Varieties

Sealants are divided not only by the type of work: for external or internal, but also by the active substance included in the composition.

Silicone

The most

Silicone is a popular sealant in the building materials market. V

the composition of the material includes compounds of silicone rubber, which has

universal properties and is suitable for use in external joints. The main

parameters thanks to which silicone sealant has gained popularity

are highly elastic, resistant to water ingress and drops

temperatures. The composition tolerates low temperatures well, does not deteriorate and

maintains adhesion to wood.

TO

the disadvantages of a sealant based on silicone rubber include the impossibility

replacing only part of the seam. If for some reason a crack has formed on the seam or

other flaw, then the entire seam will have to be removed and the material reapplied.

In addition, this type of sealant cannot be stained. If during the work it is necessary to give the material a different shade, then the dyes will not remain on the silicone material. Silicone sealant has a low degree of adhesion to materials with a porous structure. If the seam is planned to be led over concrete or plaster, then there is a high probability of poor adhesion to the surface.

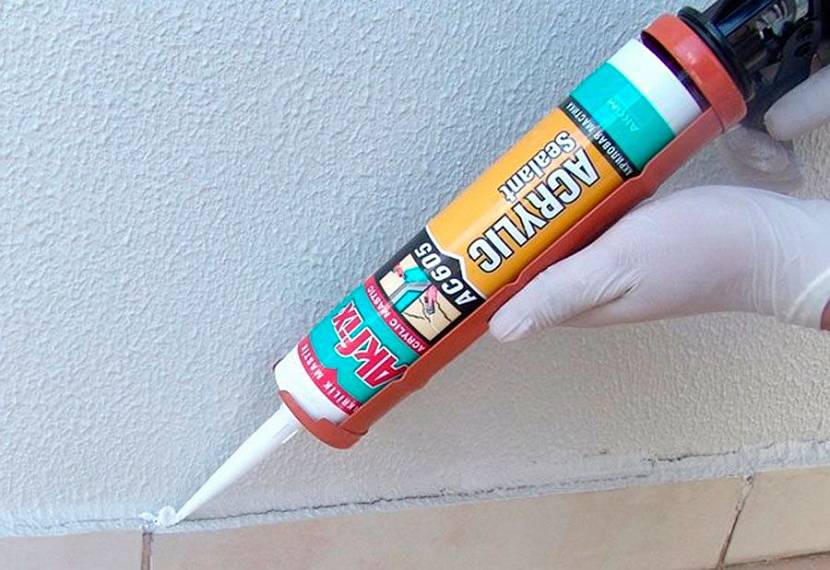

Acrylic

In acrylic sealant in

acrylic polymers are used as active ingredients. Such

the type of sealant is safe for people and the environment without emitting

harmful fumes. Acrylic material is often chosen for sealing joints and

joints in wooden structures, since acrylic based sealant

polymer has a high level of steam transmission.

The sealant is moisture resistant,

but for its full functioning, it is advisable to keep the seam for a day

dry without exposure to water. Despite the fact that the composition can be

maintain strength in wet conditions, exposure to water directly on

material is not desirable.

The acrylic sealant for outdoor woodwork is UV resistant, and if the seam is flawed, the damaged part of the seam can be repaired. If necessary, the sealant can be tinted in the desired color.

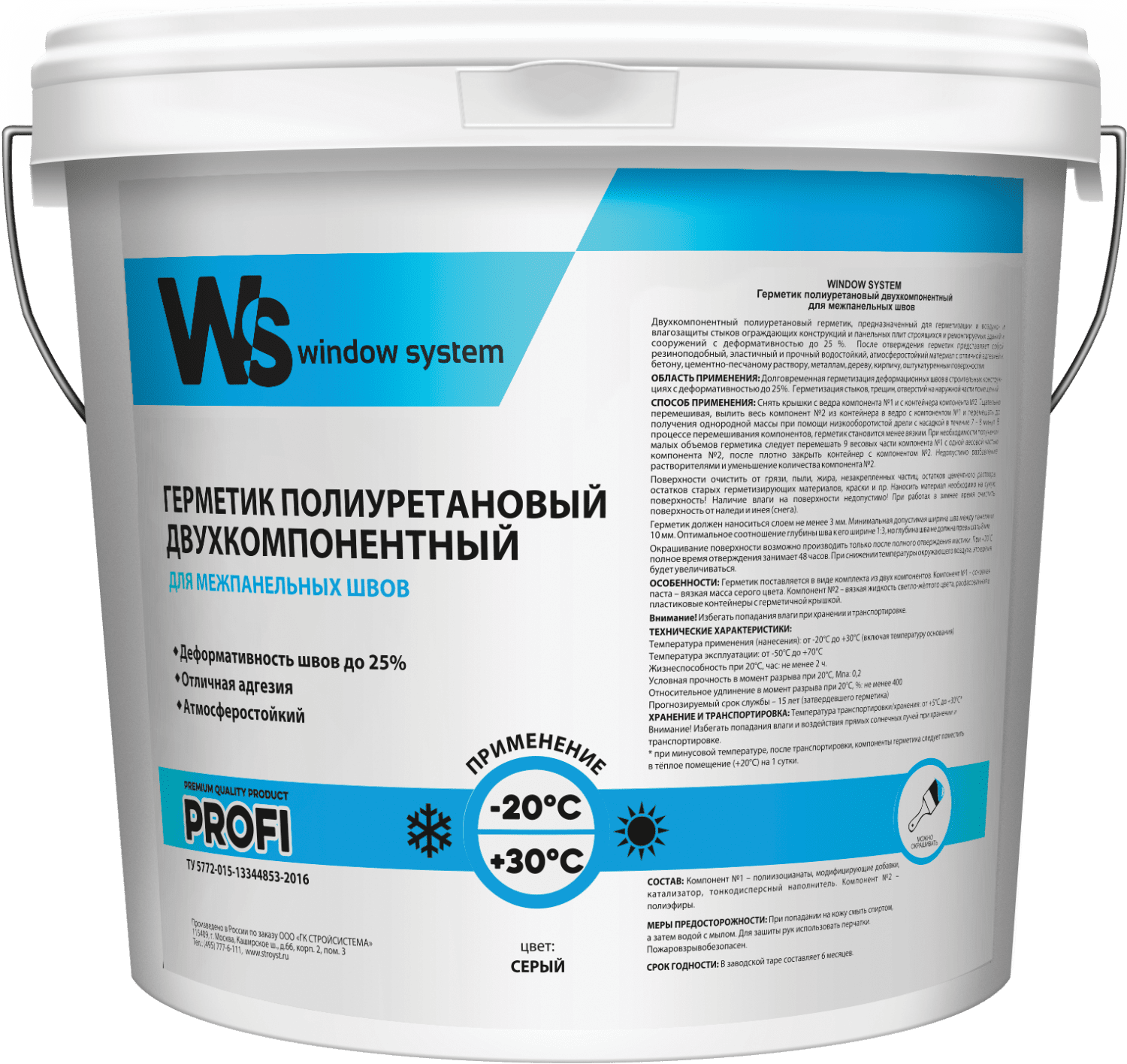

Polyurethane

Polyurethane

sealant appeared on the building materials market relatively recently, but

quickly became popular. The positive qualities of such material:

- resistance to impact

water; - wear resistance;

- tolerates low

temperatures (up to -60 degrees) and high; - resistance to

ultraviolet light; - low shrinkage

after taking a solid form.

This type of sealant interacts well with wood materials and has a long service life.

Rubber

Rubber

the sealant contains synthetic resins. After hardening, such material

similar to rubber and becomes a barrier between the material and the damp outer

environment. The advantages of using a sealant is that, after polarization, it

protects the material from rust, exposure to sunlight or

water. The rubber sealant tolerates low temperatures well down to -50 degrees.

After hardening, the material can be painted with ordinary facade paint. In addition, a big plus is the ability to apply the composition to the wet surface of the product.

Bituminous

Bituminous sealant is a bitumen-based compound. Its main field of application is the sealing of joints during roofing work.Has a good degree of adhesion to metal and other materials for roof repairs. Such the composition protects the metal surface from corrosion, preventing the appearance of moisture in the seams. Bituminous sealant for wood and other materials is sold in transparent color, but its price is higher than conventional sealant based on bitumen and rubber.

Silicone

This type of sealant is by far the most popular among users. It is used both for industrial and domestic purposes, indoors and outdoors. This soft elastic substance is based on silicon: it is from it that polymer resins are made for the production of silicone.

Silicone sealant has a number of advantages:

- It is elastic and difficult to tear. Sometimes the degree of stretching of the material can reach up to 800% of the original dimensions. Silicone sealant has good shape memory, which allows it to accurately resume its original dimensions after deformation. This makes it possible to use silicone seals to seal unstable joints subject to vibration or movement. First of all, this applies to wooden houses, for the construction of which timber or logs were used.

- Adheres well to almost any material. This is due to the widespread use of silicone sealant in various areas of construction and renovation.

- It is not afraid of ultraviolet radiation and other climatic influences. This makes the material well suited for outdoor use. It is also resistant to biological attacks, it is not afraid of temperature fluctuations and exposure to moisture.

Can silicone sealant be used in low temperature environments? Ordinary silicone feels comfortable in the temperature range from -50 to +200 degrees. Some special seals are reported to have increased heat resistance

When choosing a suitable frost-resistant sealant, it is important to consider that the silicone material is not paintable. Considering that the color palette of painted seals is not very rich, it is not always possible to choose the most suitable shade for your facade.

It is the aesthetic component that makes us consider other types of frost-resistant sealants.

Usage

No matter how manufacturers care about the waterproof and frost-resistant parameters of their product, almost everything is in the hands of users.

It is extremely important to follow the technology to the smallest detail, otherwise the result is not guaranteed. First of all, you should take care of cleaning all seams from dust particles, old paint and just dirt.

It is not allowed to treat a non-uniform surface with a sealant. If the material delaminates, it is at least naive to hope for a strong bond with it.

Observe, of course, the manufacturer's instructions, especially regarding the exact application temperature.

Important: these are just the maximum permissible limits, whenever possible, even a polyurethane sealant should be used in a warm environment. With regard to the curing time of the sealing agent, it is worth distinguishing between the curing period of the top layer and the duration of complete curing.

The first stage is sometimes completed within 30 minutes after the release of the reagent to the surface. The second one lasts several days.

The two-component polyurethane sealant is almost 100% elastic. Storage of material should be organized in places known to be inaccessible to children and pets. Also, excessive heating during storage is unacceptable. When the normal, compliant handling conditions for the sealant are maintained, even in an open container, it will retain its properties for up to 10 months.

Types of sealant

Choose a waterproof sealant (this can also be an aquarium sealant). In conditions of practically constant air humidity, the product is resistant to moisture.The second important point is the availability of anti-fungal supplements. In their composition they are written as "fungicide" (the name may be different, but more often it is). This additive is anti-mildew on the sealant.

Silicone

Silicone is often used for bathroom building purposes and this is not strange. After all, it has excellent water repellency and fungicide additives against mold. It conveniently fills in voids, cracks in the wall, seals objects between themselves and can glue them to the wall (for example, a washbasin, a shower stall, a bathtub). The main substance in this type of sealant is silicone. The material is durable, capable of adhering tightly to almost any degreased surface. You can find two types in stores - neutral and acidic.

Acid

Acidic is produced by the manufacturer more simply than neutral and its cost is always lower than the second in composition. A significant disadvantage is the oxidation of metals in contact. Use where the surface is protected against oxidation (enamel, stainless steel, ceramics, etc.).

Neutral

Neutral silicone sealant is more expensive, has disadvantages, and can be used anywhere. Will show itself only on the strong side on surfaces from acrylic to metal.

Acrylic

Unlike silicone sealants, acrylics cost less money. The main advantage is the complete absence of harsh chemical odors, elasticity of the seam. Recommended for use on elements subject to vibration and slight deformation. However, the grip is worse than the first one. Acrylics are both moisture resistant and not having this property. When choosing acrylic for your bathroom, make sure the manufacturer mentions water resistance on the packaging.

Silicone-acrylic

This type of product combines the advantages of silicone and acrylic sealant while eliminating all their disadvantages. When using such a product, you will get a strong, elastic and durable seam with water repellent properties. In addition, it can qualitatively glue objects together or glue something to the wall.

Popular brands

Here are a few "good" waterproof that are often used by craftsmen when working.

All of them contain an antiseptic that prevents mold growth. All of them are also waterproof, excellent for use in places where water accumulates. Penosil All Weather Sealant - contains solvents, elastic. It is based on synthetic rubber. Suitable for use even on damp, level surfaces. Perfectly adheres to the surface without pretreatment. Drying in 20 minutes, complete drying in 24 hours, joint mobility 24%. Recommended for indoor and outdoor use, for facades sealing, glazing, ventilation works.

Sanitary moment for bathroom and kitchen - has a transparent structure on a silicone base. The vinegar smell that emanates during application indicates that this silicone sealant is acidic (as we know there is also neutral), so read the manufacturer's recommendation for information about where it is used, whether it will break the enamel with its acid. The range of work is from -40 to +150, which is quite enough for home use, and the application temperature is +5 to +40 degrees. This product is resistant to fungal growth, therefore, its use in places where water is accumulated is justified.

Penosil S white H1199 is a sanitary product. Recommended for use in rooms with high humidity. It has antiporazitny additives (fungicides) in its composition that prevent the spread of mold, fungi. Its water resistance makes it a good choice for water congestion areas. UV resistant. The temperature range for use is + 5 / + 100 degrees. Application temperature -40 / + 40.

MF915 MAKROFLEX - Another Water Resistant Sanitary bathroom sealant rooms. Works with objects covered with acrylic, polyurethane. Also works well with polystyrene, gypsum, ceramics, concrete, plasterboard, wood and stone. Adhesive sealant is an excellent solution for swimming pools, saunas and bathtubs due to its water repellency, elasticity and prevention of the spread of bacteria and resistance to UV rays. Application temperature from -7 to +40. The operating mode is from -30 to +80 degrees Celsius.

Manufacturers

Today there are many manufacturers producing high-quality and reliable polyurethane-based sealants. Let's take a closer look at some of them.

"Moment"

This manufacturer is one of the largest and most famous. The assortment of the company is very rich. Moment offers not only sealants, but also adhesive tapes, different types of adhesives, chemical anchors, and tile products.

As for polyurethane sealants, among them it is worth highlighting the popular product "Moment Herment", which forms a hard and elastic adhesive seam, which is highly resistant to water, household chemicals, oils, petroleum products, acids and salts.

This popular product is used for insulation and bonding of materials in construction and industry. It adheres easily to wood, skirting boards and various decorative objects.

Izhora

The Izhora production company is located in St. Petersburg and offers high quality polyurethane-based adhesives to consumers.

Izhora produces both one- and two-component compounds that can be used to seal joints on facades and plinths, when processing seams and cracks on ceilings, as well as for external processing of door and window openings.

In addition, the company offers formulations in gray, blue, green, yellow, brick, pink and lilac colors.

Olin

It is a renowned French manufacturer of high quality polyurethane sealants. The brand's assortment includes the popular Isoseal P40 and P25 compounds, which easily adhere to concrete, ceramics, glass, aluminum, steel and wood.

These polyurethane formulations are sold in 600 ml tubes and 300 ml cartridges. Olin polyurethane sealants are also available in a variety of colors: gray, beige, dark beige, dark gray, terracotta, orange, black and teak.

Retel car

Retel Car is a popular Italian manufacturer of polyurethane joint sealants that are non-drip and perfect for vertical surfaces. They are used in the automotive industry, for sealing containers, for laying air ducts and air conditioning systems.

Sikaflex

The Swiss company Sika produces a range of high quality products based on polyurethane. So, Sikaflex sealants are multi-purpose - they are used for roofing work, when installing air conditioning systems, as well as when pouring deformations on concrete.

Also, Sikaflex polyurethane sealants can be used when gluing window sills, steps, skirting boards, and various facing elements. They have excellent adhesion and adhere easily even to plastic.

Dap

It is a well-known US brand offering silicone, polymer and polyurethane sealants. The company's products are distinguished by affordable cost and good performance characteristics. For example, the popular Dap Kwik Seal, which is ideal for sealing joints in the kitchen or bathroom, can cost from 177 to 199 rubles (depending on the volume).

Consumption

Before going to

the hardware store for the sealant must calculate the amount of material,

which you need to work. To determine the volume of the required sealant, you need

measure the width and depth of the seams to be processed. By volume

may be affected by the material to which the sealant is applied.

"The volume of the sealant is calculated

as the seam depth times the width. The data for the calculation are taken in

millimeters. And the resulting value will be an indicator of the consumption of sealant per 1

meter of seam in grams of substance. "

If the shape of the joint is triangular,

then its use will be lower than that of a parallel joint. Using

sealant on a wooden surface, there is a standard value for

consumption - 6 mm per 1 meter of the seam. However, if the crack to be repaired

is slightly larger than the standard size, then the consumption of sealant will be higher

accepted. Consumption can be reduced by placing a silicone cord in the seam.

Recommendations from the masters

Usually, when working with them, there are no special difficulties. However, for a successful seal, we advise you to follow a few rules:

- the workplace must first be cleaned and processed from dust residues;

- if compaction has to be performed in winter, the surface is also cleaned of snow;

- to enhance adhesion, the seam section is initially primed;

- we recommend buying a sealant only in trusted stores in Moscow;

- use it with the help of special attachments - this will allow you to evenly distribute the seams;

- We advise you to seal the joints on a warm day without rain, because the drying time of the sealant depends on this.

Types and physical properties of sealants

Let's consider in more detail what sealants are offered on the market today and what their properties are.

Acrylic sealants

All acrylic-based sealants have the following properties:

- Virtually do not change their size after drying. The seams treated with them should not be subjected to tensile and compressive effects;

- The thermal expansion of the treated joints should not exceed 8-10% (the optimum quality of the joint is observed at a constant temperature);

- Odorless, environmentally friendly;

- After drying, the seam can be painted (with water-based or oil paints).

Sealing compounds based on acrylic are divided into non-moisture-resistant and moisture-resistant. The first type can only be used for indoor work on dry walls made of concrete, brick, plasterboard, wood, skirting boards and furniture.

Moisture-resistant acrylic sealant withstands temperature extremes better, therefore it can be used in the bathroom and in the kitchen (without constant contact with water). They cannot handle a wet seam. The adhesive qualities of moisture-resistant acrylic are higher, so it can be used not only on monolithic surfaces, but also on porous ones.

This composition goes well with foam concrete, tiles, wood, plastic and ceramics. It is not recommended to use it outdoors.

Acrylic silicone sealants

The main disadvantage of acrylic is that it was possible to overcome its low water resistance by adding silicone to it. The combined composition is not afraid of rain and temperature fluctuations, therefore it can be used for outdoor work. The resistance to deformation of acrylic silicone is higher. The seam is elastic and tight.

With this composition, you can close up small leaks in doorways, seams in window frames, plaster, tiles, siding and glass. Once dry, the joint can be painted with oil or latex paint.

Silicone sealants

The most common type. Silicone is not sensitive to water and is very elastic (it can change its size without destruction by 2-3 times). The disadvantage of seams treated with colorless silicone is the impossibility of staining and restoration.

Additives are introduced into the composition of this sealant, giving it the necessary qualities:

- antiseptic (can be used in wet rooms);

- heat-resistant (sealing of hot joints);

- neutral (do not have a chemical effect on materials);

- acidic (designed for sealing plastic, it cannot be applied to metal).

Polyurethane

It is a versatile sealant. It is durable and elastic at the same time. Equally well suited for sealing outdoor and indoor seams. Reliably insulates joints in hard materials: metal, concrete, plastic, wood and their combinations. It is not afraid of moisture, high temperatures and aggressive environments. It can be used for pipes, roofing, windows and doors.

Polyurethane-silicone

A fairly new universal material. Siliconized polyurethane (MS polymer) creates a strong, chemically inert, elastic and durable joint that is easy to paint and repair.

It has high adhesion (adhesion) to the surface. For this quality, it is often called an adhesive sealant. The heat resistance of such a material is in the range from -40 to + 90C.

Bituminous sealants

A classic material designed exclusively for outdoor use. They are based on a combination of bitumen and rubber.

Types and benefits

Today on sale you can find a variety of compositions, and each of them has both advantages and disadvantages. Immediately, we note that the price segment of these products is very wide, so you can easily find a product at an affordable cost.

There are 5 main types of frost-resistant sealants that deserve attention. We will consider them further.

Silicone

One of the most common remedies. It is considered versatile and excellent for outdoor work when you need to seal the joints.

Silicone sealants allow you to create an elastic joint that has:

- wide range of operating temperatures;

- resistance to moisture, water and dampness;

- excellent adhesion (except for porous materials, including plaster and concrete).

Some sealants of this type have an unpleasant sour odor, which is produced by the release of acetic acid vapors during curing. However, neutral compounds can also be found on the market.

Acrylic

These compositions are considered the most environmentally friendly, since they do not contain harmful substances. Thereby they are suitable for sealing private buildings. In addition, they are known for good vapor permeability, which makes them different from other products.

Acrylic compounds are suitable for the treatment of wooden structures. With their help, you can seal the joints between a bar or a log, providing excellent insulation from negative environmental factors. Other advantages of acrylic sealants include:

- ease of use;

- versatility, because due to high adhesion, these compounds adhere well to both smooth and porous surfaces, including stone, metal, concrete, glass and others;

- resistance to UV radiation;

- the possibility of partial or complete restoration of the seam;

- fire safety.

These compounds are cheap and readily available. When buying, it is recommended to read the instructions on the packaging and make sure that the sealant is frost-resistant (there must be a corresponding mark).

Polyurethane

Despite the fact that this type has appeared on the market not so long ago, its popularity is growing rapidly. In addition to good water resistance and high resilience, these sealants are known for excellent frost resistance. They can withstand temperatures down to -60 degrees Celsius and keep the seam as tight and undamaged as possible.

Products of this type are characterized by slight shrinkage after polymerization. They are resistant to direct sunlight. Their curing occurs upon contact with atmospheric moisture. If we are talking about two-component sealants, then polymerization proceeds by mixing the substances that make up the composition.

The service life of polyurethane products is also curious. It reaches 20 years old, and the seam does not require renewal (except for mechanical or any other damage). As for the field of application, these compositions are suitable for sealing:

- foundation;

- roofing;

- interpanel seams;

- window and doorways.

Rubber

These sealants are known for their unusual formulations, which, in addition to elastomers and oligomers, can include:

- bitumen;

- solvents;

- resin;

- various fibers.

These compositions can withstand frosts down to -50 degrees Celsius and at the same time allow to protect materials from the formation of corrosive processes, thanks to which they have become very famous in the professional field. They are not afraid of either water or ultraviolet radiation, and after polymerization, the sealing seam can be coated with paint. This type of sealant is applied even to a damp surface without fear of loss of adhesion.

Bituminous

Bituminous sealant is intended mainly for roofing work. It allows you to eliminate damage to both roll materials and corrugated board, while preventing moisture from entering the under-roof space.

Of the advantages of these compositions, one can single out:

- ease of application;

- good adhesion to metal surfaces;

- no need for preliminary preparation;

- fast curing.

Interesting: Silicone transparent sealant - features of choice

Properties and scope of polyurethane sealant

Polyurethane sealant is a viscous elastic material that is used in installation and insulation works not only as an insulating compound, but also as an adhesive. It is based on polymers with highly elastic properties of synthetic origin. The sealant has the following properties:

- Elongation level 50-150% (in some species up to 1000%).

- High adhesion to substrates of any geometry and structure: concrete blocks (including young concrete, up to 28 days), glass, ceramics, drywall.

- Adhesion to other types of waterproofing mixtures.

- Does not deteriorate under the influence of moisture and UV rays.

- The service life is more than 30 years, it is not destroyed by vibration loads.

- Frost resistance from -50 ° С to + 90 ° С. When using winter compounds, the minimum temperature during installation is up to -10 ° C.

- The sealant does not spread even on vertical surfaces up to 1 cm.

- Does not shrink after fully cured.

- Harmless for repairs in residential premises.

- Polymerizes on contact with moisture.

Areas of use:

- The material is used as a heat-insulating filling in the gaps when installing door and window structures.

- Sealing the seam distances between concrete, plasterboard, reinforced concrete, log blocks.

- Waterproofing works in rooms with high humidity (bathrooms, kitchens, showers). In this case, the density of the material must be at least 25 kg / m3.

- Sealing of roof joints: pipes, ridge, parapets, gutters.

- Installation and fastening of auto glass and insulation of units of engine cooling systems.

- Reinforcement of deck frames in shipbuilding.

Representatives of the best frost-resistant compounds

Based on the positive feedback from the masters, the frequency of purchase, a list of the best frost-resistant sealants has been compiled:

- Ettrilat PU25 is a multi-component, low modulus polyurethane material. It is used in the absence of a primer, providing high adhesion to construction surfaces. Easy to use, resistant to water, moisture, solar radiation. After drying, staining is permissible. It is used for outdoor work in construction: butt concrete parts, ceramic, wood, etc. Not used with polypropylene, polyethylene, Teflon.

- Titan Wild is a universal silicone that provides reliable adhesion to concrete, stone, brick and other coatings. Perfectly fills seams and cracks. Increased resistance to weather conditions, temperature extremes from -40 to 80 degrees. The surface, after complete drying, can be painted.

- Sikasil-C is a water-frost-resistant acriplast.It is used for sealing construction joints, for non-porous surfaces, as a putty when installing windows, etc. Sealant 100% neutral silicone. Contains components that prevent the formation and reproduction of fungal formations. Produced in a palette: white, gray, black, brown, transparent.

- Rubberflex is a white, unary polyurethane sealant. It is used for external, internal work in the construction of roofs, swimming pools, sewerage, etc. Work on the application is carried out from -10 to 40 degrees. Working temperature from -60 to 90 degrees, briefly up to 120 degrees. Adhesion to all construction surfaces.

- TENAX TENALUX 112 is a one-component acrylastic for roofing work. Has a high viscosity, does not spread when applied vertically. No shrinkage, no smell. After complete drying, staining is possible. Resistant to climatic changes. Used with an assembly gun. The main production color is gray.

- Sazilast 24 - produced on a polyurethane base. Not affected by alkalis, acids, sunlight, moisture, vibration. The service life after complete polymerization is 15 years. It is used for laying, repairing roofs, walls, floors. Complete polymerization after two days. It tolerates temperature changes well. Adhesion to any building materials.

Peculiarities

Until the middle of the last century, various joints were sealed with rubber or cork. At that time, these materials were quite expensive and people were looking for more affordable alternatives.

The first experiments on the synthesis of polyamides were started in the USA, but German scientists, who also took part in new developments, achieved success in this matter. This is how the materials popular today - polyurethanes - appeared.

Most buyers opt for polyurethane formulations, since they have many positive qualities.

Let's get acquainted with some of them:

- The polyurethane sealant is highly elastic. It often reaches 100%. It is very easy to work with such a composition.

- Such mixtures boast excellent adhesion to many types of materials. They fit seamlessly on concrete, brick, metal, wood and even glass. In addition, good self-adhesion is inherent in polyurethane-based sealants.

- Such compositions are durable. They are not afraid of high levels of humidity or aggressive UV rays. Not every binding material can boast of such characteristics.

- Polyurethane sealant can be safely chosen also because it perfectly copes with its main task. This building mixture guarantees excellent sealing and waterproofing of the necessary parts for quite a long time.

- Also, temperature drops are not terrible for polyurethane sealants. It easily tolerates exposure to subzero temperatures down to -60 degrees.

- A similar composition can be used at any time of the year. For example, it could be winter with cold ambient air. In such conditions, the sealant will still easily fall on one or another base, so repair work will not have to be postponed to a warmer period.

- The polyurethane sealant does not drip. Of course, this property takes place in cases where the applied layer does not exceed 1 cm in thickness.

- This composition gives minimal shrinkage after polymerization is complete.

- Polyurethane sealant is also convenient because it dries up in the shortest possible time and hardens rather quickly.

- The polyurethane-based sealant can be colored or colorless.

- If the air contains moisture, then under its action, such a sealant will polymerize.

- Polyurethane compounds are not susceptible to rust.

- Such materials are not afraid of mechanical damage.

It is worth noting that the polyurethane-based sealant is similar in many characteristics to polyurethane foam during its drying process, since it polymerizes in the shortest possible time and becomes hard.

In the composition of modern sealants there is such a component as polyurethane with a one-component structure. Also in stores you can find two-component options that boast improved sealing properties.

As you can see, such building mixtures have a lot of advantages. However, polyurethane sealants have their own weaknesses.

You should also familiarize yourself with them if you have to work with these materials:

- Although polyurethane sealants have excellent adhesion properties, in some cases they are not enough. A similar problem can be encountered if you seal structures made of certain types of plastics.

- According to experts and manufacturers, polyurethane compounds cannot be laid on substrates with a moisture level exceeding 10%. In this case, they should be "reinforced" with special primers, otherwise you simply will not be able to achieve sufficient adhesion.

- It was indicated above that temperature drops are not terrible for polyurethane compositions. However, it should be borne in mind that prolonged exposure to temperatures of 120 degrees can lead to the fact that the sealant will lose its performance.

- Few people know, but disposal of polymerized sealant is an expensive and very difficult operation.

Scope of application

Frost-resistant and water-resistant sealants are used in the winter season, because other options will not cope with the peculiarities of the climate. In construction, this material is used to seal roof joints, especially if it is made of modern materials, because they need additional protection along the joint line. Facade sealant will help hide any flaws on the front side of the building, and the ability to paint this material makes it invisible, which is very convenient.

For panel houses, cracks are a very common problem, which cause drafts, especially noticeable in winter. With the help of only one sealant, you can get rid of this situation, but only if the gaps are small.

In addition to the upper part of the building, it is worth paying attention to the lower one, because the whole foundation is the key to the stability of the building and its reliability. The sealant, due to its versatile properties, is able to stop cracking of the base and strengthen it for many years

Outside of both new and old buildings, there are always some flaws that need to be dealt with in the early stages, as long as the destruction is minimal and can be dealt with with simple means. With the help of a universal silicone sealant, you can connect parts of concrete and metal, fill in voids and correct what initially did not work out or deteriorated over time.

It is especially easy and effective to use the sealant during the installation or repair of windows

It is important to finish everything inside so that no traces of this substance are visible, but at the same time that all the cracks are reliably closed. Outside, you can pay more attention to protecting the window opening by filling all the cracks with a sealant

By choosing a transparent option, you can achieve the fact that it will be difficult to find places on the facade where the work was carried out, and the use of color options will help to mask the area where the repair was carried out.

The scope of use of the sealant is large and it is difficult to imagine the repair of any room, both inside and outside, without the use of this building mixture.