Types of paints for plastic surfaces, which one to choose, criteria

Plastic paint on sale is offered in a variety of assortments. In order not to get confused and choose the most suitable and most convenient option, you should study all their features. Having studied all the information, choose what to paint the plastic with will be easy. The most common types will be described below.

Plastic paint on sale is offered in a variety of assortments.

Water based formulations

Paints and varnishes are suitable for painting plastic products, they are also called acrylic enamel on water.

Typically, these dye products are created from two elements:

- The base itself is the dye;

- A hardener is a component that makes acrylic enamel for plastic more reliable and well tolerant of external influences. This component is transparent, odorless.

It helps paint easily, lays down, is stable, does not lose color brightness for a long time, it is not afraid of even ultraviolet light, it looks aesthetically pleasing. When using these paints, priming and other additional work are not required, with the exception of surface contamination. Great view for outdoor use.

When using these paints, priming and other additional work is not required.

Matte soft-toch paints

Items that are often touched with hands should be as pleasant to the touch as possible. This type is an excellent choice for painting phones, furniture handles, plastic toys, cosmetic bags, construction tools. This dye, in addition to a comfortable touch, also mutes sound and light, and can give an object an aesthetic appearance.

Often purchased for painting vehicles, due to its wear-resistant properties, and the ability to cover vertical planes, it also has the effect of smoothing corners.

This dye, in addition to a comfortable touch, also mutes sound and light, and can give an object an aesthetic appearance.

Water-based polyurethane-acrylic paints on PVC

This type is used when it is necessary to carry out a large amount of work. They are not matte, more often this water-based plastic paint with polyurethane and acrylic components is used to cover siding, panels, PVC profiles, window frames, etc.

They are distinguished by their quality and stability. The paint is waterproof, indelible, covers the surface with a protective layer, giving the object hardness, elasticity, while they are not sticky. Shows good results during application and drying for the absence of adhesion of products to each other, no formation of defects, and preservation of decorative properties.

PVC itself is actually colorless, so it is dyed to make it more pleasant to look at. The composition of the coloring material is as follows:

- Basic acrylic paint of the required color;

- Thick white or milky liquid, i.e. a hardener that can give, either bed tones, or vice versa, bright colors (red, yellow, brown, green, generally any). It is possible to get an unusual texture by adding texture elements to the composition that will give the appropriate effect: wood, mirrors, plaster and others.

They are distinguished by their quality and stability.

Spray paints for plastic

Many believe that only professionals can paint with spray cans. In fact, they are very convenient to apply paint, there is a large selection of colors, there is no need to mix the composition. With an aerosol, a person who first decides to paint plastic on their own will feel confident.

These paints in spray cans are produced in two types:

- The previously mentioned soft-toch, which, after complete drying, is pleasant to the touch and slightly rough, which allows you to hide some of the product's shortcomings. It is also a great option for giving the interior a twist;

- Monad enamel, on the contrary, will give a gloss to the surface, it will sparkle in the sun, it is suitable for PVC.

In this variety, it is easy to choose the necessary cartridge for a specific purpose.

Aerosol benefits:

- There is no need to buy brushes, rollers, etc .;

- Easy to use;

- The paint composition covers the product with an even and smooth layer;

- With their help, you can reproduce any coating (mirror, metal, wood, etc.);

- Maintain brightness for a long time;

- Long-term storage;

- Economical;

- If they decide to apply on a different color, then it will be easy to paint over it.

The paint composition covers the product with an even and smooth layer.

Plastic painting technology

Plastic has a property that is inconvenient for technologists - adhesives and paints do not adhere well to it. Technologists have developed many ways to overcome this unpleasant property. One of them is a preliminary primer. But it is not needed for every type of material. This is verified as follows. It is necessary to set a piece of this plastic on fire and see - if the combustion is with thick soot, then a primer is not required. The same conclusion is drawn if the plastic does not sink in water.

Tools and materials

Before starting work, you should prepare everything you need:

- the selected paint in the right amount;

- a can of acrylic paint;

- white-spirit or solvent in a bottle;

- protective accessories;

- masking or paper tape;

- fine sandpaper;

- a bucket of water and rags.

Painting tools

Painting tools

Degreasing and priming

First you need to degrease with isopropyl alcohol. Another type of degreaser must be checked for the absence of acetone in its composition. Next, 2-3 layers of soil are applied to the part and drying is performed for about 1 hour. Then 2-3 layers of acrylic paint are applied with a brush or from a spray can. Drying takes 30 minutes. After that, the painted surface should be varnished. Finishing operation - polishing.

Plastic primer for paint

Plastic primer for paint

Plastics painting technology

During painting, it is advisable to maintain the temperature in the area of \ u200b \ u200bthe workplace +18 ° C. Drying is carried out at a temperature from +18 to +60 ° С.

Applying the coloring agent with a brush

A small amount of paint is collected on the brush from the bath and smeared with a light movement on the part along its long side. So the whole area is smeared. When applying the first layer, do not be afraid of unpainted. They will close on the second and third covers. It is necessary to ensure that there are no paint smudges. Therefore, if possible, the part should be held horizontally and rotated slowly.

The process of working with a spray can

A spray can of paint should be held at a distance of 25-30 cm and should be carried along the area to be painted without stopping. You need to press the valve before starting the movement of the hand. Also monitor the prevention of smudges and non-staining. Drying takes 30-40 minutes.

Polyurethane quality enamel for concrete

Concrete enamels based on polyurethane are versatile and can be used both outdoors and indoors. These are two-component compounds, the preparation of which is carried out exactly before use. The technology for using such paint compositions is somewhat different from ordinary enamels - the first layer of polyurethane paint for a conventional concrete base must be made very thin.

This is a kind of primer, which, after complete drying, is covered with a more saturated layer, which performs protective functions. Such concrete enamel dries much longer than epoxy analogue, as a rule, this process is delayed by two weeks.This paint is not ready for use after a couple of days, only after a week it receives mechanical strength and after another week chemical resistance.

This is a kind of primer, which, after complete drying, is covered with a more saturated layer, which performs protective functions. Such concrete enamel dries much longer than epoxy analogue, as a rule, this process is delayed by two weeks.This paint is not ready for use after a couple of days, only after a week it receives mechanical strength and after another week chemical resistance.

If we talk about the advantages of such enamel for concrete, then we can highlight the following points:

- Profitability. Unlike other versions, it is applied more economically. It is somewhat cheaper than other enamels.

- Very high strength values.

- Does not react to strong chemicals.

- After drying, it forms an almost mirror-like surface, the color of which lasts for a very long time.

The disadvantages of such concrete enamels include a long drying period. In all other respects, it is a very good paint that can be applied anywhere.

Polyurethane compounds are one-component and two-component. In the first case, they polymerize due to the humidity in the ambient air. No hardener is required here, so the cost of the work is significantly reduced.

One of the disadvantages of one-component paint is that it cannot be applied in a thick layer, since polymerization reacts with moisture. It does not penetrate deep into the surface. As a result, defects appear in the form of craters or bubbles on the finished surface, which leads to partial delamination of the coating. The advantage of enamel is that the coating can be done even at low temperatures.

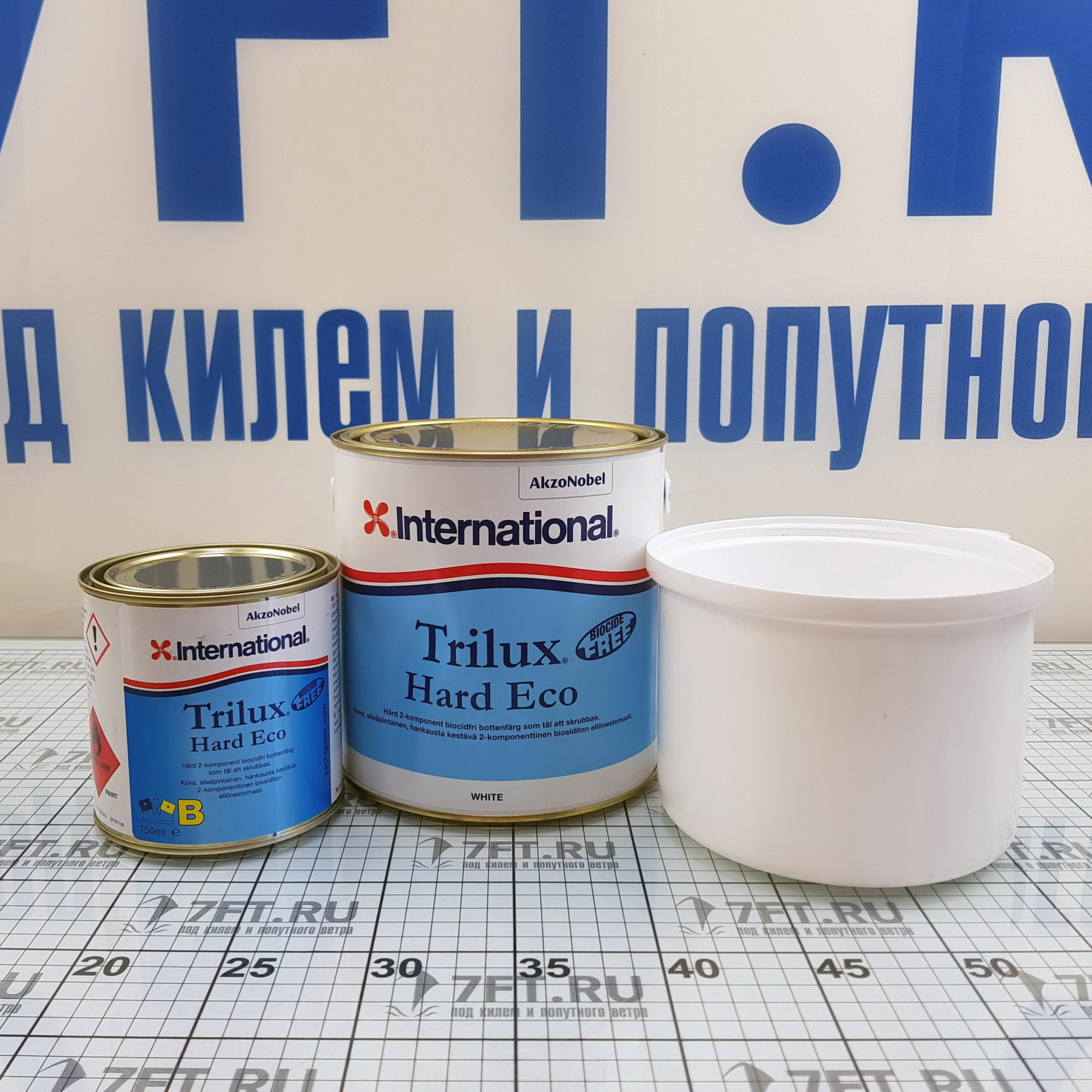

Two-component formulations are mixed with a hardener before use. Their advantage is the ability to apply the desired layer thickness on the first application, which occurs within a short time. But it should be borne in mind that if the duration of the painting is incorrectly calculated, the paint can more quickly set directly in the bucket or tank designed to connect the components. Another disadvantage is the temperature limitations within which a two-pack paint is allowed. The process can only take place at positive temperatures.

Two-component formulations are mixed with a hardener before use. Their advantage is the ability to apply the desired layer thickness on the first application, which occurs within a short time. But it should be borne in mind that if the duration of the painting is incorrectly calculated, the paint can more quickly set directly in the bucket or tank designed to connect the components. Another disadvantage is the temperature limitations within which a two-pack paint is allowed. The process can only take place at positive temperatures.

The advantages of this kind of products include, first of all, environmental friendliness, the ability to use them outdoors and durability. In addition, the popularity of polyurethane enamels has been won due to the fact that they give a very beautiful smooth glossy surface. In addition to concrete, these paints can be used to treat wood and metal.

The disadvantage of this type of dyes is, first of all, that they dry out for a very long time. The polyurethane layer is sticky and begins to dry only 2-3 days after application.

Polyurethane enamel is well suited for protecting surfaces, be it wood, concrete or metal, and protects against environmental influences. Such compositions are made from various polymers. They are characterized by a high degree of protection against negative influences, which other types of paints cannot boast of. Polyurethane paints are often used as protective coatings for various surfaces.

Design and colors

It would be too difficult to consider all the existing options for plastic products and conclude which color and design is better for them.

Therefore, it is worth paying attention to PVC-based doors and windows, which are often found in residential buildings.

When choosing a painting option, it is advisable to focus on the general style of the structure. If it is necessary to decorate a house in the Russian style, it is worth maintaining a balance between the colors of windows, doors and the tone of the roof. Natural shades will be appropriate here. Dark brown paint can be used. It perfectly masks rain streaks and street dirt.

Light colors (beige, yellow, bluish, orange) are recommended to be used only in combination with similar roofing colors.

Modern manufacturers have learned to create beautiful sparkling and iridescent dyes.Gold paint looks elegant and chic, sometimes even a little pompous. The mirror paint gives a very attractive chrome effect to the surface. The film formed by such a composition turns out to be relatively thin, but at the same time as strong and resistant to external influences as possible. For obvious reasons, anti-corrosion properties are not very important here, however, protection against negative atmospheric phenomena is very much appreciated.

Matte soft-toch paint is intended primarily for those objects that are constantly in contact with human hands. It is pleasant to touch them, a feeling of velvety and warmth is created. The color can be anything - black, silver, bronze and so on.

Glossy black paint is considered by most car owners to be great for car interiors.

Embossed (structural) paint is recommended for coating:

- moldings;

- boxes of external mirrors;

- bumpers;

- parts of salons.

It effectively tackles any visual imperfections, including scuffs and cracks. The dye is able to reconstruct the original appearance of plastic, give it its characteristic roughness and hide minor damage.

It is possible to apply a layer of paintwork materials, even without special skills and experience in such work. Fast drying allows you to appreciate all the attractiveness of the textured surface in a matter of minutes. The use of an additional layer of varnish is not required.

Unlike cars, where nothing should distract the driver from the road and instrument readings, any (silver or even bright) colors can be used at home. You just need to maintain a balance between different shades of the environment, adhere to the selected color temperature (cold or warm).

It is worth focusing on personal taste, and on how well a certain solution fits into a particular interior. For example, painting "silver" is not always appropriate. By evaluating the environment in which the plastic product will be used, you can eliminate mistakes when choosing a tonality and texture.

Views

Polyurethane paints and varnishes are divided into two groups:

- Two-component. Such coatings require mixing, and their components are sold in different containers.

- One-component. The products are used immediately after purchase, they do not require additional manipulations, because all components are included in the main composition of the coating.

Two-component polyurethane enamel consists of two cans, one of which is filled with resin, and the other with hardener. These mixtures are of high quality, they have a high degree of strength and are a good barrier against destructive external factors.

Classification of one-component enamels by type of base

One-component enamels are usually classified as follows:

- Products based on organic compounds;

- Alkyd urethane options;

- Water-dispersion mixtures.

The components of the first item on the list, in addition to the main components, are toluene or xylene. For products, manufacturers have provided special solvent compositions. The material hardens under the influence of moisture and air. In this connection, it should be noted that the time of complete drying directly depends on the humidity of the air.

The second item on the list includes alkyd-urethane varnish. The main advantage of the composition is the short drying time, which usually does not exceed 90 minutes. White spirit is chosen as a solvent for this agent.

The third point owes its name to the solvent used when working with the coating, it is ordinary water. Water-dispersion mixtures do not require the use of protective agents when painting, as they have a high degree of safety. Hardening is due to the moisture in the air.

Powder and epoxy-polyurethane enamels

It should be noted another type of polyurethane products - powder formulations. They are produced as a homogenized mixture. Its components are: pigments, polyester resin, filler and hardener.

Products belong to thermosetting dyes, which are used to treat a product or base, and then are subjected to thermal action. Due to the processing, the components are firmly bound to each other, forming a reliable and hard coating. Therefore, powder formulations are indispensable in mechanical engineering.

Epoxy-polyurethane enamel is characterized by high durability. It is successfully used in the industrial field when painting various structures, which, due to their purpose, are forced to regularly contact an aggressive environment. The composition, in turn, provides a high level of protection.

Classification by application method

Classifying polyurethane compositions according to the method of application, the following varieties are distinguished:

- aerosol products;

- enamel, for which you need to use a roller or paint brush.

The first item on the list is headed by aerosol products, which are used for application to a metal surface and are distinguished by their ease of use.

Polyurethane enamel for metal is realized in special cans, it is indispensable for motorists, as it creates a uniform coating during painting and eliminates the occurrence of smudges and stains.

The next item is a composition that requires the purchase of a special tool. Before starting work, you must take care of the availability of a suitable brush or roller.

Painting process

Substrate preparation is required before applying paint. To do this, the surface needs:

- Wash. Small parts are submerged in water, but a portable car wash is recommended for large areas.

- Treat with "sandpaper". Depending on the smoothness, the base is either sanded or, conversely, scratched with sandpaper.

- Degrease. White spirit is most often used for this purpose, but you can take any other alcohol-based degreaser.

- Prime if necessary. If in doubt whether to prime or not prime, then apply a primer. An extra primer will only improve the quality of the final result.

- Dry and you can start painting.

- What is the load on the product. The greater the likelihood of abrasion or damage to the surface, the more layers must be applied.

- A new layer can be applied only after the already applied layer has completely dried.

- It is recommended to use the painted product one day after applying the last layer. During this time, complete polymerization of the material will occur, the decorative film will acquire all the strength characteristics.

Types of paints

Polyurethane compounds can be separated in the following ways: by the type of application and by the material to be coated.

Application type:

- aerosol;

- brush.

The first type is most often car paints, which are used to protect the body from rust. It is used as an alternative to other balloon paints, since it is much stronger than them.

Paint for application by brush or roller is more common in interior decoration. It is often used as a protective lacquer layer for wooden floors - so the pattern of the tree will be visible and the floors will not wear off.

Type of material:

- metal;

- wood;

- stone.

Most often, it is these surfaces that need to be protected from any external factors. And here you need to understand that when using polyurethane paint for painting metal, it must be primed.

The tree must be well dried. It is not necessary to prime it. But, due to the fact that the tree very well absorbs any compounds applied to it, several layers must be applied to it.Otherwise, you can stay with the product, the surface of which will have a nondescript color and shade. The more layers are applied, the better the color will reveal.

If this is a room, then polyurethane enamel plays the role of protection from physical influences on the surface of the stone, thereby protecting it.

Quite often, polyurethane varnishes are used for outdoor work. In this case, varnishes are used in order to strengthen the structure of certain types of stones that is unstable to external influences. The varnish opens the stone with a thin film and no longer allows water to pass to the latter.

By the way, polyurethane paint differs according to the place of application. For example, for the outer wall of a house, this is a common composition. But if you want to achieve a pleasant "gloss", then you need to buy a two-component polyurethane paint. After drying, this second component gives the painted surface an interesting glossy texture, on which chips and sharp changes in the surface level are completely invisible (provided that the latter was initially even).

In addition to glossy polyurethane paints, there are also matte paints. This is the same two-component polyurethane enamel, which contains a coloring pigment. Often this is polyurethane paint for metal. When applied to a metal surface, the paint produces a very interesting mat effect.

Review of the best brands

Polyurethane two-component compounds of foreign manufacturers are distinguished by their high strength.

Cosmo SL-660.120

German glue for plastic windows of white color and thick consistency, does not stand out on light panels, does not turn yellow over time. Grabs in 60 seconds.

Advantages and disadvantages

dries quickly;

does not form a crust, plastic;

does not crack in the sun.

unpleasant odor;

after opening, thickens in a tube;

the nose quickly clogs.

If you work in a ventilated area, the smell is hardly noticeable. So that a cork does not form in the spout, a nail is inserted into it.

I like1Dislike

КМ CRYSTAL CLEAR

A two-component transparent polyurethane compound intended for casting decorative elements, optical lenses. Manufacturer - USA.

Advantages and disadvantages

does not turn yellow in the sun;

lasting.

darkens from time to time;

vacuum degassing is required, otherwise bubbles will form;

gives off toxic fumes.

Crystal clear polyurethane is intended for professional use.

I like1Dislike

PolyCast

Italian-made two-component plastic is used to make sculptures, models, jewelry and products with imitation bronze. The composition is mixed and poured into molds. The plastic hardens at room temperature in 10-20 minutes. White color.

Advantages and disadvantages

after solidification, strong parts are obtained;

suitable for coloring.

narrow scope;

in liquid form is hazardous to health.

PolyCast plastic is used only for casting into molds. For household purposes, it is not suitable.

I like1Dislike

NATICAST

Italian product from a series of polyurethanes for shaped casting. 200 grams of the mixture hardens in 5 minutes with manual mixing.

Advantages and disadvantages

allows you to create figurines with small details;

allows you to create figurines with small details;

contains a poisonous substance polyol;

for industrial use only.

High-strength structural elements, milling plates are cast from Naticast plastic.

I like1Dislike

EasyFlo from Polytek

The American product is used in decorative arts and industries for the manufacture of plastic parts, models and structures.

Advantages and disadvantages

has a low viscosity and does not require degassing;

mixes easily;

wear-resistant;

to be painted;

resistant to weak solvents.

the composition hardens very quickly;

not for home use.

The components are measured in a separate container, poured into a common container and mixed thoroughly.

I like1Dislike

Axson F160 from Axson

One of the world's best polyurethane plastics for model casting is considered a French product. The two components are mixed by weight in a 1: 1 ratio.

Advantages and disadvantages

lack of smell;

product strength;

ease of coloring;

low viscosity and foaming.

when mixing by volume, the quality of the products decreases;

a precipitate is formed in the mixture.

Plastic is suitable for casting milling blanks, figurines, decorative magnets. Shake well before pouring.

I like1Dislike

JETICAST

Chinese-made polyurethane is also intended for the manufacture of models, furniture decor, wood and metal imitations.

Advantages and disadvantages

does not form bubbles;

freezes quickly;

does not have a pungent smell.

the mixture gives a precipitate;

you need to work in protective gloves and goggles, in a ventilated area.

In cold weather, after transportation, the components must be warmed up to room temperature before mixing.

I like1Dislike

Paint application technology

The staining process differs from the application of other CMs and is divided into four stages:

- Preparatory work. The surface is cleaned from rust. After that, it is degreased, treated with a primer and dried. To improve the tenacity of the dye with the base and increase the service life, zinc phosphating of steel surfaces, chrome plating of aluminum products, etching of other metal surfaces are used.

- Paint application. The composition is sprayed onto the parts. Coloring is carried out using two technologies: electrostatic and tribostatic method. LK powder is sprayed onto the product in a chamber with a recuperator. This technology allows unused powder to be collected and re-sprayed.

The first electrostatic technique is based on the transfer of an electrostatic charge to a powder. The surface is evenly coated with electrified powder and held onto it. Excess powder dye spills into the recuperator. This allows you to save powder as much as possible, use it by 98%. At the same time, the environment is not polluted, finances are saved.

A less effective and practically used tribostatic method of coating a surface with a polyester dye. The electrostatic charge of the particles is created by rubbing them against the walls of the atomizer made of an electrifying type of material, for example, Teflon. The powder is evenly blown with air, which creates its pseudo-liquid state. For coloring, the part is placed in a container with such a pseudo-liquid composition.

The speed and ease of the dyeing process depends on the flowability of the material. The flow rate will be low if the particles are large, rough and the powder is wet. To prevent the CM from absorbing moisture, the warehouse where it is stored must be dry, the factory container is waterproof.

PURACOR

PURACOR

| 375 RUB / kg |

PURACOR is a one-component polyurethane primer-enamel with the addition of high-strength corundum particles. Produced according to German technology: Dehysol plasticizer (BASF) and TRI-REZ polyol (BASF) are used. Universal primer-enamel PURACOR is designed for long-term, reinforced protection of concrete, metal, wood in objects with high mechanical and chemical stress. Forms an impact-resistant, highly elastic thin-layer polymer coating, resistant to various chemicals, as well as to temperature extremes from -50 to +100 degrees.

Scope of application of polyurethane enamel:

- Car services, car washes

- Parking lots (multi-level, underground, etc.)

- Warehouse and retail space, hangars, garage complexes

- Oil refineries

- Tanks with water, reagents, technical fluids

Characteristics of PURACOR polyurethane enamel coating:

- Chemical resistance (acids, alkalis, fuels and lubricants, salt solutions)

- Impact resistance, wear resistance

- Elasticity, thixotropy

- Moisture resistance, waterproofing properties

- Anti-corrosion properties

- High adhesion (concrete, plaster, brick, wood, metal).

Mode of application:

Clean the surface from dust and dirt, oil, dry. The moisture content of the base should be no more than 7%. On metal, concrete grade M300 and higher, PURACOR polyurethane primer-enamel is applied in 1 layer, on concrete of lower grades, wood, brick - in 2 layers.

- Application temperature: from +5 degrees

- Drying time between layers at a temperature of +20 degrees: 12-16 hours

- Consumption: 0.2-0.3 kg / m2 in one layer

- Solvents: xylene, orthoxylene

- Shelf life: 6 months

- Bucket weight 25 kg

- Basic color: gray, RAL tinting

Store PURACOR polyurethane enamel in a tightly closed container, at a temperature not lower than 0 degrees, protecting it from heat and direct sunlight. Do not heat.

The KRASBYT company informs its customers that all materials produced by KRASBYT are intended only for professional work, which should be performed by the customer's profile specialists who have successful accumulated experience in working with similar materials.

Specifications:

| Film appearance | Uniform semi-gloss surface |

| Mass fraction of non-volatile substances,% | 85 |

| Drying time of the coating to degree 3 at a temperature of +20 gr. and humidity 65%, h, no more | 4 |

| Film strength on impact, cm, not less | 50 |

| Bending strength of the film, mm, no more | 1 |

| Resistance to static effects of water at a temperature of +20 gr., H, not less | 48 |

| Resistance of the film to the static effect of fuels and lubricants at a temperature of +20 g., H, not less | 48 |

| Film hardness after 72 hours, according to the pendulum M-1, conv. units | 0,55 |

| Abrasion, kg sand / mm | 5 |

| Grinding degree, micron, no more | 60 |