Advantages of hyper-pressed bricks

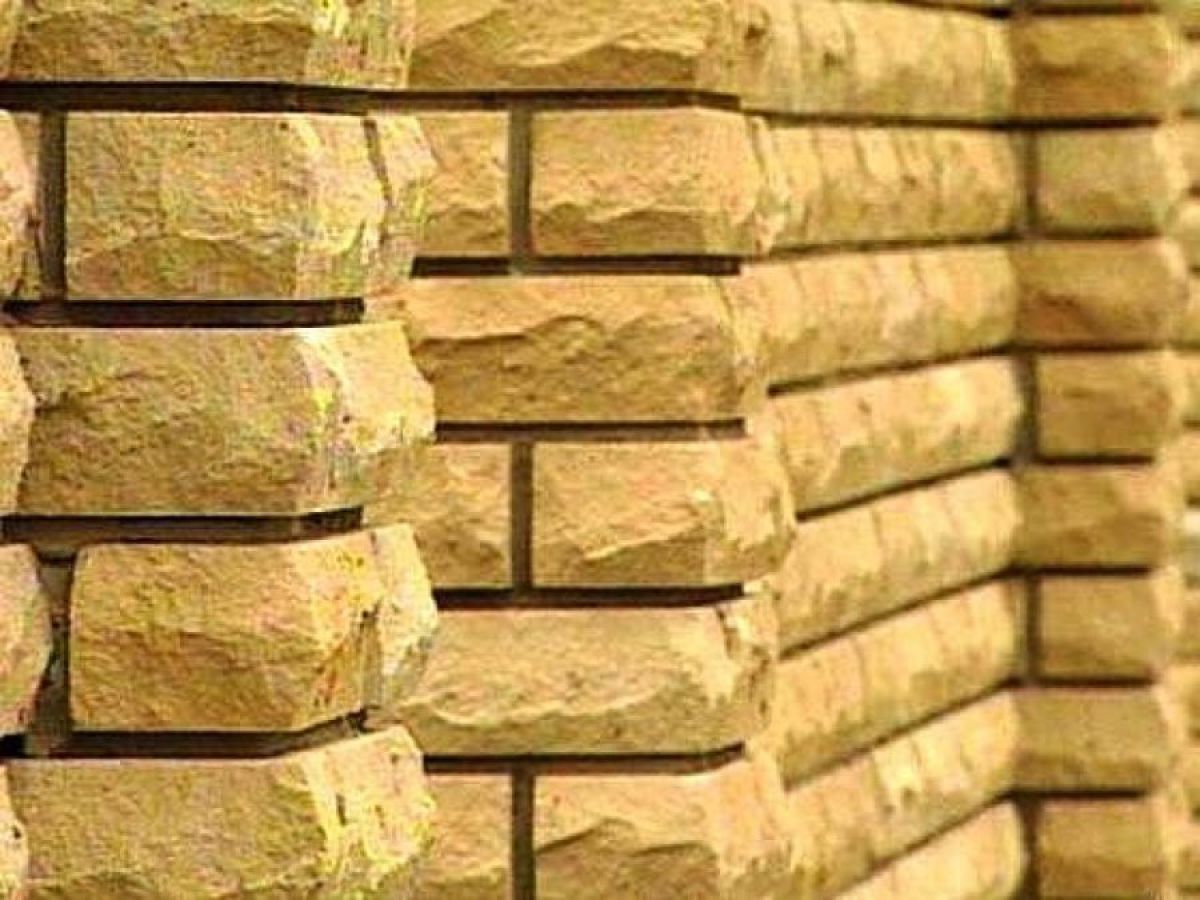

Hyper pressing allows to manufacture products with perfect geometry. Chipped bricks are used for cladding, and smooth bricks are used both in ordinary masonry and as front. A variety of shapes, textures and a wide palette of colors allows you to create complex architectural elements. In addition to its aesthetic advantages, such a brick also has a number of technical advantages:

- High strength and resistance to aggressive environment.

- Low water absorption.

- Ecologicaly clean.

- Easy to handle. Perfectly cut with an ordinary grinder.

- "Spetszakaz" - the ability to produce building materials with increased strength - up to M 500 and frost resistance - up to F300.

- It can "breathe", since a cement film does not form on the products, which also reduces the adhesion with the mortar.

Hyper-pressed brick GOST

March 30, 2020

Hyper-pressed brick appeared on the territory of the Russian Federation at the end of the 80s of the XX century. Soviet engineers adopted the production technology from Western specialists, and not without their own merits related to unraveling the "secret" of the raw material composition. In 1986, an exhibition of the achievements of building technologies was held in Moscow with the participation of representatives from far abroad

Among the abundance of high-tech equipment presented by European partners, the attention of Soviet specialists was attracted by hydraulic presses for the production of soil-concrete building material

The management of the Tula brick factory purchased an exhibition copy of a hydraulic machine, and soon the first batch of bricks made from a semi-dry mixture of soil and concrete was made, which brought great disappointment to the manufacturer. As it turned out, this brick was completely unsuitable for use in construction work, being characterized by weak frost resistance and low strength.

However, the engineers continued their experiments, experimenting with different types of fillers, and soon achieved the desired results, using crushed limestone as the main raw material. So in Russia, the first hyper-pressed brick appeared, which soon aroused interest among developers, due to its unique strength, density, aesthetic appeal and resistance to negative environmental influences.

Since 1990, technical requirements established by state standards have been applied to HYPERPRESS materials. Currently, it applies to hyper-pressed bricks GOST 6133-99 compiled in 1999 under the wording ‘concrete wall stones’. For hyper-pressed bricks, GOST provides for compliance with the technology and chemical composition of products.

In accordance with GOST 379-95, the minimum permissible tensile strength of hyper-pressed products must correspond to the M-150 grade. Other technical characteristics of products are not regulated by GOSTs, however, they are due to the technology of obtaining the material. Products have water absorption from 4.5 to 8%, thermal conductivity of 0.4-0.45 W / m * K ° and minimum frost resistance of the F-100 brand (see Hyper-pressed brick characteristics).

Having such a short history of application in the territory of our country, hyper-pressed brick belongs to the representatives of a new generation of building and finishing materials. The new standard of the technological process allows you to get an extremely durable material without waste and significant energy costs.Among other things, natural raw materials of natural origin are used as a filler, which guarantees the environmental friendliness of products.

Today, hyper-pressed products are used for a wide variety of purposes - to strengthen and decorate the facade of buildings, to lay plinths and foundations, to create fences and small architectural forms, cladding interior elements, construction of protective dams and other loaded objects.

The advantages of hyper-pressed bricks are its versatility, elegant appearance, and immunity to the whims of nature. Low hygroscopicity and good frost resistance ensure durability and guarantee that stone walls will stand, without needing repair, for at least 100 years.

Articles News

Characteristics of Lego bricks

May 30, 2020

Working qualities and density of hyper-pressed bricks

May 27, 2020

Fences and pillars from Lego bricks

May 24, 2020

Lego hyper-pressed hollow brick

May 21, 2020

Hyper-pressed products

May 18, 2020

Briefly about hyper-pressed brick

Before studying the technological process, it will be relevant to understand: what is a hyper-pressed brick, what properties it has, and why it is so remarkable for developers.

Main characteristics, types and scope of application

Basically, the products are made from a mixture of lime and cement. It also contains some supplements, which we will discuss in more detail later.

Now let's pay attention to the main technical characteristics of the products:

- Strength - 100-400 kg / cm2... This is a fairly high figure. Such a numerical value allows the material to be used in the construction of buildings, the number of storeys of which is not limited.

- Thermal conductivity. Due to the high values of density and strength, the thermal conductivity of the material is slightly increased. It ranges from 0.43 to 1.09 W * ms.

- Water absorption... Hyper-pressed brick is hygroscopic, but the value is not at all high and amounts to 3-7%.

- Frost resistance products can reach up to 300 time-based freezing and thawing cycles. Not many of the wall materials can boast of such an indicator.

- Hyper-pressed brick belongs, in accordance with GOST, to non-combustible materials, which only increases its attractiveness in the face of consumers.

- The volumetric weight is 1900-2200 kg / m3.

It is also worth noting that the material is environmentally friendly and extremely durable.

Hyper-pressed brick has several classifications. By appointment, it is divided into front and private; depending on the shape - on the correct, curly; in accordance with the design - into hollow and corpulent.

The standard size is 250 * 120 * 65. However, other options are being released. Narrow products are characterized by a size of 250 * 60 * 56, spoon - 250 * 85 * 65.

Some possible sizes of hyper-pressed bricks

The weight of a standard product is 4.2 kg.

If we talk about the scope, then in hyper-pressed bricks it is extremely wide

It is used in the construction of buildings, load-bearing structures, for which strength is an important characteristic. However, under the condition of wet operation, it weakens

Therefore, when erecting plinths and the underground part of the foundations, this type of brick is not used.

Facial products are actively used in cladding, construction of fences, gazebos, and landscape design.

Strengths and weaknesses of the material

Like any other product, hyper-pressed brick has its own set of positive and negative sides. Let's consider them.

The advantages are:

- Strength characteristics, as already mentioned, are extremely large for hyper-pressed bricks.

- Frost resistance of products - a significant plus. The indicator leaves behind many material competitors.

- Reduced hygroscopicity... The value of 3-7% is not great, therefore, in general, this fact should be attributed to the positive features of the products.

- Durability of the material leaves no doubt. A building can last up to 300 years without a significant decrease in property indicators.

- The range of products is also great... Bricks can be of various shapes, sizes, colors and purposes.

- The material is characterized by climatic resistance.

- Aesthetic appearance and almost perfect geometry of products.

- Wide scope of material application.

- The ability to carry out work on the construction of structures with your own hands.

- All-season work.

- Environmental friendliness, fire resistance.

- Ease of material handling.

- Good adhesion to masonry mortar.

The disadvantages boil down to the following:

- Hyper-pressed brick cannot be called a budget material. Its price is comparatively high.

- The products are of considerable weight, which significantly increases the load on the base of the building. As a result, the foundation must be strong and massive, and this is an additional cost of time and money.

- The material needs a drying procedure before masonry work, and the maximum possible time.

- Reduced ability to maintain temperature due to high values of density and strength.

As you can see, the disadvantages are minimized, so we can safely say that the hyper-pressed brick is more close to the ideal material than many.

Characteristics and composition

Hyper-pressed brick is an artificial stone, for the manufacture of which granite screening, shell rock, water and cement are used. Cement in such compositions acts as a binder, and its share in relation to the total mass is usually at least 15%. Mining waste and blast furnace slag can also be used as raw materials. The color of the products depends on which of these components will be used. So, screening out of granite gives a gray tint, and the presence of shell rock paints the brick in yellowish-brown tones.

In terms of its performance characteristics, the material is quite similar to concrete and is distinguished by its high strength and resistance to aggressive environmental influences. In terms of its reliability and durability, pressed brick is in no way inferior to clinker models and can be used as the main building material for the construction of capital walls. Visually, it is somewhat reminiscent of natural stone, due to which it has become widespread in the design of building facades and fences. In addition, the cement mortar is able to mix well with various pigments and dyes, which makes it possible to produce bricks in a wide range of colors and use them as decorative cladding.

The main characteristics of hyper-pressed bricks, which determine its working qualities, are density, thermal conductivity, water absorption and frost resistance.

The strength of hyper-pressed bricks is largely determined by the density of the material, which averages 1600 kg / m3. Each series of artificial stone corresponds to a certain strength index, which is denoted M (n), where n denotes the strength of the material, which for concrete products ranges from 100 to 400 kg / cm2. So, the best strength indicators are possessed by models with the M-350 and M-400 index. Such a brick can be used for the construction of masonry bearing walls of the structure, while the products of the M-100 brand belong to the front models and are used only for decoration.

An equally important characteristic of a stone is its thermal conductivity. The heat-saving ability of the material and the possibility of its use for the construction of residential buildings depend on this indicator.Full-bodied hyper-pressed models have a lower thermal conductivity index equal to 0.43 conventional units. When using such a material, it should be borne in mind that it is not able to retain heat inside the room and will freely remove it outside. This must be taken into account when choosing a material for the construction of capital walls and, if necessary, take an additional set of measures to insulate them. Hollow porous models have the highest thermal conductivity, equal to 1.09 conventional units. In such bricks, there is an inner layer of air that does not allow heat to escape outside the room.

Frost resistance of hyper-pressed products is indicated by the index F (n), where n is the number of freeze-thaw cycles that the material can transfer without losing the main working qualities. This indicator is greatly influenced by the porosity of the brick, which in most modifications ranges from 7 to 8%. Frost resistance of some models can reach 300 cycles, which makes it possible to use the material for the construction of structures in any climatic zone, including the regions of the Far North.

The water absorption of a brick means how much moisture a stone can absorb in a given amount of time. For pressed bricks, this indicator varies within 3-7% of the total volume of the product, which allows you to safely use the material for exterior facade decoration in areas with a humid and maritime climate.

About efflorescence

Efflorescence is the result of salt crystallization on the brick surface. Crystallization is preceded by the migration of water-salt solutions in the pores of the material with their subsequent release to the surface.

The brick consumes water from the solution. Water-soluble salts are absorbed by the brick and, when dried, are carried out through the capillaries to the surface, where, after evaporation of the water, salt crystals precipitate in the form of whitish spots - efflorescence.

How to prevent efflorescence?

- use cement with a low content of soluble salts, i.e. not lower than М400;

- use a hard (thick) solution;

- do not smear the mortar on the front of the brick;

- do not lay bricks in the rain and cover fresh masonry at the end of work;

- bring the house under the roof as soon as possible;

- cover the facade with a protective water-repellent composition;

- at the end of the construction of the walls, the installation of gutters and drainage is carried out.

After the masonry has been erected, to prevent the appearance of efflorescence on the facades, it is recommended to use water-repellent coatings - water repellents. Recommended remedies are listed below:

- "Tiprom K" - water repellent with antifungal, water-repellent effect (consumption - 0.08 l / m2);

- "Facade-1" - water repellent based on ultrafine acrylic dispersion. Protects against moisture and efflorescence without changing the color of brickwork (consumption - 0.3 l / m2);

- "Armocryl" - polyacrylic varnish. Waterproof, steam proof, UV resistant. Gives the surface an attractive glossy effect, protects against color fading, fading and washout, increases the strength of not only brick, but also cement mortar due to polymerization of the protective layer of varnish. It is recommended to apply two layers of Armocryl varnish with an interval of 12 hours (consumption - 0.21-0.26 l / m2);

- "BETOLAS III" - acrylic-based impregnating sealant. Provides complete hydrophobization, saturates the natural color of brickwork (consumption - 0.3-0.35 l / m2);

- Varnish "VVM-M" - moisture resistant impregnating varnish based on organosilicon compounds. Has a water-repellent property, protects against efflorescence, exposure to an aggressive acidic environment, is an antiseptic agent for giving mold-, fungus-, thermite resistance to concrete and brick structures (consumption - 0.3-0.35 l / m2).

What to do if efflorescence has already appeared?

If, nevertheless, a mistake was made in the masonry technology and efflorescence appeared, then:

- use folk remedies - a solution of 0.4% acetic acid (2 tablespoons of 9% table vinegar per one liter of distilled water) or 5% hydrochloric acid solution, or ammonia solution;

- use special means: "Facade-2" - a liquid facade cleaner from atmospheric pollution (consumption - 0.4-0.5 l / m2) or "Tiprom OF" - a cleaner from efflorescence and atmospheric pollution (consumption - 0.25 l / m2);

- be patient and wait - most of the efflorescence is washed off by rains in a year or two.

Stages of business organization, a brief analysis of profitability

Since we have decided to talk about profitability, it is worth briefly reviewing the main stages of creating a business that precede the launch of production.

Opening an organization, organizing production

Let's use the table. Table 1. Business plan for the production of hyper-pressed bricks: stages of implementing a business idea.

Stage name Its content, terms and comments

Preparation of constituent documents, administrative procedures

This process will take from 2-3 days to several weeks. Much depends on the form of ownership, the number of founders and some other factors.

Searching for a suitable premises for a warehouse, production and legal address

The timing is purely individual. Better to give preference to places with good infrastructure.

The expenses of the organization directly affect the level of income and, as a result, the future profitability.

Choosing an equipment supplier

Especially crucial stage

Attention should be paid to the cost, packaging, delivery time and the country of origin. Chinese models are usually less expensive, but not always of high quality

Mistakes made when choosing a set of machines can have an extremely negative impact on the result.

Search for suppliers of raw materials, purchase

The most relevant will be the purchase of raw materials through a tender announcement. Firstly, this will help to choose the most inexpensive option, and secondly, the requirements for suppliers, in this case, practically exclude the possibility of concluding a supply agreement with an unscrupulous seller.

Adjustment and installation of equipment, trial batches

It usually takes no more than 2-3 days. The next stage after adjustment will be testing and release of a trial batch of goods.

Production start

Possible after completing all the previous steps.

Sales routes, advertising and marketing

Advertising is an important part of running a successful business. Agree, in advance, before buying, a potential consumer must learn about the existence of the organization. And the greater the reach of the audience, the greater the chances of early implementation.

It is worth working in all directions at the same time. These are mailings, message boards and all kinds of other advertising steps.

Implementation

Accompanied by paperwork and, as a rule, delivery.

It is best to get your own transport. It is beneficial and convenient for the buyer.

Technical and economic component

The profitability of production is influenced by many factors, which include:

- The region and its climatic conditions. That is, a climate suitable for using the material.

- The purchasing power of the region.

- The expenses of the organization related to the conduct of business activities, strict adherence to the business development plan.

- The cost of raw materials and equipment and, as a result, the cost of products.

- The quality of the original products and much more.

It is not possible to make an accurate calculation of economic profitability, since everything is individual for each development path. We can only guess.

- Imagine that the cost of 1 unit of bricks with texture is 18 rubles. Its market value is 22 rubles.

- The prime cost will include all expenses, including the tax base, deductions, employee salaries, rent, utility bills, and so on. In general, everything, besides the cost of the equipment.

- The daily output is, let's say, 4000 bricks. If we manage to sell all the products, then the income will be: 4000 * 4 = 16000 rubles. As a rule, factory production runs smoothly and seven days a week.

- The monthly income, in this case, will be 480,000 rubles.

- The cost of a budget conveyor line is about 5,000,000. This means that production will pay off in about 10 months.

This course of events cannot be called the most optimistic, but it is as close to reality as possible. If the volume of production is twice as large, then more expensive equipment will be needed. In most cases, the maximum payback period is one year.

Types and features

Hyper-pressed products have a fairly branched classification, which can be based on their shape, size, number of textured planes or purpose. These parameters more affect the decorative properties of stones, and the performance and cost are determined by the design. Here, cladding is traditionally divided into two types:

- corpulent;

- hollow (perforated or slotted).

Not so long ago, another type appeared - a hyper-pressed Lego brick. Thanks to its unusual shape, it was possible to solve the problem of poor adhesion of piece material with masonry mortars. As a result, the labor costs of builders for the construction of false walls have decreased and the speed of work has increased. But at the cost of a big gain, it did not work out, since ordinary sand cement is not used here - you will have to buy special glue, although its consumption is low.

Other advantages of "Lego":

- Less weight due to large through holes.

- Simplicity of installation - only the first row is set according to the level.

- Possibility of hidden communications.

Testing of hyper-pressed bricks

In the Russian Federation, in ROSTOVAGROPROMSTROY, in 1996, comparative tests of the adhesion strength of ceramic and hyper-pressed bricks with cement mortar were carried out, in accordance with GOST 24992-81 "Stone structures". Methods for determining adhesion strength in masonry - at 14 days of age. Used masonry mortar with a strength of 100 kg / cm2, 28 days of age.

Adhesion strength of ceramic and hyper-pressed bricks with mortar

Thus, the strength of masonry made of hyper-pressed bricks with cement mortar is 50–70% higher than that of ceramic ones with the same mortar.

The intra-layer strength of masonry made of hyper-pressed bricks of traditional geometry (smooth) is 1.7 times higher than the intra-layer strength of ceramic bricks of the same geometry and on the same mortar.

The layer-by-layer strength of masonry made of hyper-pressed bricks of traditional geometry (smooth) on masonry mortar is 1.7 times higher than the layer-by-layer strength of ceramic bricks of the same geometry and on the same mortar.

Bearing in mind that hyper-pressed bricks themselves are 50–70% stronger than ceramic bricks, and their adhesion to mortar is 75–100% higher than with ceramic bricks, the strength of brickwork from them is 50–70% higher than from ceramic ones.

Manufacturing technology overview

And now it's time to take a closer look at the technological process. It's worth starting with a list of the necessary equipment and materials that will be needed to start production.

Necessary equipment and materials

As in the production of almost any product, the equipment can be used in different types, depending on the level of automation of the entire process.

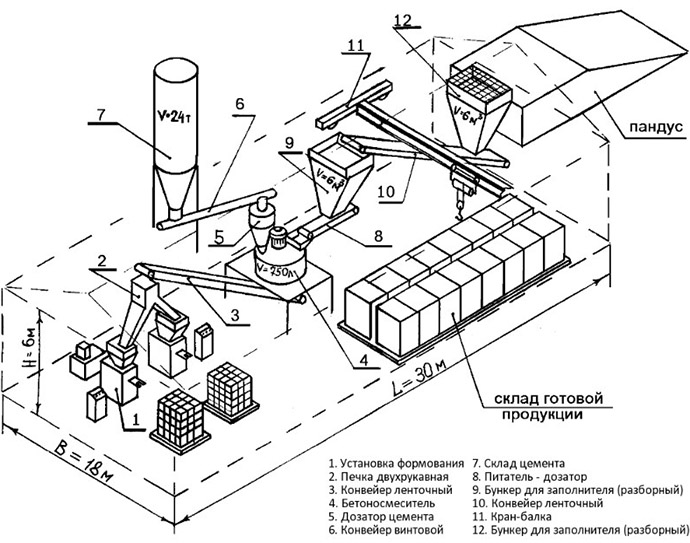

The most expensive and efficient in terms of the volume of daily output are conveyor-type lines. They are operated by the operator.All actions take place in a purely automatic mode. The products are of the highest quality.

Fixed lines are more budgetary. The release volume can reach 50-80 m3 per day.

Stationary hyper-pressed brick production line

A standard set of equipment includes the following set of machines and installations:

- Forming plant;

- Several conveyors (belt and screw);

- Component dispensers;

- Mixer;

- Bake.

Diagram of the production of hyper-pressed bricks

The composition of hyper-pressed bricks includes the following components:

- Cement grade 400-500 - about 15%;

- Lime;

- Granulated blast-furnace slag;

- Crushed stone screening;

- Iron oxide pigment - about 7%;

- Clay brick scrap;

- Some wastes left over from ore processing, minerals.

Hyper-pressed brick: the composition is characterized by a high lime content

It is also worth noting that in addition to factory production, it is possible to make hyper-pressed bricks with your own hands. In this case, the production of bricks by dry pressing requires a hand press.

The product mix can be kneaded either manually or using additional devices.

As a rule, self-release is organized in order to save money. When choosing inexpensive equipment, this is quite feasible. However, it is worth being prepared for the investment of time, and significant.

Step-by-step analysis of the release process

The technology for the production of hyper-pressed bricks, or rather its main feature, is that slightly moistened components are subjected to strong pressing. This provokes the adhesion of the solution molecules.

As a result, the products are extremely durable and dense; in terms of properties, such a brick is as close as possible to natural stone. This process is somewhat similar to cold welding technology.

The production technology of non-fired bricks contains a number of stages. The instruction is as follows:

- Component batchers supply raw materials in the required volume;

- The mixture is kneaded;

- Next, molding is performed by pressing;

- The molded products are dried, as a rule, in specialized chambers (ovens), while the products are not fired;

- Further, the brick must be aged for about a month in the finished product warehouse. Storage is mandatory at above-zero temperatures.

Assortment of finished products

In the absence of a furnace, for example, in case of self-production, the brick can be left raw for 5 days. The effect will be the same.

Non-fired brick can be additionally subjected to rustication - processing of the product, as a result of which decorative chips are created.

Finished rusticated brick

There is no state standard for the release of such products. The production of pressed bricks is carried out based on the standards for the manufacture of ceramic products. This applies to dimensions, permissible deviations and some other indicators.

As for the values of technical characteristics, hyper-pressed brick is several times ahead of ceramics.

The video in this article: "Hyper-pressed brick production business plan" contains detailed information on all stages of the manufacturing process.

Advantages and disadvantages

High consumer demand for dry-pressed concrete bricks is due to a number of indisputable advantages of this material.

- The increased resistance of the stone to extreme temperatures and high humidity allows the use of stone in construction and cladding in any climatic zone without restriction.

- The ease of installation is due to the correct geometric shapes and smooth edges of the products, which significantly saves mortar and facilitates the work of bricklayers.

- High bending and tear strength distinguishes hyper-pressed models from other types of bricks.The material is not prone to cracks, chips and dents and has a long service life. Products are able to maintain their operational properties for two hundred years.

- Due to the absence of a concrete film on the surface of the brick, the material has high adhesion with cement mortar and can be used at any time of the year.

- The absolute safety for human health and the ecological purity of the stone are due to the absence of harmful impurities in its composition.

- The surface of the brick is dirt-repellent, so dust and soot are not absorbed and washed away by rain.

- A wide assortment and a wide variety of shades greatly facilitates the choice and allows you to purchase material for every taste.

The disadvantages of hyper-pressed bricks include the large weight of the material. This obliges us to measure the maximum permissible load on the foundation with the mass of the brickwork. In addition, the stone is prone to moderate deformation due to thermal expansion of the material, and over time it can begin to swell and crack. At the same time, the masonry looses and it becomes possible to pull out the brick from it. As for cracks, they can reach a width of 5 mm and change it during the day. So, when the facade cools down, the cracks noticeably increase, and when it heats up, they decrease. Such mobility of brickwork can cause many problems with walls, as well as with gates and gates built of solid bricks. Among the minuses, they also note the tendency of the material to fade, as well as the high cost of products, reaching 33 rubles per brick.

Where to buy hyper-pressed brick in Belgorod

HyperBel Company

The company "HyperBel" is a large trading and production company, successfully operating in the Belgorod market, the company has formed a high economic and human capital, being one of the leaders in the building materials market.

Brick 24 company

Brick 24 (Brick Ceramics LLC) was founded in March 2009. Today the company employs over 30 people. The first office of the company was opened in Belgorod, the second sales office was opened in Yaroslavl in April 2010, the third in October 2011 in Moscow. In 2014, a sales office and a regional warehouse were opened in Voronezh. At the end of 2015, a sales office and a warehouse were opened in Sevastopol. In February 2017, a sales office was opened in Simferopol.

Azbuka company at home

The ABC of the house was created in 2010, at that time there were already many trading companies on the market, our proposal was simple - to really professionally inform visitors about the product, its qualities and prices. The ABC of the house is the official representative of the Litos company in Belgorod