Applications for dry sand

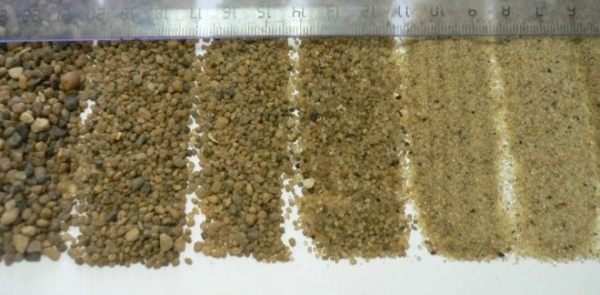

Dry sand is divided into three main fractions:

- fine - grains up to 0.5 mm in size;

- medium - 0.5–2 mm;

- large - 2–5 mm.

The scope of application of the material depends on this indicator. The most popular and convenient medium-grained sand for construction.

Depending on the type of work to be done, sand of a certain fraction is selected

Depending on the type of work to be done, sand of a certain fraction is selected

Coarse sand is used for drainage and arrangement of base cushions when laying foundations, building roads, laying communications. It is also used by designers and artists in decoration and landscape architecture.

The fine fraction is suitable for creating filters, filling sports and children's playgrounds, making ceramics, glass. It is added to masonry and plastering compounds.

Medium-grained sand is considered the best option for concrete and cement mixtures. According to IS&A research, the maximum strength of a concrete stone is achieved when using dry sand with the following composition: 30–50% - fraction 0.325–1.25 mm; 50% - 1.25–5 mm; 10% and more - fractions 0.325–0.16 mm (for filling micropores). It is preferable to use dry quarry sand with coarse grains not run in with water.

Dry sand of the middle fraction is optimal for creating a high-quality concrete mix

Dry sand of the middle fraction is optimal for creating a high-quality concrete mix

Additional areas of application:

- as an abrasive for sandblasting machines;

- filler for paints and grout;

- in the production of paving slabs;

- when decorating garden and park spaces;

- in the improvement of adjoining territories;

Seeded sand production technology

It is economically unprofitable to use raw material obtained by hydromechanical method or raised from the bottom of reservoirs for the production of sown sand. Therefore, the ideal option is open pit quarry sand. Loose rock is often processed right on the spot, but in order to obtain the highest quality sand, it must first be sieved and then washed, for which trough-type washers are used. If the end user needs a material containing clay or silt impurities (to improve the adhesion characteristics), then it is not washed, but simply sifted through a system of sieves with different cells. To give the material maximum flowability, it is dried, and heated gases are used for this.

Description

The presented sand is considered one of the most versatile materials, which is used in almost all industries and agriculture. Most of all, quarry sand is used for the arrangement of various territories and buildings, for example:

• road construction;

Road construction

• used as a special filter for buildings to level the sites for the construction process;

• GOST 8736 sand is added to dry mixes, which are intended for filling or equipping self-leveling floors;

Already from the name it can be understood that this type of matter is mined from quarries.

Also, the method of extracting sand affects certain properties; there are several ways: washing, screening and open-pit mining.

In order to obtain high-quality sand for construction work, the moisture coefficient should not be more than 7%. Impurities and other components should be about 3%, sulfur not more than 1%.

Applications

Due to its characteristics, quarry sand is used in various fields. For example, it is used in construction, it is used in the arrangement of territories, in the creation of asphalt concrete mixtures. Despite the low cost of mining, such material cannot be called universal, it is not suitable for all construction work.The more dust, clay and other suspended matter in it, the less its suitability in the construction industry.

As for the illiquid variety, such sand is purchased for dumping roads, trenches and ditches. With its help, the composition of the soil is improved. A variety with a large grain size is often combined with crushed stone. The coarse-grained type is applicable for filling swampy areas of land, as well as flooded lowlands.

Quarry sand has found application in everyday life. It is used to create pedestrian walkways. A small layer of material allows you to protect yourself from ice in winter. It is also an excellent material used in agriculture and horticulture. It is a component of nutritional mixes used by gardeners and gardeners. It is added to the soil, used for growing seedlings. It is used to preserve the harvested crop (it is in it that the harvested vegetables are stored).

Quarry sand has filtering properties. Thanks to this feature, it is a means of cleaning equipment at wastewater treatment plants. It is also used in cases where it is necessary to level the site before laying the foundation. Some varieties, due to their composition, are used in the glass industry.

In addition, it is used for facades. Moreover, depending on the size of the fraction and the type of decorative material, it can imitate the texture of different materials, be it the so-called "fur coat" or "bark beetle". It is sold in small and large quantities. The price per kilogram today varies from 170 to 400 rubles for 1 cubic meter... In addition, quarry sand is sold in 50 kg bags.

Varieties of sand

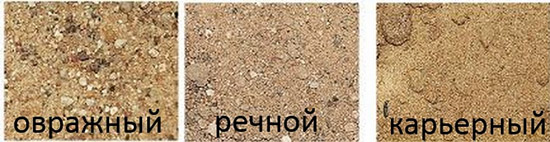

In the trade in building materials, sand is usually classified according to the method of its processing and place of origin:

- 1. River sand - is versatile and the cleanest in comparison with other types of material, but also the most expensive. It is mined not only in river beds, but also in any other water bodies of natural origin. The color of the rock is gray or yellow, and the grains have a regular rounded shape;

- 2. Quarry sand is a sedimentary rock of the usual reddish color. Unlike river sand, it contains impurities from clay, stones and other dust-like particles. The material has a reddish tint. The low cost of quarry sand makes it attractive for construction organizations of municipal facilities and roads;

- 3. Washed sand is a type of sand extracted from a quarry using a special processing method.

- All impurities (clay, loam, dust, etc.) are washed out of it by a hydromechanical method. It can also be mined from ASG (sand and gravel mixture) by separating gravel from sand. It is highly popular in horticulture, construction, and landscaping;

- 4. Seeded sand is obtained by conventional sifting and separation of the composition from larger stones and grains of the same sand. You can buy seeded sand one and a half or two times cheaper than washed sand;

- 5. Building sand is formed by the destruction of rocks in a natural way, or with the participation of processing equipment. The size of its fractions is about 5 mm, and it corresponds to GOST.

What it is?

For any geologist, sand is just "one of the varieties of fine-grained rock fractions." However, various impurities are added to the fine fractions themselves.

Only sown (free from mechanical impurities) sand is suitable for any work. Extraction of raw materials is carried out in sand and mixed (sand and gravel) quarries. In the overwhelming majority of cases, they are developed by an open method. During hydromechanical treatment, the rock mass is developed under strong water pressure. The "wet" option implies extraction by a dredger in water bodies.

The problem is that only the "career" method, with rare exceptions, is economically inexpedient.The processing of the rock is often carried out directly on site. However, only thorough sifting and washing (possible, we note, only under conditions of prepared production, with "trough" sinks) can guarantee the excellent quality of raw materials. Refusal to wash is also practiced - in some cases, the end customer needs seeded sand with the inclusion of silt and clay particles. If the task is to maximize flowability, drying with heated gases is practiced.

Advantages and disadvantages

The most important material in enterprises engaged in the extraction of sand, as well as the sale of its various types, is the use of the quarry sand itself.

This is explained by such factors:

- enterprises do not use their own reserves for cleaning the resulting sand. Based on the fact that quarry sand cannot be processed and resorted to other methods, production saves money on cleaning and screening of the extracted material.

- it is not at all difficult to get sand with the help of special devices. The open-cut method is the most accurate and inexpensive, therefore most enterprises resort to using this mining method.

- Delivery of quarry sand is also not a big financial cost. Today, there are a large number of sand deposits in the quarries, so at any time you can find the right amount of sand nearby.

The norms and coefficient ratio of this sand are not always equal to that of alluvial or sown sand, however, the low cost and a number of other characteristics that indicate high-quality material make the sand more popular and in demand than similar types of quarry sand.

Application

Quarry sand is widely used in the construction industry due to its high technical characteristics and excellent quality. Sand is also used in agriculture, for design and decoration.

The most popular use of sand is for the manufacture of bricks and concrete, as well as for the construction of residential buildings and road transport routes.

In winter, such sand is most used for dusting roads with it, so that friction is formed, and the chance of falling is minimized. Moreover, the material is widely used by avid summer residents to store fruits, vegetables and preservation in the cellar throughout the winter.

Also, the extracted grains are often used for the so-called filter for treatment facilities. It is most often used for concrete with a high percentage of strength, such sand is also used for various iron structures.

This material does not have any impurities or other components, and the resulting products will be distinguished by their durability and special strength.

For coating and surface solutions, sand with fine grain is used, thanks to this type of material, a pleasant appearance of the resulting mixture can be achieved. Fine sand is widely used for decoration and landscape design.

Industry use

Filling roads with medium-sized sand Depending on the mining method and the type of material obtained, its use also differs.

Ground sand is used for filling roads and other highways. In agriculture, it is used for drainage and improving the composition of soils.

Clean, seeded sand is used in various areas of construction, namely sand of medium size - is the main aggregate in the manufacture of concretes of all grades and reinforced concrete products. In addition, this fraction is used in the manufacture of masonry and plaster mixes, the construction of foundations for various purposes and the construction of concrete pavements.

Extraction features

The most common method is the open method, because thanks to it, specialists can get by with conventional technical equipment: bulldozers, excavators and more.This method is quite economical, does not require special costs, on the basis of this, the mined sand can not be used for all areas of application.

Open way

Quarries that have been flooded with water are destroyed with a dredger and sand is extracted. This device has a powerful pump that allows you to unload the sand to the very bottom.

The unit is installed on a floating pontoon (dredger), then fastened with anchors and strong ropes or left on the surface of a specialized vessel.

The presented method of extracting sand is called hydromechanized; it has gained wide popularity among other similar methods.

Hydromechanized method

In some cases, it is possible to use other specially equipped devices that perform the same functions and are used for their intended purpose. For example, you can take a sieve - it cleans the sand from excess stones and other substances that were mined using the open method.

Also, instead of a sieve, a conventional metal mesh can be used, capable of sifting sand with two hands.

For more information about mining sand, see the video:

Features and application of seeded sand

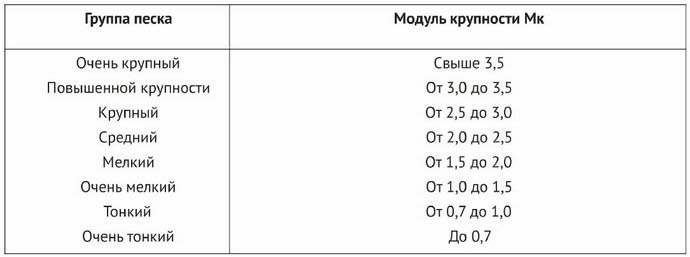

Seeded sand, like washed sand, is obtained from quarry. For this, it undergoes mechanical processing using special sieves. As a result, the material is divided into the following fractions: fine (with a particle size of up to 1 mm), very fine (1-1.5 mm), fine (1.5-2 mm), coarse (2-2.5 mm) and increased size (2.5-3.5 mm). The main difference between seeded sand from other types of this material is a higher bulk density: 1.8 t / m3 with a standard indicator of 1.65 t / m3. The uniformity of the structure contributes to its high frost resistance, wear resistance, hygroscopicity and filtering ability.

Seeded sand is used in the manufacture of concrete products, as well as in the construction of roads and drainage systems. It is used in landscaping and as an additive for planting soil. The use of this material largely depends on its fraction. So, fine and very fine sand is in demand in the manufacture of dry gypsum mixtures. The fine fraction material is optimal for obtaining building and plastering mortars and mixtures. Coarse sand is used as an additive in masonry mortars and high-strength concretes. In general, the uniqueness of this natural material, regardless of its type or method of extraction, lies in its versatility.

Fractionation prospects

So, fractionation allows for excellent homogeneity, which, in turn, makes it possible to achieve the production of high quality concrete, as well as reduce cement consumption.

Yet this technology comes with some challenges. One of them is the choice of technology, the other is the need to create conditions for the productive use of coarse and fine sand. The fact is that most industrial enterprises that use sand for the manufacture of their products do not have the ability to separately receive, store and dispense sand of two fractions.

It would be possible to organize the supply of sand already mixed in the given proportions. However, this is not so easy to do: additional technologies and equipment will be needed. The cost of this will be reflected in the price of the sand. Therefore, it is still more profitable to mix sand directly at the enterprise. Therefore, such plants need to be built and reconstructed, taking into account the need for separate reception, storage and addition of sand.

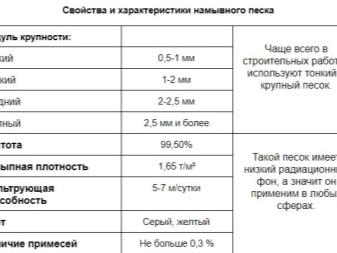

Specifications

To determine sand by category, the following properties are taken into account:

- specific gravity (bulk density);

- the degree of radioactive radiation;

- moisture percentage;

- the amount of impurities;

- filtration coefficient.

1. The specific gravity shows how much building material is in one cubic meter of the container.This parameter depends on the size of the fractions and the size of the free space between the grains. Therefore, the bulk density of coarse-grained and fine-grained grains will differ markedly. The specific weight of sand grains of coarse fractions is about 1500, medium - 1600, small - 1700-1800 kg / m3.

2. Bulk density is the weight of the un-rammed building material. Its indicator is influenced by the degree of humidity and mechanical stress. The density decreases if the sand becomes wet, as each grain is enveloped in water. Because of this, the distance between adjacent grains increases. After transportation, on the contrary, the bulk density increases, as it is compacted.

3. The degree of radioactive radiation from quarry sand depends on the place of extraction. They are divided into 3 categories - first, second and third. The scope of the first is the construction of residential buildings for people and animals, the second and third classes are allowed for the construction of roads.

4. The weight of bulk material is influenced by the percentage of moisture. The higher it is, the more it weighs. The optimal norm for sand from quarries is 5-7%. The amount of clay impurities should not exceed 3%, sulfur and sulfides - up to 1%.

5. The ability to pass water depends on the filtration coefficient. For sand from quarries, this indicator should be in the range of 0.5-7 m / day.

Application area

It must correspond to its quality and properties. Low-quality sand is intended for bedding (filling ditches, leveling the surface), for improving the soil, storing vegetables and for decorative purposes. It is also selected for the manufacture of mixtures with crushed stone and gravel and for the construction of highways. It is also used for the filter in sewage treatment plants. High quality sand is required for glass production.

The scope of application of the sifted is the erection of the foundations of buildings, it is also necessary as a filler in the production of cement-sand mortars and asphalt. Since seeded sand has good adhesion properties, it is often selected for plasters and paving slabs.

Coarse sand is added to mortars for paving slabs, and it is also used as a pillow in the construction of highways and as a drainage layer. Fine-grained is used in the production of putty mixtures, as a filling component for self-leveling floors and decorative finishes.

Cost per cube and what it depends on

A cubic meter of sand from a quarry is cheaper than a river one, since it took less money and labor to extract it. The washed type of building material is similar in technical characteristics to the river one, but externally differs. Its grains are not smooth oval, but angular and porous. It is for this reason that it is most common in the manufacture of mortars. But due to the additional processing costs, the cost of sand also rises.

Prices also depend on the size of the fractions. The smaller the grain, the more expensive it is. But at the same time, the smallest option is intended for a narrow scope of use. The average fraction is in the greatest demand. When choosing the type of sand, one should take into account the purpose for which it is needed. When choosing a low-quality building material for the construction of a building, large defects (cracks) may appear.

Table with prices for a cube of quarry sand:

| Type of | 1 m3, rubles |

| Construction quarry | 600 |

| Washed | 800 |

| Seeded | 680 |

| River | 800 |

Before purchasing sand obtained from a quarry, it is recommended to check its composition and technical characteristics, especially the degree of radiation and the percentage of impurities. The area of its use depends on these factors.

The lower the cost, the less costs were spent on processing it, but also the narrower the scope

Such material is recommended in places where quality and technical characteristics are not particularly important.For construction work, such as building foundations, making plaster mixes or laying bricks, it is best to buy cleaned sand.

Species overview

There are several types of quarry sand. According to the method of processing, each type has its own characteristics and differences. Each type has its own purpose. All types of material are mined by licensed enterprises, which, even before the start of work, submit estimates and plans for the development of quarries to government agencies. According to the type of processing, sand is washed, seeded and unpaved.

Alluvial

This type of sand is mined by means of hydromechanical devices. By using the water rinsing technique, it is possible to rid the sand of foreign suspensions. This species is distinguished by its purity, it is washed several times. It does not contain harmful components and various suspensions, they are removed immediately during extraction.

This type of sand is used in the production of concrete and bricks, reinforced concrete products. With its help, they build highways, they buy it for the construction of buildings for various purposes. This is a high quality type of material. It is mined from flooded deposits, washing out impurities and even dust.

Seeded

The method of extracting seeded sand is different. It is considered extremely simple. In this case, the technique of technical and mechanical sieving is used. In the course of cleaning, equipment with a mass of sieves and cells is used. As a result, large fractions and stones are removed from the total mass. A fine-grained product of this type is used in the manufacture of plaster mixes and mortars.

Sandy

Open pit sand is classified as a less pure variety. The content of foreign inclusions in it can reach 40%. Because of this, it is not suitable for finishing work, it is more often used as a trench filler and for leveling land plots. This is a low quality draft.

However, it is actively used in utilities and agriculture. It is he who is used in winter for sprinkling on ice. It is also used as a way to preserve vegetable crops. But it is not suitable for either concrete or cement mortars. Its impurities impair performance.

In the next video you will find interesting information about the extraction, delivery and application of quarry sand.

Transportation

Sand, enriched sand and graded sand are transported by rail, water and road transport in accordance with the rules for the carriage of goods in force for a particular type of transport.

Dry fractionated sand is transported in the form of individual fractions or their mixtures by specialized vehicles (cement trucks, capsules and other means of transportation that provide protection against moisture and contaminants). The permissible moisture content of sand is set by the consumer, while the range of permissible moisture content should be in the range from 0.1% to 0.5% by weight, unless otherwise specified in other regulatory documents.

Material characteristics

Sand of medium size All the main characteristics of sand are regulated by GOST and are given above, these are:

- Size module.

- Grain composition.

- Content of clay, dust and clay particles.

In addition to the characteristics regulated by GOST, important indicators of properties are:

The density, measured in kg per m3, depends on:

- the degree of compaction, characterized by the method of extraction and storage;

- humidity, which differs depending on the method of extraction and storage conditions;

- porosity and structure of the material;

- the presence of impurities.

The density is 1300 - 1800 kg / m3.

Specific gravity characterizes the amount of dry material per unit volume, and is also measured in kg per m3.

The specific gravity is 2.55 - 2.65 kg / m3.

Volumetric weight, characterizes the material in its natural state and differs from the specific gravity indicators. Depends on:

- the specific weight of a specific batch of material;

- the presence and number of voids in the batch of material;

- humidity in each separate batch of material.

The volumetric weight is 1.5 - 1.8 kg / m3.

Bulk density - characterizes the parameters of sand in bulk and is measured in kg per m3.

Bulk density - 1500 - 1700 kg / m3.

Porosity coefficient - divides sand according to the degree of porosity into: dense, medium density and loose, which correspond to the following values:

- Dense - K, less than 0.55;

- Average density - K, is in the range from 0.55 to 0.65;

- Loose - K, more than 0.65.

Deformation modulus - characterizes the ability of sand to compress under the influence of external loads. This indicator depends on the porosity of the material and corresponds to the following parameters:

| Porosity coefficient | 0,45 | 0,55 | 0,65 | 0,75 |

| Deformation modulus | 50 | 40 | 30 | — |

Modulus of elasticity - characterizes the strength and ability to restore the previous volume, after the application of an external load and its removal.

Elastic modulus - 120 MPa.

The compaction ratio is an important indicator when performing construction and installation work.

The compaction ratio is 0.95 - 0.98.

Specific adhesion - characterizes the strength to displacement under the influence of an external force, measured in Newtons per m2. The specific cohesion of medium sand depends on its porosity and corresponds to the following parameters:

| Porosity coefficient | 0,45 | 0,55 | 0,65 | 0,75 |

| Specific adhesion, N / m2 | 3,0 | 2,0 | 1,0 | — |

Features and types

The main difference between open pit sand and river sand is the high content of various impurities. Because of them, its technical characteristics are reduced. For this reason, sand cannot be used in its original form for the construction of any structures, since their strength is greatly reduced. Therefore, it is subjected to additional processing, sieved or washed.

Freshly mined sand contains a large amount of impurities - up to 10%. Its particles are red, yellow, or white. It depends entirely on the mineral composition. The surface of the particles is uneven and rough. It is because of this that it has good adhesion properties.

The quarry sand differs according to the following features:

- size of fractions;

- processing method;

- composition.

Depending on the size of the particles, it can be fine-, medium- and coarse-grained. Fractions of the first do not exceed 2 mm in diameter, the average - from 2 to 2.8, the third type can reach 5 mm.

According to the processing method, it can be seeded and alluvial. The first type of quarry building sand is produced by sieving through a sieve. As a result, the largest, medium and smallest particles are separated, and debris (stones and other impurities) is also removed. This type of building material is used for the manufacture of cement and plaster mortars and for the creation of foundations.

For the production of the second type of sand - alluvial, hydromechanical equipment is required. All grains are washed with water. If the quarry is not watered, then artificial reservoirs are specially created in which it is purified. After processing, it becomes clean, free of impurities and debris. Such sand has better technical characteristics than seeded sand. It also becomes similar in properties to the river. It is used for the manufacture of mortars, reinforced concrete structures and for the construction of houses and roads.

In terms of composition, quarry sand is:

- quartz;

- limestone;

- mica-quartz;

- dolomite;

- feldspar.

The most common is the first type - quartz.

The main differences between quarry and river sand

As such, there are no obvious differences between the two species presented, the essence lies in the different cost of these breeds. River sand is twice as high as quarry sand. In the process of comparing these types of sand, we can conclude that the percentage of purity is higher in river than in quarry sand.

There are slight differences in density between river sand and quarry sand. They also differ from the density of building sand.

River sand

It is mined immediately without various impurities and third-party components, and the second type has clay, which is often useful. From such characteristics, it can be concluded that it is impossible to state unequivocally which type of sand is better. It all depends on the enterprise and its goals for the use of sand.

How dry sand differs from other types of sand

Sand includes various loose substrates of nonmetallic origin. They differ from each other in composition, grain size and method of extraction.

Dry sand is one of the varieties of construction sand, which can be conditionally divided into three types:

- artificial;

- natural;

- specially prepared (including dry).

Artificial sand is mined by crushing rocks. Distinguish between perlite, expanded clay, thermosite and marble sand. These materials are homogeneous in composition, but they can have increased radioactivity, and therefore are rarely used in the construction of residential buildings.

Natural sand is mined in quarries, on the banks and from the bottom of rivers and seas. It contains quartz, mica, limestone, clay, various small inclusions of organic and inorganic origin.

Natural sand contains many different impurities

Natural sand contains many different impurities

Natural sand is not suitable for building mixes. To maintain the proportions in the manufacture of concrete, plaster and masonry mortars, dry, clean sand is needed.

Dry sand is a specially prepared material. It has a minimum of foreign inclusions, it is crumbly and 94% consists of grains of a certain size. Using it in the preparation of mortars, it is easier to calculate the exact dosage of water.

Along with dry sand, the specially prepared group includes washed, seeded, hot, molding sand, sand soils and sand and gravel mixtures.

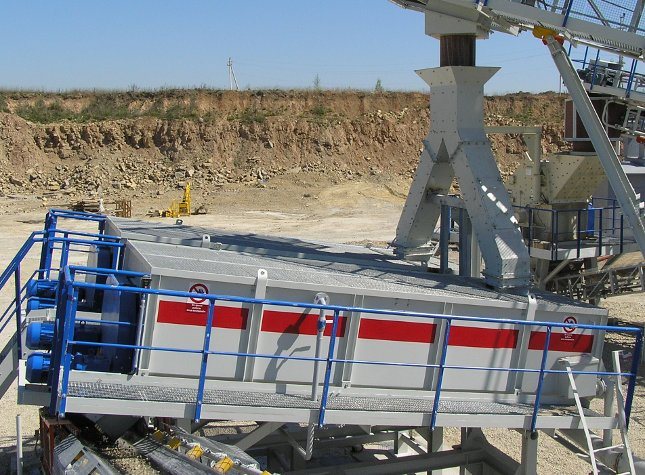

Washing sand and gravel in a trough sink

A trough sink is, as you might guess, a tank (trough) with one or two shafts with blades. The reservoir is always filled with water and the mixing paddles effectively clean the surface of the material.

| Dignity | disadvantages |

| loading medium-sized material (5-60 mm, maximum up to 100 mm); work with any content of clay or other contaminants; high degree of surface cleaning due to direct impact and mutual friction in water; there is no self-grinding of lumpy material, that is, there is no effect on the granulometry of the useful material. | there is no separation into fractions (only washing) and even separation of the drain; low productivity for solid at high power and comparable dimensions with a drum screen (up to 100 m3 / h with a unit size: shaft diameter with blades 1200 mm (x2), length up to 10.5 m; drive power for rotation is about 80 kW); large dimensions of the installation; high water consumption (up to 200 m3 / h for maximum performance) - 2 parts of liquid to 1 part of solid; subsequent dehydration of the washed material is required. |

The material is fed mainly as wet or dry free-flowing after the screen, but is discharged with water and requires dehydration and separation into fractions, at least to remove washed inclusions, as a result, there is no effective separation boundary into overflow and coarse.

Varieties

Quarry sand is usually divided into the following types:

fine-grained;

Fine-grained

medium fragmentation;

Medium-grained

coarse-grained.

Coarse-grained

The first type is characterized by a diameter that does not exceed 2 mm. Medium-grained sand ranges from 2 to 2.8 mm, and the latter type reaches up to 5 mm.

It is worth noting that the minus of this sand is the fact that it contains some impurities that do not have a beneficial effect on the properties of the material. There are times when their percentage exceeds 7%.

During the processing of materials, which are performed after extraction, the sand is divided into several types.

Alluvial

With the help of special hydromechanical equipment, specialists extract sand from flooded deposits and in places of origin. Due to the use of such a technological process, the sand can be obtained absolutely clean without unnecessary impurities and other components.

Alluvial

In the process of extraction by the above devices, dusty substances and the remaining clay are washed out of the extracted material.

Also use this type sand for construction buildings, roadways and other iron products.

Sifted sand

It is obtained by cleansing from large particles and pebbles.

Sifted

This sand is best suited for making plaster mix, forming a solution for building a foundation.

Sandy soil

A variety of this sand is distinguished by a mixture without the need for cleaning from unnecessary components. The cost of this sand does not exceed the average price.

Sandy soil

They use sandy soil in all kinds of construction areas, due to its good properties and the ability to use sand for various activities.