9.2 Marking of property classes

Symbols that should be used in the strength class markings are shown in Table 14.

Table 14 - Symbols used in marking

|

Strength class |

3.6 |

4.6 |

4.8 |

5.6 |

5.8 |

6.8 |

8.8 |

9.8 |

10.9 |

10.9 |

12.9 |

|

Marking symbol a, b |

3.6 |

4.6 |

4.8 |

5.6 |

5.8 |

6.8 |

8.8 |

9.8 |

10.9 |

10.9b |

12.9 |

|

a bFor strength class 10.9 when low carbon martensitic steels are used, see Table 2. |

For bolts and screws of small sizes, or when the marking symbols indicated in Table 14 are not possible due to the shape of the head, it is allowed to use the marking symbols given in Table 15 for the system of the dial specification.

Table 15 - Dial system for marking bolts and screws

|

Strength class |

3.6 |

4.6 |

4.8 |

5.6 |

5.8 |

|

Marking symbol |

End of Table 15

|

Strength class |

6.8 |

8.8 |

9.8 |

10.9 |

10.9 |

12.9 |

|

Marking symbol |

||||||

|

aThe position corresponding to twelve o'clock (reference mark) must be marked with either the manufacturer's trademark or a bottle. bStrength class is marked with either a dash, or a double dash, for strength class 12.9 with a dot. |

Bolt precision

Another important property is accuracy. Manufacturers produce products of two accuracy classes

Class A - implies that the rod fits into the hole with a minimum clearance. The bore diameter cannot be 0.3 mm greater than the bolt thickness. This accuracy is fairly easy to achieve in a production workshop, but almost impossible on a construction site. Fasteners of class B and C can be installed in bore holes 2 - 3 mm larger than the product rod.

The precision of the bolted connection has a noticeable effect on its strength and load resistance. In particular, the more precisely the bore is made, the less the effect of loads arising perpendicular to the axis of the rod will be.

Rating: / 5 -

of votes

9.1 Symbols

The markings are shown in Tables 12 and 13.

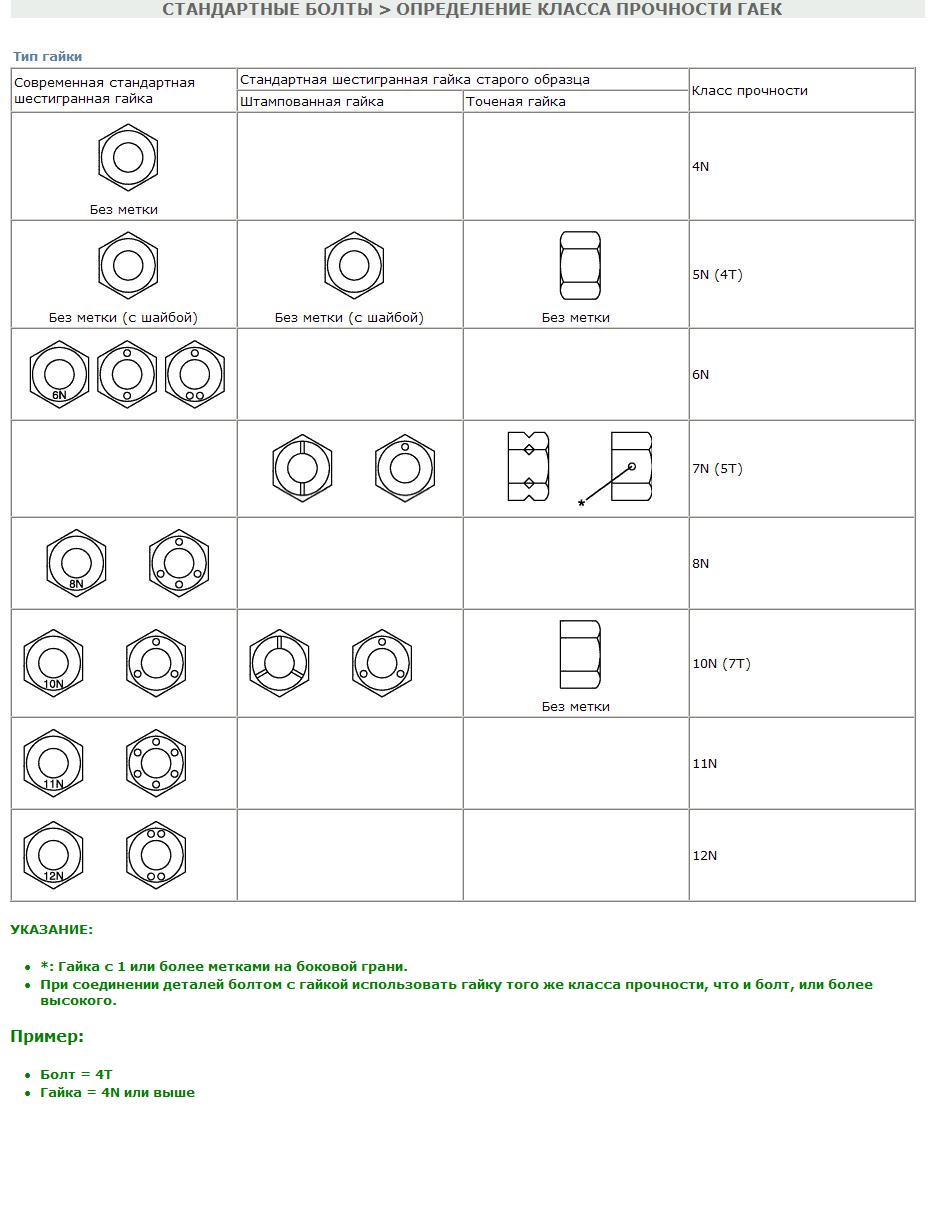

Table 12 - Marking designations of strength class nuts in accordance with 3.1

|

Strength class |

4 |

5 |

6 |

|

|

Alternative |

or designation symbol |

4 |

5 |

6 |

|

or code symbol (dial system) |

The endingtables

12

|

Class |

8 |

9 |

10 |

121) |

|

|

Alter- |

or the symbol is |

8 |

9 |

10 |

12 |

|

or a code character (system of |

|||||

|

1) At position 12, the marking point cannot be replaced by the manufacturer's mark. |

Table 13 - Marking of nuts in strength class in accordance with 3.2

|

Strength class |

04 |

05 |

|

Marking |

8.5 Proof load test for full size bolts and screws

Proof load testing consists of the following two operations:

a) applications

the established tensile proof load (see figure);

b) measuring the residual

elongation caused by proof load.

The proof load given in the tables and should be applied to the bolt installed in breaking

testing machine, axially. The full test load must act in

within 15 s. The length of the free loaded thread section must

equal to one diameter (1d).

For bolts and screws with thread up to the head, the length of the free

the loaded thread section should, if possible, correspond to one

diameter (1d).

To measure the residual elongation, the ends of the bolt or screw must

be prepared appropriately (see figure). Before applying the test load and after removing the load

measure the length of the bolt or screw with a measuring device with spherical

measuring tips. To minimize measurement errors

gloves or pincers should be used.

The proof load test result can be considered

satisfactory if the length of the bolt, screw or stud after application

test load remains the same as before applying load with tolerance

± 12.5 μm, taking into account the measurement error.

Test speed, determined by the speed of the slide with a free

stroke, should not exceed 3 mm / min.The grips of the testing machine must be

self-centering to prevent bending of the test piece.

During the initial application of the test load due to the influence

some random factors, such as deviation from straightness,

deviation from alignment (plus measurement error), permanent elongation

may be more than allowed. In such cases, fasteners

must be retested with a load greater than the initial load

3%; the test result can be considered satisfactory if

the length after retesting will be the same as before this test (with a tolerance

12.5 μm for the measurement error).

Full size bolt

Full size screw

Required sphere-cone contact between measuring points and drilled

center holes in the end face of a bolt or screw

adh - middle row according to GOST 11284 (see.

table).

Figure 2 - Application of a test load to full-size

bolts and screws

8.9 Decarburization test: assessment of the state of carbon at the surface

Using an appropriate measurement method (8.9.2.1 or 8.9.2.2)

on the longitudinal section of the thread section, it is checked whether the height of the non-decarburized zone (base metal E ) and the depth of the zone of complete decarburization ( G ) (see Figure 5).

Maximum value G and formulas that determine the minimum values E are given in Table 3.

1 — fully decarburized zone ;

2 — partially decarburized zone ;

3 — generatrix middle diameter carvings ; 4 — basic metal ( non-decarburized zone );

H 1 — height outward carvings

Drawing 5

— Zones decarburization

8.9.1 The main concepts

8.9.1.1 The hardness of the base metal is the hardness of the area closest to the surface (moving from the core to the outer diameter), measured immediately before the beginning of the increase or decrease in hardness, indicating carburization or decarburization, respectively.

8.9.1.2 Decarburization is usually the loss of carbon content in the surface layer of industrially produced ferrous metals (steels).

8.9.1.3 Partial decarburization - decarburization with the loss of carbon in an amount sufficient to lighten the tempered martensite and significantly reduce the hardness compared to the hardness of the adjacent base metal; at the same time, ferrite grains are not visible in metallographic studies.

8.9.1.4 Complete decarburization - decarburization with the loss of carbon in an amount sufficient to detect clearly expressed ferrite grains during metallographic studies.

8.9.1.5 Carburization - an increase in the carbon content in the surface layer in an amount exceeding its content in the base metal.

8.9.2 Methods measurements

8.9.2.1 Method with using microscope

This method allows you to determine the parameters E and G .

The test specimen is cut along the thread axis at a distance of half the nominal diameter (1/2 d ) from the end of the heat-treated bolt, screw or stud. For grinding and polishing, the sample is mounted in a jig or, preferably, embedded in plastic.

After installing the sample, it is necessary to grind and polish its surface in accordance with the requirements of metallographic examination.

Etching in a 3% solution of nital (concentrated nitric acid in ethanol) is usually used to detect changes in the microstructure caused by decarburization.

Unless otherwise agreed by interested parties, a hundredfold magnification is used to study the microstructure.

If the microscope has a frosted glass, then the depth of decarburization can be measured directly on the scale. If an eyepiece is used in measurements, it must be of the appropriate type, equipped with a sight or scale.

8.9.2.2 Method measurements hardness (arbitration method for partial decarburization).

The hardness test method can only be used for threads with a pitch. R ≥ 1.25 mm.

Vickers hardness measurements are carried out at three points, shown in the figure 6. Values E are given in table 13. The load should be 300 g.

hv2 ≥ hv1—

30;

HV3 £ HV1+ 30;

1,2, 3 — points measurements ; 4 — generatrix middle diameter carvings

Drawing 6

— Measurement hardness v test on decarburization

Table 13 - Values for H 1 and E

In millimeters

|

Thread pitch Ra, mm |

H 1 mm |

E min b, |

||

|

8.8, 9.8 |

10.9 |

12.9 |

||

|

0,5 |

0,307 |

0,154 |

0,205 |

0,230 |

|

0,6 |

0,368 |

0,184 |

0,245 |

0,276 |

|

0,7 |

0,429 |

0,215 |

0,286 |

0,322 |

|

0,8 |

0,491 |

0,245 |

0,327 |

0,368 |

|

1 |

0,613 |

0,307 |

0,409 |

0,460 |

|

1,25 |

0,767 |

0,384 |

0,511 |

0,575 |

|

1,5 |

0,920 |

0,460 |

0,613 |

0,690 |

|

1,75 |

1,074 |

0,537 |

0,716 |

0,806 |

|

2 |

1,227 |

0,614 |

0,818 |

0,920 |

|

2,5 |

1,534 |

0,767 |

1,023 |

1,151 |

|

3 |

1,840 |

0,920 |

1,227 |

1,380 |

|

3,5 |

2,147 |

1,074 |

1,431 |

1,610 |

|

4 |

2,454 |

1,227 |

1,636 |

1,841 |

|

4,5 |

2,761 |

1,381 |

1,841 |

2,071 |

|

5 |

3,670 |

1,835 |

2,447 |

2,752 |

|

and for R £ 1 b Values calculated based on requirements |

Determination of hardness at a point 3 should be carried out on the generatrix of the average thread diameter of the thread adjacent to the thread on which measurements were taken at the points 1 and 2.

Vickers hardness value at a point 2 (HV 2 ) must be at least the corresponding value at the point 1 (HV 1 ) minus 30 Vickers units. In this case, the height of the non-decarburized zone E at least corresponds to the value specified in table 13.

Vickers hardness value at a point 3 (HV 3 ) should be no more than the corresponding value at the point 1 (HN 1 ,), plus 30 Vickers units.

This method of measuring hardness does not allow detecting a zone of complete decarburization up to the maximum value specified in table 3.

9.3 Identification

9.3.1 Bolts and screws with hex and star-shaped head

Hexagon and Torx head bolts and screws (including flanged products) should be marked with the manufacturer's trademark and strength class designation as shown in Table 14.

This marking is mandatory for all property classes and is applied to the top of the head with raised or recessed characters or on the side of the head with recessed characters (see Figure 7). For bolts and screws with a flange, the markings should be made on the flange if during manufacture it is not possible to mark the top of the head.

Marking is mandatory for hex and star head bolts and screws with thread diameters d ≥ 5 mm.

a Commodity sign manufacturer .

b Class strength .

Drawing 7

— Examples of markings bolts and screws with hex and star-shaped head

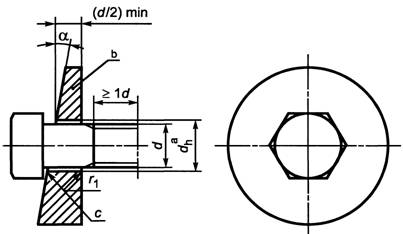

9.3.2 Screws with hex and star-shaped deepening v head

Screws with hexagon and star-shaped socket head “wrench” should be marked with the manufacturer's trademark and the designation of the strength class shown in table 14.

Marking is mandatory for property classes 8.8 and higher. It is recommended to apply marking symbols on the side of the head with recessed marks or on the top of the head with recessed or raised marks (see Figure 8).

Marking is mandatory for hex and star socket head screws with nominal thread diameter d ≥ 5 mm.

Drawing 8

— Examples of markings screws with hex socket v head

9.3.3 Bolts with semicircular head and square headboard

Square head bolts with strength classes 8.8 and higher should be marked with the identification mark of the manufacturer and the designation of the strength class given in table 14.

For bolts with nominal diameter d ≥ 5

mm marking is mandatory. It should be marked on the head with recessed or raised marks (see Figure 9).

Drawing 9

— Example markings bolts with semicircular head and square headboard

9.3.4 Hairpins

Studs with nominal thread diameter d ≥ 5 mm of strength classes 5.6, 8.8 and higher should be marked with recessed signs with the designation of the strength class in accordance with Table 14 and the manufacturer's trademark on the unthreaded section of the stud (see Figure 10).

If it is not possible to mark the stud in the unthreaded area, only the strength class may be marked at the nut end of the stud (see Figure 10). For fixed-fit studs, use markings at the nut end with only the manufacturer's trademark, if possible.

Drawing

10 — Marking studs

It is allowed to use the symbols given in Table 16 as an alternative marking of property classes.

Table 16 - Alternative symbols for marking studs

|

Strength class |

5.6 |

8.8 |

9.8 |

10.9 |

12.9 |

|

Marking symbol |

9.3.5 Other types bolts and screws

For marking other types of bolts and screws, as well as special products, by agreement between the interested parties, the same marking methods can be used as described in 9.3.1 to 9.3.4.

8.6 Tensile washer test for full size bolts and screws

Tensile test on the nipple washer is spread on the screws with a hidden head.

The tensile test on the washer should be carried out on the test equipment provided for testing metals in tension in GOST 1497, using the washer, as shown in Figure 3.

The distance from the thread of the bolt to the contact surface of the clamping device nut must be at least 1d... A hardened washer, dimensioned according to Tables 10 and 11, is installed under the head of the bolt or screw. Tensile test carry out to rupture

bolt.

adh—averagerowonGOST 11284 (cm. table

10).

b—hardnessnotless

45 HRC;

with—radiusorchamfer

45°

Drawing 3

—Trialonobliquewasherfull-sizebolts, screws

Table 10 - Test hole diameters on the washer

In millimeters

|

Nominal diameter |

dha |

r1 |

Nominal diameter |

dha |

r1 |

|

3 |

3,4 |

0,7 |

20 |

22 |

1,3 |

|

3,5 |

3,9 |

0,7 |

22 |

24 |

1,6 |

|

4 |

4,5 |

0,7 |

24 |

26 |

1,6 |

|

5 |

5,5 |

0,7 |

27 |

30 |

1,6 |

|

6 |

6,6 |

0,7 |

30 |

33 |

1,6 |

|

7 |

7,6 |

0,8 |

33 |

36 |

1,6 |

|

8 |

9 |

0,8 |

36 |

39 |

1,6 |

|

10 |

11 |

0,8 |

39 |

42 |

1,6 |

|

12 |

13,5 |

0,8 |

42 |

45 |

1,6 |

|

14 |

15,5 |

1,3 |

45 |

48 |

1,6 |

|

16 |

17,5 |

1,3 |

48 |

52 |

1,6 |

|

18 |

20 |

1,3 |

|||

|

a |

Table 11 - Angle washers

|

Nominal |

Strength classes for |

|||

|

bolts with a section of a smooth rod ls> 2 d |

bolts and screws |

|||

|

3.6, 4.6, 4.8, 5.6, 5.8, 8.8, 9.8, 10.9 |

6.8, 12.9 |

3.6, 4.6, 4.8, 5.6, 5.8, 8.8, 9.8, 10.9 |

6.8, 12.9 |

|

|

a±°30′ |

||||

|

d£ 20 |

10° |

6° |

6° |

4° |

|

20 d£ 48 |

6° |

4° |

4° |

4° |

The test is considered satisfactory if the rupture occurs in the core or in the free

the threaded portion of the bolt, not where the head is connected to the shaft. In this case, the requirement imposed on my minimum tensile strength (or in the process

carrying out tensile tests on the washer, or in the process of carrying out an additional tensile test without using the washer) in accordance with the values provided for the corresponding strength class.

For bolts and screws on the side of the head, the test is considered satisfactory if the fracture occurs in the free section of the thread, even if at the moment of rupture it extends into the area of the adapter plate under the head or the head.

For bolts of accuracy class Radiusr1, should be calculated by the formula

r1 = rmax + 0,2

wherer- the radius of the transitional flue under the head,

wherein

whereda-diameter of the transition flue;

ds- the diameter of the smooth part of the bolt rod.

For bolts and screws with a high-diameter head surface greater than 1.7 d, not withstanding tensile tests on a washer, the head can be machined to a diameter of 1.7 dand then these products may be re-tested for the earthing loss as specified in Table 11.

In addition, for bolts and screws with a high-diameter head surface greater than 1.9 d, the angle of the washer equal to 10 ° can be reduced to 6 °.

Bolt strength

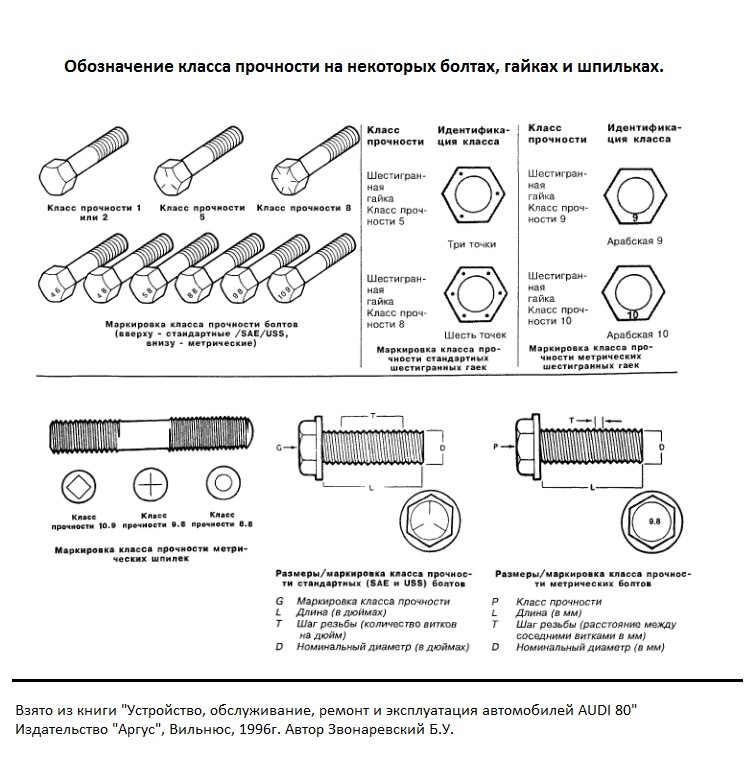

All bolts with threads greater than M6 must be marked. The bolt head is marked with the strength of the bolts in accordance with GOST or ISO, as well as their design. If the thread of a bolt or screw is more than M6, and there is no marking on the head, then the use of such a bolt should be discarded. Consider what the bolt strength class means and how it is indicated directly on the head.

The picture shows three types of markings. Bolt strength 8.8 is the most common. The bolt has a strength class of 10.9 and is therefore stronger than 8.8. An “X” on the head of the bolt indicates that the bolt is hardened, usually this is the designation on propeller bolts. There are bolt strength classes 3.6, 4.6, 4.8, 5.6, 5.8, 6.6, 6.8, 8.8, 9.8, 10.9, 12.9. The period between numbers may be missing.

Now let's talk about what these numbers mean. The first digit of the marking is equal to 0.01 the tensile strength of the bolt, in order to understand the ultimate strength, we divide the first digit by 0.01 and we get the tensile strength in MPa. The second figure is 0.1 of the ratio of the bolt's yield strength to tensile strength. If we multiply the numbers, and the result is multiplied by 10, then we get the yield strength in MPa. Let's give an example of decryption. The strength of the 12.9 bolt is deciphered as follows:

12 / 0.01 = 1200 (MPa) - tensile strength.

12x10x9 = 1080 (MPa) - yield point.

Bolts of strength class up to 5.6 are most often used in furniture production, the rest are used in mechanical engineering and construction. Moreover, the strength class 10.9 and 12.9, due to the high price, is used in the assembly of particularly critical units.

In addition to standard hex head bolts, socket head screws, flange bolts, pan head square head bolts, and others are also used. The location of the markings for these bolts is different from the standard bolts. The markings can be applied to a cylindrical surface or under the head of a bolt.

The picture shows examples of markings on a panhead bolt (left) and an Allen bolt (right).

There are also bolts intended for use in certain assemblies; they may have additional markings. For example, bolts for the construction of bridges can be marked with "ХЛ", which means the permissible use of the bolt at temperatures up to -65 0 С. Sometimes the steel grade used in the manufacture is indicated on the bolt heads.

The strength class is also indicated on the studs, it is applied to the cylindrical part, where there is no thread, but with two significant differences: 1) On the bolts, the marking protrudes above the surface, on the studs, on the contrary - the marking goes deeper into the material. 2) Studs are marked starting with strength class 5.6. On stud diameters less than M12, sometimes not numbers are marked, but conventional signs, each of which corresponds to a strength class.

Nuts are marked in a slightly different way. When marking a nut, take into account the ratio of its height to the thread diameter. According to the ratio of nut height to diameter, nuts are divided into 5 types: 1) Low H / d less than 0.8 2) Normal with a ratio of height to thread diameter 0.8 3) High with a ratio of 1.2 4) Extra high with a ratio of 1, 5. 5) Ultra low, usually not marked.

For low nuts, there are only two strength classes - 04 and 05. To calculate the tensile strength, we fold back 0 and multiply by 100. We get 400 and 500 MPa, respectively. Based on the obtained value, we look at what class of bolt strength the nut should be used with.

Normal, high and extra-high nuts have 7 strength classes - 4, 5, 6, 8, 9, 10, 12. Similarly, multiply by 100 and get the tensile strength value. Therefore, a Grade 8 nut is best used with an 8.8 bolt. In such cases, the load distribution in the thread will be uniform.

Sometimes there are other bolt markings, but this is usually very rare.The vast majority of bolts are marked according to this principle.

In the next article, I'll show you how to calculate a bolt for tension, shear, and shear.

Ask questions, leave comments, share your impressions of the article!

4.2. Shear connections

4.2.1. Under the action of the longitudinal

force passing through the center of gravity of the joint, the distribution of this force between

the bolts should be taken uniform. When acting on the joint bending

the moment the distribution of forces between the bolts should be taken proportionally

distances from the center of gravity of the connection to the bolt in question (at

triangular diagrams of the distribution of forces between the bolts, Fig. 2).

Rice. 2

4.2.2. Shear bolts from

simultaneous action of longitudinal force and bending moment, it is necessary

check for the resultant effort.

4.2.3. Estimated

the force (kN) that can be hit by one bolt should be determined by

formulas:

on a cut -

Nbs = 0,1·Rbs·γb1·A·nb,(4)

to crush -

Nbp

= 0,1·Rbp·γb1Γb2Γ(t)·ab,(5)

Designations used in formulas (4, 5):

γb1 —

coefficient of working conditions, taking into account the non-simultaneity of the inclusion of bolts in

work, which should be taken according to the table. 4;

γb2 —

operating condition factor taking into account distances along the force from the edge

element to center the nearest hole and between the centers of the holes, which

should be taken according to the table. 5;

A = nd2/4 - calculated area, cross-section of the bolt rod, cm2;

nb - number

calculated cuts of one bolt;

γ(t) - coefficient,

taking into account the thickness of the connected elements, determined

(6)

t - the smallest total thickness of elements removed in

one direction;

db —

nominal outer diameter of the bolt shank, see.

Table 4

|

connection characteristic |

Condition factor |

|

One bolt in shear calculations and |

1,0 |

|

Multi-bolt in shear calculations |

0,9 |

Table 5

|

connection characteristic |

Condition factor |

|

Single-bolt and multi-bolt in |

|

|

at 1.5d |

0,25 a/d+0,5 |

|

at a ≥ |

1,25 |

Note. Distance b there must be more distance a on

at least 0.5d... Otherwise

case a = b-0,5d.

Estimated efforts that

can be received with one bolt of a multi-bolt shear connection with one plane

slice, are given in.

Estimated efforts that can be

taken by one M24 bolt of a multi-bolt connection for crushing (with Rbp = 1,48·Run, a = 2d; b

= 2,5d), shown in .

4.2.4. Quantity n bolts in the connection under the action of a longitudinal force N (kN) should be determined by the formula

(7)

where Qb - the lesser of the calculated effort for one bolt Nbs and Nbpcalculated according to the requirements of these recommendations.

4.2.5. Connections arising during operation

the movement of the crushing of each element and from the action of the standard loads should

define:

a) at Nbp≤ Nbs - according to the table. 6.

|

Estimated |

Movements |

||||

|

1,0 |

1,1 |

1,2 |

1,3 |

1,4 |

|

|

0,94 Run |

1,0 |

0,8 |

0,75 |

0,7 |

0,65 |

|

1,17 Run |

1,75 |

1,4 |

1,1 |

0,9 |

0,75 |

|

1,48 Run |

3,0 |

2,4 |

2,0 |

1,6 |

1,35 |

|

1,58 Run |

3,5 |

2,8 |

2,3 |

1,9 |

1,6 |

The designations adopted in table.

6:

Qsettlement. —

the force acting on the connection from the design loads;

Qnorms... - then

the same from standard loads.

Note. When determining displacements

crushing of each connected element for intermediate values K= Qsettlement/Qnorms

linear interpolation is allowed.

It is allowed to take values

shear displacements of each connected element u, from the action of normative loads is less than the given

in table. 6, while the design resistance of single-bolted joints to crushing

should be determined by the formula

Rbp = K·f·Run,(8)

where f

- coefficient equal to

f = 1,08×u - at 0 u

≤ 0.8 mm, (9)

f = 0,57+0,4×u-0,032×u2 - at 0.8 u≤ 3.8 mm (10)

Coefficient f depending on the movement of the collapse of each connection of the element u given in;

b) at NbsNbp- according to formulas 9, 10 and according to; replacing in the formula () Nbp

on Nbs.

4.2.6. Strength of elements weakened

holes in shear connections should be checked taking into account the full

weakening of cross-sections with holes.

Bolt strength

All bolts with threads greater than M6 must be marked. The bolt head is marked with the strength of the bolts in accordance with GOST or ISO, as well as their design. If the thread of a bolt or screw is more than M6, and there is no marking on the head, then the use of such a bolt should be discarded. Consider what the bolt strength class means and how it is indicated directly on the head.

The picture shows three types of markings. Bolt strength 8.8 is the most common. The bolt has a strength class of 10.9 and is therefore stronger than 8.8. An “X” on the head of the bolt indicates that the bolt is hardened, usually this is the designation on propeller bolts. There are bolt strength classes 3.6, 4.6, 4.8, 5.6, 5.8, 6.6, 6.8, 8.8, 9.8, 10.9, 12.9. The period between numbers may be missing.

Now let's talk about what these numbers mean. The first digit of the marking is equal to 0.01 the tensile strength of the bolt, in order to understand the ultimate strength, we divide the first digit by 0.01 and we get the tensile strength in MPa. The second figure is 0.1 of the ratio of the bolt's yield strength to tensile strength. If we multiply the numbers, and the result is multiplied by 10, then we get the yield strength in MPa. Let's give an example of decryption. The strength of the 12.9 bolt is deciphered as follows:

12 / 0.01 = 1200 (MPa) - tensile strength.

12x10x9 = 1080 (MPa) - yield point.

Bolts of strength class up to 5.6 are most often used in furniture production, the rest are used in mechanical engineering and construction. Moreover, the strength class 10.9 and 12.9, due to the high price, is used in the assembly of particularly critical units.

In addition to standard hex head bolts, socket head screws, flange bolts, pan head square head bolts, and others are also used. The location of the markings for these bolts is different from the standard bolts. The markings can be applied to a cylindrical surface or under the head of a bolt.

The picture shows examples of markings on a panhead bolt (left) and an Allen bolt (right).

There are also bolts intended for use in certain assemblies; they may have additional markings. For example, bolts for the construction of bridges may be marked with "ХЛ", which means the permissible use of the bolt at temperatures up to -65C. Sometimes the steel grade used in the manufacture is indicated on the bolt heads.

The strength class is also indicated on the studs, it is applied to the cylindrical part, where there is no thread, but with two significant differences: 1) On the bolts, the marking protrudes above the surface, on the studs, on the contrary - the marking goes deeper into the material. 2) Studs are marked starting with strength class 5.6. On stud diameters less than M12, sometimes not numbers are marked, but conventional signs, each of which corresponds to a strength class.

Nuts are marked in a slightly different way. When marking a nut, take into account the ratio of its height to the thread diameter. According to the ratio of nut height to diameter, nuts are divided into 5 types: 1) Low H / d less than 0.8 2) Normal with a ratio of height to thread diameter 0.8 3) High with a ratio of 1.2 4) Extra high with a ratio of 1, 5. 5) Ultra low, usually not marked.

For low nuts, there are only two strength classes - 04 and 05. To calculate the tensile strength, we fold back 0 and multiply by 100. We get 400 and 500 MPa, respectively. Based on the obtained value, we look at what class of bolt strength the nut should be used with.

Normal, high and extra-high nuts have 7 strength classes - 4, 5, 6, 8, 9, 10, 12. Similarly, multiply by 100 and get the tensile strength value. Therefore, a Grade 8 nut is best used with an 8.8 bolt. In such cases, the load distribution in the thread will be uniform.

Sometimes there are other bolt markings, but this is usually very rare.The vast majority of bolts are marked according to this principle.

In the next article, I'll show you how to calculate a bolt for tension, shear, and shear.

Ask questions, leave comments, share your impressions of the article!