2 Main types of wire

You can distinguish one type from another by its diameter. They are graded in sizes from 2 mm to 8 mm. The most common in the industry is a 5mm diameter string. But even those materials with a diameter of 6 mm, 4 mm, 2 mm are quite common, since they have their own niche of operation.

How is galvanized soft wire with a diameter of 6 mm produced? The process is simple enough. The main raw material used is the so-called wire rod, which is a piece of metal obtained by using hot rolling. Such wire rod can have diameters from 5 to 9 mm.

How galvanized 4 mm wireand galvanized 3 mm are supplied as a roll. The same is with materials with different diameters. This skein can have a mass of 20 to 200 kg. Coils, whose weight starts from 800 kg and reaches as much as 1.2 tons, can also be used as a form for transportation.

Hardware in shipping bays

Wire galvanizing itself can be done in two different ways. When buying galvanized steel, we recommend that you clarify exactly how this process was carried out:

The so-called electroplating. In this case, nothing more than an electric current is used to isolate zinc from the salt solution. In this case, the string will act as a cathode, and some external electrode will play the role of an anadome.

The second method is called hot. At the same time, the material is immersed in a molten mixture of zinc and other elements.

When using this method, it turns out to reach the maximum level of zinc coverage, but if the temperature regime was violated, then the wire rod could become too fragile - pay special attention to this factor when choosing in a store. Try to bend and unbend it and inspect the trace left on the metal

If it is close to breaking, then it is not entirely reliable, and its term and its service are reduced.

Both methods have their advantages and disadvantages. The 6 mm galvanized wire rope obtained by the second method usually costs a little more, since the costs are higher. However, for practical use, you can ignore this parameter, since it has little effect. In most cases, manufacturers do not even indicate on the label how the galvanizing was carried out, since this is not required by law.

To expand the range of applications of the wire, its galvanization is used. This gives it special properties - it is not subject to metal corrosion, as a result of which it can be used in a much larger number of industrial situations.

Making a spring with your own hands

- the steel grade from which the product will be made;

- wire diameter;

- the number of winding turns;

- step of the turn.

A homemade product can be made on a mandrel and using a screwdriver. You will also need cutting pliers, a hammer, a vice, a heating source (oven, gas burner, fire), a cooling medium and additional tools.

The easiest way to make it is to wind the wire on a rod of a suitable diameter by hand. In this case, it is necessary to ensure that the turns fit tightly to each other.

The process of making a spring using a screwdriver can be seen in the video:

- The wire must be completely flat. If the product is made from an uneven or old spring, it must be aligned.

- The wire must be free of rust, oil and other contaminants. To do this, use a soda solution or chemicals to dissolve oils and remove rust. It is recommended to wipe the wire with sawdust.

- Before winding, wire with a diameter of more than 2 mm should be annealed by heating it red-hot (temperature within 400 ° C) and cooling in air.

- When winding, it is necessary to control the position of the turns relative to each other. They should fit snugly one to one.

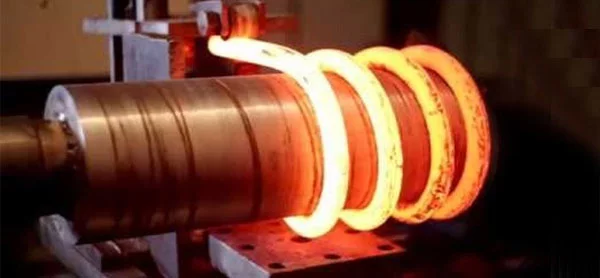

Hardening springs at home can be done in several ways: using a gas burner, heating in a furnace made of brick or stone, or just in a fire. Heating should be done up to a temperature of about 870 ° C. By eye, this is determined by the color of the wire: during the heating process, it becomes almost white. Then it must be placed in oil (transformer, spindle or other liquid medium), which will provide slow cooling. Recall that rapid cooling can cause cracking, which will negatively affect the quality of the spring.

It is recommended to keep the spring made by handicraft in a compressed state for some time. Typically, the holding time ranges from 20 to 40 hours.

The heat treatment of the spring using the available means is shown in the video:

Areas of use

Stainless wire is used very widely. As already mentioned, ropes and springs are made from it. It also serves as a raw material for a variety of mechanical parts. Wire with stainless properties is actively used in:

-

engineering industry;

-

medicine;

-

energy;

-

construction;

-

transport industry.

Stainless steel is excellent for a wide variety of welding jobs. The wire obtained from it has a matte surface and is not covered with any coatings. Most often, such products are obtained on the basis of the Sv-04Kh19N9 and 06Kh19N9T alloys. The high degree of alloying makes it possible to achieve extremely solid qualities.

These two alloys contain over 10% alloying additions. The stability of the stainless material at high temperatures and exposure to various substances allows it to be used with confidence in the production of important parts and electrical equipment. The oil industry also cannot live without wire - they make equipment for pumping towers from it. Of course, oil production and refining require the use of wire for welding as well. It is also widely used in the furniture industry.

A quality wire material can last for many years with skillful use. He is almost not afraid of loads and in this regard he shows himself as worthy as plates, sheets, plates and profiles.

The same properties determine the widespread use of stainless steel wire in the chemical industry. Because of them, it is readily used in the production of surgical instruments and precision medical equipment. Manufacturers of building materials are interested in stainless wire mainly as a raw material for making a welded seam. But it can also be used as an auxiliary component for reinforcement. Another wire made of improved metal is needed to weld the same stainless steel.

It can be used in a fairly aggressive environment. Therefore, this material is appreciated by manufacturers of aircraft, river and sea vessels. On them, it is used wherever you need the most stable and at the same time very accurate connections. Stainless wire is interesting, however, also to car manufacturers. A lot of braids, springs and cables are made from it, because it is difficult to find another blank with greater resistance to mechanical stress at the same price.

For information on whether it is possible to weld ordinary low-alloy steel with stainless wire, see below.

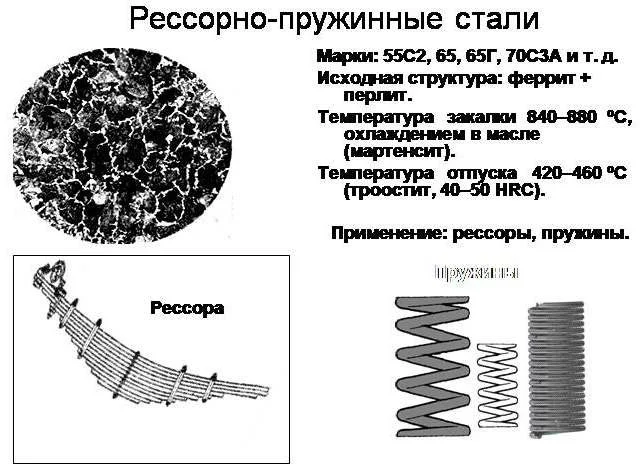

1 What is stainless steel and common spring steel for?

In many modern mechanisms, units and machines, springs and springs, as well as other elastic parts, perform very important functions. Such elements are exposed to variable multiple loads, which leads to their deformation. It is clear that for the normal operation of the mechanism, it is required that after such influences the part returns to its original state (that is, it must restore its initial geometric dimensions and shape).

A number of requirements are put forward to them. First, they must resist stress relaxation, have high rates of fluidity, elasticity and endurance. Secondly, such alloys must qualitatively resist the phenomenon of brittle fracture and be characterized by a sufficient level of ductility.

The required yield strength of various grades of spring steels is obtained by quenching, which is complemented by tempering (it is performed, as a rule, at temperatures from 300 to 480 degrees). The choice of just such a temperature range is not accidental. It is proved that in this case the elastic limit of steel becomes as high as possible. And this is exactly what is required for spring-spring alloys.

The steel grades described by us are used for the manufacture of elastic products with a high wear resistance:

4 Descaling - varieties and subtleties of the operation

The better the surface of the workpiece is prepared for drawing, the more efficiently and better the process will be. At the moment, the scale is removed from the metal by the following methods:

- chemical;

- mechanical;

- electrochemical.

The most common technique used for carbon steel blanks is mechanical cleaning. It makes sense from an economic point of view. This procedure is performed quite simply. First, the wire between the rollers of the special design is bent periodically in different planes. And then they clean the metal with steel brushes.

More expensive are chemical descaling options. They require the use of hydrochloric or sulfuric acid. In addition, working with these compounds is associated with an increased danger for specialists. Therefore, enterprises try to apply such a process only when necessary, allowing people who have undergone special training to perform operations (video lessons, special literature, safety exams, etc.). Chemical descaling is indispensable when stainless and acid-resistant high-alloy steel grades are used as wire feedstock.

Electrochemical cleaning is an electrolytic etching type. It can be cathodic and anodic, and the second method is recognized as more efficient and safer. With it, the workpiece to be cleaned acts as the anode, and copper, iron or lead is the cathode. Cathodic etching is more dangerous, as it results in active hydrogen evolution and poorly controlled scale detachment, which leads to the formation of the so-called "etching brittleness".

After descaling using chemical reagents, the workpiece should be thoroughly rinsed. This allows you to get rid of iron salts, dirt, sludge, residues of pickling elements and acid solution. If rinsing is not performed immediately after chemical treatment, all of these components will dry out. Let's add - washing is done first in hot water, and then under a pressure of about 700 Pa in cold water.

Spring steel hardening and tempering technology

To obtain a metal with the desired physical properties, tempering and hardening of spring steel is applied. Each of the stages has its own technological features:

- First, the spring steel is hardened at high temperatures. Due to hardening, the yield point of the material is noticeably increased, which makes the steel elastic, forgeable, and stable.

- However, during high-temperature hardening, martensitic compounds are formed inside the alloy, which sharply deteriorate the elasticity of the material, making it unusually brittle and hard.

- To get rid of martensitic joints, tempering of spring steel at low temperatures should be applied. During such processing, martensites are destroyed, which makes it possible to obtain a material with the desired properties.

Please note that the temperature and processing time at each stage depends on the type of spring steel used. For example: the brand of spring spring steel 65G should be quenched at a temperature of + 800-850 degrees, tempering - at + 200-300 degrees

In some cases, hardening and tempering are combined with the metal normalization procedure. This procedure allows you to get rid of unnecessary stresses inside the metal, but in most cases, normalization occurs by itself during the cooling of the material. Therefore, additional processing by the normalization method is usually not required.

Thermal hardening

Spring steel hardening is carried out taking into account the following parameters:

- Methods of metal heating, nature of material cooling, ambient temperature.

- Metal composition, presence and type of alloying additives, total carbon concentration.

- A method of maintaining the desired temperature range for quenching.

- Method of material cooling after quenching, material storage method.

Low-alloy steels are recommended to be heated quickly. Indeed, with slow heating, a gradual evaporation of carbon occurs, which is critical for low-alloy materials. However, with the heating rate, you don't need to overdo it. If the heating goes very quickly, then in this case, uneven heating of the material may occur. Because of this, the risk of the formation of various metal defects (cracks, edges, destruction of corners) increases.

The optimal heating method is to use two ovens. In the first furnace, the material is gradually heated to 500-700 degrees, and then it enters the second furnace, where the final hardening takes place.

It is recommended to use gas ovens for heating. However, during heating, the heat distribution should be monitored in order to avoid the appearance of "thermal islands" on the metal. Electric ovens heat up rather slowly, so their use in this case is problematic from a practical point of view. The only exception to this rule is the hardening of thin metals, which do not need additional uniform heating for obvious reasons.

The holding time depends on many parameters, but the average total hardening time is 80 minutes for combustion furnaces and 20 minutes for electrical installations. The shape of the product is also of some importance. When working with flat sheets, quenching can be carried out quickly. Whereas in the case of a material with a complex shape, it is recommended to perform additional heating. The best way to cool the material is outdoors.

Final thermal vacation

To avoid the appearance of hard martensite fractions, it is necessary to carry out thermal tempering immediately after quenching. The temperature regime also depends on which brand of spring steel was hardened. For tempering, both flame and electric ovens can be used. The oven type will also affect the tempering time.

Example: steel 65G is recommended to be subjected to high tempering at a temperature of + 500-600 degrees. Cooling method - air. The holding time is 30-150 minutes, depending on the type of oven. After hardening, it is recommended to carry out control measures. However, this should be done only after the material has completely cooled down so as not to damage the alloy.

Physical properties

We list the main physical properties of this type of steel:

- High resistance to elastic deformation.This figure reflects the fact how easily the plastic element is compressed in the presence of external sources of pressure. In the case of high resistance, the steel spring is difficult to compress, which helps the part to regain its natural shape after being released.

- Low coefficient of residual elongation. In the presence of an external source of pressure, such a material takes on an appropriate shape. However, after the disappearance of such a source of pressure, the part again takes on the old shape. The lower the coefficient of residual tension, the weaker the material undergoes permanent deformation when the external source of pressure disappears.

- Good toughness. When the steel spring is compressed, the part does not crack, its crystalline structure is preserved, and does not disintegrate into several parts. The natural strength of the part can be increased by introducing various alloying additives (nickel, chromium, titanium, lead) into the steel alloy.

- Good corrosion resistance (with alloying components). If the spring is made of steel with a high chromium content, then it will withstand corrosion well. The physics of the process looks like this: if there is chromium in the metal, a thin oxide film is created on the surface of the material. Such a film prevents the contact of iron with oxygen, nitrogen, which minimizes the risk of rust.

- Chemical inertness (in the presence of alloying components). Alloying additives based on vanadium, tungsten, aluminum, selenium, silicon reduce the likelihood of iron contact with external substances. Therefore, when a metal comes into contact with any chemical substance, redox reactions do not occur. This makes the spring chemically inert.

Alloy additives

In order for the steel-spring to become elastic, it must undergo annealing throughout its entire section. This point is very important. If you ignore it, then a high yield stress will occur only in certain fragments of the part. Therefore, with prolonged compression, such a part can crack, break or burst.

When choosing a steel alloy for the manufacture of a spring-spring element, one must remember the concentration of alloying additives. The optimum concentration of carbon in the alloy is 0.5-0.7%. The use of a material with a higher carbon content is allowed, but this does not make much practical sense. Indeed, in this case, the risk of cracking of the material under prolonged load increases significantly, which makes the steel spring useless.

Some additional requirements regarding the content of alloying additions:

- Silicon - not more than 2.5%.

- Manganese - up to 1.1%.

- Tungsten - up to 1.2%.

- Nickel - no more than 1.7%.

To obtain spring steel, hardening of common steel material is used. Quenching is recommended at a temperature of the order of + 800-900 degrees. During quenching, the yield point increases markedly, but at the same time a large amount of martensite is formed, which negatively affects the elasticity. Various technologies are used to destroy martensite. The best technique is to use tempering at medium temperatures (400-500 degrees).

Disadvantages of spring steel

- Poor weldability. Hardening leads to partial deformation, destruction of the outer layer of the material. In the case of welding, melting of the outer hardened layer can result in a poor, cracked weld.

- Problematic cutting. The spring steel alloy has a high resistance to elastic deformation, so it will be difficult to cut such material.

Our production

A device for aligning steel wire with a diameter of 6-10 mm and a strip of 20x3 30-4 mm with a manual drive. Serves for straightening galvanized steel wire with a diameter of 6-10 mm, as well as galvanized steel strip measuring 20x3 mm, 30x4 mm. Round and flat conductors are supplied in coils of 40-50 kg.

In order to carry out a high-quality installation of an air terminal "mesh" made of steel wire on a flat roof, it is necessary to lay the wire in the holders and connect the nodes using the terminals. The wire is laid in cells of 6x6 m, 10x10, 12x12 m in size. In order to evenly lay the conductor of the "mesh", it must be straightened from the twisted state. Galvanized steel wire of 8 and 10 mm is difficult to straighten manually, especially steel with a diameter of 10 mm, and in the straightened state there will be irregularities from uneven straightening.

For laying down conductors from lightning rods on the roof, chimneys and other structures of buildings and structures, installing conductors in holders, it is required to lay it as evenly as possible without bending. The reason for this is the aesthetic appearance, as well as irregularities, as a result of which the wire may come loose from the holders or the holder fastening itself can be damaged.

For ease of installation, our company offers this device for straightening conductors from nine rollers, which will allow you to save time on installing lightning protection "nets", as well as mount down conductors as soon as possible without fear of dismantling uneven sections of wire and strip.

The design of the wire straightening machine allows you to install it at a height of 0.5 m from the roof or floor on any structure made of wood or metal, adjust the pressure of the rollers on the conductor and achieve the evenness of the wire or steel strip.

For example:

- installation on wooden pallets - 5 minutes;

- screwing screws into wood - 2 minutes;

- setting the pressure rollers for the conductor from 5 to 15 minutes;

- unwinding a standard coil 115 m 5-7 minutes

- cutting to required lengths from 5 to 20 minutes

In total, on average, up to 1 hour, you can unwind and prepare galvanized steel wire with a diameter of 8 mm for installation. For a building with a flat roof measuring 50x20 m and a height of 10 m, approximately 3 coils of wire may be required, which means that in 3 hours you can prepare the conductor for laying on the roof and down conductors, without spending a working day on it.

Application of compression springs depending on the material

The scope of these products is very wide. The manufacture of springs according to customer drawings, as well as standard products, is in demand when assembling various mechanisms in the automotive industry, machine tools, the production of measuring instruments, etc.

The scope of these products is very wide. The manufacture of springs according to customer drawings, as well as standard products, is in demand when assembling various mechanisms in the automotive industry, machine tools, the production of measuring instruments, etc.

Alloy steel is used in the manufacture of parts that experience heavy loads in extremely high or low temperatures. Compression springs of this type are also sold on our website.

Stainless steel is a more general-purpose material; springs from it can be installed in any household appliances or mechanisms for non-industrial use. Stainless steel products have good corrosion resistance and can be used at elevated temperatures.

Non-ferrous metals are also widely used for the production of compression springs, in particular for cold drawn wire. The material is sufficiently electrically conductive, corrosion-resistant, heat-resistant.

Special high-temperature alloys are used in the production of springs that are mounted in devices and mechanisms operating at high and low temperatures. Products are widely used in industry, as they have non-magnetic properties and high electrical resistance.

Products from various materials are offered to you by the Slantsevo Springs Plant. We carry out the production of springs in St. Petersburg. Our plant is a powerful enterprise, which has all the necessary imported and domestic equipment for the production of quality products.You can contact us if you need custom-made springs in St. Petersburg. All contact details are listed on the website.

Step-by-step instruction

Step 1

The first thing to do if you are going to make a spring with your own hands is to choose the material for such a product. The optimal material in this case is another spring (the main thing is that the diameter of the wire from which it is made corresponds to the cross section of the coils of the spring that you need to make).

By picking up material from an old spring, you can be sure that the wire is made of hardened high carbon steel

Step 2

Annealing the wire for the spring, as mentioned above, will allow you to make it more plastic, and you can easily align it and wind it on the mandrel. To perform this procedure, it is best to use a special stove, but if you do not have one at your disposal, then you can use any other device that is melted with wood.

In such a furnace, it is necessary to kindle birch firewood and, when they burn out to coals, put a spring in them, the wire from which you are going to use. After the spring is red-hot, the coals must be moved to the side and the heated product must be allowed to cool down together with the oven. After cooling, the wire will become much more plastic, and you can easily work with it at home.

Step 3

The wire that has become soft should be carefully leveled and started to wind on a mandrel of the required diameter.

When performing this procedure, it is important to ensure that the turns are located close to each other. If you have never dealt with winding springs before, you can preview the training video, which is easy to find on the Internet.

You can use a screwdriver to wind a small spring

Step 4

In order for your new spring to have the required resilience, it must be hardened. Heat treatment such as hardening will make the material harder and stronger. For hardening, the finished spring must be heated to a temperature of 830–870 °, for which a gas burner can be used. You can be guided by the fact that the required hardening temperature has been reached by the color of the hot spring: it should turn light red. To accurately identify this color, also refer to the video. After heating to the required temperature, the spring must be cooled in transformer or spindle oil.

The colors of the hot steel

Step 5

After hardening, the spring should be kept in a compressed state for 20–40 hours, and then its ends should be grinded to make the product of the required size.

3 Other requirements for spring steels according to GOST

The relative narrowing of rolled products varies from 20 (65S2VA, 60 C2A) to 35% (stainless steel 50 KhGFA), relative elongation - from 5 to 10%, ultimate strength - from 980 (steel 65) to 1860 (65S2VA) MPA, limit fluidity - from 785 (60G) to 1665 (65S2VA) MPa.

Forged and hot rolled wire, strip and rods must be cut. At the same time, bending of rolled products, burrs are not allowed. In cases where cutting is carried out under hammers or on presses, the strip and rods may have insignificant crumples at their ends. However, the consumer has the right to demand the elimination of this flaw.

The total decarburization in its depth can be as follows:

- for silicon-doped alloys - 2.5% (with a thickness or section of rolled products less than 8 mm), 2% (more than 8 mm);

- for the rest - 2 and 1.5%.

Hot-rolled round bars are produced without a decarburized layer.

Spring steels 55S2 and 55S2A, 50KhGA, 50KhG and 50KhGFA, 60S2A and 60S2 are investigated for austenitic grain index. According to Gosstandart 5639, it should not be higher than the fifth number (for 50HGFA - not higher than the sixth).

The consumer may require that the steel described by us (grades may be different) be produced: