Adhesives manufacturers

A large number of polyurethane-based adhesives are sold in stores. Domestic and foreign manufacturers provide such products to the market. Here are the most popular brands:

- Anles. The range of the company includes about 10 polyurethane adhesives for industrial and household use. The adhesives "ADV", "Vilad", "Polyurethane", PVC Fix and others have earned the respect of users. All of them are used for gluing PVC, rubber-fabric products, polyurethane, thermoplastics, leather, glass, metal.

- "Titanium". Several canned adhesives are produced under this brand for professional and home use. Especially known is the foam glue "Universal" - a one-component composition for external and internal work, quick-drying, with high fire resistance. Another good composition is Bonolit "Formula of heat". This glue is so strong that it is used for masonry blocks, the construction of external and internal walls, as well as partitions. It serves as an alternative to conventional cement mortars.

- Desmokol. It is widely used in shoe factories, reliably holds rubber and polymer materials. Available in small tubes, cans and even 200 liter barrels.

- Kenda Farben. The company presents on the market a very high-quality polyurethane compound SAR 306, which has high thermal stability. It is used for gluing PU, TPE, and various rubber products. The addition of a special hardener increases the adhesion of other difficult-to-bond materials.

- Sika. This Swiss brand produces a whole line of polyurethane-based products. Especially known is the polyurethane sealant Sikaflex, which has high tensile strength, resistance to moisture, chemicals and physical stress.

- Inov. A cold-curing polyurethane binder of this brand from the People's Republic of China is used for laying seamless coatings, the production of rubber plates, rubber crumb, rolls.

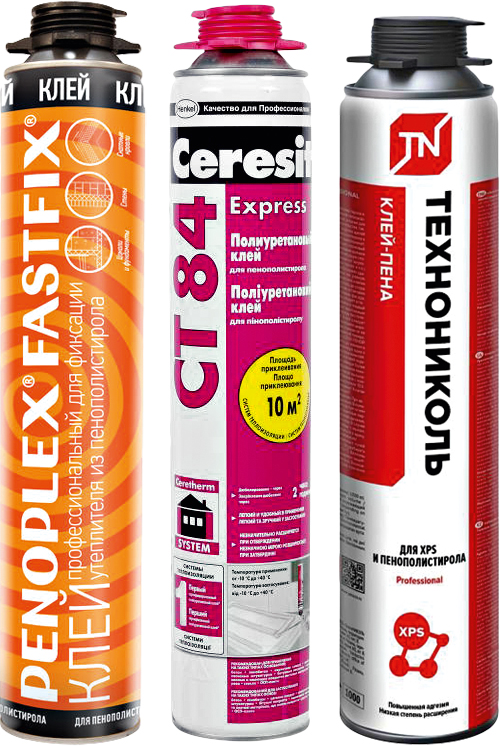

- Henkel. Products from the Ceresit line are high quality adhesives for tiles and other materials. The most famous polyurethane adhesive is Ceresit CT 84 - a means for fixing window sills, filling gaps between expanded polystyrene plates, aerated concrete blocks, for fixing thermal insulation. Also on sale is the Moment Crystal glue from Henkel - a transparent polyurethane gel for all types of materials, except for Teflon and polyethylene.

- Polinor. Polynor Stik glue is a one-component composition for fixing extruded polystyrene foam, aerated concrete, panels, mineral wool. It can be used for sealing joints and open areas, for attaching decorative elements.

- Soudal. Soudal brand produces polyurethane adhesive Soudabond Easy - a professional composition in cylinders for fixing mineral wool, cork, gypsum board, glass wool, foam blocks and fiber-cement boards.

- "Lighthouse". Glue "Super NN" from this manufacturer is intended for banner fabric, leather, laminate and parquet, all types of plastic, polyurethane, as well as rigid PVC and ABS. Before use, it is imperative to clean the bases with Cosmofen solvents.

Also, polyurethane-based adhesives are produced by Neomir, Rastro, Cleon, Adesiy, Bostik, Duayen and others. The funds have different prices and volumes, but, for the most part, are of good quality. You can get excellent polyurethane glue at any hardware and hardware store.

Appointment

Polyurethane-based glue is used for interior and exterior work, as it is not afraid of moisture and frost.Polyurethane is used for the production of flexible stone, where graphite, limestone and marble chips are glued to the fabric base. The polymer composition is used to connect the details of the window profile, PVC edges, lamellas, used for gluing glass into the frame.

It is used in the professional construction and improvement of children's and sports grounds with modern coatings. The plot is glued with artificial turf grass or special rubber mats. Polyurethane is a binder in the production of tiles and coatings from rubber and rubber crumb... Even ordinary foam sponges stick together with this product.

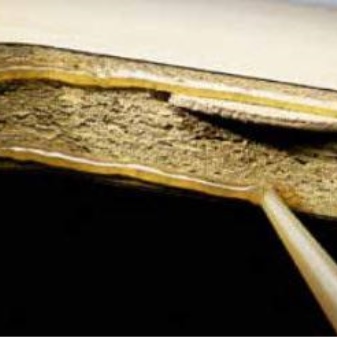

The adhesive composition was widely used in the production of sandwich panels. Fibreboard cladding is bonded with mineral wool or polystyrene core using polyurethane adhesive. During curing, SIP panels are under load with further drying.

In everyday life, the use of polyurethane glue is justified for all types of repair work and the repair of various products. He is irreplaceable for fixing ceiling plinths, cornices and moldings to the walls and ceiling. Suitable for repairing wooden moldings, plastic parts. It is used as a glass glue for gluing ceramics, plexiglass, porcelain. Indispensable in the repair of garden and home furniture made of wood and metal.

A special polyurethane shoe composition is produced for self-gluing of soles, heels and insoles. It reliably holds leather, fur, suede, fabric with different types of soles. The adhesive is suitable for repairing rubber boats, PVC pools, inflatable rings and balls.

In construction work, polyurethane is used as a tile adhesive for fixing porcelain stoneware, mosaics, ceramics, decorative stone, marble to any base. Its use for laying ceramic tiles is recommended by manufacturers and craftsmen. The adhesive base does not flake off, it tolerates moisture and adverse outdoor conditions well.

A special polyurethane-based parquet adhesive is produced, which is intended for arranging a wooden floor. Suitable for gluing mosaic and end parquet, solid wood parquet boards and engineering multilayer boards, plywood, laminate. The heat-resistant properties of polyurethane make it possible to use it in underfloor heating systems.

When building a house from aerated concrete, polyurethane adhesive foam is used as a masonry material. Laying aerated concrete blocks on foam serves as an alternative method for the construction of walls. Foam glue is also suitable for bonding gas silicate blocks and aerated concrete. The minimum thickness of the seam reduces material consumption and excludes freezing of the structure along the cold bridges.

For fixing polystyrene foam, foam glass, polystyrene foam, polystyrene foam and other artificial plate heat-insulating materials, special polyurethane glue in a cylinder is used. The ready-made adhesive foam allows you to evenly and quickly distribute the composition using a nozzle. The mixture allows the sheets to be adjusted within 10 minutes before setting. And also the adhesive mixture for insulation is suitable for sealing joints in thermal insulation, replacing the usual foam.

Types of adhesive for PVC tiles

Thomsit UK 400

A universal adhesive for the installation of textile materials and PVC tiles on surfaces with an absorbent base, such as cement or concrete screed. Used for interior work. Possesses high adhesion and elasticity, well tolerates the impact of the legs of heavy furniture. The adhesive can also be used when installing underfloor heating systems. The composition does not have organic solvents and is considered environmentally friendly. Store in a warm place, but short-term exposure to cold, such as during transportation, will not affect the quality of the adhesive. Average cost $ 26 for a 14 kg container.

Thomsit K188E

Adhesive for PVC tiles Thomsit K188E for special purposes is used for laying tiles on non-absorbent substrates due to the larger amount of polymer components in the composition. Like its previous counterpart, the glue is considered environmentally friendly and does not have vegetable solvents. The composition has increased thermal and sound insulation performance. Average cost $ 26 per 14 kg.

Deco bond SSANGKOM

The manufacturer of this adhesive is South Korea and it is also used as a universal compound for substrates with poor and good moisture absorption. Before gluing PVC tiles with this glue, the surface must be carefully prepared. It is used for interior work on laying PVC tiles in household and public premises. Environmentally friendly and its curing time is 20 to 27 hours. The time for adjusting the tiles is from 20 to 30 minutes, depending on the temperature. A feature of the glue is the ability to use at temperatures from +5 to +50 degrees Celsius. The price of the adhesive composition is from 12 to 18 dollars for a container of 10 kg.

Homakoll 208

Homakol glue for PVC tiles is made on the basis of PVA glue with the addition of acrylic resins and is universal for different types of surfaces. Depending on the temperature in the room, one kilogram of glue is enough to cover the surface from 2 to 4 square meters. The composition is a white liquid mass, which is poured onto the surface and spread with a spatula. The cost of the composition is $ 20 for 14 kg.

Read more about how to lay PVC tiles yourself and the technology of laying PVC tiles.

Scope of application of plastic mixtures

The plasticity of the adhesive is due to the presence of plasticizing additives, polymers, epoxy, rubber and polymer compounds in its composition. As a result of the properties of the glue, it is recommended to use it for the processing of the following substrates:

- concrete with a cellular structure;

- Chipboard;

- cement-bonded particle boards;

- drywall;

- plywood;

- aerated concrete;

- old tile;

- concrete screed;

- wood.

In addition, flexible tile adhesive is often used for lining bathrooms, swimming pools and underfloor heating systems.

This mixture must have not only good elasticity, but also effective adhesion (at least 1 MPa). With this type of glue, you can mount the following finishing materials:

- porcelain stoneware;

- ceramics;

- marble and glass mosaics;

- acid-resistant and clinker tile products.

Elastic mixtures for gluing drywall are versatile. With their help, you can finish with any materials. This glue contains Portland cement, polymer and modified fillers, plasticizers, quartz sand, plasticizing additives and moisture-repelling substances.

2 Properties and characteristics - why is the composition better than a liquid solution?

Polyurethane foam is the only adhesive for the installation of foam. It reliably adheres extruded polystyrene foam to any surface. Before the advent of this composition, it was believed that this material was not suitable for adhesive installation. True, craftsmen came up with technologies for gluing foam to the walls, but they had to install it only at their own peril and risk. Foam glue is recommended for the installation of this insulation by the manufacturers themselves, for this it was developed.

The possibility of reliable adhesion of foam is associated with the ability of liquid polyurethane foam to adhere well to any surfaces, including the smoothest ones. In addition, thanks to the additives, the composition has high technical characteristics:

| Specifications | Meaning |

| Adhesion to concrete, MPa | 0,3 |

| Adhesion to expanded polystyrene, MPa | 0,1 |

| Application temperature, ° С | -10 +40 |

| Thermal conductivity coefficient, W / mK | 0,040 |

| Consumption of one cylinder, m2 | 10 |

| Setting time at a temperature of +20 ° C, h | 2 |

The table shows that the adhesive foam has not only good adhesion, but also a number of other advantages, such as:

- Low thermal conductivity - due to this quality, the composition is used to insulate the seams. Thus, you can get rid of not only cold bridges, but also glue the expanded polystyrene together. As a result, the likelihood of cracking in the plaster is reduced.

- High speed of solidification - already two hours after the installation of the plates, you can proceed to the next stages of work - grouting and reinforcement.

- The ability to carry out installation at negative temperatures. But not all types of glue have this property. Therefore, before buying a composition for the winter, carefully read the instructions.

Foam glue has other advantages:

- Increases the speed of work - unlike a cement-based mixture, the foam does not need to be dissolved with water and brought to a homogeneous consistency with a mixer. It is applied simply and quickly. Therefore, the process of fixing the plates to the wall is performed five times faster than in the case of using a liquid solution.

- It has a low weight - as a result, it simplifies the transportation of the material and reduces the load on the foundation. If the slurry increases the weight of the board by ~ 3 kg, foam has practically no effect on this indicator.

Therefore, it makes sense to use such glue not only for penoplex, but also for ordinary foam, especially if you need to perform installation work quickly. True, its big drawback is its high cost.

Two-component and one-component - what is the difference

Two-component formulations do not require moisture to cure. Bonding starts after mixing the two components.

On the one hand, this is inconvenient, since additional equipment is needed for preliminary kneading, for example, a drill with a nozzle at low speeds, and on the other hand, it bonds well glass, PVC, laminated boards, plywood, and brick at any humidity air.

Two-component polyurethane adhesive

One-component polyurethane adhesive

One-component compounds are similar in properties to two-component ones, they are distinguished by an elastic, durable seam. They harden on contact with moisture in the air or in the materials themselves with which they interact. The convenience of such glue is that there is no need to mix the components, and the time until irreversible processes begin will be about forty minutes, so the master may not be in a hurry.

Examples of use - gluing shoes

When problems arise with shoes, there are few options - to throw it away, send it to the workshop or fix it on your own. If the sole is leaky or the heel breaks, it will be difficult to solve the problem on your own, but minor difficulties in the form of a detached sole can be removed with the help of modern polyurethane adhesives.

Polyurethane glue for shoes is optimal for working with highly oily leather, adhesion of soles to textile and synthetic materials, natural leather. The composition includes a hardener and rubber.

The glue is kneaded and heated.

- Before starting work, the surfaces are cleaned, degreased, treated with acetone.

- Then the composition is applied to both dispersed surfaces, kept for about ten minutes.

- Then both parts are pressed with force and left for several hours, depending on the characteristics of the surface.

There are two methods of application - cold and hot

- In the first method, the glue is applied in a thin layer for ten minutes, then a second layer is applied and dried for another ten minutes.

- After that, the surfaces are pressed for several minutes and left for a day. It is possible to influence the gluing mode, reducing the drying time.

- In the hot method, glue is applied to the entire surface and dried for about twenty minutes, then heated to + 80C and compressed for several minutes. The product can be used in just four hours.

Work should be done in well-ventilated areas. The glue is stored in a closed container. If the composition crystallizes, it can be heated in warm water.

On an industrial scale, the composition is used for fastening leather and rubber soles, thermoplastic elastane, polyurethane soles, natural leather, as well as for molding PVC soles.

We use for PVC boats

Polyurethane adhesive for PVC boats

High-quality polyurethane adhesives for PVC boats set when heated.

- The repair begins with the preparation of the composition, when both components are mixed in the right proportions, and the patch and the area itself are degreased with acetone.

- The applied layer of glue is kept for the time indicated on the package,

- Then the patch is applied and rolled, while heating the surface with a hairdryer.

- Then the boat is slightly inflated and left for two days. During this time, the glue is completely set.

The author of the article is Kristina Sekushina

Special two-component epoxy adhesives for construction

IC-Top Adhesive EP 01 is a glue for gluing old and new concrete, as well as gluing building structures and products. New possibilities - power bonding.

IC-Top Epoxifix EP 01 is an epoxy adhesive for fixing ceramic tiles and stone, as well as for filling tile joints (can be tinted by adding pigments), it is also recommended for power bonding and installation in construction and for repair and restoration of mineral and stone surfaces. Possesses high alkali and acid resistance and increased compressive strength, adhesion to various substrates, as well as high water resistance and frost resistance.

All ICT Chemical products are certified.

Our managers will select for you an individual solution to any problem, take into account all the features and pay attention to details. ICT Chemical is professionalism you can trust

You can verify this by simply calling us.

You can get more detailed information about products and consultation of our managers by calling us by phone (495) 229-44-31.

How long does it dry?

The setting time of polyurethane glue depends on the additional components in the composition, on average from 20 minutes to 1 hour. While the glue is liquid, it is necessary to firmly press the surfaces to be glued and fix for a few minutes. If possible, you can place the product under the press for 1 hour to ensure a snug fit. The closer the parts are to each other, the higher the quality and strength of the glue line. If part of the adhesive has emerged on the surface after hardening, it is necessary to remove the excess mechanically.

Full curing occurs within 24-48 hours, during this period strength is gained in the glue line. At this time, the glued product should be at rest, no mechanical action should be applied. Drying time depends on the ambient temperature. If polymerized with a hot method, then complete cure will take place after 4 hours.

Features and benefits of polyurethane glue

Polyurethane glue is an adhesive based on solid synthetic resins. The amount of such resins is the main difference between this glue and its analogues: the specified components are up to 95% here, while in other adhesives it is much less. Polyurethane adhesive has a special curing principle: a chemical reaction begins after the composition interacts with water vapor. As a result, bubbles of carbon dioxide are released, and the layer of glue turns into a strong film.

The appearance and behavior of the adhesive are similar to those of polyurethane foam. After applying a thin layer of glue, it gradually expands, the excess crawls out of the seam. As it hardens completely, it can be carefully cut off with a knife, chisel. This composition has a lot of advantages:

- Strong adhesion of homogeneous and dissimilar materials.Thanks to tough and reliable bonds, polyurethane-based products tightly bond wood, plastic, metal and many other materials. It can be used on damp wood or wood treated with an antiseptic - this will only speed up the curing.

- Water resistance. Polyurethane compounds are indispensable at high humidity, as well as when products come into contact with water. They do not deteriorate from such conditions, because the glue seam will be moisture resistant and can serve as a sealant.

- Sufficient open time. Even a beginner can work with polyurethane. The glue does not freeze within 20 minutes, and during this period you can easily adjust the parts, install the clamps. For a reliable connection, you need to fix the product for 1 hour, although it is allowed to fully use it only after a day.

- Ease of operation. Thanks to its convenient application, easy sliding of the composition, it is not difficult to use it.

- No harm to materials. The adhesive does not oversaturate porous substrates with moisture, and does not cause the risk of warping. Thanks to this, it can even be used for laying parquet without the danger of swelling of the dies.

Polyurethane adhesives are resistant to temperature extremes, freezing and heating. They are chemically resistant to gasoline, oils, aggressive compounds. Only silicone, polyethylene and polypropylene can not be glued with polyurethane, since the adhesion quality will be low.

Surface preparation

To prepare the subfloor for its subsequent cladding, you need to remove the old coating: linoleum, carpet, parquet and others. If this stage is neglected, there are great risks of incorrect installation of coating fragments.

If you plan to install the tiles on an uneven wooden floor, then it is recommended to level it with plywood first. Care should be taken to ensure that all fasteners are recessed and the holes are filled. In order to avoid waste of glue by reducing the absorbency of the substrate, it is recommended to prime the subfloor with a primer. After preparatory work, the surface must be degreased and cleaned of debris - even the smallest particles of dust can lead to peeling of the tiles.

How to choose?

When buying glue, not only polyurethane, special attention should be paid to its characteristics. Even the smallest details must not be overlooked

The time that the applied glue retains its elasticity - during this period, you can carefully apply the composition, remove excess, qualitatively adjust the glued elements of flexible metal or wood. That is why it is recommended for beginners to choose formulations with the highest given indicator.

Quick drying materials will be a lot of hassle.

Flow rate - this property is important to consider in two situations: when gluing tiles on vertical surfaces or in the presence of a base with many disadvantages, such as pits or bulges. Too thick composition does not spread over the material, accordingly, it does not fall into all voids, and high-quality adhesion is not guaranteed, no matter what material it is - PVC, SIP panels, expanded polystyrene or ceiling plinth.

- Shelf life for application - this property is taken into account when buying two-component adhesives. After mixing the two substances for several hours, the glue retains its properties. The amount of the prepared solution depends on the time after which the composition loses its characteristics.

- Scope of operation - some solutions are best used for aerated concrete or parquet, and some for sandwich panels or stone. Some mixtures are suitable for stucco molding on curved surfaces, gluing cornices to ceilings, while others are suitable for high-quality thermal insulation from inside or outside the room.

Application Tips

To achieve high-quality and reliable gluing of surfaces, you must follow all the rules and recommendations of specialists. Thoroughly clean all elements from dust, dirt and treat them with a degreasing agent. The glue is applied in a thin layer using a brush, spatula, spray gun, or special equipment, if we are talking about manufacturing enterprises.

Please note that excess glue may spill onto a clean surface. In order not to worry later about how to remove the dried composition, it is better to remove it immediately with a special solvent.

Different materials can be glued using different technologies.

- Hot method - it is used with Desmokol glue, the solution is applied to both objects and left for half an hour. The properties of the substance are activated under the influence of high temperature (approximately 85 degrees) within a few minutes. After this, the surfaces must be strongly pressed against each other.

- Cold method - to glue objects, you need to apply the mixture to both surfaces, after 10 minutes, reapply the glue with a thin layer, dry for a few minutes and connect the elements.

- Moistening the surface - for high-quality adhesion, the glued elements are sprayed with water and pressed against each other. This method is appropriate to use when there is a special press, since it requires the strongest possible compression.

It is necessary to work with glue in special clothing, a respirator and goggles.

In winter, the polyurethane composition does not lose its characteristics, but it becomes more viscous, so it is more difficult to work with it. Many people believe that it can be diluted or constantly heated, but experts do not recommend doing this. The optimum temperature for working with glue is +20 degrees. Therefore, if you work at low temperatures, it is better to heat the barrel once and pour the glue into small containers that close tightly.

Please note: containers with glue cannot be kept near an open flame, much less heated over a fire. To maintain the optimum temperature, it is recommended to store the glue in a thermos

Do not heat the product above +40 degrees, and do not glue hot surfaces. If the objects to be glued have a temperature higher than +80 degrees, the glue will harden faster and its adhesion will increase.

If at the end of the work you still have the composition in the container, squeeze the bottle and close tightly so that all the air comes out of it. This will prevent rapid deterioration of the substance, and it can be used more than once.

For information on how to use polyurethane glue, see the next video.

Views

Polyurethane adhesive is polymer in structure. Depending on the composition, one-component and two-component polyurethane glue is distinguished. One-component mixture is produced ready-made, the polymerization process takes place in the presence of water. The moisture-curing compound foams better when the air humidity is at least 60%. During the reaction, the volume increases and the expanding composition comes out at the edges of the seam.

A two-component product consists of two components that are mixed before gluing. You cannot make homemade glue, because when the proportions of the hardener are changed, a chemical reaction and hardening will not occur. A quick-drying composition is produced, which is subjected to treatment with hot temperatures from 80 to 110 degrees.

Universal one-component contact adhesive for bonding various material combinations. The polyurethane compound is capable of replacing heat-resistant automotive sealant for repairing car parts and anti-corrosion protection. To fix the heaters, a special polyurethane assembly glue, similar to foam, is used.

Types of adhesives

All adhesives for penoplex on the market have a high level of adhesion.Thanks to this, there is a reliable adhesion of the composition to the surface, thereby hardening the finish and increasing its quality.

As a rule, adhesives come with instructions for use and a brief description of the technical characteristics, which include:

- temperature parameters for installation and further operation;

- air humidity indicators;

- what type of surface is this material intended for;

- type of surface to be insulated.

The range of adhesives for penoplex is divided into several types.

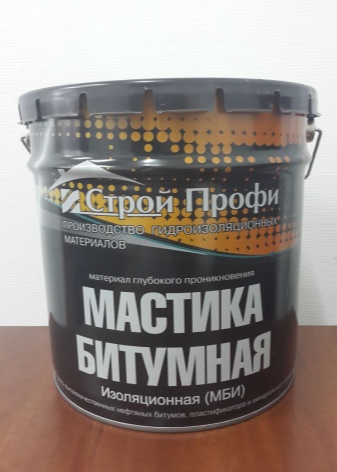

Bituminous mastic

This material is a thick bitumen-based mixture that retains its original properties even at sub-zero temperatures. Bituminous adhesives are widely used in construction, in particular, for waterproofing foundations. In addition to its direct purpose, it is an excellent hydrophobic joint filler during the installation of foam.

It is preferable to work with a spatula or a spatula.

Liquid Nails

This material is suitable for working with any surface. However, the work should take into account the peculiarity of the place where the repair work will be carried out. For installation inside a building, conventional compounds are used, but for external insulation, specialized means are used that are resistant to frost and temperature extremes.

On sale, the composition is presented in tubes. It is best to apply to the base with a "snake" over the entire surface of the sheet. For gluing the foam to the surface, just 10-20 seconds is enough - "liquid nails" have time to grab during this time.

The only negative is the rather high price of the material.

Mineral

Mineral adhesives are presented in the form of dry mixes and are diluted with water to the desired consistency before use. They are distinguished by high adhesion and go well with concrete, brick and gas silicate surfaces. Their advantage is their high plasticity, which allows the material to be applied in a thin layer.

Apply with a notched trowel. After drying, they do not "shrink", retaining their volume.

For outdoor work, there are special moisture and frost-resistant compounds.

Polyurethane

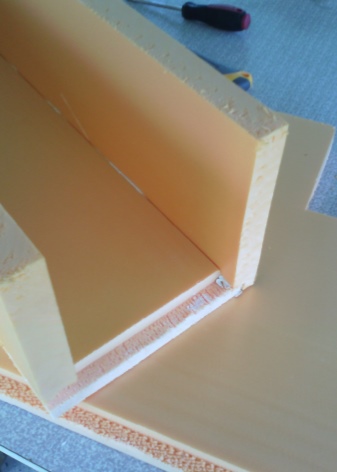

Such adhesives are produced in special metal cylinders and can only be used with the help of special equipment - a gun for polyurethane foam. When applied correctly, the material will lay flat on the substrate in even zigzags, allowing a bond to be achieved over the entire surface area.

Such compositions are distinguished by quick setting - it is enough to hold for half a minute, and the material will be firmly glued. But at the same time, the elasticity of the material remains for about 15 minutes.