Features of operation

Self-Locking Nuts are advanced mechanisms that hold units together, which are subjected to high vibration loads and shock manipulation. If ordinary fasteners can crack after several blows, then self-locking does not. The finished hardware should be characterized by the reliability of locking, the ease of tightening the thread. In this case, the master should know that the thread of such a nut can be unscrewed and tightened more than once. The principle of operation of self-locking hardware is frictional locking, due to which a high level of friction in the threaded turns is ensured. Ideally, such a nut should be tightened on the correct side and then heat treated.

To prevent the fasteners from unwinding, it is worth following the following recommendations:

- use lock nuts;

- to carry out installation with a spring washer;

- fix the thread with a special type of glue;

- use nuts with nylon or polyamide ring.

Difficulties in using self-locking nuts include the following:

- the need for special surface treatments;

- creating additional stress in the case;

- danger of crushing the conical bearing surface;

- impossibility of full tightening in some cases.

Self-locking fasteners do not unwind, so their reliability is especially important in the manufacture of aircraft and missiles. They replaced standard nuts with less efficiency and difficulty in tightening. These mechanisms are not afraid of vibrations and vibrations, therefore, if there is a choice, experts advise buying self-locking fasteners.

For self-locking nuts, see the video below.

Operating tips

KMT (KMTA) high precision lock nuts are equipped with 3 pins, the distance between which is the same. It is these pins that must be tightened (tightened) together with the screws to fix the nut on the shaft. The end face of each pin is machined to match the shaft thread. Such nuts, however, cannot be used on shafts with grooves in the threads or on adapter sleeves.

The tightening speed of self-locking nuts should be the same, but not more than 30 turns per minute. Remember that the design torque may not be able to provide the required pull. The reason is the pronounced spread of the coefficient of friction force. The conclusion is obvious: critical connections should be created only with careful control of the applied force. And, of course, you should take into account the recommendations of the manufacturers.

See below for nuts and their mounting features.

What it is?

The best way to explain what a lock nut is is to compare it with conventional samples. The "classic", when interacting with the bolt, guarantees a completely reliable connection. But this persists only until stable intense vibrations appear. After some time, they break the mechanical adhesion, and weakening, unscrewing begins. In theory, the stopper can be provided with locknuts and lock washers.

That is why lock (self-locking) nuts are in great demand, and their importance only grows over the years. There are quite a few types of such fasteners. The release of lock nuts in Russia is regulated by GOST standards.

So, hexagonal steel nuts with automatic locking must meet GOST R 50271-92. Products without galvanic coating are designed for temperatures from -50 to 300 degrees. In the presence of electroplating, the maximum permissible heating is 230 degrees. If the nut contains inserts made of non-metallic materials, the critical temperature level is 120 degrees. The standard regulates:

-

test load voltage;

-

Vickers hardness level;

-

Rockwell hardness level;

-

the amount of torque.

Self-locking nuts can save the prevailing torque even with multiple tightening and unscrewing. The chemical compositions of the steels used are also standardized. The nut inserts responsible for the prevailing torque cannot be made from steel alloys - completely different materials are needed for this purpose. Fasteners made of free-cutting steel also comply with the standard (if its use does not violate the supply agreement). The highest sulfur content in nut steel should be 0.24%.

The regulation strictly prohibits the use of hydrogen brittle material

This is especially important when applying special coatings.

The standard strictly stipulates the temperature requirements during operation - stable use at an air temperature of + 10 to + 35 degrees. If necessary, an additional study of these properties can be carried out by means of a full-scale test. The standard covers self-locking nuts made of solid metal or with non-metallic elements that have:

-

triangular cutting ISO 68-1;

-

combinations of diameters and pitches specified in ISO 261 and ISO 262;

-

large groove gap (M3 - M39);

-

small groove gap (М8х1 - М39х3).

What it is?

The fastening element in the form of a self-locking nut is recommended as a connecting piece between elements of various structures. Standard hardware can only be screwed onto products that have threads. To make the connection stronger in this case, it can be strengthened with a grover, cotter pin, washer. The self-locking nut has a nylon retaining ring, so it can be used on its own without any additional fasteners. The advantage of hardware made in accordance with GOST is that it works with high quality and reliably connects the elements to each other. If the consumer prefers a self-locking nut, this means that he can be sure that this hardware is made of high quality steel and at the same time has a zinc anti-corrosion coating.

The construction of this type of hardware has the following components:

- an ordinary nut with six faces;

- side with one-sided increase;

- nylon spacer.

What to consider when choosing?

All metal products are good where small local distortion of the thread is acceptable. It is useful to be interested in whether the compression was performed by the radial method, by the axial method, at an angle to the axial thread from the end or at an angle to it from the end ledge. As for models with a spring-type threaded insert, they are equipped with a crimped coil, which guarantees the elasticity and reliability of the fastener clamping. All such products must have screw-in and out-out torques in accordance with the requirements of ISO 2320. The presence of a flange is welcome - it increases the overall reliability.

The tightening force can only be measured with instruments with a maximum error of 5%. Of course, all measurement results are checked against the regulatory documents and accompanying materials for the products. It is worth considering that models of nuts with a toothed support end on the flange are completely devoid of the prevailing moment. For them to work effectively, an exact match in the size of the attached part is required.

The described type, as well as fasteners with a captive toothed washer, are not reflected in any standard. Their locking properties are assessed based on the results of bench tests. In any case, you need to require a certificate of conformity ISO 2320. Of course, you need to contact only trusted companies, ideally - to direct manufacturers and their partners. The size of the fasteners is selected taking into account the problem being solved.

Lock nuts of modifications KMT (KMTA) can be used in conditions when it is important:

-

maximum accuracy;

-

ease of assembly;

-

fixation reliability;

-

adjustment (compensation) of angular deviations of the mating parts.

Species overview

Like any other hardware, the self-locking nut is available in several varieties.

- With nylon ring. This device looks like an ordinary nut, in the upper part of which a nylon ring is hidden. Hardware with insert can be made in strong and high strength class. This nut is usually used in conjunction with a bolt or screw.

- With a puck. Nuts of this type are considered a modern type of fastener, which is quite functional. The presence of a washer in the fastener prevents the connection from untwisting.

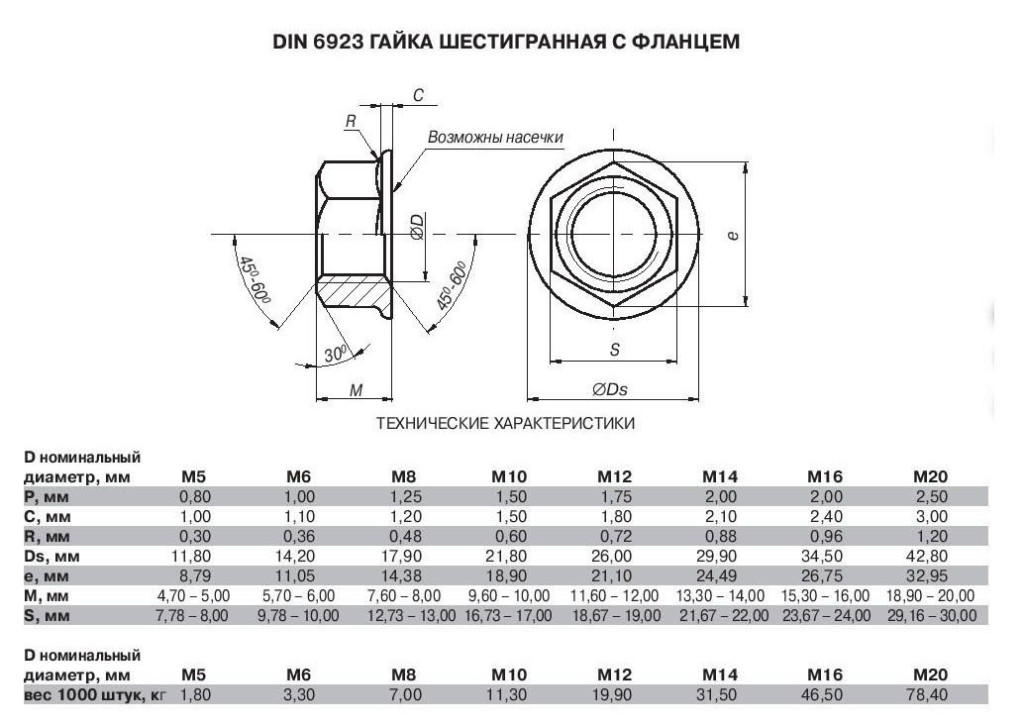

- Flanged is a nut that has a hexagonal shape. Such hardware is made of solid metal and can have a diameter from M5 to M16. It can be used in conjunction with fasteners that have a similar thread. Due to its high strength, the hardware is able to ensure the reliability of fastening.

- The self-locking cap nut is equipped with a nylon ring and is available in thread sizes from M4 to M16. An analogue of this hardware is considered to be a device without a non-metallic ring. These nuts are used to protect threaded fasteners from oil leakage. Self-locking fasteners have found their way into the assembly of vehicles and specialized types of equipment.

It is worth highlighting a few of the most common self-locking nut models.

- DIN 982. The galvanized product is equipped with a nylon ring. When using this hardware, you can get high locking parameters, as well as the reliability and durability of the fasteners. Consumers often give preference to this product, as it is able to fix details with high quality, while it does not need additional equipment.

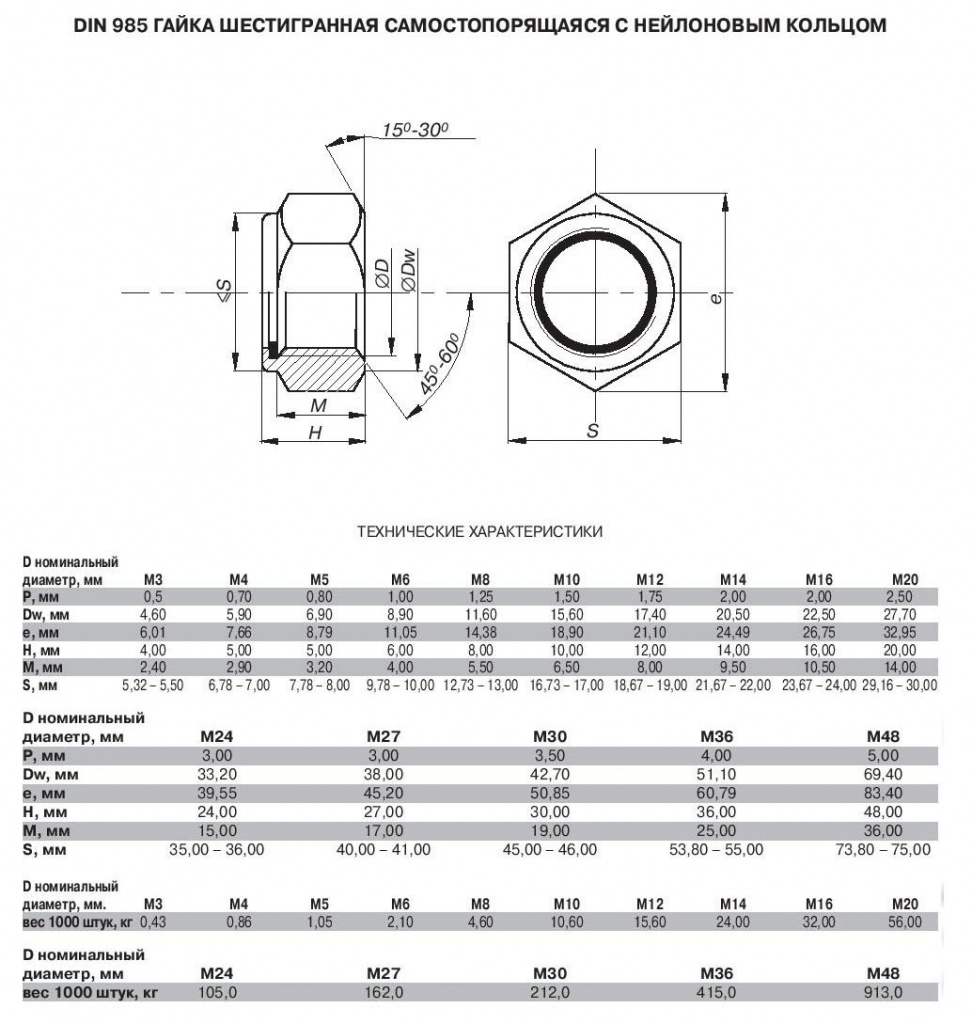

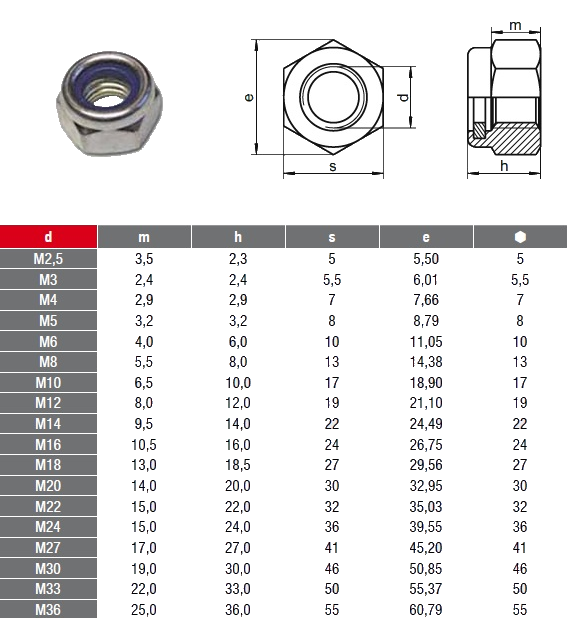

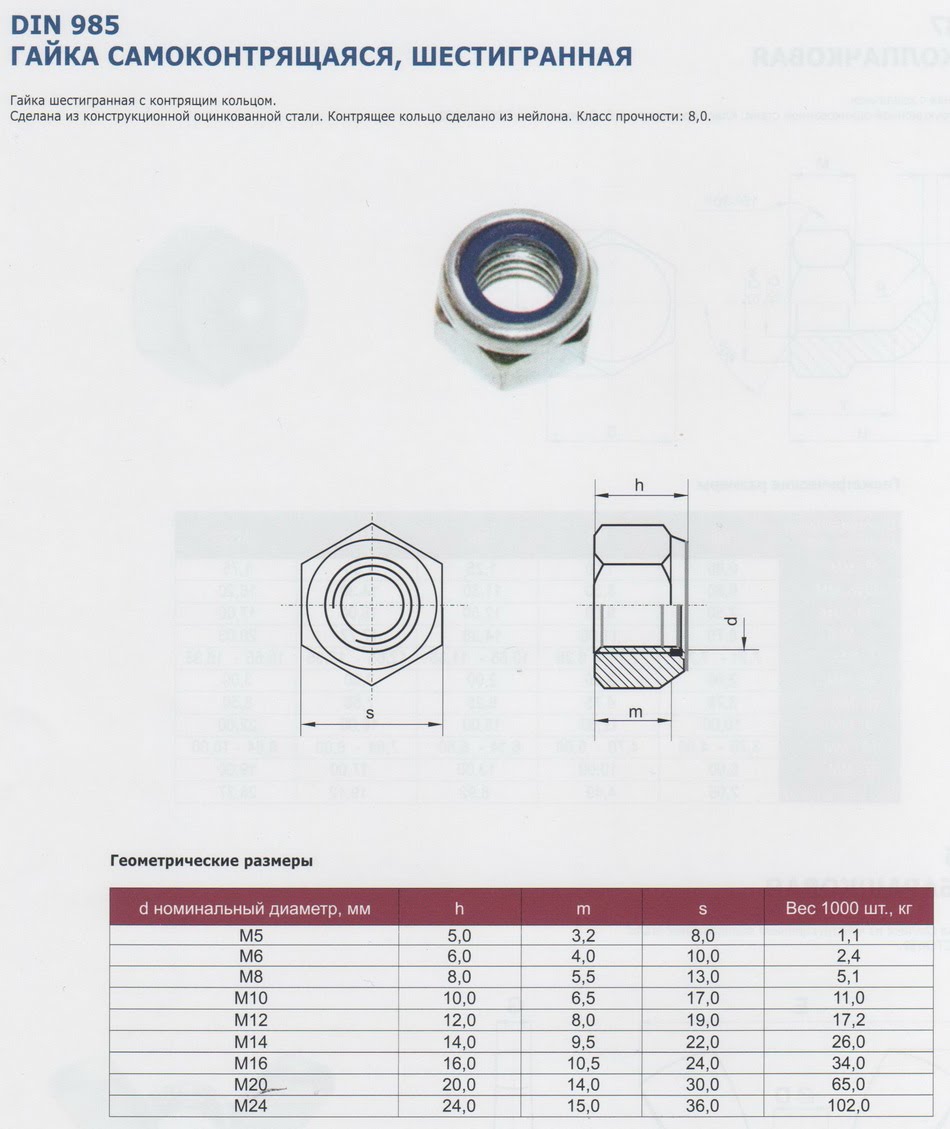

- DIN 985 A2 and A4 are made of stainless steel. This type of fastener does not rust and protects the connection from the negative effects of environmental factors. During the manufacture of A4 nuts, manufacturers add molybdenum, so the product is reliably protected from chlorine and alkali.

- Nut DIN 6927 8.0 and 8.8. This nut model is equipped with a flange, so it can be used in various industries. This hardware does not have a non-metallic retaining element. It has found its way into harsh conditions. In this case, the use of a washer or a grover is not required.

DIN 980 Form M

Self-locking hex nut is an all-metal, two-piece. The design contains an additional stopping element - a ring. This product complies with international standards:

- ISO 7042 ISO 7719 - with standard threads

- ISO 10513 - for fine threads

Dimensions DIN 980 M

| d1 | h | s |

| M3 | 3,7 | 5,5 |

| M4 | 4,2 | 7 |

| M5 | 5,1 | 8 |

| M6 | 6 | 10 |

| M8 | 8 | 13 |

| M10 | 10 | 17/16 |

| M12 | 12 | 19/18 |

| M14 | 14 | 22/21 |

| M16 | 16 | 24 |

| M18 | 18 | 27 |

| M20 | 20 | 30 |

| M22 | 22 | 32 |

| M24 | 24 | 36 |

| M27 | 27 | 41 |

| M30 | 30 | 46 |

| M33 | 33 | 50 |

| M36 | 36 | 55 |

| M39 | 39 | 60 |

DIN EN ISO 10513 Type 2 - All-metal self-locking hexagon nuts with metric fine thread. This standard partially replaced the old standard DIN 980 in 1998. In the part of the main thread, DIN 980 is replaced by DIN EN ISO 7042)

Nut size table ~ DIN 980 M (0.9d) hexagon nut self-locking with metal spring insert (Spring-Stop)

| d1 | h | s |

| M5 | 4,6 | 9 |

| M6 | 5,4 | 10 |

| M8 | 7,3 | 14 |

| M10 | 8,5 | 17 |

| M12 | 10,4 | 19 |

Nut size table ~ DIN 980 M (0.6d) hexagon nut self-locking with metal spring insert (Spring-Stop) low

| d1 | h | s |

| M6 | 3,6 | 10 |

| M8 | 5,3 | 14 |

| M10 | 5,8 | 17 |

| M12 | 7 | 19 |

There is another type of hex nut DIN 980 Form M. This is a similar modification ~ DIN 980 Form M. It differs in the presence other ring model... Slotted ring, also called FS spring insert.

Dimensions and weight

It is most convenient to present the relevant information in the form of a table.

|

Brand |

Height (mm) |

Width (mm) |

Depth (mm) |

|

М4 |

120 |

65 |

10 |

|

M5 |

4,7 — 20 |

8 - 30 (turnkey) |

— |

|

M6 |

30 - 160 (most often 120) |

65 (turnkey) |

10 |

|

М8 |

8 |

17.9 (maximum width) |

10 |

|

M10 |

10 |

15 |

— |

|

М10х1 |

4 – 20 |

5,5 – 30 |

— |

|

M12 |

Before 18 |

Up to 25 |

15 |

|

M14 |

14 |

21 (turnkey) |

— |

M16 flange nuts are usually made of high-quality steels. Carbon metal grades are predominantly used. Considered interaction with various types of metric fasteners. This nut has the following dimensions:

-

thread section from 5 to 20 mm;

-

cutting step from 0.8 to 2.5 mm;

-

height from 4.7 to 20 mm;

-

turnkey width from 8 to 30 mm.

Typical for M18:

-

cutting step 1.5 or 2.5 mm;

-

section inside from 18 to 19.5 mm;

-

head height - 14.3 - 15 or 16.4 mm;

-

wrench size 27 mm.

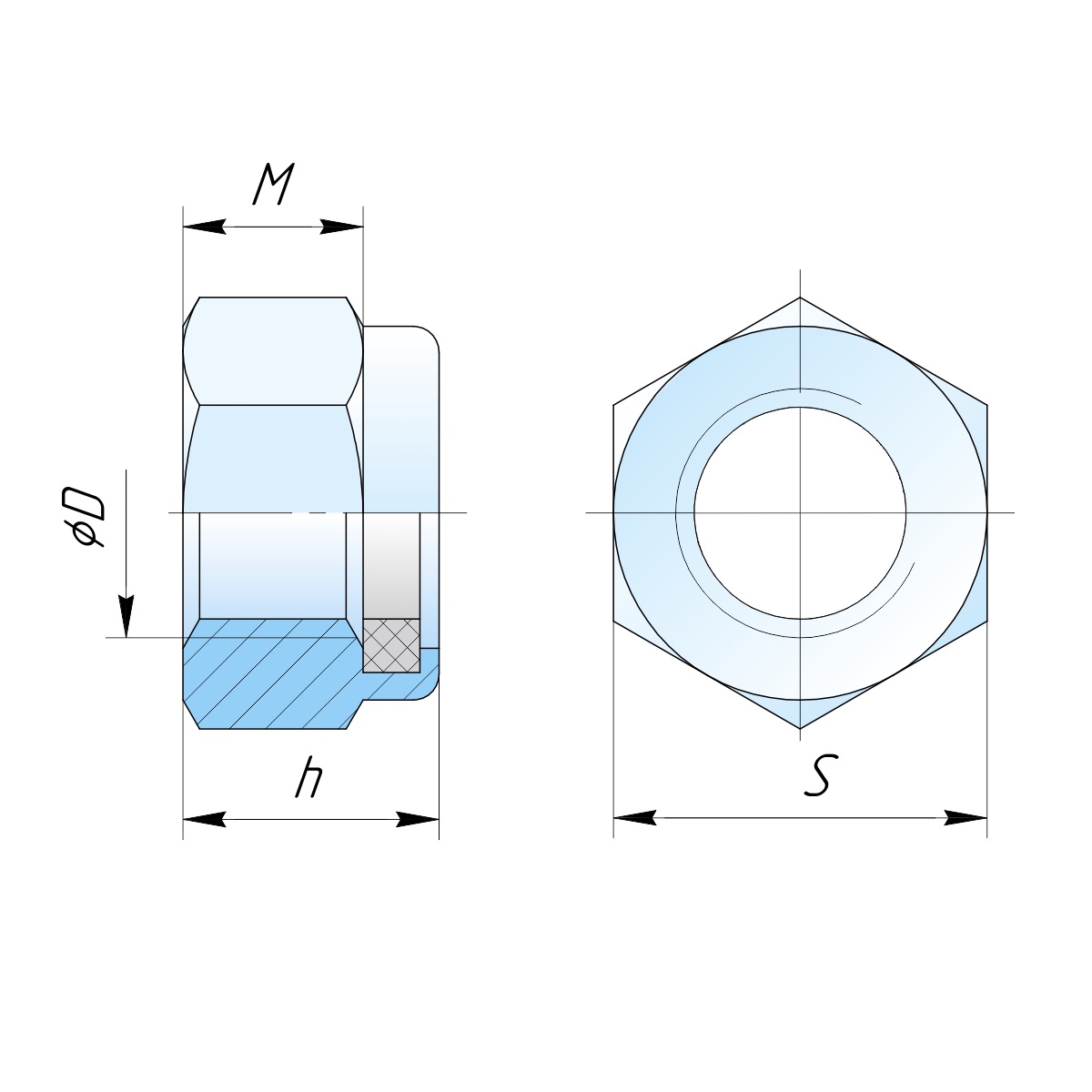

M20 nuts have the following dimensions:

-

height 2 cm;

-

turnkey size 3 cm;

-

flange section 4.28 cm.

According to DIN 6923, the weight of 1000 pieces of nuts is normally:

-

M5 - 1 kg 790 g;

-

M6 - 3 kg 210 g;

-

M8 - 7 kg 140 g;

-

M10 - 11 kg 900 g;

-

M12 - 20 kg exactly;

-

M14 - 35 kg 710 g;

-

М16 - 40 kg 320 g.

M4 flange nuts are designed to create some pressure on the joint surface. Typically, a household package contains 25 pieces. Such products are made of galvanized steel. As for the M6 hex nuts, they can be packaged in 0.581 kg. Basically, the right-hand thread predominates.

See the video about the flange nut below.

DIN 980 Form V

One piece hex nut. There are no additional elements in the design of this product. Clamping occurs due to a modified nut body. It is deformed (crimped) on both sides, and the inner hole is an ellipse. The element meets the standards:

- ISO 7042 - higher strength classes, increased heights

- ISO 7719 - small strength classes, the height cannot be too high

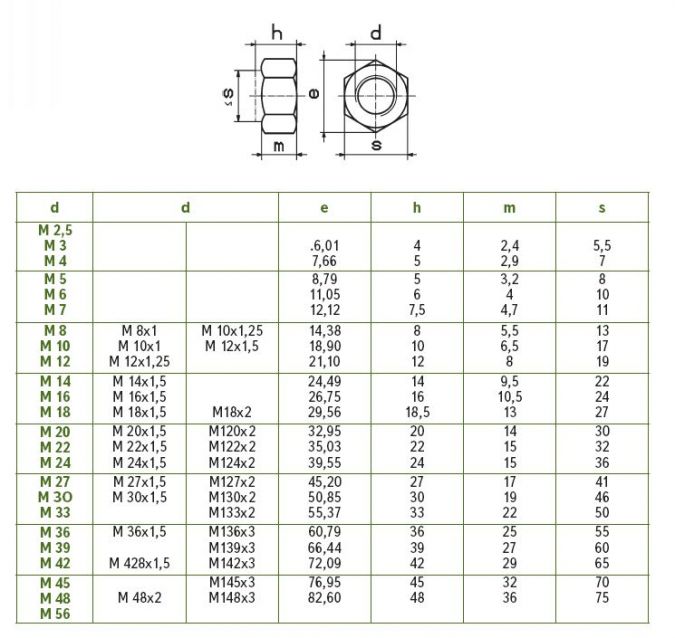

| d | d

fine pitch |

h | m | s | |

| M3 | 3,7 | 1,65 | 5,5 | ||

| M4 | 4,2 | 2,20 | 7 | ||

| M5 | 5,1 | 2,75 | 8 | ||

| M6 | 6 | 3,30 | 10 | ||

| M8 | M8 × 1 | 8 | 4,40 | 13 | |

| M10 | M10 × 1 | 10 | 5,50 | 17 | |

| M12 | M12 × 1.5 | 12 | 6,60 | 19 | |

| M14 | M14 × 1.5 | 14 | 7,70 | 22 | |

| M16 | M16 × 1.5 | 16 | 8,80 | 24 | |

| M18 | M18 × 1.5 | M18 × 2 | 18 | 9,90 | 27 |

| M20 | M20 × 1.5 | M20 × 2 | 20 | 11,00 | 30 |

| M22 | M22 × 1.5 | 22 | 12,20 | 32 | |

| M24 | M24 × 1.5 | M24 × 2 | 24 | 13,20 | 36 |

| M27 | M27 × 2 | 27 | 14,80 | 41 | |

| M30 | M30 × 2 | 30 | 16,50 | 46 | |

| M33 | M33 × 2 | 33 | 18,20 | 50 | |

| M36 | M36 × 2 | M36 × 3 | 36 | 19,80 | 55 |

| M39 | 39 | 21,50 | 60 | ||

| M42 | M42 × 3 | ||||

| M48 |

Variant ~ DIN 980 Form V3 is distinguished by the presence of three deformed sides of the nut.