessness, can lead to serious injury.

To give the building maximum stability, you need to carefully tamp the sand at the base of the foundation - this will protect the building from water and shrinkage.

Such a pillow can be made of concrete or rubble, but most builders choose sand.

High-quality compaction of sand is a guarantee of a durable base.

Before the start of tamping, the thickness of the future cushion is determined, which will be necessary for the foundation of the building. The sand layer can be from 10 to 30 mm, but this factor completely depends on the mass of the future building - the more weight, the thicker the layer should be. If the sand base is for a road or site, the thickness should be about 150 mm.

Homemade vibrating plate

Factory ramming settings cost a lot. Therefore, some craftsmen prefer to make a vibration compactor on their own. This process will require welding skills and a small set of tools.

Homemade advantages

The cost of a self-made device is much lower than that of ready-made equipment. In appearance, it resembles a walk-behind tractor with a vibration motor. Quality and durability are ensured by simplicity of design. The efficiency of such a vibrator is not lower than that of a purchased one, and sometimes even higher. Advantages of a homemade vibrating plate:

- Full compliance with the working conditions for which it was made, allows you to perform the assigned functions with high quality.

- The owner chooses himself which vibrating plate to make: with an electric motor or internal combustion engine.

- Everyone is also concerned about their own safety on their own. Therefore, all the necessary protection systems will be provided and installed.

- Having your own device will allow you to choose the time and place of work according to your circumstances.

Traction device selection

First of all, it is necessary to decide the question of which type of fuel to prefer. It can be a 220 V vibrating plate made by hand, but its use will be limited. The diesel engine is too noisy and heavy, so it is preferable to stay with a gasoline engine. Such a drive will allow compaction of earth, sand, bulk building materials, tiles and asphalt pavements.

A single or two cylinder engine is suitable to ensure acceptable seal quality. There are many of them on the market. In the more expensive category, the most popular are models from Honda and Kipor, as well as the cheaper Lifan, DDE and Champion.

Materials and fixtures

Everything you need to build a gasoline powered vibratory plate is usually available nearby or inexpensively purchased on the market. Materials to be used:

- Gasoline engine.

- A metal sheet measuring 0, 80 by 0, 45 meters and a thickness of 8-0 millimeters.

- Two pieces of channel.

- 4 bolts 12.

- Grip tube - fits to the palm of your hand.

- Shock absorbers from a car engine.

- 2 wheels.

As a last resort, there is such a service as tool rental. Renting the necessary equipment will be inexpensive. Accessories required for work:

- Welding machine and electrodes.

- LBM and discs to it.

- Drilling device (drill or machine).

- A hammer or small sledgehammer.

- Ruler, chalk or scribe, tape measure.

- Protective equipment: welder's mask, goggles, gloves.

Vibrating table manufacturing

First of all, the working platform is made. The edges of the sheet metal must be folded 30 to 40 degrees relative to the ground. To do this, the surface of the plate must be filed 10 centimeters from the edge, no more than half its thickness deep. Then bend along the notch line with a hammer. The seams at the folds must be welded for rigid fixation. Such a sole design will allow the future vibratory plate to slide over the surface, and not bury itself in it.

The most crucial moment is the welding of the channels to the sole. They need to be measured exactly according to the size of the plate and welded, focusing on the center - so that there are 70—00 millimeters between them. To prevent the stove from leading, the material to be welded should not be overheated. For fastening, it is necessary to mark the channel according to the motor mount. You can simply attach it to the channel runners and mark the points with chalk or a marker. You can also measure these distances with a tape measure. After drilling the hole, the motor is put in place and bolted in place.

Peculiarities

Mechanized soil placement is not always possible. Before proceeding with the manufacture of a rammer, you should study the features of the tool's operation with crushed stone and sand. Novice builders do not always understand why it is necessary to tamp crushed stone, but there are several nuances here.

- Due to the fact that crushed stone is obtained by crushing larger stones, the resulting particles have different shapes and sizes. In this regard, in the process of laying the underlying layer, there is a loose fit of the elements to each other. Thus, to achieve the required layer strength, one more tamping is required.

- When compaction is completed, the thickness of the paved rubble decreases. The preliminary thickness of such a base is determined by calculation, which takes into account the required loads.

- Compaction of crushed stone gives a more durable base that can withstand impressive loads. It is interesting that in the case of laying the material on rocky ground, tamping is not required - it is enough to level the gravel in places inaccessible for tamping.

Additionally, in the process of processing crushed stone material, ripping should be carried out - dividing the gravel into fractions. To do this, you will first need to lay out a layer of larger stones and tamp it manually, then - the material of the middle fraction, which will also need to be compacted. The topmost crushed stone layer should include fine particles. It needs to be leveled and walked with a tamper.

As for the features of using a rammer to compact sand, the procedure has a number of nuances that must be taken into account. To organize a strong and durable base, it is recommended to use a gravel type material of medium or fine fraction. However, when erecting a monolithic structure, it is worth choosing river sand, which subsequently will also need to be tamped.

In order to prevent erosion of the future base, it is necessary to lay out the bottom with geotextiles before filling the sand.The sand itself needs to be sieved to get rid of impurities that can negatively affect the composition of the base.

Buying a unit

If, nevertheless, a decision is made to purchase a unit, it is necessary to take into account both the main criteria and minor nuances that will facilitate the work or increase its service life. However, one cannot fail to mention the manufacturers of vibratory rammers.

On a special account, equipment from European manufacturers. German technology is distinguished by its reliability and long service life. Even rolling samples show good quality and pace of work. All equipment has a double safety factor. Wacker, Weber, Ammann, Bomag produce professional equipment.

Israeli Shatal and Czech NTC have less resource than the Germans, but they also turn out to be good workers at construction sites and in private estates.

The South Korean technique each Jeonil Minery is not inferior to the products from the Czech Republic or Israel. In the Asian market, this is the best offer among all vibrators.

Russian products from Splitstone, Motorprom and SZPO companies are inferior to the average European models in terms of convenience and functionality. However, the modernization continues, and new, more advanced models appear on the market.

The Chinese, as usual, take the price. Their products are only suitable for occasional, relaxed work. Among the mass of unknown manufacturers, TEKPACK, MASALTA, DYNAMIC, CIMAR stand out.

Vibratory plates

Vibratory plate is a surface vibratory soil compactor designed for ramming incoherent or poorly cohesive soils and dumps of small thickness - from 10 to 30 cm. Vibratory plates of various capacities compact sand, gravel and crushed stone, as well as paving slabs and asphalt. The vibratory plate for soil compaction copes with ramming areas with a slope, where it is difficult or impossible to use a large-sized roller. Vibratory plates are rightfully in greatest demand among developers and are gradually replacing vibratory rollers.

Healthy! Sometimes the not quite correct name is attributed to vibrating plates - a surface vibrator. This misunderstanding is due to the fact that the operation of the surface vibrator resembles the compaction of sand with a vibrating plate. However, it has a different field of application - the compaction of thin-layer concrete fill in monolithic construction. A surface vibrator is sometimes used to make homemade vibrating plates.

The quality of compaction depends on the level of soil moisture: with sufficient indicators, the soil becomes plastic and the compaction process is faster. If there is a lack of moisture, the rammed layer is additionally spilled with water, if there is an excess of it, they wait for drying. The humidity level is controlled by an electronic moisture meter.

| Soil type | Moisture level at maximum compaction,% |

|---|---|

| Sandy | 8 – 14 |

| Sandy loam | 9 – 15 |

| Loamy | 12 – 18 |

| Clayey | 16 – 26 |

Healthy! When ramming loamy and sandy loamy bases with a vibrating plate, additional wetting of the working plate of the device is necessary to protect against soil adhesion.

The structure and principle of operation of the vibrating plate

The vibrating plate is equipped with an electromechanical eccentric, inside which unbalanced masses create mechanical vibrations. With the help of a belt drive, torque is transmitted from the engine to the eccentric shaft. The vibrations propagate to a metal plate (plate) that is in direct contact with the ground surface and causes it to vibrate. For convenience, the vibratory plate device has a handle for the operator.

Varieties of vibrating plates

Vibratory plates are classified by weight into:

- lightweight (up to 75 kg) - designed for landscaping and finishing works, effectively compacting a layer of soil 10-15 cm thick;

- medium weight (from 90 to 140 kg) - provide processing thickness up to 35 cm; designed for layer-by-layer compaction;

- heavy (from 200 kg) - used as an alternative to vibratory rollers;

- universal (75-90 kg).

Depending on the type of engine, the compaction plate can be diesel, electric or gasoline.

The most popular are gasoline models. They are economical and provide freedom of movement around the site and the ability to work at subzero temperatures.

Diesel vibratory plates are reliable and durable. Like gasoline, they are independent of the power source. Disadvantages are due to heavy weight, high noise levels and difficult work in frosty weather.

Electric vibratory plates limit the working area to the length of the power cable, but are the most environmentally friendly. They are used in closed rooms with limited access to fresh air, where the use of gasoline models is unacceptable due to the risk of poisoning from exhaust gases.

According to the method of movement, vibratory plates are divided into:

Reversible. Such models are more maneuverable, but they are distinguished by their high price and high weight. As a rule, they are equipped with a diesel engine. The advantage of reversible vibrating plates is the possibility of reverse movement without turning the equipment. Therefore, they are indispensable for compacting sand and bulk soil in narrow trenches.

The performance of vibrating plates is determined by:

- base area;

- operating frequency;

- vibration force;

- engine displacement (for gasoline and diesel cars).

Sand Compaction Features

Do-it-yourself ramming of sand has some nuances that should be considered when creating a solid foundation for a concrete slab.

First of all, it is worth deciding on the type of sand that is best suited for these purposes. It is better to use gravelly material, however, it is not recommended to fill up fine sand for tamping. The larger the grains, the more compressive strength the base will have, so that shrinkage of the future house or parking area can be avoided.

If you plan to build a monolithic structure, then it is best to give preference to river or quarry sand of the middle fraction. However, even in this case, the underlying layer will be influenced by groundwater. Therefore, in order to prevent the process of erosion of the base, it is necessary to lay geotextiles at the bottom of the trench, and only then fill up the sand.

In addition, before filling the sand, it must be sieved, since the presence of impurities (especially clay) can affect its properties. Monitor the moisture level of the material, the ideal consistency will be if a small ball can be rolled out of the sand, which does not immediately crumble. Accordingly, the moisture content of the sand should be in the range of 8-14%.

Accordingly, 50% of the successful laying of a gravel-sand bed depends on the material itself, the remaining 50% falls on the equipment. As mentioned earlier, specialized machines can be used for these purposes, but it is much cheaper to make a manual rammer yourself.

Tamping rules with a vibrating plate

The ramming of soil, sand, gravel or crushed stone has its own characteristics, which are associated with the properties of these materials. If they are not taken into account, then it will not be possible to qualitatively compact the poured layer, which will further affect the durability of the erected structure.

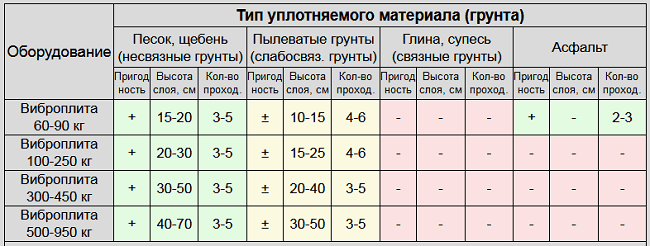

Vibratory plates are divided into several groups by weight. The greater the weight of the unit, the thicker the layer of poured bulk material can be tamped with it.

Getting started, you should take into account such nuances.

-

Light equipment

(weighing up to 75 kg) can increase the density of a layer 15 cm thick, therefore it is widely used in landscape work and when laying paving slabs. -

Universal models

technicians (weighing 75-90 kg) can already tamp 25 cm of the poured material. They are used for paving asphalt, as well as for partial road repairs. -

Medium-weight aggregates

(weighing 90-140 kg) are designed to work with layers up to 60 cm thick.With their help, they carry out the compaction of backfilling of trenches and pits, as well as the construction of road embankments. -

Heavy vibration equipment

(weighing more than 140 kg) are used to perform the same working operations as medium-heavy equipment.

The table shows that loosely bound soils

(dust) it is more efficient to compact with vibration equipment weighing from 300 to 950 kg.

When working with a vibrating plate, the following general tips should be followed:

- it is necessary to take into account the characteristics of the surfaces to be tamped;

- it is impossible to skip certain sections;

- the optimal number of passes by the slab is from 4 to 6;

- the maximum layer thickness should correspond to the capabilities of the technique used;

- the surface of the prepared site should not have drops exceeding 2 cm;

- each layer of the multi-layer pad is sealed separately;

- it is necessary that the building materials used correspond in their properties to GOST.

As for how many revolutions should be on the vibrating plate, here is the following pattern: the higher the frequency, the more convenient it is to work with fine-grained soils.

So, for example, for compacting crushed stone or gravel with the size of individual stones up to 10 mm (or less), as well as sand, equipment with 6000 rpm is well suited. If the stone is 6 cm in size, then you can use a device with 3000 rpm.