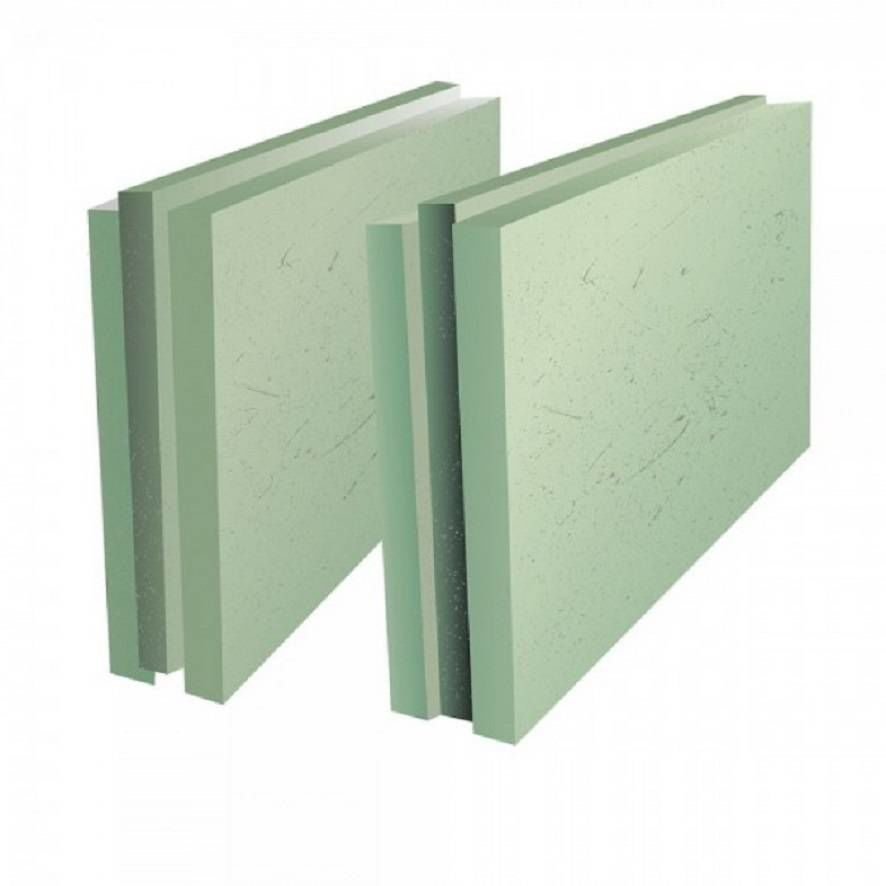

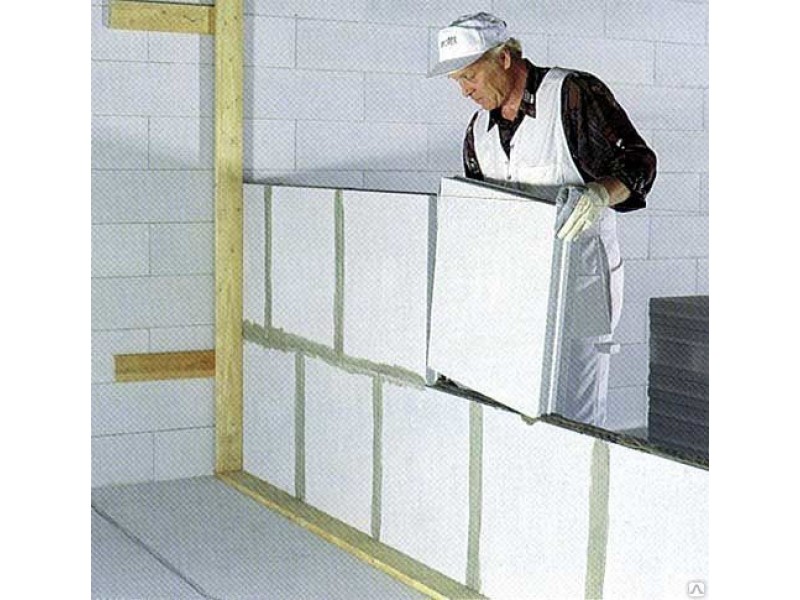

Varieties of tongue-and-groove blocks

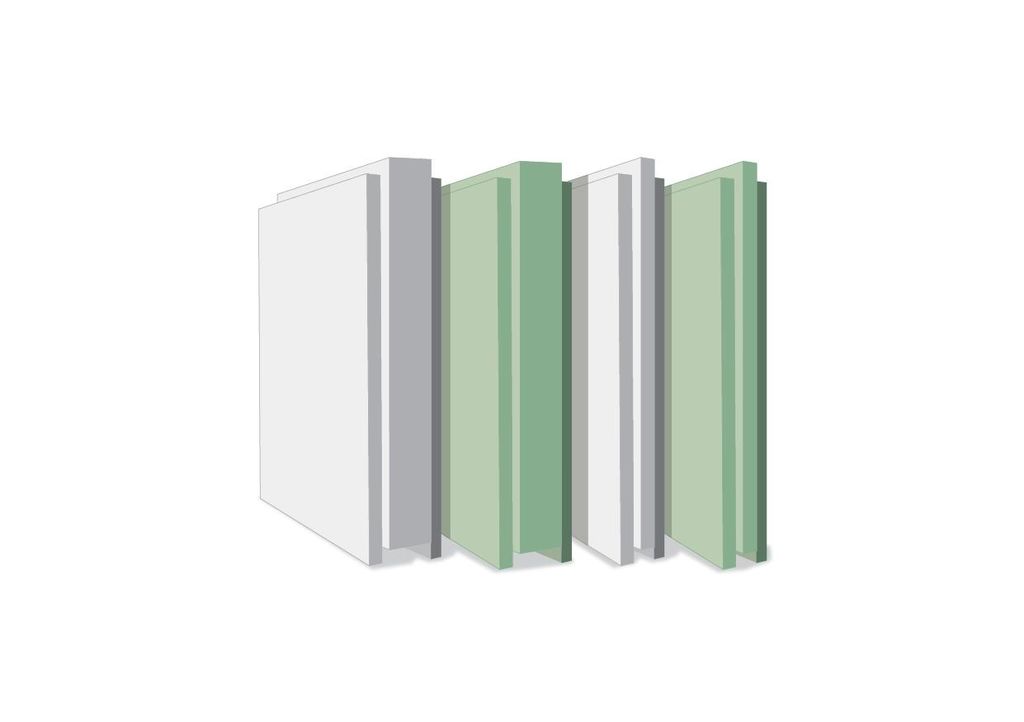

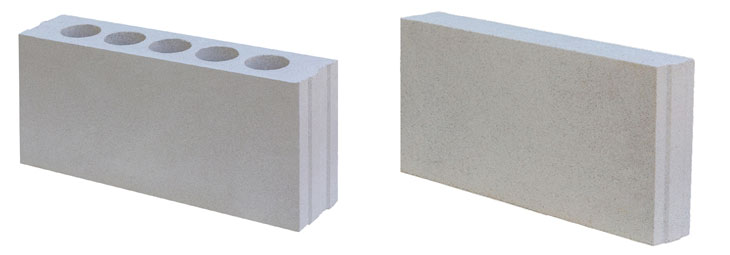

Conditionally, tongue-and-groove slabs can be divided into hollow and

full-bodied. It should be noted that the weight of hollow blocks is 25% less, and in

therefore, the soundproofing characteristics are lower. Hollow structures

used in the construction of partitions for residential premises of apartments and houses. What

concerns corpulent, then they are correctly used for the construction

partitions in production halls and public buildings.

@PGP

@PGP

Also, products can

be standard and hydrophobic. Standard type constructions are not

recommended for use in the manufacture of partitions in damp rooms.

For these purposes, you need to use hydrophobized ones. In addition, there is also

shungite blocks made of coal, the color of such products is black.

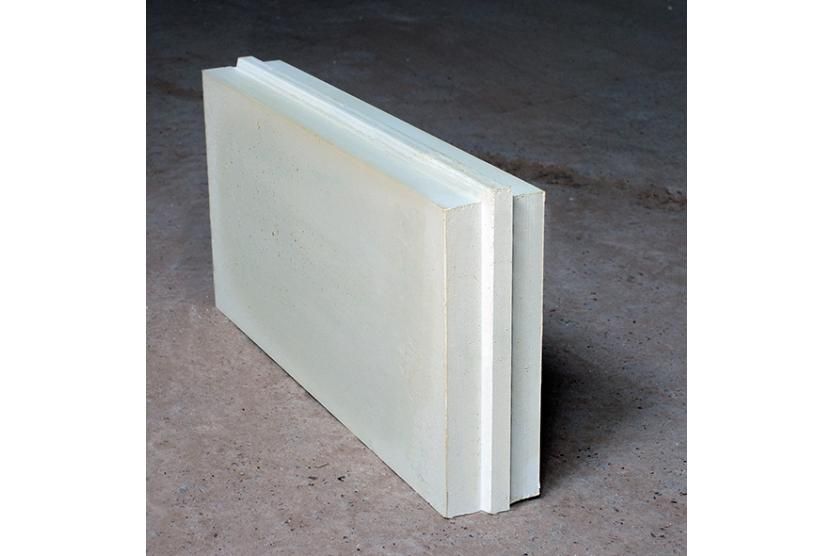

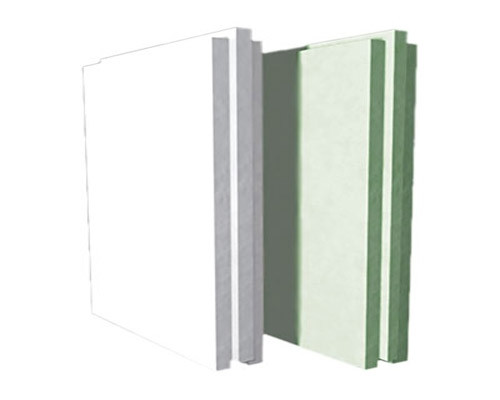

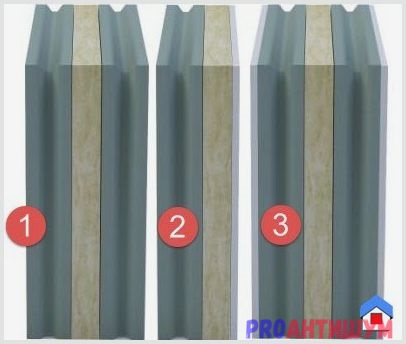

To improve the soundproofing qualities of partitions made of GWP

install a double structure. A double wall is made with emptiness

in the middle, and is filled with soundproof materials, in particular, cotton wool.

Also, in this design, you can hide communications and cables.

Advantages and disadvantages of GKL partitions

Among the positive qualities of this material for creating interior partitions, the following can be distinguished:

Light weight - this quality is especially important when constructing partitions in multi-storey buildings

Easy assembly - DIY installation of drywall partitions can be done by people who do not have special education and construction skills

Low cost - the construction of plasterboard structures will cost significantly less than the installation of a conventional brick partition. The production of gypsum plasterboards is a fairly cheap process, so the retail cost of the material is also not too high.

High thermal insulation - the construction of walls can be carried out without the use of additional insulation

Small size of the area - the thickness of the drywall sheet for the partition usually does not exceed 12 mm, so such a wall will "eat" a very small area

Environmental friendliness - the building material does not contain any harmful impurities

Laying of communications - the width of the plasterboard wall allows you to place electrical cables in the cavity between the sheets

Installation of arches - the material bends easily, so it will be possible to easily make both a rectilinear partition and curved structures, and the doorway to the room can also be made in the form of an arch

With the help of this material, you can assemble a structure of the most bizarre and non-standard type.

The disadvantages of plasterboard partitions include:

Low mechanical strength of the structure - a wall made of this material is not able to withstand excessive loads and can be significantly damaged if furniture falls or when bulky objects are carelessly moved

Low moisture resistance - even special moisture resistant drywall should not be exposed to direct liquid

Poor sound insulation - gypsum plasterboard is a poor barrier to the propagation of a sound wave

As you can see, there are not so many drawbacks of this material, and if it is necessary to fence off a room in which the air humidity is low, and to fix a mineral sound-absorbing mat between the sheets of gypsum board for its sound insulation, then during the operation of the partition, only its fragility will be the only drawback.If a decision is made to use this material, then before proceeding with the manufacture of a drywall partition with your own hands, the step-by-step installation instructions for which will necessarily be described in this article, it is recommended first of all to purchase the necessary materials and tools.

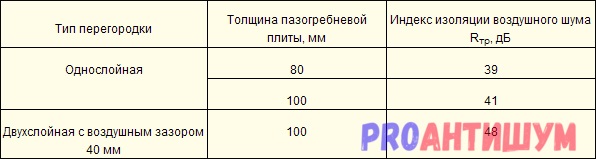

Sound insulation of tongue-and-groove plaster partition

When a major overhaul with installation is planned in the apartment

interior partition, then most people prefer inexpensive

building materials, these include tongue-and-groove plates. These products are easy to

installation, have a low weight and their cost is quite acceptable. The only one

the disadvantage is poor sound insulation. To maximize the partition

effectively kept extraneous sounds, it must initially be correctly erected

taking into account sound insulation.

@PGP

@PGP

As you know, to provide coziness and comfort in an apartment can

noise insulation, while not one surface, but completely walls, ceiling and floors.

It is worth noting that the construction of a partition from PPG should be done only

after the floor and ceiling work has been completed. The thing is that

the partition, even if it is not a carrier, can

transmit vibrations and structure-borne noise. To exclude this possibility, initially

complete insulation of the ceiling and floors is made.

For the floor, a floating floor will be the optimal solution, so that it will be possible to protect the flooring from unnecessary vibration. Installation of GWP plates is carried out in such a way that the blocks at the top do not fit tightly to the ceiling. If you make a rigid screed, you can forget about the soundproofing of the partition. Some people use polyurethane foam to blow in the upper space, but in fact, this is not correct.

Construction foam becomes hard when it dries, so all vibrations will be transmitted to the partition, if used, then special soundproof materials. Alternatively, you can put mineral wool in the opening and cover with a sealant that will keep vibration.

Sound insulating properties of GWP

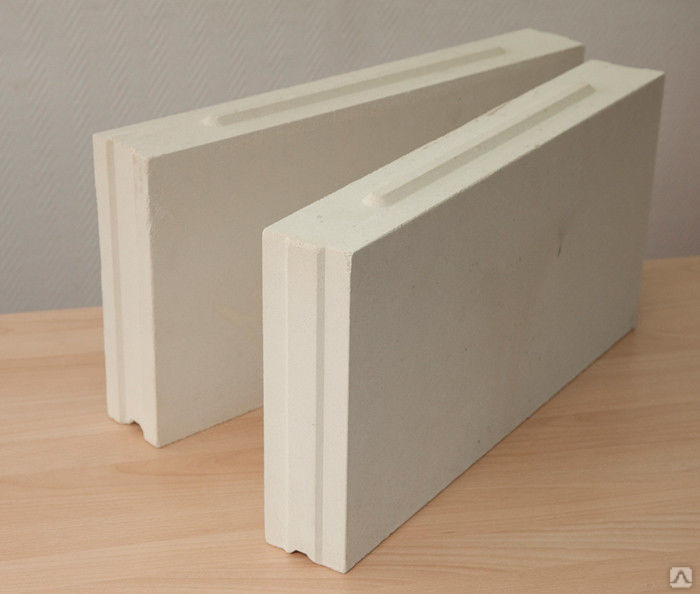

Today, two types of GWP are used in construction.

slabs: gypsum and silicate. As for the former, they are made by casting

from plaster and special additives. Due to the production technology of the product

get the correct shape with grooves. Slabs are also made from quicklime lump

lime, sand and other additives for pressing technology. It should be noted that

in gypsum structures, heat and sound insulation indicators are slightly higher than in

silicate blocks.

@PGP

@PGP

Both materials

are made on the basis of environmentally friendly materials, due to which they are widely

used in frequent construction, and in particular for the construction of interroom

partitions. Also, the features of the building material include incombustibility.

products and hypoallergenic characteristics. If you install a partition from

tongue-and-groove plates, then it is imperative to do an additional

noise isolation, since the degree of retention of sound waves is only 41

decibel.

Installation features

There are certain requirements when working with

tongue-and-groove structures and should not be forgotten.

- Work

with PGP plates is needed before finishing work and the manufacture of a floor

cover. - Air

in the room planned for the construction of the partition should not be lower than five

degrees Celcius. - Front

how to start the installation of blocks, it is necessary to initially treat them with a primer,

to improve the performance of the product.

As for the installation works themselves, they provide

certain milestone activities, which consist of:

- preparatory work;

- main;

- final.

At the preparation stage, it is necessary to clean the surfaces from

dirt and dust, and if necessary, you can make a screed on the floor. After drying

marking of the future partition is done

It is important to initially indicate in the markup where

there will be an entrance and an approximate place of passage of communications and wiring

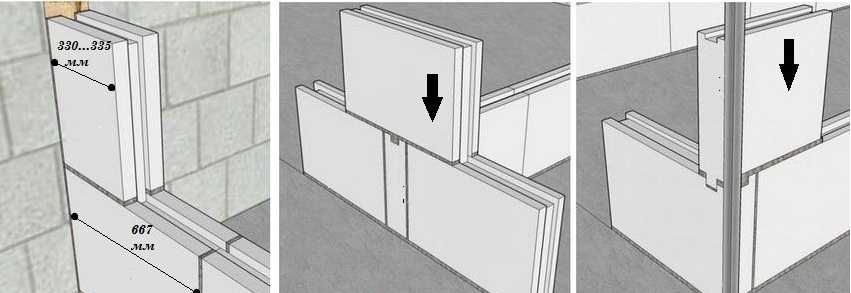

@PGP

@PGP

The main stage of work involves gluing the gasket

along the entire perimeter of the proposed partition. The gasket is glued to the ceiling,

wall and floor. Only after the glue has completely dried can you begin to install

blocks for glue.

The shrinkage of the slab is done with a rubber mallet to

the structure did not collapse from the impact. So that the plates lay down correctly and evenly when

building level assistance, measurements and exposures are made. Blocky

the structure must be flat both vertically and horizontally. If during

work, it is necessary to cut off part of the product for this you will need an ordinary manual

a hacksaw that easily copes with the task.

Selection Tips

Some suppliers sell small-sized tongue-and-groove blocks. They are lighter than full-size ones, which makes it easier to work with. However, the problem is that the groove / ridge may be missing on horizontal surfaces

It is imperative to also take into account the level of thermal conductivity. Regardless of the manufacturer's promises, an additional noise-absorbing layer is required

For baths and other humid rooms, it is recommended to purchase a solid slab with increased resistance to moisture, that is, any silicate modification. If possible, you should choose lighter versions (each manufacturer offers its own versions with different weights). It is required to carefully check the certificate. Finally, you should definitely read the reviews.

Good products are supplied by:

- Knauf;

- "Magma";

- EKO (Yaroslavl);

- KZSM.

Silicate or gypsum?

If we compare the sound insulation characteristics of gypsum blocks and silicate blocks, the latter, with equal parameters, conduct sounds worse (40-43 dB for gypsum blocks and 48-52 dB for silicate ones). So we choose silicate for better sound insulation.

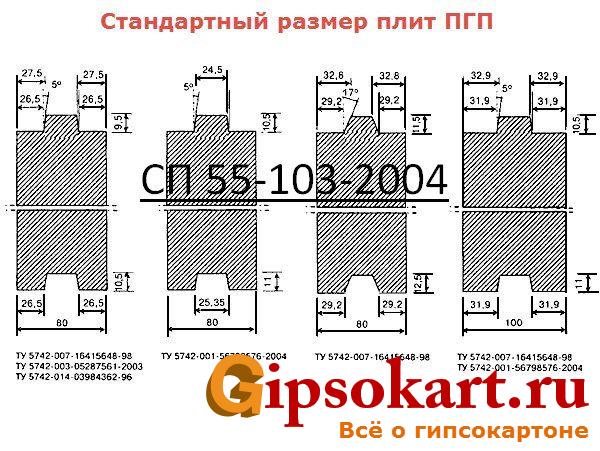

Dimensions according to GOST and TU

But silicate blocks of the same size have more weight and higher thermal conductivity (they conduct heat better). The key in the choice is weight, since sound and thermal insulation can be improved with the help of additional layers of special materials, but there is no way to reduce the weight of the partition. And if its mass is critical for overlap, nothing good can be expected.

Installation rules

The most important requirement in preparation for the installation of the tongue-and-groove plate is a perfectly leveled platform. Even small slopes are unacceptable, because because of them, the structure may crack. Sound insulation can be increased by laying down a damping tape based on polyethylene foam at the very bottom. The same tape is placed in the gaps separating the slab from the main part of the building. Panels, like bricks, are laid with a bandage. It is absolutely impossible to combine vertical seams! Hand sawing is practiced only for small amounts of work. More large-scale construction already requires mechanization. The saw cut provokes the release of a mass of dust. Therefore, such work is more correct to perform on the street.

You can connect the silicate plate with the capital part of the building using self-tapping screws and metal corners. The connection with steel plates helps to increase the rigidity. They are placed every 2 panels. The installation points of the door blocks cannot be covered with lintels - the exception is openings more than 90 cm wide. A gap of about 2-3 cm remains from the partition to the overlap; you can close it with masonry mortar or polyurethane foam.

In the next video, you will see the laying of walls made of silicate tongue-and-groove slabs.

Gypsum tongue-and-groove plates

They are made of gypsum grades G-4 or G-5 using casting technology.

Plaster of paris is an environmentally friendly and breathable material. Therefore, the partitions made of it comply with strict sanitary and hygienic standards governing the quality of finishing materials.To improve the operational and strength characteristics, plasticizing additives are added to gypsum.

Modern gypsum tongue-and-groove plates, depending on the degree of moisture absorption, are divided into ordinary and moisture resistant. To reduce water absorption, granulated blast furnace slag and Portland cement are added to the feedstock. In order to distinguish such plates from ordinary ones, they are painted green.

Standard gypsum partition blocks can be used only in buildings with dry and normal humidity levels, and moisture-resistant (hydrophobized) ones can also be installed in damp rooms (according to SNiP II-3-79 requirements)

Tab. No. 1 Main technical characteristics of gypsum tongue-and-groove plates

|

Parameter |

Unit rev. |

ordinary |

moisture resistant |

|

Density |

kg / m³ |

1350 |

1100 |

|

Water absorption |

% |

26-32 |

5 |

|

Brand |

M 35 |

M 50 |

|

|

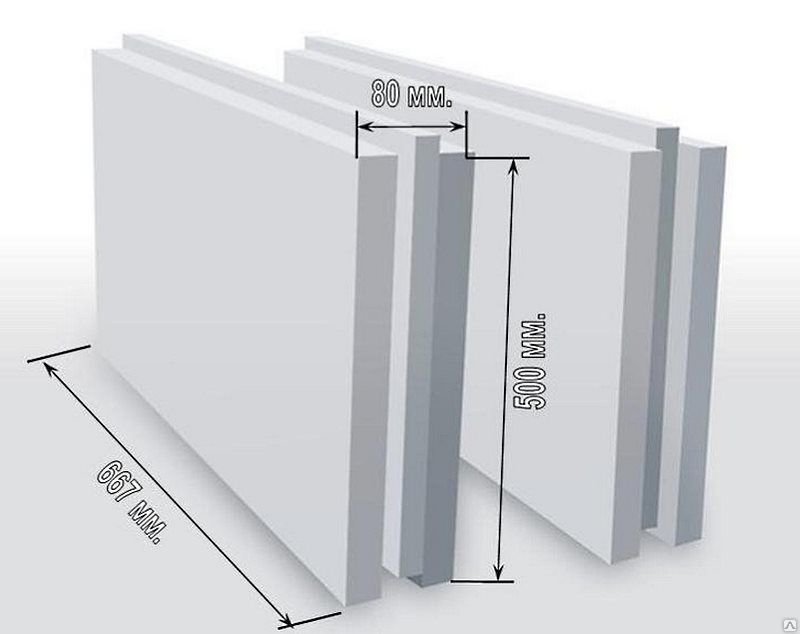

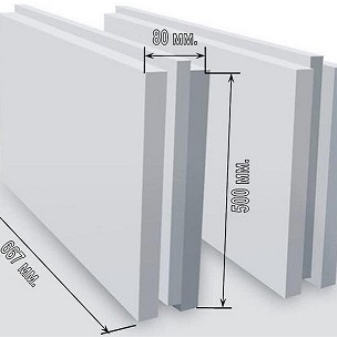

Dimensions (edit) |

mm |

667x500x80 |

667x500x80 |

In terms of thermal insulation, a tongue-and-groove gypsum slab 80 mm thick is equivalent to a 400 mm thick concrete wall. Its sound insulation coefficient is from 34 to 40 dB, which is a good indicator for partition structures.

The fire resistance of solid gypsum blocks is very high. They are able to withstand the direct impact of fire (temperature about +1100 C) for 3 hours without losing their bearing capacity.

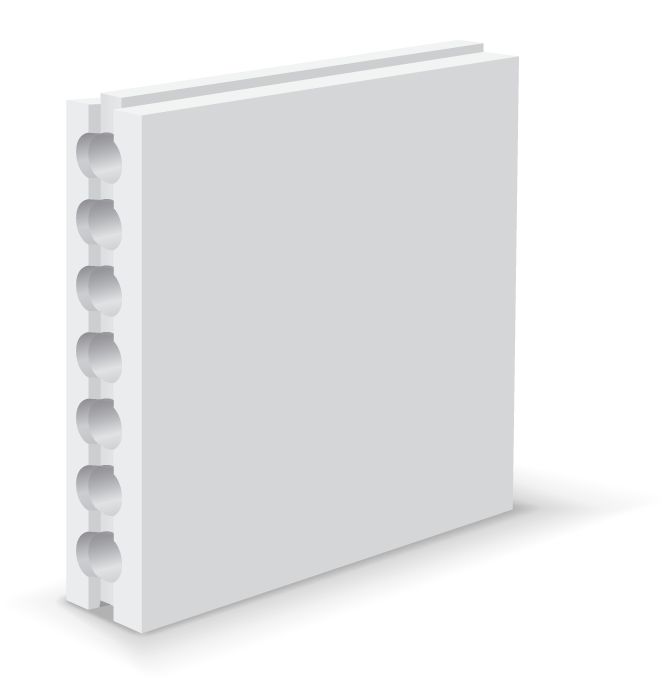

To reduce the weight of the masonry, hollow gypsum boards of the standard size 667x500x80 mm are produced. Their mass is almost 25% less than that of corpulent ones (22-24 versus 30-32 kg).

In addition, there is a gradation of gypsum boards depending on the shape of the ridge and groove (rectangular and trapezoidal). However, this parameter does not significantly affect the quality and strength of the partitions.

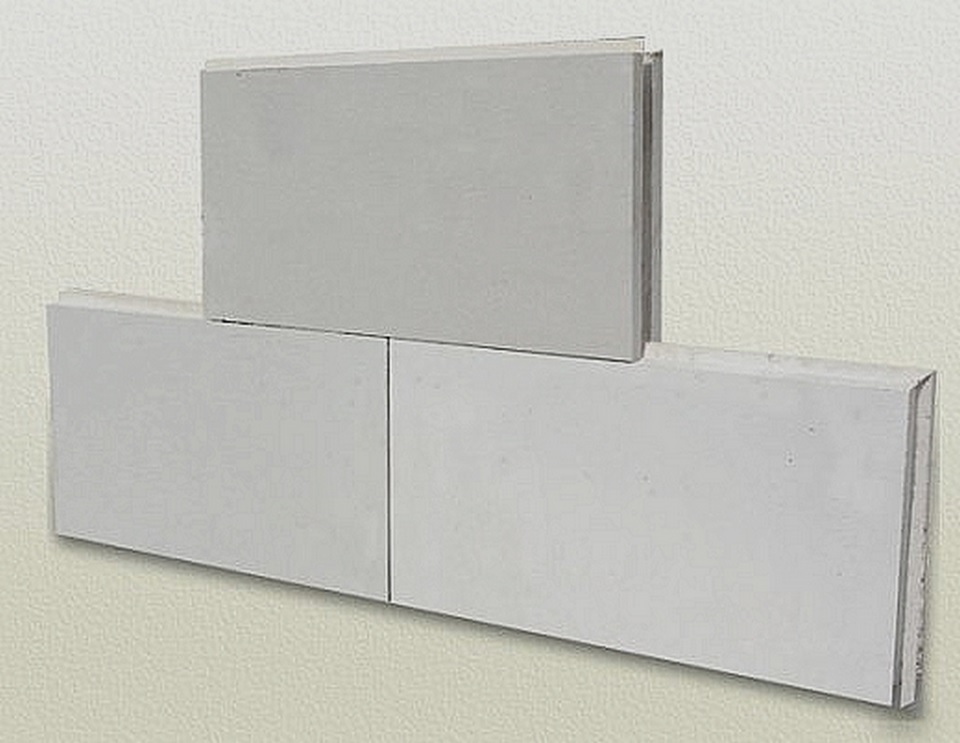

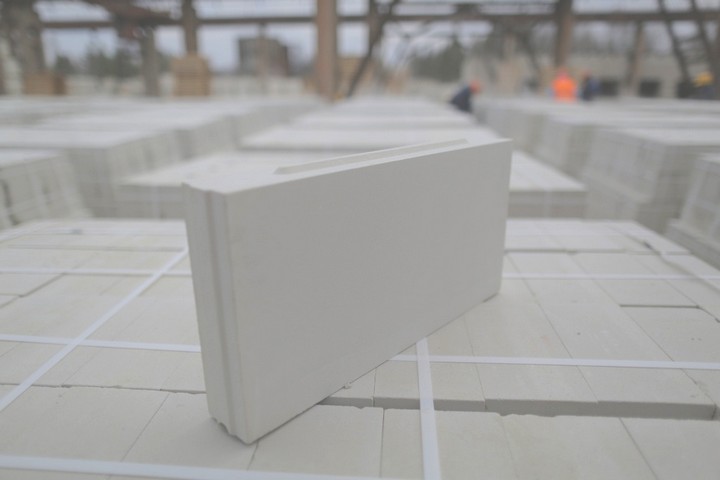

What are they?

A typical partition plate is rectangular in shape. It has a locking tongue-and-groove, which gave the name to the entire product. The standard version is intended for dry or low-humidity rooms. It is also used as a cladding of load-bearing elements of a building. The key differences between the baffles concern primarily the filling level and moisture resistance.

The solid block has a relatively high strength. It is heavy and has a high bearing capacity. Such a product is suitable for a partition, inside which a door is placed. The hollow type, thanks to the through longitudinal channels, improves protection from frost and from extraneous noise.

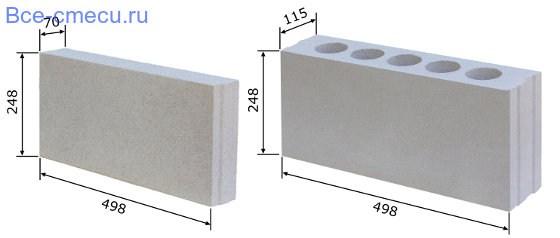

Wall privates PGP, according to official standards, most often have the size:

- 66.7x50;

- 90x30;

- 80x40;

- 60x30 cm.

The thickness is most often 8 or 10 cm. Density is at least 1870 kg per 1 m3. The thermal conductivity coefficient is normally 0.29 or 0.35. The large-format wall block 498x70x250 is popular. Usually, cement M-150 is used for its manufacture, and 80 pieces of blocks are laid out on a pallet.

Good results can also be obtained from the use of products 498x80x249 mm. Such products are supplied, for example, by the Yaroslavl Specialized Plant. The product is produced by pressing a wet sand-lime mixture. There is no need to use additives, but further curing with steam is required. Plates 498x115x250 mm are produced in a similar way.

What is this material and its types

Tongue slabs (abbreviated as PGP) or blocks are large-format building material for erecting partitions in the form of a slab, at the ends of which a ridge (spike) and a groove are formed. Hence this name - tongue-and-groove slabs. They are:

- gypsum-based (cast gypsum);

-

from sand and quicklime, pressed under a certain pressure and steam-treated in an autoclave (silicate).

Plasticizers and hydrophobic (water-repellent) additives are added to the solution to improve the properties. Gypsum GWPs have another name - gypsum boards. It is understandable: the gypsum solution is poured into molds. Here is the "source" of this variant of the name.

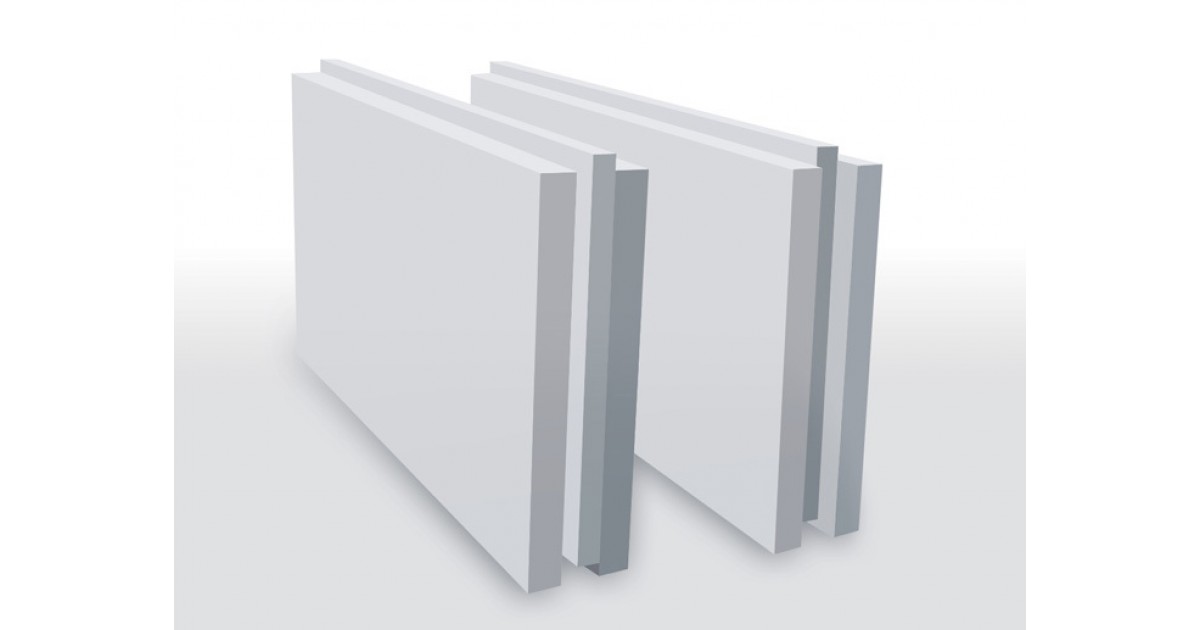

Moisture resistance and voidness

According to the area of use, tongue-and-groove plates can be designed for normal operating conditions (normal, standard) or for damp rooms (moisture resistant). Moisture resistant for better identification tinted greenish.

Solid and hollow differ in weight and strength

Both gypsum and silicate tongue-and-groove slabs are solid and hollow. Full-bodied, more durable, hollow due to lower weight, create less load on the floors. The choice between corpulent and hollow must be made based on several factors:

- Soundproofing characteristics. A monolithic material without voids conducts sounds better, so it is used if sound insulation will be made in a separate layer (the best option) or if it is not so important.

- Partition loads. If you need to hang shelves, furniture on the walls, fix some heavy objects, it is better to use a monolith.

- Floor or floor loading. It is better to place less heavy (hollow) blocks on wooden floors or old wooden floors.

Considering several factors, sound insulation is the last thing to consider. It is possible to increase noise protection using a special mounting technology (on vibration damping pads), as well as by making an additional layer of soundproof materials.

Specifications

If we compare ordinary and moisture-resistant tongue-and-groove plates, the differences in characteristics are only in water absorption and strength. Moisture resistant, due to the large amount of hydrophobic additives, they almost do not absorb moisture. Because of the large number of these additives, they are more expensive, since these additives are expensive. At the same time, they increase the strength (M50 compared to M35).

By the way, you can check "without leaving the checkout" if you really have moisture-resistant GWP or just standard green-colored ones. Just pour some water on the surface. Standard plates will quickly absorb it, and on water-repellent plates it will stand for a long time in a puddle.

Main technical characteristics of gypsum and silicate PPGs

If we compare gypsum and silicate partition blocks, the increased strength of the latter immediately catches the eye - M150 compared to M50 and M35. That is, the strength of silicate slabs is comparable to concrete of not the worst grade. If you are going to hang something very heavy on the partition, it is better to use silicate. Manufacturers also produce blocks with a thickness of 115 mm, which are called inter-apartment blocks.

Technical characteristics of tongue-and-groove gypsum partition blocks

How else do silicate boards differ from gypsum counterparts? The fact that in the standard version they do not have such a high absorbency. It is not as low as that of moisture-resistant blocks, but this material can be used without problems in any damp room (13% versus 26-32%). The disadvantages of this material are more weight (with equal dimensions) and lower thermal insulation characteristics.

Installation features

The laying of partitions from tongue-and-groove blocks is carried out after the completion of the installation of load-bearing and enclosing structures of buildings, before the start of the installation of a clean floor and finishing works.

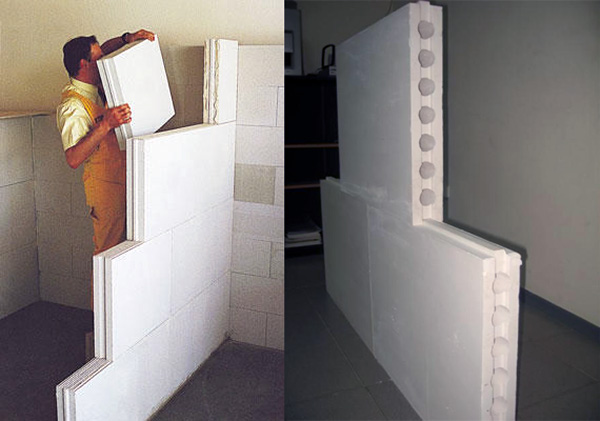

When redeveloping or reconstructing residential and civil facilities, tongue-and-groove partitions can be erected not only single, but also double. The latter option is used in cases where it is required to perform a hidden laying of engineering networks or insulate a partition, one side of which goes into a cold room.

At the facility, the installation of tongue-and-groove plates is reduced to joining along the seams, with periodic monitoring of the verticality and horizontalness of each row. When assembling interior partitions, the plates are placed both with a groove down and up. The norms recommend that they be laid with the groove up, since in this case the mounting adhesive mixture is evenly distributed in the groove-and-groove space.

Standard aerated concrete glue or Fugenfüller putty can be used as an adhesive base for installation.

Installation sequence

The base for the partition is leveled with a cement-sand mortar, after which the first row of partition plates is placed on it according to the level. Before joining, the surfaces of the groove and the ridge of each plate are covered with an adhesive solution so that the thickness of the seam at the joints does not exceed 1-2 mm.

Installation is carried out with the bandaging of the joint seams. To create an elastic abutment to the enclosing and supporting structures, tongue-and-groove partitions are fastened with special brackets.

The bracket is installed in the groove of the slab and fixed with a self-tapping screw to the floor panel or with an anchor dowel to the enclosing structure.

In addition, in such joints, the standards recommend the use of cork or bitumen felt gaskets, installing them around the entire perimeter of the external joint.

If the width of the doorway does not exceed 80 cm and only one row of tongue-and-groove plates will be installed above it, then the norms allow not to use a lintel. Its role is played by a door frame or retaining structure, which is removed after curing with an adhesive solution (Fig. 1)

Picture 1

With a larger opening width, the installation of a steel or wooden lintel over it is required (see Fig. 2)

Picture 2

All contact zones of partitions with load-bearing walls and ceilings are sealed with gypsum mortar.

Reviews of tongue-and-groove partitions are mostly positive. They emphasize not only the simplicity of their installation, but also good soundproofing properties.

An obligatory moment to which you need to pay attention is priming the surface of the slabs before finishing. Reliability of adhesion of paint and wallpaper to the surface of the plate depends on its quality.

This work is best done using a deep penetration primer.

Reinforcement of a freestanding GWP partition

Frankly speaking, installing a GWP partition without reliable contact with the walls is not the best option. If the decision has already been made, then this structure should be secured against falling with a "clip" from a steel corner installed on the side ends. To attach the corner to the ceiling and floor (to the floor slab), you need to use steel plate thrust bearings. They are fixed to the corner with the help of electric welding.

For a more reliable attachment of the angle to the gypsum board, several holes can be made along its entire length for installing dowels.

When finishing the laying, pay special attention to the reliability of the contact of the GWP partition with the ceiling. On both sides, it must be fixed with corners or steel pins, hammering them into the floor slab

After that, the seam is sealed with a solution, glued with a fabric tape and putty. The fastening pins protruding to the surface of the partition will be hidden by the installation of a decorative cornice (baguette).

We also note that the best alternative to the free-standing GWP partition is a plasterboard construction. It is lighter than gypsum boards. The required degree of rigidity is provided by the profile frame.

Useful video on the topic:

Types and features of products

Partitions made of tongue-and-groove plates (hereinafter referred to as PGP) are a prefabricated large-block structure. The blocks are made by molding. They are distinguished by increased accuracy - the deviation of the working surfaces is no more than 1.5 mm from the specified one. Depending on the raw materials used, they are divided into two types:

- Silicate. Produced by silicatization of quartz sand and lime in an autoclave at high temperatures. This technology makes it possible to obtain a durable, moisture-resistant, non-combustible material.

- Plaster. The main raw material is gypsum. To achieve the desired characteristics, plasticizers and other chemical additives are introduced into it. This makes it possible to obtain the necessary strength and moisture resistance. Depending on this, the products are divided into types.The environmental safety of raw materials makes it possible to use it without restrictions even in children's rooms.

Photo: Instagram @ ecodom.khv

Photo: Instagram @kladka_penoblokov

The dimensions of the tongue-and-groove blocks for partitions may vary from manufacturer to manufacturer. Let's list the most common options:

- 667x500;

- 250x500;

- 300x900;

- 599x199.

Partition plates of all standard sizes are produced in thicknesses of 70, 80 and 100 mm. Depending on their design, they are divided into two types:

- Corpulent. They are solid monolithic elements. They are used if you need to provide high strength, for example, hang heavy shelves or cabinets.

- Hollow. They have round perforations. This makes them lighter and therefore easier to install. Due to the voids, the products have increased sound insulation. They can also be used as conduits for electrical wiring.

Depending on the purpose of the premises, the inner wall can be made single or double. If you place mineral wool insulation between the gypsum panels, you can achieve one hundred percent sound insulation between adjacent apartments.

Photo: Instagram @verysamara

Between the double partitions, you can lay not only insulation, but also communication networks. In this case, it is necessary to provide free access to them for maintenance, for example, install inspection hatches.