Scope of application

First of all, this type of composition is used to dilute paints and varnishes. The R-5 brand solvent is used together with solutions based on the PSKh LP and PSKh-LS resins. The consumable interacts remarkably with other compounds with organosilicon, polyacrylic, epoxy resins, rubber and other elements that form a film on the surface. When working with varnishes and paints (enamel), an effective composition is added in small portions, carefully monitoring the changes in the state of the paintwork.

It is necessary to pour in the solvent carefully, constantly stirring the main composition until you achieve the desired result. Despite the fact that the substance has a wide scope of use, it cannot be called universal. In certain cases, professionals strongly recommend that you completely abandon it in favor of a different composition. Given the huge selection of products, it will not be difficult to find the right product.

Composition R-5 can be used to clean already painted surfaces or equipment and tools that were used for painting. The composition will help remove particles of varnish and paint. Special components easily dissolve a variety of organic compounds, removing even old and stubborn traces.

If we are talking about carrying out large-scale painting (decoration), then you cannot do without an effective tool. In this case, large batches of solution are purchased.

Application area

The production and use of R-12 is carried out in accordance with GOST 7827-74.

This document defines that the solvent is used for dilution:

- paints and varnishes (LM) based on PSC LN or PSC LS;

- polyacrylic resins;

- a variety of synthetic or natural substances, upon application of which a film is formed on the surface.

Despite the clearly marked points, this tool is also often used for cleaning tools, used for aquaprint. Some people resort to using it in everyday life, removing "difficult" stains.

In auto repair shops, R-12 is usually used for diluting base and acrylic car enamels. The composition does not change the properties of such paints. They lie flat on the surface, do not lose color and other characteristics. Dilution of acrylic enamels is justified by the fact that they are based on acrylic resins, and not aqueous formulations.

Special attention should be paid to the use of R-12 in the technology of applying aquaprint. One of the stages of this work is activation. To apply the pattern, it is necessary to soften the immersion film. Professionals use special formulations, but for amateurs this type of solvent is a good and inexpensive replacement. It is evenly sprayed over the entire surface from a spray bottle or in another way.

The solvent of this brand is also used as a replacement for other mixtures, for example, the R-5 solvent. Paints and varnishes must be mixed with the solvent gradually, adding it in small portions, constantly stirring the composition. The mixing ratio is determined according to the manufacturer's instructions.

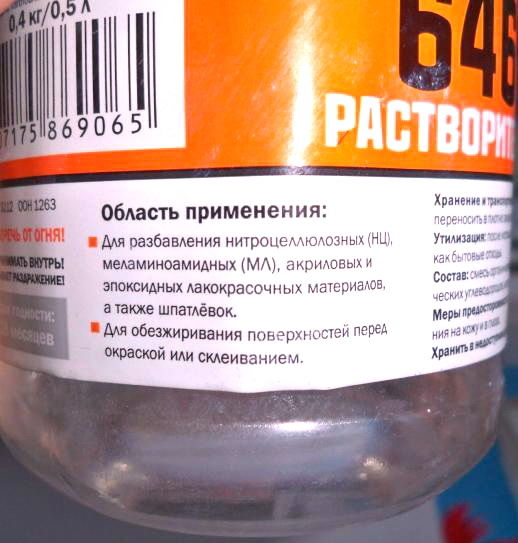

Application area

R-647 copes well with the task of increasing the viscosity of substances and materials that contain nitrocellulose.

Thinner 647 does not damage surfaces that are weakly resistant to chemical attack, including plastic ones. Due to this quality, it can be used for degreasing, removing traces and stains from paint and varnish compositions (after evaporation of the composition, the film does not turn white, and scratches and roughness on the surface are noticeably smoothed out) and can be used for a wide range of works.

Also, the solvent can be used to dilute nitro enamels and nitro varnishes. When introduced into paints and varnishes, the solution must be constantly mixed, and the direct mixing procedure must be carried out strictly in the proportions indicated in the instructions.Thinner R-647 is most often used with the following brands of paints and varnishes: NTs-280, AK-194, NTs-132P, NTs-11.

R-647 can be used in everyday life (subject to all safety precautions)

Technical properties and characteristics of the solvent composition of the R-647 grade in accordance with GOST 18188-72:

- The appearance of the solution. The composition looks like a transparent liquid with a homogeneous structure without impurities, inclusions or sediment. Sometimes the solution may have a slight yellowish tint.

- The percentage of water content is not more than 0.6.

- Volatility indicators of the composition: 8-12.

- The acidity is not higher than 0.06 mg KOH per 1 g.

- The coagulation index is 60%.

- The density of this dissolving composition is 0.87 g / cm. cub.

- Ignition temperature - 424 degrees Celsius.

Solvent 647 contains:

- butyl acetate (29.8%);

- butyl alcohol (7.7%);

- ethyl acetate (21.2%);

- toluene (41.3%).

What to replace?

Solvent P-4 has its analogs. If for some reason it was not at hand, or a different composition with the same quality indicators is fundamentally needed, you can replace it with the following means:

- P-4A. This solvent is the closest analogue of the agent under consideration for diluting paintwork materials. Unlike P-4, the 4A variety does not contain butyl acetate. Due to this, it can interact with enamels of the XB-124 type.

- R-5 / R-5A. These formulations are characterized by a wider range of applications. The concentration of chemical components in them is somewhat different: toluene is present in the composition of 40%, acetone and butyl acetate account for 30% each. These solvents are suitable for use with rubber, silicone and polyacrylic resins.

- P-12. In this solvent, acetone is replaced by xylene. Therefore, the ignition temperature of this material is significantly lower and is +490 degrees C. It is used in auto repair shops. With this composition, you can dilute car enamels and remove old car paint.

However, the composition is not so versatile, so it must be mixed with care. For example, when combined with hydrogen peroxide, acetic or nitric acid, it forms explosive mixtures

It is aggressive towards plastic surfaces. Choosing P-4 or its analogues, you can take a closer look at the products of different brands. For example, a well-known solvent manufacturer is the Dmitrov Chemical Plant, whose products are now known and in demand not only in the domestic market, but also in 70 countries around the world.

No less famous developer of solvents is the Belarusian company Naftan. The company is constantly improving the efficiency of its assortment, offering customers high-quality R-4 solvents for household use in packages of 1 and 2 liters.

You can take a closer look at the Solv and Profi solvents. The first composition is actively used for dilution to the desired consistency of glyphthalic, acrylic, epoxy, melaninoamide and nitrocellulose paints and varnishes. The solvent "Solv", depending on the variety, is used to dilute ethyl silicate and epoxy paints and varnishes.

For information on the difference between a solvent and a thinner, see the next video.

Solvent 647

Composition and specifications

Another inexpensive and popular solvent has the number 674. It differs from 646 in composition and scope. This thinner does not contain acetone, therefore it is less aggressive, including to plastic.

The technical characteristics of the P 647 are as follows:

- looks like a clear liquid, yellowish or colorless, free of suspension, homogeneous,

- water content - no more than 0.6%,

- volatility - 8-12,

- acid number - does not exceed 0.06 mg KOH per 1 g,

- coagulation number - not less than 60%,

- density - 0.87 g / cc.

When diluting nitro enamels, the film should not turn white when the solvent evaporates.Streaks and scratches on the enamel surface should be smoothed out.

It includes:

- ethyl acetate,

- butanol.

- toulol,

- butyl acetate.

Application

Also 647 is used to increase the viscosity of materials containing nitrocellulose. What is the difference between solvents 646 and 647 by application?

P 647 is less active, therefore it does not damage plastic, and therefore it can be used for bodywork, degreasing various surfaces, removing varnish and paint films, if respect for the surface is important. This solvent is introduced into soluble paints and varnishes, constantly stirring, in the proportions indicated in the instructions for a particular paint or varnish.

This solvent is introduced into soluble paints and varnishes, constantly stirring, in the proportions indicated in the instructions for a particular paint or varnish.

Security

Precautions when working with it are the same as when working with the P 646

- Solvent 647 must be stored in closed containers in a fireproof room, away from direct sunlight.

- The room where the work is carried out must have good forced ventilation. The solvent is toxic and dangerous to inhale.

- Avoid contact with eyes. You need to work with gloves, in case of contact with the skin, wash with soap and water.

Like P 646, P 647 is sold for domestic use in cans ranging from 1 to 10 liters, and for industrial use in steel drums.

Scope of application

R-4 is extremely popular among people involved in the renovation of premises, as it is practically universal and necessary for a wide range of works.

Most often it is used for painting work, since it is very effective for the high solubility of paints and varnishes used in interior decoration. It was specially developed for materials based on vinyl chloride, epoxy, PVC and chlorinated resins. It is suitable when it is necessary to dilute or dissolve synthetic or natural film-forming compounds.

It should be noted that the use of a solvent significantly reduces the cost of repair work, since its price is low, and the consumption of paint in a more liquid consistency is significantly reduced. In this case, the quality of the staining does not suffer.

Although the main purpose of the solvent is to thin varnishes and paints, it can be used to clean and degrease surfaces. To do this, wipe them with a cloth soaked in solvent.

Contamination comes off very easily and the solvent evaporates quickly, leaving a thin film. The resulting film is an excellent protective coating that will ensure the subsequent high-quality staining of the surface.

To prevent brushes and other tools from being damaged, they must be washed after work. However, this cannot be done with soap and water. R-4 will come to the rescue here too.

Degreasing is also necessary for many other non-staining work. For example, for the subsequent application of glue or other compounds when repairing shoes, furniture or appliances, when gluing broken fragments. The degreasing procedure can be carried out using P-4.

Properties and specifications

This is not to say that the R-5 brand solvent is a universal remedy, but it is used quite widely. The solvent is used both in everyday life and in the industrial sphere. The tool is successfully used for degreasing surfaces, as well as for diluting almost any type of paint.

The main purpose of the solvent is to lower the viscosity of paints and varnishes. Most often, the substance is used when carrying out painting work. When a solvent is used, painted products become especially smooth and can last much longer than usual.

It is sometimes appropriate to use a blend to remove organic stains. When degreasing surfaces, the consumption of the product is minimal.The mixture contains components that make it possible to dissolve many organic substances.

The product perfectly removes paint from tools. It is enough just to swipe over the subject with a napkin dipped in the mixture.

If there are any stains, the surface should be treated with the solvent again.

The main characteristics of the solvent:

- the substance has a liquid consistency;

- the solvent has no color, therefore it is most often colorless or completely transparent;

- the product does not contain any additional impurities in the form of shock absorbers;

- The substance is highly flammable and volatilisable, so it is better to store it away from open fire and close it tightly with a lid after use.

Solvent R-5 differs from solvent 5A in its density, which is why it is more preferable. The shelf life of the R-5 solvent is limited. The manufacturers only allow the product to be used for one year after the date of manufacture.

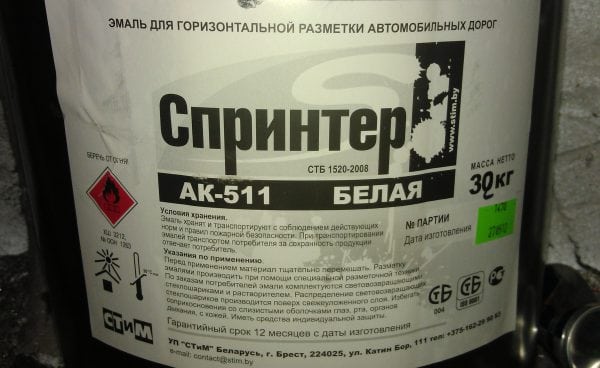

Purpose of paint

The enamel for road marking AK-511 is produced in accordance with GOST R 52575-2006 and is used for drawing safety lines on public highways. The enamel is intended for those trails where there is heavy and moderate traffic, it is excellent for the following surfaces:

- cement concrete;

- asphalt concrete.

Horizontal road markings made with paint are widely used in areas near warehouses, parking lots, parking lots, and airfields. Black material is used not for road markings, but for demarcating old markings (painting over it). To ensure the marking of reflective properties, additives are introduced into the enamel - special glass beads. According to GOST, it is permissible to apply the agent on the carriageway of 1-4 category roads.

Safety and precautions

The solvent is an unsafe substance and can have a negative effect on the human body

- Store in a tightly closed, fully sealed container, away from fire and heating appliances. It is also necessary to avoid exposing the container with the diluent to direct sunlight.

- The solvent composition, like other household chemicals, must be safely hidden and out of the reach of children or animals.

- Inhalation of concentrated vapors of the solvent composition is very dangerous and can cause poisoning. In the room where painting or surface treatment is carried out, forced ventilation or intensive ventilation must be provided.

- Avoid getting the solvent in the eyes or on exposed skin. Work must be carried out in protective rubber gloves. If the thinner does get on open areas of the body, you must immediately wash the skin with plenty of water using soap or slightly alkaline solutions.

- Inhalation of high concentration vapors may damage the nervous system, hematopoietic organs, liver, gastrointestinal tract system, kidneys, mucous membranes. The substance can enter organs and systems not only by direct inhalation of vapors, but also through the pores of the skin.

- In case of prolonged contact with the skin and lack of timely washing, the solvent can damage the epidermis and cause reactive dermatitis.

- Composition R-647 forms explosive flammable peroxides if mixed with oxidizing agents. Therefore, the solvent must not be allowed to come into contact with nitric or acetic acid, hydrogen peroxide, strong chemical and acidic compounds.

- Contact of the solution with chloroform and bromoform is fire and explosive.

- Spraying with solvent should be avoided, as this will quickly reach a dangerous degree of air pollution. When spraying the composition, the solution may ignite even at a distance from the fire.

You can buy R-647 brand solvent in building materials stores or in specialized markets.For household use, the solvent is packaged in plastic bottles from 0.5 liters. For use on a production scale, packaging is carried out in cans with a volume of 1 to 10 liters or in large steel drums.

The price for a solvent of the R-647 brand is on average about 60 rubles. for 1 liter.

Consumption

Solvents are also used if necessary to quickly and effectively degrease the surface. Composition R-5 is also suitable for these purposes. Even a small amount will be sufficient to remove grease and oil stains from the substrate. No calculation is required for standard cleaning. It is enough to moisten a rag with the composition and carefully treat the surface. Do not pour solvent on the surface: aggressive components of the composition can cause irreparable harm to it.

After treatment with solvent, it is necessary to remove its remnants with a dry cloth made of thick paper or cloth. Evaluate the result: if greasy stains remain, repeat the cleaning procedure. However, given the effectiveness of this brand of solvent, one wipe is sufficient. Do not rub the solvent into the base to avoid ruining it. There are certain conditions under which it is desirable to carry out the degreasing process.

Peculiarities

Enamel NTs-132 has been produced since the 70s of the last century, and it is hard to believe that currently no paint and varnish compositions have been invented that would surpass it in their characteristics. Unlike paints, enamels, after complete hardening, form a smooth, uniform layer that protects the surface from various influences.

Initially, the main difference between enamel and paint was the type of thinning liquid. For enamel paints and varnishes, volatile organic compounds were used. In the case of paint, it could be drying oils or ordinary water. Over time, more and more water-dispersible enamels and paintwork materials based on acrylic began to appear.

The letters NTs indicate that this enamel belongs to the group of nitrocellulose, that is, paintwork materials made on the basis of nitrocellulose. It is a white fibrous structure, loose in appearance, reminiscent of ordinary cellulose and obtained from it using nitrogen treatment.

The composition of NTs-132 includes volatile and non-volatile parts. The first group includes alkyd resins (No. 188 according to the classification of resins), colloxylin- nitrocellulose with nitrogen content 10.7-12.2%, plasticizing additives and pigmenting particles. The non-volatile group is different for different types of enamels. It includes either 40% toluene, butyl or ethyl alcohol, about 15% active high-boiling solvents and slightly less low-boiling ones. In the second case, xylene is added instead of toluene, and the solvents reach 30%. An anti-flotation and fire retardant additive can be added to enhance decorative properties, smooth surface distribution.

Manufacturers pay attention to the exceptional resistance of NTs-132 enamel to various influences. In addition, such positive qualities are noted:

In addition, such positive qualities are noted:

- high strength and wear resistance;

- elastic structure is suitable for using any shape and shape of surfaces;

- water resistance allows the use of enamel in structures with high humidity and outdoors;

- ease of care for surfaces covered with paintwork materials - can be washed with any household products;

- a layer of enamel can be sanded and polished to give a glossy shine, which will further affect the decorative appearance of products;

- the coating does not fade in the sun and does not lend itself to ultraviolet radiation;

- withstands strong temperature fluctuations;

- the material is economical and has a low price;

- long service life. When processing the surface with enamel in two layers in moderate climatic conditions, the coating can retain its decorative and quality features for up to two years.

Consumption

So that the applied paint does not later begin to flake off due to uneven application and lumps, it must lie on the surface in an even layer. The added solvent will solve this problem.

There are regulatory documents to determine the solvent consumption. Some time ago they were convenient to use. However, at present there is a huge assortment of paints and their manufacturers, so you should definitely follow the recommendations from the manufacturer. Each type of paints and varnishes may have its own nuances.

The material of the surface to be painted, the temperature and humidity of the environment, the type and "age" of paint, enamel, primer or varnish and their brand, method of application

For example, for varnish XB-784 or enamels XB-124 and XB-125, 50% of the solvent from the mass of paint or varnish will be required for pneumatic application and 25-35% - airless. These products are not applied with a brush. If you apply these enamels with a brush, the solvent consumption will be 13-15%.

To find out how much solvent you need, you must first calculate the amount of paint you need. Manufacturers, as a rule, indicate on the packages information about the size of the area for which 1 kg or 1 liter of paint will be needed. It is more convenient to use the indicator of material consumption per 1 m2. Usually, these indicators differ not only for different types of paint, but also for different colors of paint of the same type.

For oil formulations, the spreading rate is also important. It shows how thick the dried layer should be after painting, at which this layer will not be transparent. All these indicators take into account the amount of the finished, that is, diluted, composition. Having calculated its quantity, taking into account the area and quality of the surface, you can calculate how much paint you need to buy and the consumption of solvent.

For example, to decorate a room, you need 10 liters of the composition. If you apply the paint in an economical pneumatic way (where 50% of the solvent is needed), then using not the most tricky calculations you will determine the ratio of the components. Since in this case you take 100% paint and 50% solvent, then in 10 liters they will be 150%. Make a proportion and make calculations. It turns out that you need about 3.3 liters of solvent, and 6.6 liters of paint.

If you use a brush when you need 15% solvent for mixing, then 10 liters of it will need 1.3 liters, and for paint - 8.7. Do not forget that after work you will need to wash the brush and wipe off any dirt.

Peculiarities

Solvents include rapidly evaporating reagent mixtures consisting of several active components. They dissolve organic substances and form homogeneous compounds with them.

The main task of the solvent is to dilute paints and varnishes, giving them the required working consistency, therefore, certain requirements are imposed on them:

- lack of any reaction with paints and varnishes;

- high evaporation rate;

- the composition must be non-hygroscopic;

- the interaction of the solvent and the coloring composition should take place without any effort.

The solvent affects the paint only at the moment of its application, after which it evaporates without a trace. Each paint and varnish product corresponds to a certain type of solvent.

Thinner number 646 is a universal composition with a wide range of uses.

The active components of P646 are:

- toluene - 50%;

- butanol - 15%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- ethyl cellosolve - 8%;

- acetone - 7%.

The latter does not contain acetone, it is considered not so active, due to which it is used on coatings that require the most careful and delicate handling, for example, when working with plastic. In all other cases, it is worth giving preference to the 646 brand.

Today, solvent manufacturers are conducting research aimed at reducing the concentration of toluene and acetone in the reagent.This is due to the fact that these substances are often used in the manufacture of synthetic drugs.

Solvent 646

Composition and specifications

This composition is used for dissolving and diluting various paints and varnishes, removing stains, cleaning surfaces and tools from paints and varnishes. The GOST standard describes its composition:

- acetone - 7%;

- ethyl cellosolve - 8%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- butanol - 15%;

- toluene - 50%.

Also, solvent 646 is made according to TU, with the differences that the content of toluene and acetone is reduced in it. This is due to the fact that toluene and acetone can be used in the production of drugs.

The description of solvent 646 includes the following specifications:

- appearance - a clear, colorless or yellowish liquid without suspension, not stratifying, without precipitation,

- boiling point - 59 С,

- flash point - -7 С,

- autoignition temperature - 403 С,

- the density of the solvent is 646 - 0.87 g / cc, due to this it mixes well with other solvents and paints and varnishes,

- specific gravity - 0.68 kg / l,

- water content - 0.09%,

- acid number - 0.06 mg KOH / g,

- coagulation number - 40 g / o,

- volatility (ethyl ether) - 12,

- does not freeze

- does not leave dull or whitish spots.

Application

The solvent R 646 is used to dissolve and dilute various varnishes and paints. It was originally intended to dilute nitro paints and nitro enamels. Later it was found that the 646 solvent is also effective in relation to other types of paints and varnishes, as well as epoxy or glyphthalic primers, melamine amide, alkyd, epoxy paints and varnishes, putties, and the film was distinguished by gloss and strength.

It is used to bring paints and putties to the desired viscosity, dilute thickened paints, putties, film-forming varnishes, and gives shine. After drying, the whitish film and the smell of the solvent do not remain. Paints and varnishes with the addition of solvent 646 form a film faster than paints and varnishes without it, have a beautiful gloss. Also used in the production of nitro paints, nitro varnishes, nitro enamels.

It is quite aggressive, especially against plastic, so it should not be used on plastic surfaces. Solvent 646 can be used for degreasing, and it is one of the most effective formulations for this purpose, but due to its activity, the surface properties must be considered. For plastic, use less aggressive products.

Consumption per 1 square meter for degreasing is approximately equal to:

- for outdoor surfaces - 0.147 kg;

- for metal and wooden surfaces indoors - 0.12 kg;

- for concrete - 0.138 kg.

For surfaces that will be affected by water and other aggressive factors, the consumption per square meter is 0.169 kg.

Security

Solvent 646 is toxic, its environmental hazard class is 3. When inhaled, it causes a narcotic effect - headache, dizziness, disorientation, as well as irritation of the eyes, respiratory tract, effects on the gastrointestinal tract, liver. With prolonged inhalation, toxic damage to the liver, bone marrow, changes in the composition of the blood are possible, which lead to serious consequences. Therefore, it is necessary to work with P 646 solvent in a room with good supply and exhaust forced ventilation or outdoors. To protect the respiratory system, use a respirator (such as a "petal").

If it comes into contact with the skin, it does not cause burns, but with prolonged interaction with it, contact dermatitis is possible. Do not allow it to get into the eyes, work must be carried out with gloves and goggles, and in contact with the skin, the substance is immediately washed off with soap and water.

It is volatile and flammable, so care must be taken when handling it.The flammable solvent is extinguished with sand, foam, sprayed water

It is stored in an airtight container, in places where the direct rays of the sun do not fall, at a temperature of -40 to +40 degrees. You cannot store it outside. In the room where the composition is stored or work is in progress, the occurrence of any sparks must be excluded. Do not smoke near containers with the substance.

P 646 is sold in metal drums for industrial use and in 1-10 liter canisters for domestic use. It is completely ready to use, no additional preparation is required. The warranty period during which the composition retains its properties is 12 months.

Usage

Solvent R-12 has found wide application in the automotive industry. With its help, you can achieve exactly the consistency of varnish or paint, which allows you to get a high-quality, smooth, even coating. In other industries, the substance is rarely used, as it is too dangerous for human health.

Some people use P-12 to apply aquaprint, where one of the stages is activation (softening of a special immersion film with a pattern). As a rule, this requires a special liquid, but for non-professionals R-12 is an inexpensive and high-quality analogue. In order to apply in this technique, you need to pour liquid into a spray bottle and completely treat the surface with it.

The substance is mixed with paint or varnish gradually, in small portions, thoroughly stirring the resulting mixture. If more solvent is added than necessary, the varnish or paint begins to curl or delaminate. Therefore, it is necessary to strictly follow the instructions for use.

After applying a mixture with a solvent to the surface to be painted, certain conditions must be observed.

Ventilate the room as much as possible

It is best to use the paint in an open area, but if this is not possible, then after application it is worth opening all windows and doors.

If you are going to approach the object of staining, be sure to wear a respirator or special protective suit to avoid inhaling vapors and getting them on exposed skin.

It is important to avoid open flames or high temperatures in the vicinity of the painted object due to vapors creeping along the ground or floor.

For more information on this solvent, see the following video.