Selection Tips

Polymer is not an ordinary plastic that has little resistance to mechanical damage. Above the chain-link with a polymer coating, you will have to work hard to damage it. Therefore, such a hedge is at a great price, and the demand for it is great.

Here it is only important to choose a fence in accordance with the requirements of GOST

The strength of the mesh depends on the thickness of the wire used in its manufacture. The strength indicator is also influenced by the size of the cells themselves. The smaller their diameter and wire thickness, the more unreliable the design. The price for it is certainly more affordable, but is such savings appropriate in this case? The netting is more dense, woven from thick wire with small cells.

There are several indicators that the buyer relies on when choosing.

The surface should be as flat as possible.

It is important that there are no bumps, drops, sagging or gaps.

In a high-quality mesh, made on a machine, and not handicraft, all cells are the same in shape, with smooth edges.

It is important to carefully inspect the product for damage and dents. If the fence is deformed after the fence is erected, the defect will become noticeable

In the finished version, this cannot be fixed. For a more aesthetic look, the netting is sometimes placed in frames. The choice of color, cell size and the chain-link roll itself depends on the goals and budget of the buyer.

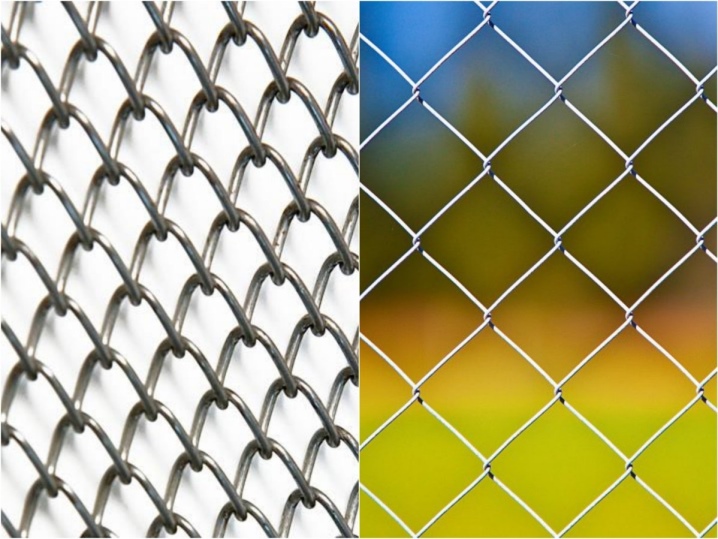

Types of coated nets, photo

There are two types of polymer-coated nets - a chain-link and a welded one.

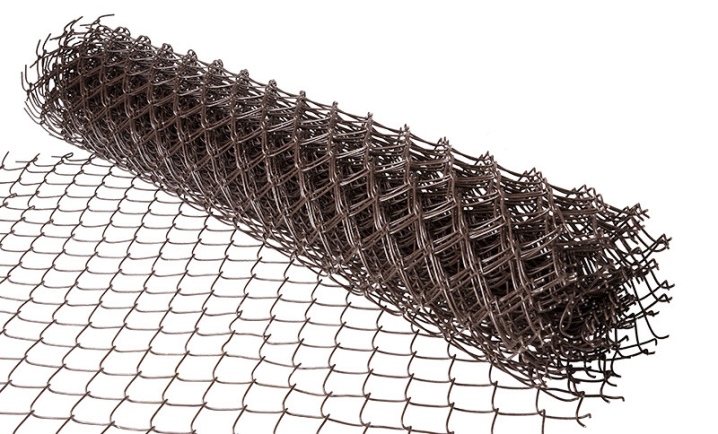

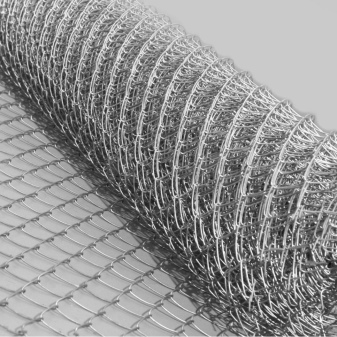

Chain-link

The chain-link is the most popular option for the construction of a strong and reliable fence or fence. It is popular with buyers, because it combines all the positive characteristics of the metal, and due to the application of a layer of polymers, its performance increases. Fences made of such a mesh look aesthetically pleasing and neat, easy to assemble during installation and dismantling.

Important! The chain-link does not darken the area like other fences!

A mesh chain-link with a polymer coating is the same chain-link, only on top it is covered with an anti-corrosion compound. Such a metal sheet withstands a humid climate very well, and the advantage is its low weight and an affordable price.

The service life of the mesh with the application of a chemical composition of polymers increases several times compared to ordinary or galvanized ones.

The coating itself has such advantages as environmental friendliness and safety.

Important! The chain-link has no sharp ends and irregularities, which is safe when used on the territory of children's educational institutions.

The polymer-coated fencing has many advantages: long service life, sturdy construction, quick installation and disassembly. After dismantling, the structure can be reused.

When installing such a fence, there are no dark spots on the territory, due to which the area of the space visually expands.

Metal, galvanized, welded, fence and fencing

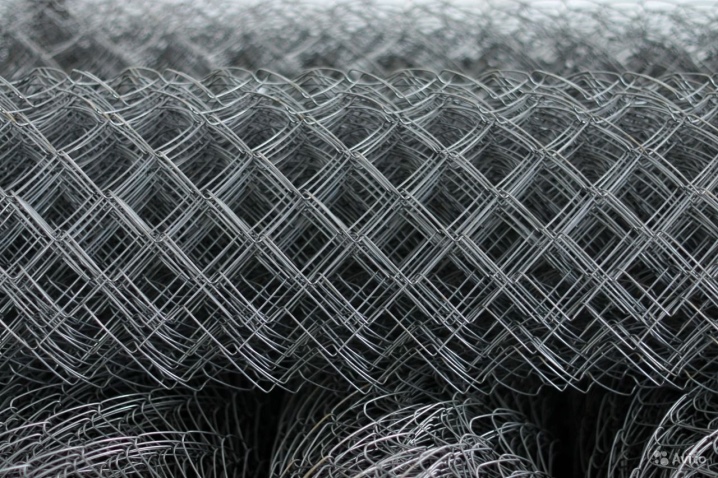

A roll of welded mesh with a polymer coating

The galvanized welded structure, thanks to its coating, is reliably protected from corrosion. This mesh is often used in the construction of fences and fences.

Welded mesh is more labor intensive to manufacture. The metal sheet is pre-welded to the steel frames. This type of canvas is often installed in the form of fencing sports facilities and private areas. The welded structure consists of a strong steel wire with a diameter of 3-5 mm. and a total size of 2x2.5 m.It is used for fencing animals and birds and in the construction of brick walls.

The fence is one of the most common building materials used for the construction of fences. The fence mesh has a long service life, is easy to install and reuse when dismantled.

The mesh for the fence can be either a metal frame or a plastic one. These types of structures are widely used from construction and summer cottages to parking lots.

Attention! It is necessary to understand the advantages and disadvantages of each type of mesh for proper use as a fence or for the safety of the site.

Green, black, white and other options

In hardware stores, there is a small selection of colors. However, the different colors allow for interesting compositions in combination with the enclosed area and natural landscape. The mesh netting, in addition to the standard colors, is covered in green or brown. Also it can be chosen in red or black color scheme.

The welded structure is often painted white or green. In the assortment of hardware stores, you can find a welded product in blue or red.

Plastic canvas is more varied in its shades. This type of mesh is painted orange, yellow or even light green.

In order to choose for yourself the most practical and long-term fencing with a polymer coating, you need to decide where and in what quality to use it. If you plan to build a fence, then the choice is better to stop on a polymer-coated mesh, galvanized or painted. These types of fences last longer and fit perfectly into any conditions.

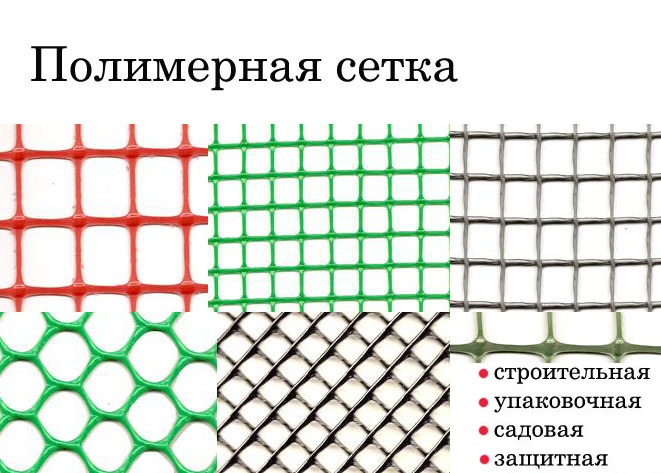

1 Properties and features of use

Polymer mesh is most often created on the basis of steel, but steel is covered with a layer of special plastic, which is a kind of protective coating.

This makes this mesh doubly convenient. Indeed, on the one hand, it has the advantages of steel. Namely, it is very durable, practically does not tear and has excellent performance.

On the other hand, it will not be susceptible to those standard diseases of the metal mesh netting or any other products of this type.

For example, if ordinary steel mesh for fencing can quickly rust, then polymer mesh does not face such a problem at all.

Types of polymer meshes

It can be operated without problems for decades, unlike the chain-link.

And during this period, not a single trace of destruction or significant damage will appear on it. This is provided that the polymer coating was not seriously worn out or damaged during installation. But it is very difficult to do this, because the extrusion process gives a very high-quality adhesion of polymer and steel.

This material also does not need coloring or additional protection with waterproofing compounds. Grids of this type are used in a wide variety of areas.

For example, such as:

- construction industry (in this craft, polymer networks compete with chain-link networks, although the latter are now used less and less);

- household;

- agricultural;

- when creating design projects;

- for the creation of protective and strengthening structures.

Polymer mesh fencing

Polymer networks are divided into several types, which are distinguished by density, types of cells and other parameters. Most often, such grids are used in the planning of design projects (for example, when you need to make the exterior of a house), as well as when erecting barriers and reinforcing elements.

The types of polymer networks have the general name "STRENS", and the differences, in addition to the parameters and properties, are only in the final digital marking.

There are only four markings for polymer nets: 12, 14, 15 and 16. It is noteworthy that absolutely all types of polymer nets have frost resistance, quality materials and strength.

1.1 Application

Recently, a network of polymer elements began to be used for the following purposes:

- for fences of houses and summer cottages;

- for fences of children's areas and playgrounds;

- for gardens and industrial areas;

- to make work on the construction site safe (protection against falling from a height of tools or any other objects).

In addition, polymer nets can, although impractical, be used in the creation of fences in poultry and pig breeding. It should be used for enclosures only when enclosures are designed for medium-sized animals (pigs, dogs, cats, sheep, etc.) or domestic birds (geese, chickens, ducks, and so on), otherwise it is better to use chain-link fences.

Summing up, we can confidently assert that the polymer mesh has a huge scope, and its initial data and properties allow it to be used in places where metal and wood analogs are unsuitable for use.

Which, however, are already gradually fading into the background and are less and less used in the construction of certain construction projects.

Welded fence mesh from China

Not so long ago, the choice of material for the construction of fences was rather scarce, but with the development of industry in our time, you can choose both in quality and price. So the welded fence mesh from China allows not only to save the family budget, but also to give an aesthetic look to the well-groomed area.

The mesh fabric consists of a metal wire interlaced at right angles, welded by means of spot welding at the weave points. The wire is pre-coated with protective materials to prevent rusting. The mesh is realized in rolls with rectangular and square cells, less often trapezoidal cells or ...

Advantages and disadvantages

This processing technology provides increased resistance of the mesh to corrosive and alkaline influences. As a result, these meshes are suitable for fencing in coastal areas where high levels of salt in humid air lead to rapid formation of rust on the metal surface. Products are installed in industrial and industrial areas, warehouses, car parks.

Fences are mounted along the perimeter of agricultural land: farms, pastures, poultry houses and aviaries. In addition, polymer-coated nets are perfect for arranging hedges. The green design blends harmoniously with living plants.

The polymer coating also gives the product an attractive appearance, so meshes are used for:

- creating decorative fences in the garden or on the territory of the summer cottage;

- fences of municipal institutions: kindergartens, schools, hospitals;

- arrangement of public gardens, parks, squares;

- fencing of sports and playgrounds.

Coated mesh fence

Other advantages are:

- light enough weight, so when installing the fence, you do not need to fill the foundation;

- erection of structures does not require high qualifications of the performer, strict adherence to instructions allows you to build a fence yourself;

- gardeners appreciate the transparent structure of fences that let in sunlight;

- no need for periodic painting;

- resistance to temperature extremes;

- significant service life, which is about 25-30 years;

- a variety of colors, the customer has the opportunity to choose a product with any color according to the RAL system;

- the price of the mesh is much lower than other materials used in the construction of fences: stone, metal, wood.

In addition, do not forget about some of the disadvantages:

- transparency of fences is not always an advantage, many clients prefer privacy and prefer to choose "deaf" designs;

- openness of the territory to wind, dust;

- lack of sound insulation.

Prices for mesh and finished fences in Moscow and St. Petersburg

The cheapest chain-link mesh will cost from 30 rubles. for 1 sq. m., more durable - over 500 rubles. for 1 sq. m. The cost of installing a 1.5 m chain-link fence is from 364 rubles. per 1 running meter (r.m.), with a height of 2 m - from 450 rubles. for 1 r.m.

The price for a welded sheet with dimensions of 50 * 50 * 3 mm in cards of 0.5 * 2 m starts at 78 rubles. per 1 m, with dimensions 100 * 100 * 5 mm in cards 2 * 3 m increases to 115 rubles. for 1 m.

Installation of ready-made sections 2.5 m wide from galvanized mesh with cells of 50 * 50 mm, 2 m high will cost 1150 rubles. Patterned welded wire sections will cost twice as much.

With a competent approach to the choice of mesh for fencing, you can find quality material at an affordable price that will last a long time.

With your own hands

Bracket "Spider" for attaching the net to the posts

An important advantage of polymer-coated mesh fences is the relative ease of self-installation.

- Work begins with the preparation of the area, cleaning up items or debris that may interfere.

- Marking the territory, it is recommended to install beacons, which are used as wooden pegs. A rope or cord or harness is located between the beacons, for the convenience of installation work.

- Formation of holes for pillars, the depth of the holes varies from 50 to 100 cm, depending on the height of the fence, the type of soil and the region of work, a drill is used.

- Installation of support pillars, their concreting. It is also possible to fill the holes with rubble and tamp, this technique is a good alternative to concreting. In order to install the pillars of the same height and not be mistaken, it is recommended to use a level and a plumb line.

- The installation of the mesh is required after the concrete solution has completely solidified. Depending on the type of construction, sections are installed or the mesh is stretched. To mount the sections, you will need brackets or clamps or a welding machine. The tension is carried out in various ways, the performer may need a wire used for the upper and lower broach, on which the mesh is attached with the extreme cells or the reinforcement is welded to the posts, for fastening on the sides, hooks.

- There is no need to prime and paint the structure.

Hinged mesh

Hinged mesh is a worthy alternative to traditional fencing materials. A number of weighty advantages associated with the design and production features allow it to compete with the chain-link, welded and other types of wire mesh.

What is this material

The hinge mesh is a carbon steel wire product. It is characterized by increased lightness and strength. It is sold in rolls of different lengths.

The name "articulated" refers to the method of connecting the wire mesh elements to each other. For fastening the transverse and longitudinal wires, the DFL hinge unit is used. Such a fixation is beneficial ...

How and from what are they made?

Polymer-coated mesh is produced by the same method as a standard metal mesh made of soft wire from low-carbon steel, in accordance with GOST 3282-74. At an additional stage, the wire is covered with a protective polymer layer made of polyvinyl chloride. Modern PVC coatings are able to withstand temperatures ranging from -60 ° C to + 60 ° C. It is noteworthy that in this case the coating does not deteriorate and reliably protects the base material. The polymer layer also serves to give the product an excellent glossy finish.

PVC is characterized by elasticity, due to which the integrity of the polymer coating remains unchanged under various deformations. The mesh protected in this way is not affected by salty sea air, high humidity, UV rays. The chain-link remains in its original state for a long time. Even in harsh climates, the polymer-coated mesh is guaranteed for at least 7 years.

The material is weaved on special machines, working with one or more wires in parallel. Modern equipment can be used to produce both small volumes of products and minimal batches. It is possible to locate production in small areas. In the process of weaving, flat wire spirals are interconnected, and then bent along the edges.

A polymer composition is applied to the finished wicker product, which solidifies and turns into a reliable barrier to moisture, frost and sun. Plastic coating is applied to both conventional and galvanized wires.

Views

The mesh in polymer is supplied in a compact euro-packing or rolled up in rolls according to the standard (“classic” type). The polymeric coating of the steel mesh can contain coloring pigments of different shades. Colored wire is even made individually, in a shade according to the customer's preference.

A metal mesh is produced, covered with a polymer layer, from heat-treated low-carbon wire. It can be galvanized or non-galvanized.

A distinctive feature of the plastic chain-link is that thanks to polymers, the fence is painted in almost any shade. This factor facilitates the task of decorating a summer cottage. For example, if you need to choose a fence to match the overall landscape design.

The green chain-link is most often used as a land survey at a summer cottage and the like. And red and other bright options often surround football fields, parking spaces, playgrounds.

Brown PVC mesh with a fine mesh is a frequent choice of gardeners. The advantage of the product is that it can be from 1x10 meters (where 1 is the height, 10 is the length), up to 4x18 meters (similarly) and does not need to be re-painted.