Which option is better when building a log house?

It's impossible to say unequivocally which assembly technology - a warm corner or a bowl - is better. With qualified installation in terms of thermal performance, they will have approximate parity: both options have low thermal conductivity and are not blown out.

But there are other aspects as well:

- When installing the bowl, the cost of purchasing the material increases due to the formation of a protruding part on each beam. The increase in cost is not too large, but on a large-scale project it can be noticeable.

- A house or cottage, assembled in a warm corner, is more economical in terms of material. But the construction itself will take longer, and the work will need to involve a more qualified team of builders (with a corresponding difference in wages).

- It is also worth considering whether your own thermal insulation of a log house is enough for you. If the walls are not thick enough to keep the house warm, you should choose a warm corner. So you can install external insulation - either right at the construction stage, or later, if it seems to you that the effectiveness of the thermal insulation is insufficient.

Tags: timber, assembly, log house, warm, corner

«Previous post

Expert's recommendations for screeding of lumber crowns

The most popular are dowels made from hard wood. The most durable options are oak or birch spikes. It is not possible to deform, bend, or break them. However, there is one condition. They must be correctly fixed. What is their shape and size?

The installation of dowels in a bar is a mandatory rule for bar and log structures. Birch spikes are the most common option. Such pins cannot become an analogue of self-tapping screws or primitive nails. If they are used, then it is impossible to guarantee the stability and reliability of the structure.

- the formation of condensation;

- covering the surface of the thorns with rust;

- decay of the entire layer of wood.

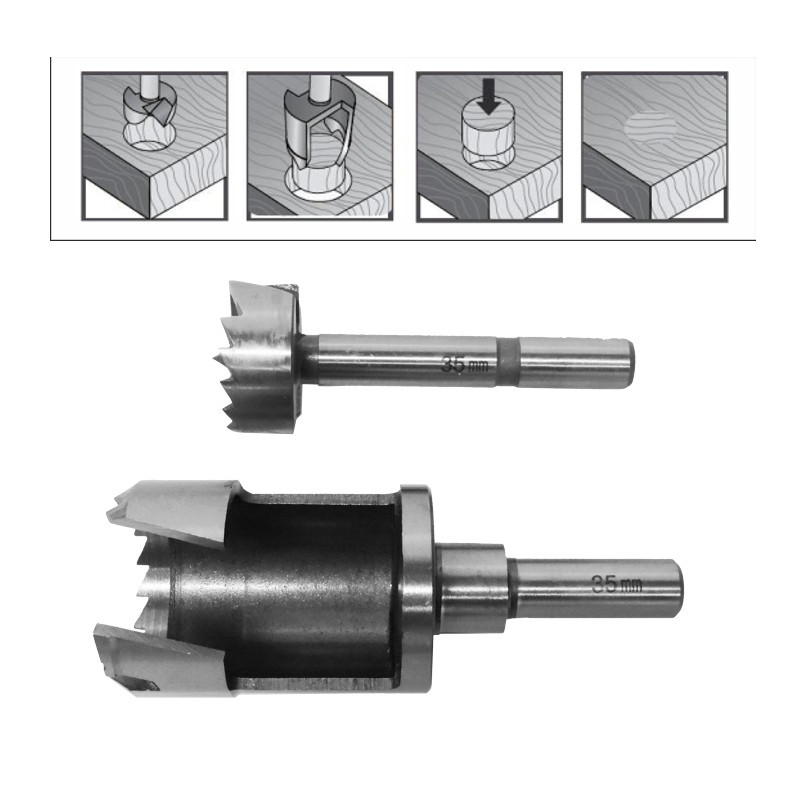

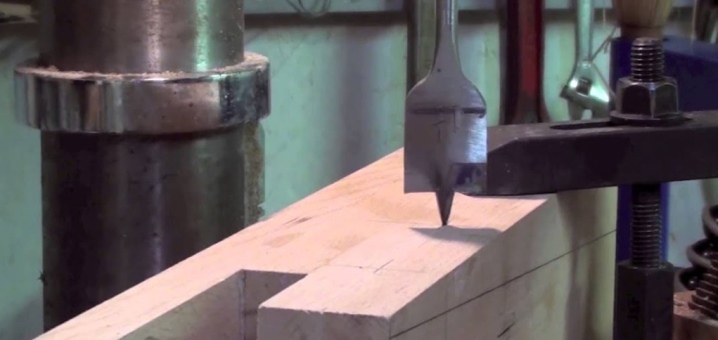

How to drill a log or a thick bar? Of course, with a twist drill

We continue to deal with the equipment with which you can work with wood. In general, you can drill a tree with different drills, in the last article we analyzed the efficiency of a Forstner drill, figured out how and where it is recommended to use it.

There are a great many types of drills for wood, and very often it happens that they are ideal for some work, but not at all for others. Therefore, a home craftsman must understand how and how to drill a tree. Today's article will be about a twist drill, also called a spiral drill.

It is on wood and will help out in cases where it is necessary to drill a deep hole. For example, you have a blockhouse through which you need to stretch a water pipe or bundle of cables. And only a twist drill can handle thick wood. Of course, nothing prevents you from trying to use a regular perk, however, as I said, it is inconvenient to drill for them and it is not a fact that you will be able to do the work to the end.

Here is a photo:

As you can see, the tip is made in the form of a thin thread, which helps to perfectly screw in the drill at the initial stage of drilling. Chips are ejected at the expense of the helical edges (as with any drill or brace), so drilling is easy.

Choosing a drill for drilling under a nagil

It is very important that the tongue-groove connection in this case is tight, with a minimum gap - the degree of heat of the formed corner depends on this. In each corner joint of a bar, according to the rules of construction, a layer of insulation must be laid

As a rule, this is flax-jute fiber. Also, following the rules, we alternate spikes with grooves, so that in the end we get a kind of dressing that increases the adhesion of the walls to each other.

In each corner joint of a bar, according to the rules of construction, a layer of insulation must be laid. As a rule, this is flax-jute fiber. Also, following the rules, we alternate spikes with grooves, so that in the end we get a kind of dressing that increases the adhesion of the walls to each other.

An allegedly warm corner is undoubtedly more expensive for the customer. The average cost is 2.000 rubles per row. The increase in price is associated with an increase in the time spent by the brigade. And, in fact, that's all.

Why is there an alternative to the "warm corner" and is it really necessary?

Answering this question, we can confidently say that an alternative to a "warm corner" exists for several weighty reasons: 1) If your house is intended for permanent residence, then it is simply necessary to insulate it from the outside with basalt wool, close it with wind protection and finishing material (siding, imitation of a bar , block house). We definitely recommend that you go through all the joints of the house from the outside with a special sealant - this is simply a must !!! It is not clear why so little attention is paid to sealants in Russian housing construction? And if your house is closed from the outside with such a "bullet-proof" pie, the question is - why do you also need a warm corner ?! That's right, there is nothing. 2) If you need an off-season log house. Then it is possible not to sheathe it at all, but only to go through all the seams and joints with a special sealant (if this is a house from a profiled bar, since it is impossible to dig in it) or to dig it in - if it is a house from a straight planed bar. And if you still have to caulk everything around, despite the fact that the house is essentially a summer cottage. Then the question arises again - what magic role does the "warm" corner play ?! And none. It is better to purchase the notorious sealant with this money. Moreover, just the same groove of the "warm corner" in houses made of raw timber has a completely natural property to dry out and even, alas ... to fall off. That we had to observe more than once on some houses. And then an honest question to the carpenters arises: what did they take the money for, friends? That is why in our company you, dear fellow citizens and dear ladies, do not see this expression anywhere - a "warm" corner.

Description

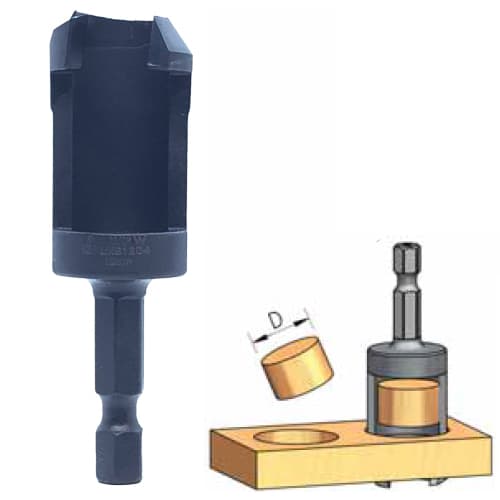

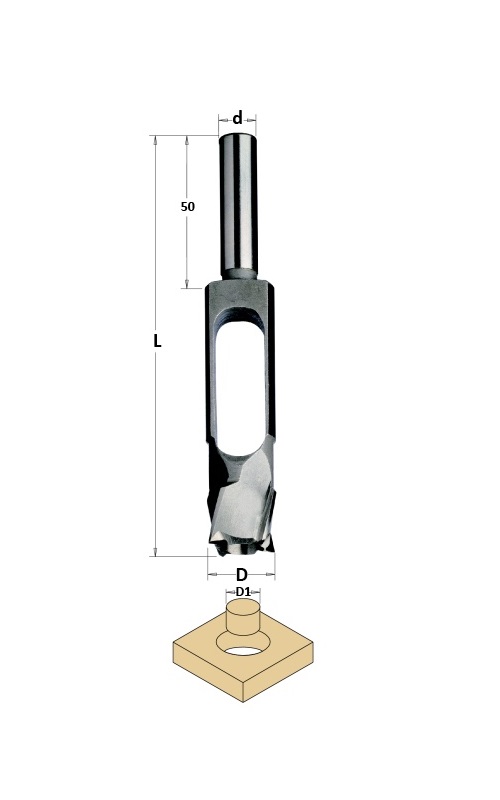

The cork drill, or cork cutter, is used not only for the manufacture of wooden corks. Such a drill attachment is essential for those who have to work on wood.

The essence of the tool is simple. A hole is drilled through the material, and the plug remains inside. If necessary (this is usually used in the furniture industry), then the cutter is not completely immersed in the wood, a piece of cork is picked out, and the necessary recess in diameter remains.

Plugs, which are obtained as a result of using the described tools, are used as decorative sealing of holes or bolts embedded in wood.

If we talk about the application in the professional field, then it is often possible to see how the master easily and naturally drills out knots and other defects in the tree with the help of such a drill.

Despite their versatility, not everyone likes these drills. Many masters argue that it is not always safe to use them, it is much more convenient to use Forstner drills in work.

There are models that can be used in a hand router, they differ from the usual ones by the presence of a shank. It is also worth mentioning that such rigs are supplied for sale in two versions:

- conical;

- cylindrical.

If you do use a cork cutter, it is better not to use a hand drill for this. The reason is simple. In this particular case, centering cannot be done, which means that the drill can simply go to the side at any time. It will not work to achieve an even plug in this way.

Moreover, when using a hand drill, the user will have to apply additional force, but at the same time maintain a right angle between the tool and the material. It would be more convenient in this case to use a milling cutter, or a drilling machine.

Dimensions (edit)

One of the advantages of plug drills is that they come in a wide variety of diameters. In the manufacturer's table, you can find options for 15 mm, and 35 mm, and even 44 mm. In fact, this parameter can vary from 8 to 100 mm.

But it should be understood that equipment, which has a diameter of more than 5 centimeters, is used exclusively for machine drilling. This primarily ensures the safety of the user.

On the market of modern devices, you can find sets of several drills, different in diameter, or you can purchase the item by the piece. Usually the direction of rotation is RH.

Diameters of 15 mm and less are considered to be among the most demanded ones. These are drills for 8, 10, 12 mm.

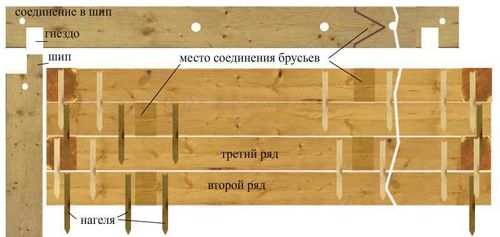

What is a dowel

This is a pin - metal or wood, with which the beam and the log are held together. Its advantages are most obvious in the construction of boats and small vessels, since sea water significantly increases the corrosion of metal, quickly destroying nails. In addition, under the influence of moisture, the tree swells and increases in volume, which ensures its tightness.

Fastening the timber with dowels is designed to prevent lateral displacement and deformation, but at the same time not to interfere with the natural longitudinal deformation. Since both the boards and the log shrink after construction, this decision is fully justified here.

The part is made on lathes from hardwood - oak, birch. Only wood of the first or highest grade is allowed, well dried, without knots, curliness and other things. The diameter of the dowel is selected in accordance with the dimensions of the product, but cannot be less than 2.5 cm. The dowel for a 150x150 bar, for example, should be 25 mm in diameter. The diameter must remain the same along the entire length of the product. Two types of pins are milled:

- square - installing a square dowel in a round hole raises doubts, since removing the ribs can provoke jamming. Therefore, such products are rarely used;

- round - are most widely used when assembling the frame of the house and the walls of the log house. Their use does not cause any difficulties. In the photo you can see pins made of wood of different shapes.

How to do it yourself?

If it is not possible to buy a cork cutter, then you can make it yourself. For this, an old chisel drill is used.

Tools will require a circular saw, a lathe, a clamp, and an electronic vernier caliper.

To make a cork cutter of the desired diameter, it is worth using a feather drill that has a similar parameter to the required one. In our case, the width of the scapula was taken as 4.1 cm.

First, we take a wooden block and make a hole in it with a screwdriver, suitable for the shank. We insert the equipment there, which we will change.

The distance between the incisors should be 3 cm, we measure it and make a notch. Insert a bar with a feather drill into the clamp

It is very important to fix the part well, since the safety of the master depends on it.

On the grinder, we first cut off the point, due to which the centering is carried out. It doesn't need a corkscrew. Two cuts are made according to the markings drawn in advance.

It is important to handle the drill upside down

The central part is removed completely. This makes it look like a fork with two tines. During operation, such a rig easily drills a cork of a given diameter in a tree.

Connection of a bar with dowels: features

It is preferable to choose pins from the same wood species as the walls of the house: the expansion coefficient for different woods is quite different, and the coincidence in this parameter guarantees the absence of deformation.

The metal pin is used in heavy structures as well as wood materials.

- In frame buildings, the dowel is used for joining the elements of the lower strapping and installing vertical racks. In a log house or house, the walls of which are entirely erected from a bar, a pin holds the material together, forming a single surface.

- The difference here is the anchoring depth. The assembly of a beam on a dowel in a frame building involves the joining of two elements of the lower trim and a vertical corner post. The construction of a wall from bars of 150 * 150 mm requires that the dowel connect at least 2 rows.

- In a log house, the same condition is met: the pin holds at least two rows. Fastening is carried out in a checkerboard pattern with a step of no more than 2 m, and each piece of wood must be fastened with two dowels.

Drilling holes

The use of pins made of wood during assembly involves the production of holes in a log or board of any section at the joints. Drilling can be through - for a bunch of rows, or blind - when attaching a vertical post, for example. The drill for drilling a bar under the pins must be powerful enough - at least 1.5 kW, with a wide chuck, so that a drill of the corresponding diameter can be installed. A slow-speed drill is recommended for working with a log.

- The connection of the bar with dowels begins with drilling holes for it. It is advisable to use a template in order to achieve an exact match of the hole parameters in the jointed bars.

- The holes are drilled strictly vertically, otherwise there is a danger of the row sagging.

- It is recommended to make the hole diameter 3-4 mm larger than the pin diameter. This technique allows you to exclude jamming of the dowel when the wood shrinks and dries out. In this case, the wooden block hangs, forming cracks. Too tight docking provokes this situation.

- The depth of the hole is 2–3 cm greater than the length of the fastener. This eliminates the sagging of the tree during shrinkage.

The wooden dowel in the wall of the house "works" for bending, that is, it prevents lateral deformation. The longitudinal sliding of the log must be free. The video examines the assembly of wood on dowels.