Applications depending on dimensions

HDF boards are used in various fields.

- Furniture manufacturing. Most often they are used for drawers and back walls of high quality furniture: cabinet or upholstered.

- They make excellent interior doors to an office, a house, a summer cottage, a cafe, and so on.

- Due to their high strength and reliability, excellent partitions are obtained from the panels. Their dimensions make it possible to erect them at high speed.

- Internal work. The small thickness of the slabs allows you to save more usable space in the room. At the same time, it is possible to mount them not only on the walls, but also on the ceiling, which significantly expands the list of areas of their application. They can be used as a backing for laminate flooring. The dimensions of the slabs contribute to an increase in the speed of work.

- Kitchen aprons. Various methods are applied to the slabs with a pattern, and from them an excellent replacement for tiles is obtained. Nice cost and absence of seams is a big plus in kitchen decoration. Custom sizes can be used to reduce material consumption.

- Decor. Grilles are made from these plates to hide ventilation openings, picture frames. They also make excellent screens that cover heating radiators from prying eyes, holes are cut into them for free air passage.

- Finishing. Light weight and high reliability make it possible to use this material in the upholstery of car and passenger car interiors.

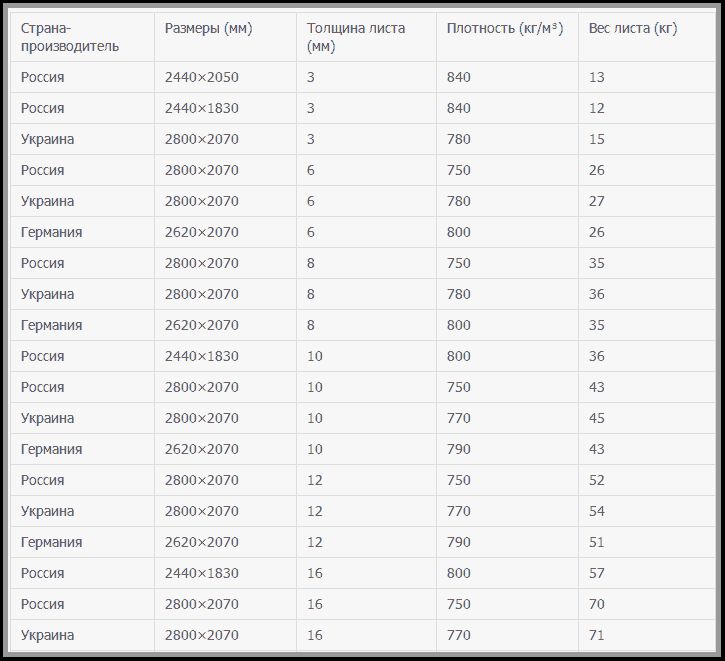

Standard sheet sizes

When assessing the dimensions of MDF, it is necessary to take into account the existing regulatory documents: GOST 32687-2014 and TU 5536-022-0273643-95. They reflect the main indicators

There is also a provision that the dimensions of the slabs can be determined by agreement of the parties.

Wood fiber panels have a wide range of uses, so each direction is classified according to its own standards.

Wood fiber panels have a wide range of uses, so each direction is classified according to its own standards.

Thickness

The most common value is from 3 to 30 mm, the maximum is 60 mm. Large items are made exclusively to order and can be decorative veneered.

The gradation depends on the specific field of application of the product:

- Panels up to 4 mm thick are used only for the manufacture of parts that will not experience mechanical stress. Fragments of cladding, universal corners for cladding joints of adjacent surfaces are obtained from such material.

Thin MDF is widely used for the production of decorative furniture inserts

- Fibreboard with a thickness of 6 to 10 mm is most often used for the production of parts to be mounted on walls or ceilings, and overhead moldings. They can act as a decorative insert for furniture facades or doors for sliding wardrobes.

- Products with a thickness of 10 mm are used for cladding door leaves and making platbands. There are two main decorative types used: laminated and veneered.

According to statistics, about 70% of platbands are now made of MDF

- Thickness of MDF from 10 to 16 mm assumes the use of products for roughing and finishing, depending on the class. With these slabs, walls and other surfaces can be leveled, and interior partitions can be erected. It is taken into account that such a finish contributes to additional thermal insulation of the room and a decrease in noise pollution.

- Plates with a thickness of 16–18 mm are the standard furniture option. They are perfect for the production of framed or solid facades. The structure of the sheet allows for complex surface treatment and the creation of parts of various shapes and reliefs.Thanks to modern technology, the material meets all safety standards, which makes it possible to make wardrobes and beds from it for a children's room.

- MDF sheet with a thickness of 22, 25, 28 and 30 mm can also be used for the production of interior items or reinforcement of interior partitions. The material provides almost complete soundproofing of the room, therefore it is suitable for cladding vertical and horizontal surfaces.

By combining different types, you can get a finish that will not only protect the house from extraneous sounds and heat loss, but also create an individual interior.

Lenght and width

These figures vary greatly depending on the area of use of the product. Many manufacturers are trying to expand their assortment in order to ensure the greatest demand for material for various jobs.

- The standard lengths are 215, 220, 244 and 366 cm. Sheets that are used for rough work or are used for cutting for furniture parts have this size. Wall panels are most often 260 cm long as the surface heights vary within this range. Variants with lengths of 240, 270 and 280 cm are much less common. Although vertical bases are in length from 200 to 400 cm, such elements are made in limited quantities or to order.

- The standard widths are 122 and 183 cm. In reality, the range is much larger. The width of slatted panels ranges from 15 to 30 cm, sheet panels - 60–207 cm.

There are no uniform requirements for the dimensions of MDF panels, and each country develops its own standards

There are no uniform requirements for the dimensions of MDF panels, and each country develops its own standards

Interesting: Knauf Fliesen tile adhesive - features and specifications

Types of decorative wall panels

In fact, it is not enough to paste over the wall with any panels you like. Only those finishes that are correctly selected in size, texture and material will be able to achieve the desired result, supplement, decorate the interior. Before embarking on such design delights, it is worth familiarizing yourself with the features of the existing options, their advantages, as well as disadvantages.

Gypsum panels

Gypsum panels are one of the most common, they are safe, non-toxic, resistant to temperature extremes, provide additional noise insulation, and have a long service life. The possibility of coloring allows you to update the room in just a few hours, add new notes. During installation, a seamless surface can be achieved. In case of damage, sandpaper and putty will help to carry out a quick restoration.

Plastic

In the manufacture of PVC wall panels, technologies are used that allow you to create an imitation of many natural materials, including finishing stone and wood. Polymers also successfully imitate the texture of fabric or leather, and some collections include panels that are really covered with high-quality leathers or textiles. Plastic panels have no equal in a variety of colors and textures. The depth of the relief depends on the thickness of the material and ranges from 30 to 120 mm. Plastic tiles are lightweight, waterproof and easy to maintain.

Glass

This type of decoration appeared one of the last, has not yet had time to become very popular. Glass 3d panels for walls look very beautiful, have excellent quality characteristics, but not everyone can afford their cost. In addition, due to their heavy weight, they are not suitable for all walls, especially partitions.

Aluminum

Recently, they have been used with pleasure by both professional designers and ordinary homeowners who have decided to update the interior on their own. The finish is not afraid of exposure to temperatures or moisture, it is resistant to ultraviolet light, various alkaline environments. No further processing or staining is expected. Manufacturing technology allows you to experiment with texture and color.Due to their light weight, they can be mounted even on plasterboard partitions, but the panels are attached to a frame made of metal profiles, so they will take some area from the room.

Embossed MDF panels

Like the previous options, MDF panels can have a different texture, texture, color. They are made of a high quality compound that ensures stability and a long service life. However, they are not recommended for use in rooms with high humidity, for bathrooms, saunas, baths. Painted surfaces most popular with designers. A feature of MDF panels is the ability to use them not only as a decoration for walls, but also for decorating partitions, furniture facades, doors.

Properties: pros and cons

PVC panels are a unique cladding product made from polyvinyl chloride and used to decorate rooms with high humidity. The composition of the material includes rock salt and elements of petroleum products. Thanks to special manufacturing technologies, these components are converted into an ultra-strong polymer that is resistant to high temperatures and has excellent performance characteristics. In addition to the main raw materials, various additives are also used in the PVC production process, which provide the panels with color, porous structure and high protection against moisture.

The main advantages of this material include:

- Affordable price. Such cladding is considered budgetary and everyone can afford it.

- Huge selection of colors and textures. The market is represented by products of various colors, which not only imitate natural materials, but are also decorated with photo printing.

Durability. Since PVC is a waterproof product, it prevents mold and mildew from forming on the surface of the finish, thereby extending its lifespan.

Good thermal insulation and sound absorption

The internal structure of the material is designed in such a way that it retains heat and external sounds well, which is very important for bathrooms. In addition, during the installation work, a frame is installed, on which you can additionally lay another layer of insulation.

Environmental friendliness

The raw materials from which the material is produced are absolutely safe for human health.

- Fast installation. It is quite possible to carry out all the work on the assembly and cladding of the structure on your own, without having any special skills. In addition, there is no need to use a special tool for finishing. Wall panels also hide all connections, wiring and utilities, giving the bathroom a stylish look. Sheet plates are flexible, so they can be easily attached both horizontally and vertically at any angle.

- Easy to care for. To clean the finish from dust and dirt, it is enough to wash or wipe the plastic with water. No special cleaning agents are required.

- Possibility of installation without preliminary surface preparation. The walls and ceiling, which are planned to be sheathed with PVC, do not need to be plastered and leveled, since the frame is attached to them and after finishing all the flaws will disappear. The most important thing is that the facing surface is dry and clean.

As for the disadvantages, the wall panels are fire hazardous, subject to deformation at temperatures below -18 degrees and, when installed, slightly reduce the bathroom space. The disadvantage of the products is their low strength, due to which they are unstable to the formation of scratches and chips. Installation in rooms where direct sunlight penetrates, which adversely affects the finish, is not recommended. But, as a rule, windows are not provided in bathrooms, so this disadvantage can be excluded.

Varieties of PVC panels

First of all, the panels differ in purpose and among the main types there are such as:

- wall;

- ceiling.

Wall panels differ significantly from the ceiling version in their weight and strength. In order to improve the strength of the wall plastic strips, you have to increase their weight and use more material. In addition, the wall type of finishing material does not have the property of replacing elements, and all this is due to the fact that many strips differ from each other in size, as well as strength and quality. The length of the wall planks can be up to 6 meters, the width is 25–30 cm, and the thickness is 6–10 mm.

The ceiling version, on the other hand, is designed to have less weight. This is understandable, because the strength for the finishing material on the ceiling is not the main criterion, but weight plays an important role. Also, the ceiling version of plastic panels has more variety in the stylistic sphere. The size of the ceiling panels can reach from 6-10 meters in length, 25-30 cm in width and at the same time have a fairly thin wall, which does not exceed 4 mm.

One of the main advantages of using plastic panels is that there is no need to prepare walls or ceilings before installing them. On the contrary, PVC plastic lamellas can perfectly close all cracks, chips or irregularities in walls and ceilings, and at the same time there is no need to carry out preliminary work. Also, to install plastic panels, you do not need to use special tools.

It seems that the material is quite simple, but it also has a large number of advantages, of which sound and thermal insulation can be distinguished. Panels can help hide wiring or plumbing. If some parts of the finishing material are deformed, everything can be easily repaired or the damaged part can be replaced. You don't even need to take care of the PVC plastic panels, and all you need to do is wipe the surface with a damp cloth.

Varieties of panels according to the connection method

PVC plank connections can be divided into types such as:

- embossed;

- seamless;

- panels with rustic (chamfer).

Seamless plastic strips are most often chosen for ceiling installation. The bottom line is that the lamellas are installed quite tightly with the help of seams. If done correctly, the connecting line will be almost invisible.

There are also rectangular relief models, which are also popular, but already for wall decoration. In terms of their shape and method of laying, PVC plastic strips are more reminiscent of lining. The embossed finishing material has good wear resistance characteristics, they are more durable, but at the same time their price is higher. Rectangular planks are best for cladding problem areas or wooden walls.

Rustic PVC panels are not much different from the seamless type. The only difference is that rustic strips have decorative grooves (chamfers) at the ends. This material is suitable for wall and ceiling cladding.

Varieties of PVC panels by size

- sheet panels;

- square shape;

- rectangular shape;

- lining.

Lining PVC planks are sold at a low price and you can easily find the right size. Basically the size of the material, reaches 3 meters in length and 10 cm in width. The width can be up to 12.5 cm if a double profile is used. There are two options for lining planks. The first option is the "European", which differs in that it has a wide lock for fastening and this option is much more convenient to use when mounting the material. The second option is "polka", which has a narrow fastening lock.

MDF: characteristics, description, properties

When planning a renovation or purchase of furniture, you always want to know more about existing materials, their advantages and disadvantages. With comprehensive information, it is easier to understand for what operating conditions certain things are intended, calculate the approximate service life and make an informed choice. This article will focus on MDF, a substitute for solid wood, which is often confused with particle boards.With a number of advantages, which will be described below, this material is excellent for construction, interior decoration, furniture, doors and decor production.

Varieties and characteristics

All panels of this type are made of plastic called polyvinyl chloride, which everyone is used to calling PVC for short. The differences between all types of such strips are their size, coating and thickness. These are the main parameters by which they can differ from each other.

The standard sizes of PVC ceiling panels vary widely and are:

- Width - 25 centimeters

- Length - from 3 to 6 meters

- Thickness - from 5 to 12 millimeters

Non-standard dimensions are also made, while the length of one part can reach 6 meters, and the width reaches 50 centimeters. But, such solutions can be met very infrequently. Basically, the decoration is carried out in traditional sizes and the main difference is the thickness of the material and the finish of its front side.

The latter characteristic mainly influences the choice of a particular model. The main thing is the appearance of the resulting coating and here another feature appears - the coating can be either with clearly visible boundaries between the parts used, or without seams.

This is influenced by the appearance of the panels - they can be seamless or regular. Seamless design means that after installation, such strips are connected tightly, without any gaps, ensuring a solid plane. Such panel options are slightly more expensive than conventional ones.

On standard parts, there are no gaps between them either, but the junction is quite noticeable. What the ceiling looks like from those and other types of PVC panels can be seen in the photo below.

A classic example of using this material. The cover is installed in the bathroom. Its characteristics allow you not to worry about the safety of such a ceiling for many years. Such a finish is not afraid of moisture and various fungi or mold will not start on them.

Here, seamless PVC panels are used for the ceiling decoration. They really create an almost solid plane and the joints between the planks are almost invisible. This is largely due to the special pattern on the front side of the part.

Views

Depending on the parameters, PVC lamellas come in several varieties.

Tiled

The tile material is similar in appearance to ceramic tiles. The standard dimensions of this product are 30x30 cm, 98x98 cm, 100 x 100 cm. Their thickness can be from 1 to 5 mm. Tiled panels can be used in combination with plain tile variations that mimic natural stone.

Wall

Wall slats are used to decorate wall surfaces. Thanks to the large assortment of products, it becomes possible to create an original image in the interior of the room. The width of the products varies from 15 to 50 cm, size - 2.6 m, 2, 7 m, 3 m, thickness - from 6 to 10 mm.

Leafy

These panels differ from the previous variations in large parameters. When working with this type of product, a large area of the working surface is covered. The standard width of the lamellas is 50-122 cm, the size is 0.9-2.44 meters, the thickness is 1-6 millimeters.

Sheet products often imitate various materials:

- wood;

- brick;

- mosaic;

- tile.

Lining

This type of plastic product has a sanded surface. Manufacturers make lining of various colors and textures. The connection of the products is carried out by means of the existing spikes, as a result of which even an inexperienced craftsman can perform the assembly. The width of the products is 10-30 cm, the size is 90 cm - 3 m, the thickness is from 4 to 8 mm.

PVC lining is made in 2 variations:

- "Euro lining" is a product of a standardized size with a wide locking structure. Width - 10 cm, width - 3 m.

- "Polka" is a product of a standardized size with a narrow locking system.Length - 3 meters, width -10 cm.

PVC wall panels also differ in the connection method:

- embossed lamellas;

- seamless plastic building materials;

- panels that are chamfered.

Seamless type finishing materials are commonly used for ceiling cladding in various premises. With the correct installation, you can achieve an effect in which the joint between the parts will be almost invisible. The seamless joining method allows you to create continuous lines and patterns when covering various surfaces.

Beveled panels are somewhat reminiscent of seamless products. The only difference is that in the first version there is a chamfer in the end part of the building material. The chamfer is a recess for joining the plastic panels together.

Embossed lamellas are commonly used for wall surfaces. In appearance, they are similar to the clapboard. Embossed products differ from the previous variations in a high coefficient of strength and wear resistance. Thanks to such technical characteristics, they have a high cost price.

3D effect

This type of product is used not only in the design of residential buildings and apartments, but also in office buildings and shops. The original drawing allows you to create a unique design in the room. Lamellas with this effect imitate natural wood, natural stones, ceramic tiles. Standard parameters: width - 25 cm, 37 cm, 50 cm, size - 2.7 m, 3 m, thickness - from 8 to 10 mm.

With thermal transfer

The manufacturing technology of this type of product is carried out in such a way that an image or a pattern is displayed on a polymer film, after which, on specialized equipment, this image is transferred to a plastic building material under the influence of high temperatures. Panels with thermal transfer are considered the most popular among homeowners, because they have a high resistance to high temperatures, and installation will not cause much difficulty even for a novice builder. The width of the panels is 25 centimeters, the size is 2.7, 3 and 6 meters, the thickness is from 8 to 10 mm.

Laminated products

The method of manufacturing laminated panels is that a film with an image and dressing is glued to the front part. Such a manufacturing method gives the finishing material additional performance characteristics; such a pattern or image is rather difficult to spoil. Laminated panels are treated with an antiseptic, which prevents small dust particles from settling on the surface of the products. The quality of panels of this type is certified by the appropriate quality certificate. Width - 25 centimeters, size - 2.7 and 3 m, thickness - from 8 to 12 mm.

Recommendations for working with plastic

Before installing the finishing product, it is necessary to keep the panels in the room where such an installation is required. The product must be acclimatized. This is necessary so that the building material gets used to the room temperature.

In addition to finishing materials, you will need additional elements:

- inner corner;

- initial profile;

- finishing profile;

- plinth.

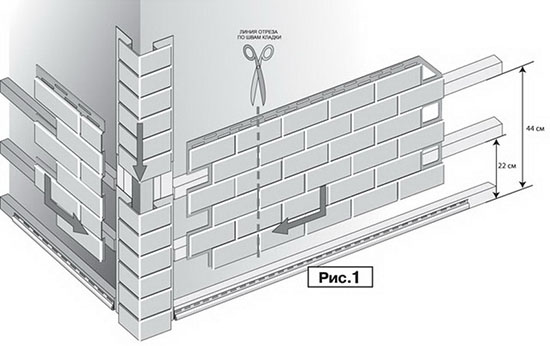

Installation begins from the corner of the room towards the window or doorway. The inner corner is mounted first. The lamellas must be cut to size and the slabs are cut depending on the installation method.

The plastic product is inserted into the corner profile and mounted on the crate. For this purpose, you can use a construction stapler, but clamps are considered the best variation. They are installed in the lower region of the groove, and the fastening is carried out through a hole in the clamp. This method of fastening does not deform the plastic product, and also provides one hundred percent fixation of the building material. Fasteners are selected at the rate of 2 dowels per 1 meter of the profile and 2 self-tapping screws with large caps per 1 meter of the size of the PVC lamellas.

Subsequent elements are assembled using the “tongue-in-groove” method. In this case, the panels should dock as tightly as possible. At the end of the cladding, a joint is formed between the wall surface and the floor, which must be closed with a plinth. To seal the joints on the ceiling, a more decorative ceiling plinth is used, which should be in harmony with the overall finish of the ceiling.

The number of skirting boards is calculated based on the total ceiling area. The standardized skirting board is 3 meters. The total perimeter of the ceiling surface must be divided by the size of the plinth, after which the resulting value is rounded up to a multiple of 3.

Working with plastic products can be carried out at temperatures from -5 to +50 degrees, therefore, wall decoration in baths and saunas is not performed. In places where switches and sockets are located, special boxes should first be installed and an electric cable laid. When installing the lamellas, it is necessary to cut holes for switches and sockets.

There are 2 methods for attaching plastic products:

- on the crate;

- on the adhesive solution.

The installation of lining or sheet panels can only be carried out on the frame. This is due to the large dimensions of the products. The frame in this case can be made of wood or metal slats. The height of the frame depends on the amount of unevenness on the working surface.

Plastic building materials in the form of tiles are mainly attached to the glue. In this case, it is necessary to carry out preparatory work. The surface must be cleaned of various contaminants, leveled and treated with special products. Tiled panels are glued as tightly as possible so that voids do not form under the products.

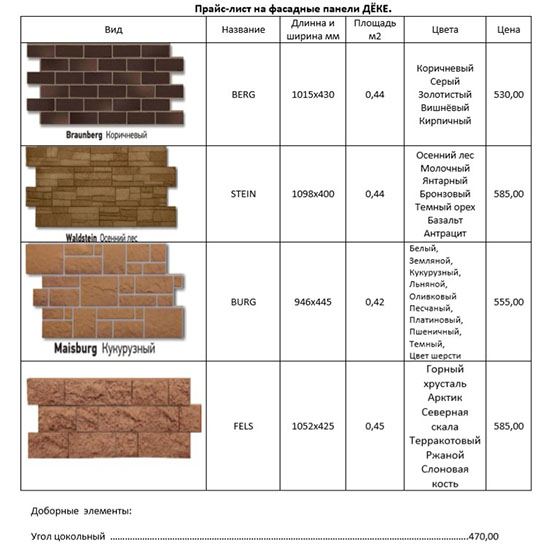

Facade panel sizes: different materials and manufacturers

One of the most

popular types - vinyl siding. The reason is low prices, lightness and

simple installation. But the material can be brittle when frozen, has

high coefficient of thermal expansion.

But the specifics

operation allows for such shortcomings. Also worth noting

high-quality imitation of various wood species. Manufacturers produce panels

with various sizes. But the allocation of such average values is permissible:

- Profile

thickness from 12 to 40 millimeters. - The weight

1 panel - 1.5-2 kilograms. - Width

- 0.2-0.3 meters. - 2.5-3.8 meters

length. - Thickness

0.7-1.2 millimeters.

They produce triple or single, double types of panels. S, D, T - markings for each type. The adjacent numbers indicate the inch width. They must be taken into account when organizing the calculation of facade panels for a house.

Metal

By strength and

stability in all other varieties clearly wins

metal variety. But the demand decreases somewhat due to high prices.

Indicators

metal and vinyl products are very similar to each other.

Dimensions (edit)

describe as follows:

- 4-5

kilograms weighs 1 square meter. - 0,5-1,1

the thickness reaches a millimeter. - Width

- from 22 to 36 centimeters. - Length

up to 8 meters.

Basement

Often instead of a name

"Basement" use the designation "front". Originally designed for cladding

the bottom of the house with contrast. But the material quickly developed specificity,

appointment for work inside and outside.

Forms of such

panels often simplify the installation procedure. Initially, the basement siding was

metal, now vinyl varieties are also produced.

With the dimensions of the case

are as follows:

- One

the panel weighs 1.8-2.5 kilograms. - Height

profile up to 26 millimeters. - Thickness

will be 1-3 millimeters. - Width

is within 0.45-0.59 meters. - Length

- 0.79-1.25 meters.

Ceramic

A source

material - Japan, brought to Russia recently. The material is porous

structure, based on a cement composite, which undergoes a special

hardening inside furnaces.

The manufacturer guarantees a service life of up to 30 years. The panels are characterized by a high level of quality. But such cladding is 4-8 times more expensive than other types of cladding. Therefore, the practical use of ceramic cladding is somewhat limited, but online calculators help to cope.

Surface

can imitate wood and stone, other materials. Installation is enough

difficult, it is not recommended to carry out work independently in most cases.

Majority

panels have the following parameters:

- The weight

1 square meter - 18-20 kilograms. - Thickness

comes up to 14 millimeters. - Width

- from 45 to 91 centimeters. - Length

up to 3 meters.

Cement

They can be attributed

to the group of ceramic products. But the manufacturing technology has certain

differences. In this case, they include other components - water with cement and

sand, as well as - cellulose fibers as one of the additives.

Dimensions (edit)

suggest the following figures:

- One

the panel weighs up to 10 kilograms. - Thickness

within 10 millimeters. - Width

- 19 centimeters. - Length

- 3.6 meters.

Wooden

Right now in

production uses special panels of pressed wood. She passes

special treatment, due to which shrinkage is reduced, or a set

stresses in the material. Connection methods are different, as well as options

profile executions.

Additional

processing is also required to protect against mold, the appearance of various

microorganisms. Description of the main dimensions is as follows:

- Thickness

- from 15 to 40 millimeters. - Width

- 14 centimeters. - Length

- from 3.5 to 5.5 meters.

Major panel differences stand out depending on the manufacturer's conditions. Experts recommend choosing a thickness of no more than 20 millimeters. The maximum width is 14 centimeters. The sizes and prices are chosen by the buyer himself.

For furniture

Particle board is also widely used in furniture production. Most often, due to the rather high cost, MDF is used only for facades, while the main body of furniture is made of cheaper chipboard. As a furniture material, MDF is characterized by the following advantages:

- easily deformable, thanks to which it is possible to make semicircular and fantastically curved facades from it;

- has high strength, which makes it possible to fix various furniture fittings and lamps in it;

- moisture, heat, wear resistant;

- has dirt-repellent qualities, is not afraid of washing with household chemicals.

You can read about how much a moisture-resistant wall panel under a tile costs from this article.

Facades are made to order at factories, where they are veneered, covered with film or paint

It is very important to accurately calculate their size, since in the future it will no longer be possible to fit them under the body. Just like wall panels, MDF sheets for furniture have different sizes and thicknesses.

MDF panels, its price and sheet dimensions can be found by reading this article.

Recommendations for working with plastic when finishing

If the wall is flat, then the material can be attached directly to it. It makes sense to make a frame when you need to close the old finish (wallpaper, paint, tiles) or level the wall without plaster.

In addition, the lathing improves sound insulation, helps to retain heat, and leaves space for ventilation behind the plastic.

It is economical and simple to make a base from wood. Modern antibacterial compounds contribute to the long service life of timber structures. The bars are installed parallel to the direction of the PVC panels, after 50-60 cm.

The frame is also made of U-shaped plastic profiles. Its advantage is that it is insensitive to moisture, lightweight, does not deform from temperature extremes, and is not electrically conductive.

The profile must be fixed in increments of no more than 30 cm, with screws or dowels every 0.5-1 m.For joining U-shaped parts to each other, cuts are made at 90˚, 45˚, 30˚. To attach the plastic, you need clamps (clamps).

To work with panels, you will need moldings:

- internal and external corners;

- joints;

- the edges; skirting boards;

- finishing elements;

- F-profiles.

Living rooms

If treated with an antiseptic, then it is acceptable to make the frame in the living room from a wooden bar.

The premises are finished with wood, stone, white bricks. Use decorative, laminated or mirror plastic.

One of the walls can be decorated with other forms of PVC material. Apply rectangular or square designs 0.3-0.98 m in size, highlight the seams.

Bathroom and toilet

For a bathroom, it is better to make a frame from a galvanized profile or plastic. The material is more suitable without a relief - fungus or mold can form from high humidity, and the textured surface is poorly cleaned.

Bathroom panels go well with ceramic tiles, textured plaster, or paint. The main thing is to choose the right shades. It will work out well if you alternate the width and contrast of the elements.

Prints and patterns in different colors will help create an original drawing. PVC panels for the bathroom go well with a slatted ceiling, into which mirror inserts can be made.

Kitchens

An inexpensive alternative to ceramics for finishing the kitchen can be economical panels (panels at low prices).

You can choose combinations for brick and natural stone masonry, mosaic, drawing or ornament.

There are tiled modular options, of which images are made; patterns are combined to decorate the kitchen completely or its individual zones.

Some additional tips:

When buying plastic material, you should pay attention to the absence of surface flaws, crumpled joints. There should be no translucency at the stiffeners.

Tears and cracks should not form if you press lightly on the product.

Select the width of the panels so that there is less waste

For small apartments, it is impractical to use a panel with a width of 500-600 mm.

The quality of the material can be checked by bending it. There should be no cracks or cracks.

In most cases, the more expensive the material, the better it works.

Leave (from mildew and mildew) ventilation holes.

If you want to make backlights or lamps built into it on the ceiling from PVC panels, it will not hurt to make a markup and prepare holes in advance.

Application

Its properties have provided the material with wide distribution and application. Most often they are used to form smooth walls or prepare wooden products, especially those that require wide dimensions.

Walls

Thicker versions of MDF boards allow them to be used for the formation of flooring.

Flooring

Good wear resistance is ensured during operation. The main quality of mdf boards is the homogeneity of the material, which ensures the popularity of the tool for both furniture and acoustic systems.

Furniture

In everyday life, MDF is found most of all in: wardrobes, dressers, tables, walls, cabinets.

Dresser

Typically, the processing of plates takes place through the use of milling machines, which allows you to apply various beautiful patterns to MDF, producing a high-quality finish and enriching the material with decor.

The main differences between mdf panels: sheet dimensions, weight, type of raw materials used, purpose and price.