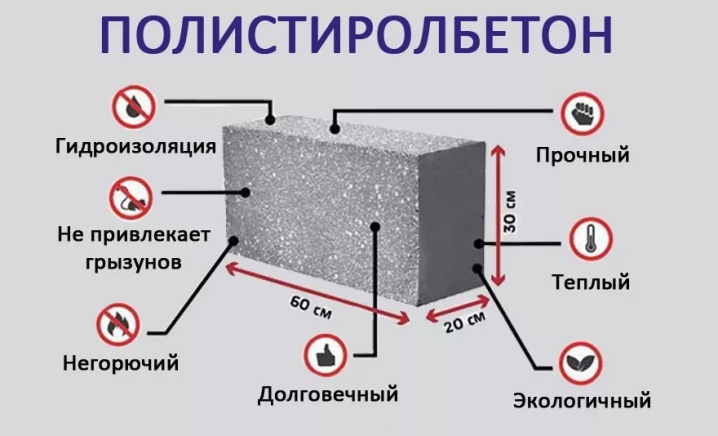

Pros and cons, expediency of application

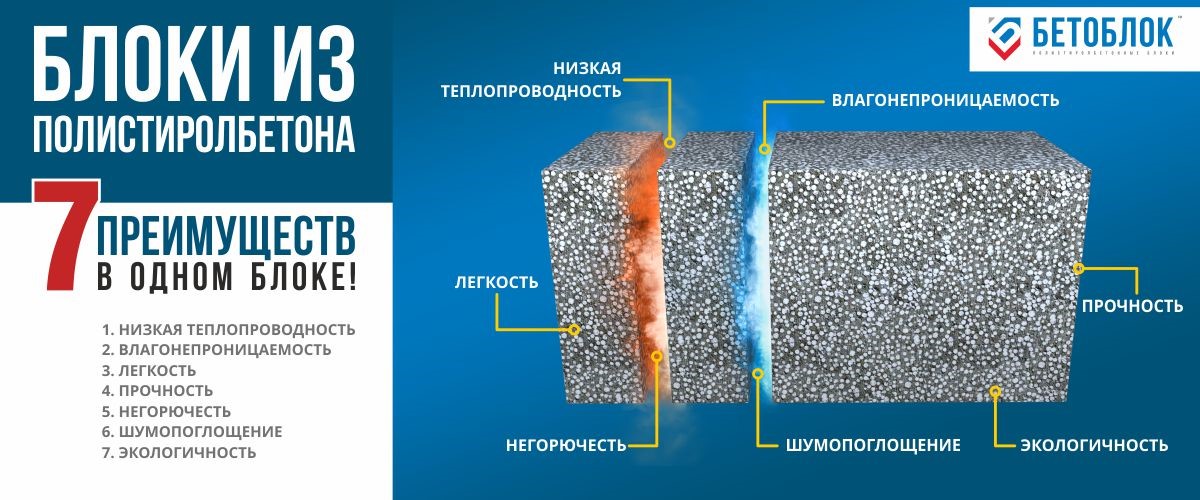

Most owners of polystyrene concrete houses evaluate the material positively, the advantages include:

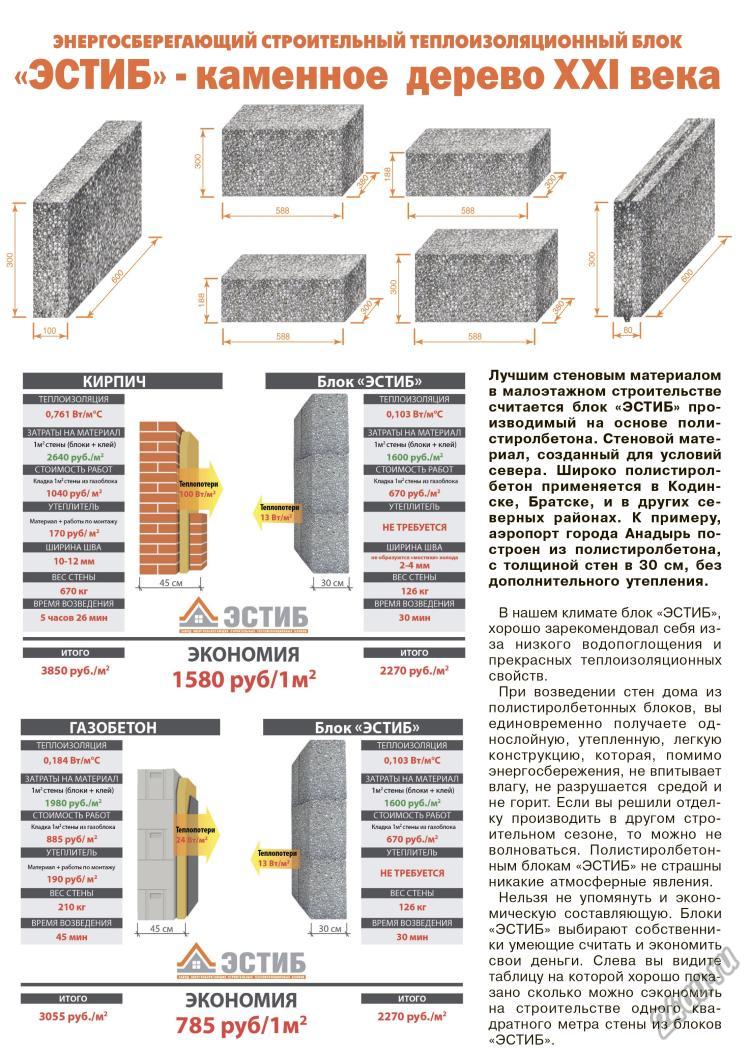

- Good insulating properties, reviews note the ability to absorb noise and keep the temperature at the desired level with a minimum of energy consumption. When erecting buildings made of polystyrene concrete, there is no need for additional external insulation.

- Acceptable cost.

- No serious load on the foundation and minimal labor costs for transportation, block lifting and laying.

- Ease of processing: according to reviews, polystyrene concrete blocks are similar in this regard to wood, they are cut into the desired parts without problems.

- High frost resistance and hydrophobic properties.

- Environmental friendliness and absence of harmful substances in the composition (for certified brands).

The disadvantages of the material are associated with poor adhesion of the foamed filler with the rest of the concrete components and its low strength, as a result, during operation, the following disadvantages of polystyrene concrete houses appear:

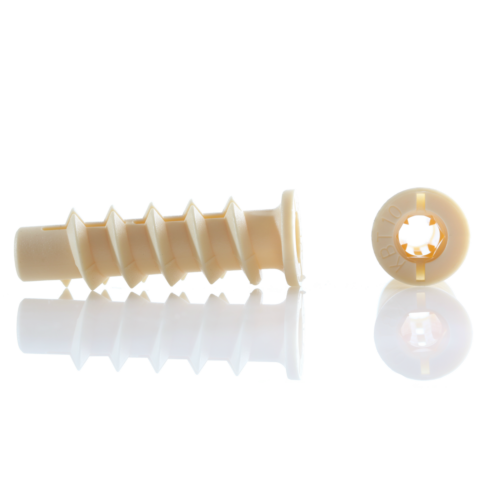

Problems with the installation of anchors and other fastening systems. An acceptable fixation can be achieved only by pre-drilling the hole, filling it with cement mortar, and after hardening - by planting a self-tapping screw.

Looseness of doorways, distortions of window frames, according to reviews, are observed in the first 2-3 years.

Shrinkage of blocks up to 1 mm / m. In comparison with autoclaved concrete or other cellular brands on a mineral basis, the polystyrene variety is three times inferior in this regard.

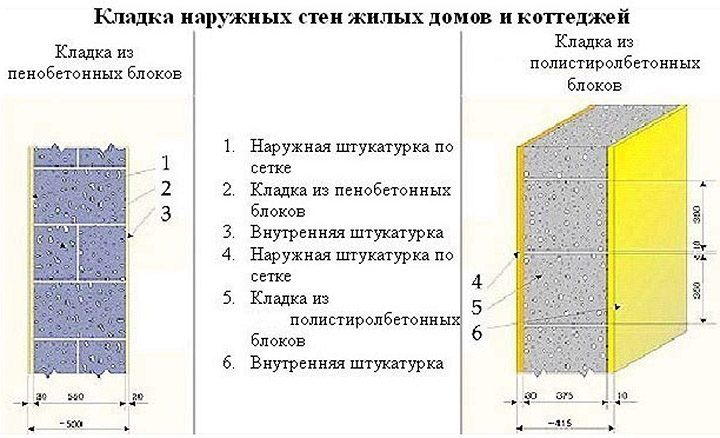

The need for mandatory processing of walls on both sides. Preference is given to a thick layer of plaster, and such application, in turn, is possible only with reinforced reinforcement and surface coating with special primers.

The need to organize a ventilation system, in conditions of high humidity, polystyrene concrete blocks are not suitable (they simply do not remove steam to the outside)

This property cannot be unequivocally attributed to disadvantages, it is it that helps to retain heat, but it is important to take it into account, otherwise the microclimate in the house will not be comfortable.

The optimal scope of application includes the construction of residential buildings, sound and heat insulation of vertical and horizontal structures, insulation of interlayer space

Polystyrene concrete is used both in the form of finished products and as a solution, but in the latter case, special attention is paid to the type of raw materials to be filled in, the uniformity of mixing and maintaining the proportion of the mixed water at a minimum level. Poured polystyrene concrete is also called monolithic

The specific application option depends on the brand: polystyrene concrete within the D200-300 range is not used in load-bearing structures; for low-rise construction, blocks of at least D400 are needed.

How to do it yourself?

Expanded polystyrene concrete blocks can be made independently. First you need to prepare components such as:

- granular polystyrene;

- cement;

- sand;

- water;

- additives.

You can't do without inventory. To make blocks you will need:

- shovel;

- concrete mixer;

- buckets;

- forms for filling.

The prepared ingredients for the connection must be placed in a concrete mixer. To make foam polystyrene concrete with your own hands, it is recommended to follow the suggested instructions:

- Strictly observing the proportions, combine the polystyrene additives used to improve the quality of the finished product, water.

- Put the components in the concrete mixer, mix for 1.5-2 minutes.

- Add cement and stir for another 3-4 minutes to get a homogeneous mass.

- Put the finished dough into molds greased with petroleum jelly or other technical oil.

- Leave the blocks to harden for 25 hours.

- Remove the seized product from the mold and let it dry for 1-2 days. in a cool, well-ventilated area.

Pros and cons of polystyrene concrete

So, the advantages:

- possessing good heat-insulating and energy-saving characteristics, this material allows you to abandon the additional use of insulation (foam, mineral wool, foam glass, etc.);

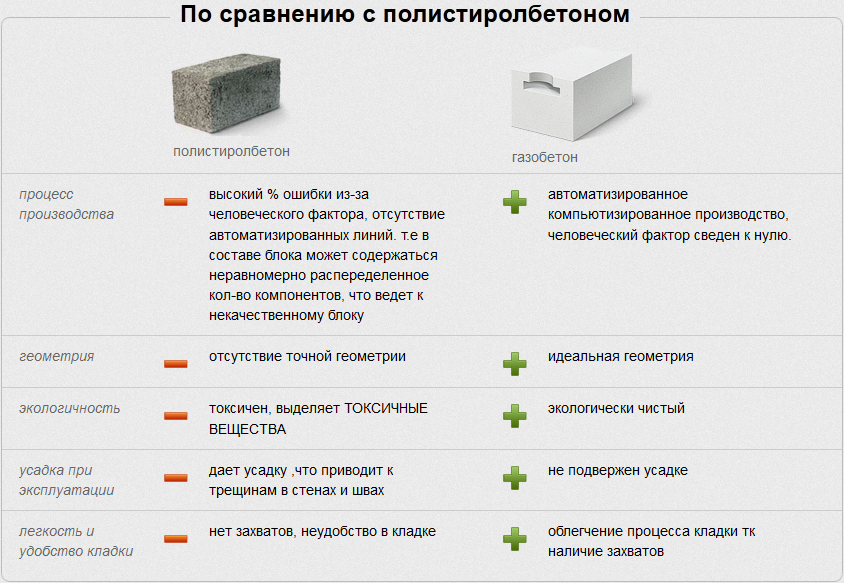

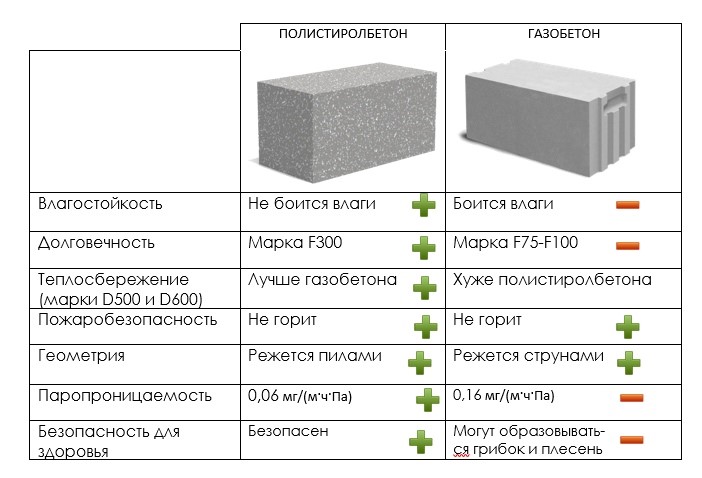

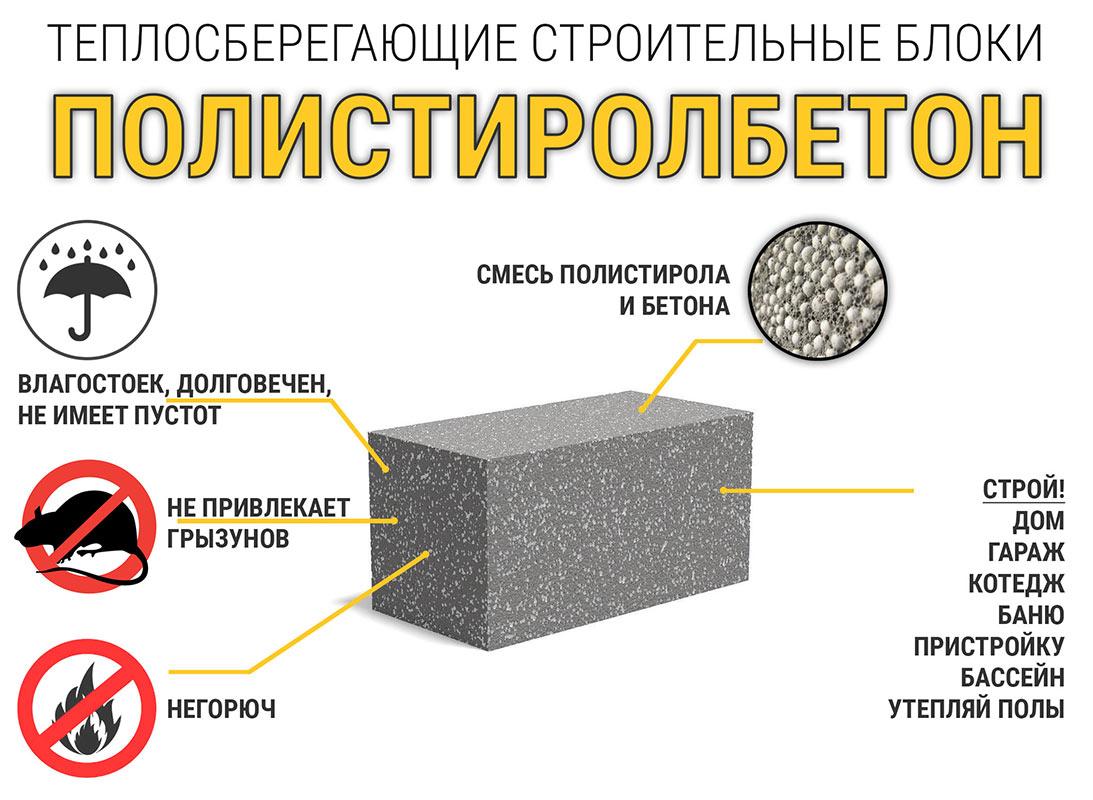

- polystyrene concrete does not need to be waterproofed, unlike aerated concrete;

- excellent biological resistance, as well as fire safety. This material is not susceptible to decay and does not grow moldy due to low water permeability (up to 4% of the surface of the material is susceptible to water absorption). As for fire safety, it must be emphasized that the material does not burn, however, with long-term exposure to high temperatures, it can lose its strength and deform;

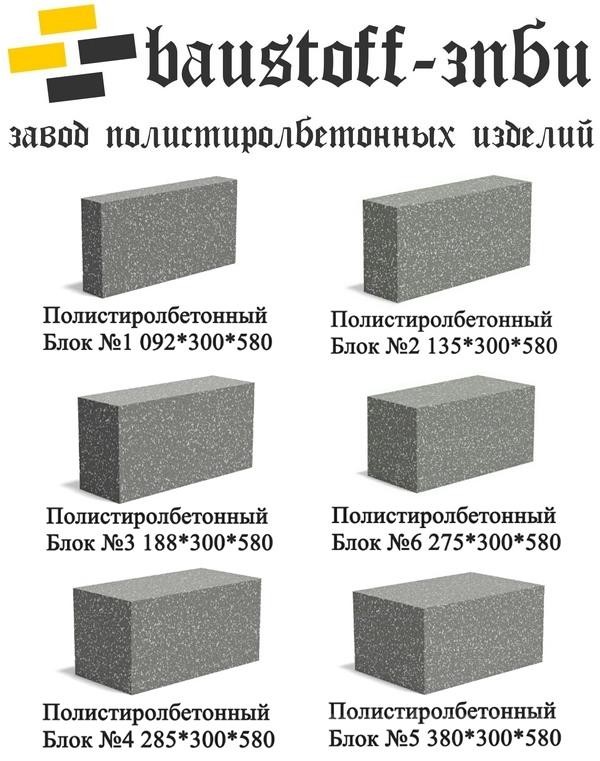

- This material is well characterized by the dimensional accuracy of the geometry of the finished blocks and the uniformity of properties throughout the volume. This seemingly trifle allows for laying with a seam thickness of about only 3-5 mm and significantly saving mortar. Among other things, the ease of installation and processing is very high: it is perfectly sawn, drilled, and also placed in any direction, in relation to the required wall thickness;

- low density. This property contributes to the manufacture of blocks of sufficient strength with low weight, respectively, the load on the foundation will be small;

- low coefficients of water absorption and vapor permeability contribute to the remarkable frost resistance of buildings.

- rather high cost of the material;

- relatively low durability. The manufacturers of this material guarantee that buildings made of polystyrene concrete can last up to a hundred years. However, most likely, they base this conclusion, not relying on the chemical analysis of the polymer component, but only taking the strength characteristics of concrete as a basis. It should be emphasized here that polymers are subject to destruction over time, and even more so, in the foamed state, this process is even accelerated. Of course, concrete remarkably protects the component from direct solar radiation, but the blocks are still heated, and, accordingly, the destruction of the granules continues. Therefore, most likely, before a hundred years, they will completely collapse;

- obligatory cladding of external walls of buildings is required;

- it is difficult to attach heavy objects to the walls. There is a need to use through anchors or other devices;

- increased requirements for block manufacturing technology;

- due to the low density of the material, installed windows and doors loosen over time;

- due to poor adhesion of polystyrene concrete to plaster, it is difficult to finish the walls;

- shrinkage of the material.

It can be seen from the article that using polystyrene concrete blocks in construction, you can not only significantly reduce the cost of building a house or outbuildings, but also provide yourself with the desired square meters. In any case, the decision is up to you, we hope that our advice and recommendations were useful. The proposed video and photographic materials will be an additional help in making a decision. All the best!

Disadvantages of polystyrene concrete

Of the minuses of this building material, it is worth noting:

- Reduced vapor permeability. Because of this, high humidity inside the room may occur;

- The complexity of the fasteners. The usual self-tapping screws are unlikely to work here. Developers most often use anchor bolts, in which the sleeve from the outside resembles a petal;

- Dependence of material quality on production technology.If the latter is violated, polystyrene concrete blocks will not differ in strength. The fact that the products meet the requirements of GOST is evidenced by the certificate. Be sure to check it when buying material;

- Severe damage from prolonged exposure to high temperatures. Polystyrene concrete blocks do not burn, but they lose their strength after prolonged heating;

- It is not easy to build from polystyrene concrete. Developers often have similar problems with the installation of door leaves and windows (distortions). Due to the period that is required for the material to solidify, walls and other structures must be created in one go;

- Restricted defrost and freeze cycles. The shelf life of the material is long, but by no means eternal;

- Reaction to ultraviolet rays. Foam balls, under prolonged exposure to direct sunlight, tend to collapse.

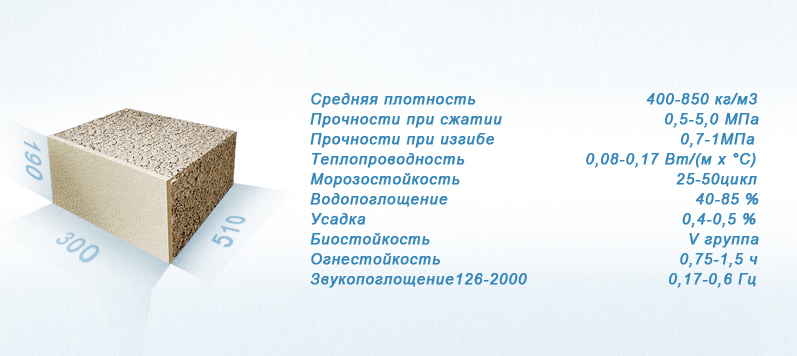

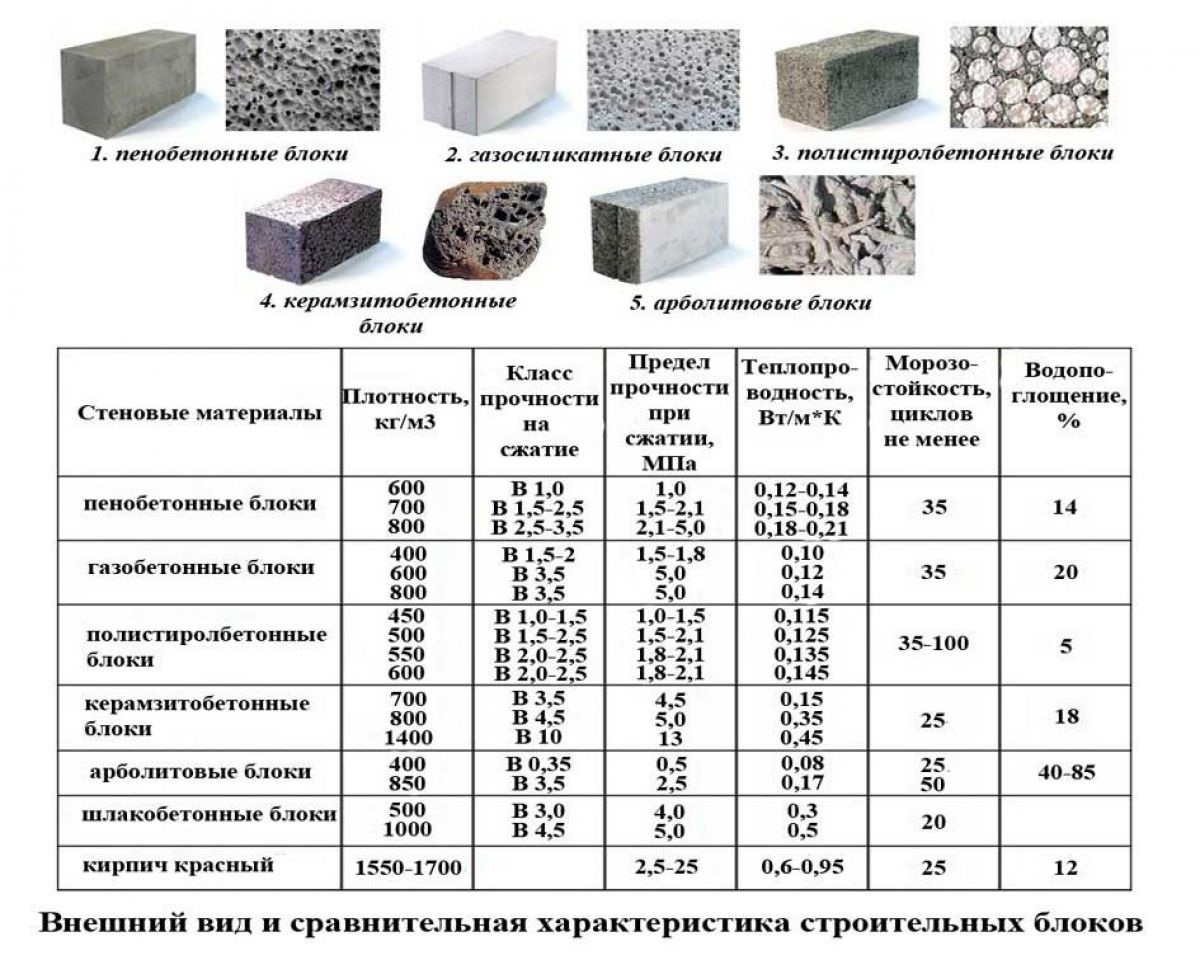

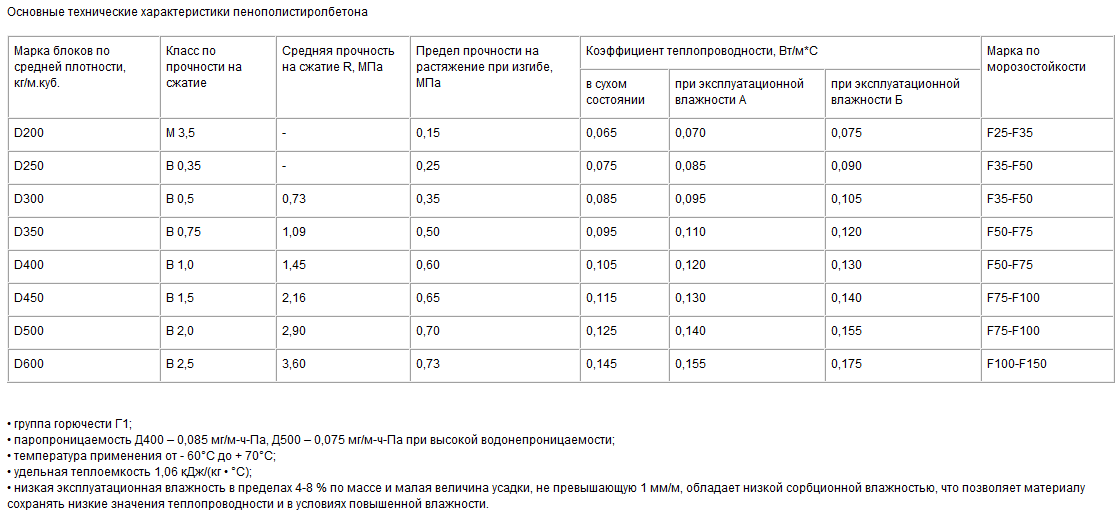

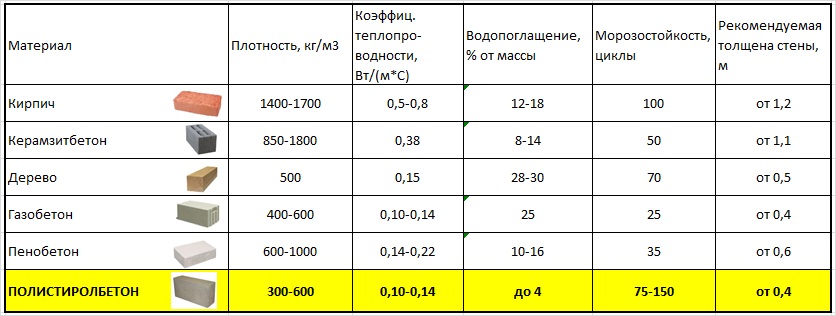

Properties and indicators

- density - 150-800 kg / m3;

- frost resistance - 30-150 freeze-thaw cycles;

- thermal conductivity coefficient - 0.055 W / mS-0.145 W / mS;

- compressive strength - B0.35-B2.5;

- flammability - group G1 (hardly combustible);

- vapor permeability - 0.05 mg / (m · h · Pa).

This is, for example, compressive strength. The value is rather low, therefore it is not recommended to erect buildings of polystyrene concrete with a height of more than two floors. There is a possibility of material deformation.

The next parameter is low vapor permeability. The value is very good for the material. But you can still note the pros and cons of this indicator.

Polystyrene blocks practically do not absorb and do not allow moisture to pass through, which is why frost resistance is very good. Unlike aerated concrete blocks, you do not have to worry about how the material will behave during seasonal rains and snow. But any structure must "breathe", and structures made of this material will not be able to, since steam simply cannot penetrate through it.

I would like to dwell on the environmental friendliness of polystyrene concrete as a separate item. There are many questions for manufacturers here. Laboratory tests and hygiene certificates confirm that this material is absolutely harmless to the environment.

However, there is an opinion of a number of skeptics that gaseous styrene is released into the air during operation. We would like to give you specific data and facts confirming or refuting this, but, alas, there are no such studies in the Russian segment of the construction market.

Density is exactly the parameter that allows you to determine the direction of application of this material. Based on the gradation of application, polystyrene concrete is almost completely consistent with them. Polystyrene concrete blocks with a density of 150-300 kg / m3 belong to the first group, they are usually used for the manufacture of internal, non-bearing, walls, as well as for finishing buildings outside.

The second group includes blocks with a density of 350–500 kg / m3. They are already used for the construction of load-bearing walls inside buildings.

Material with a density of more than 500 kg / m3 belongs to the third group and is called structural. Excellent for laying external low-rise walls of buildings (but no more than two floors, we wrote about this earlier).

In addition to the above, the blocks are successfully used for sound and heat insulation of floors, roofs, ceilings. They are well suited for solving non-standard tasks, for example, to reduce the weight of a structure with a "weak" foundation or when constructing a fence (fence).

No. 2. Pros and cons of polystyrene concrete

The peculiarities of the production technology and the composition of the blocks allow us to talk about the numerous advantages of the material:

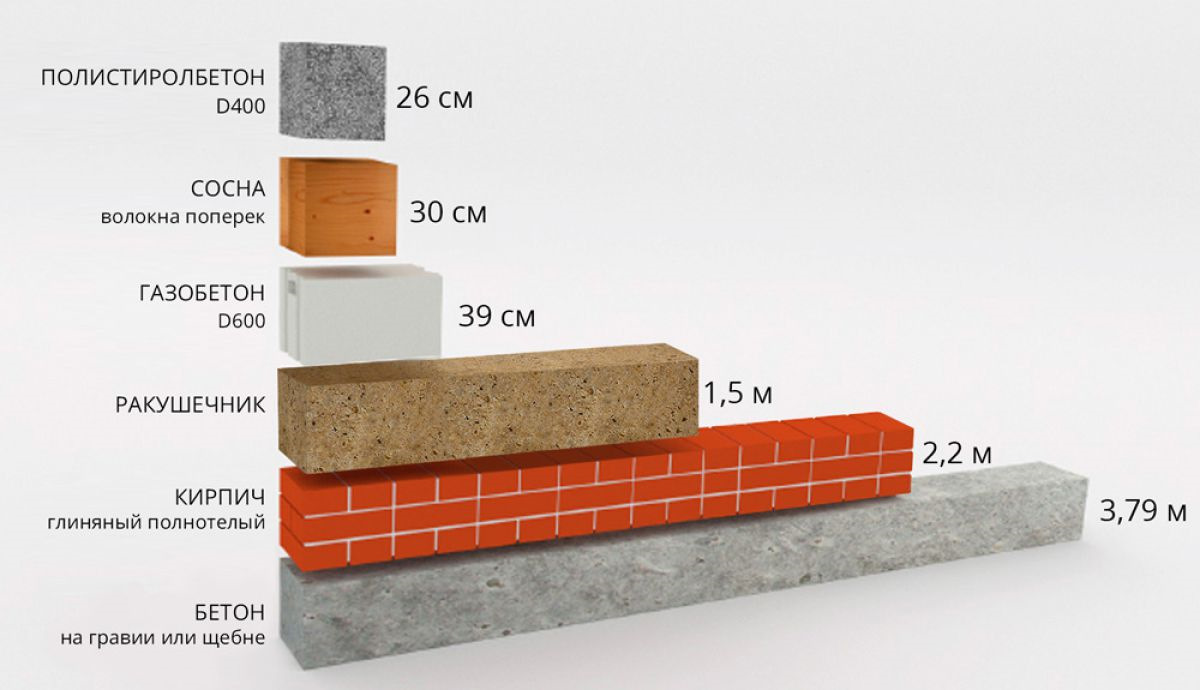

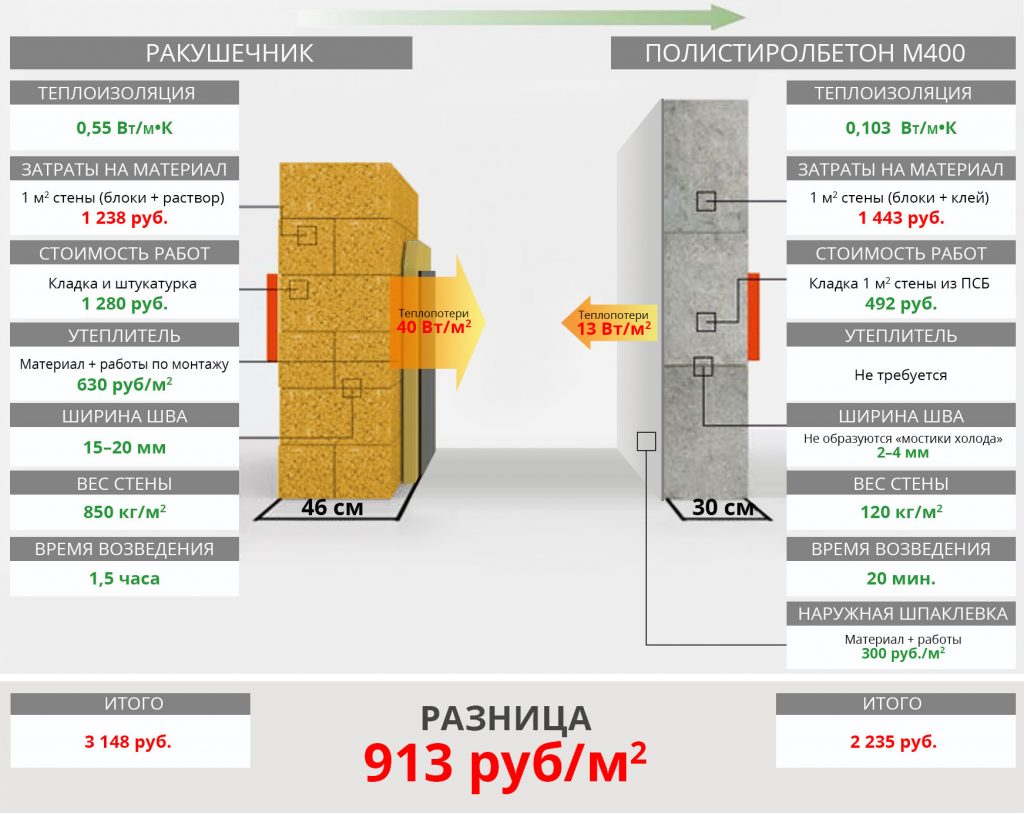

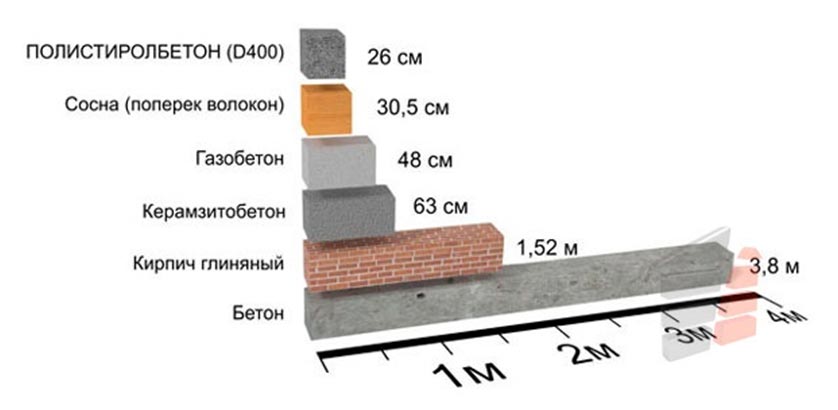

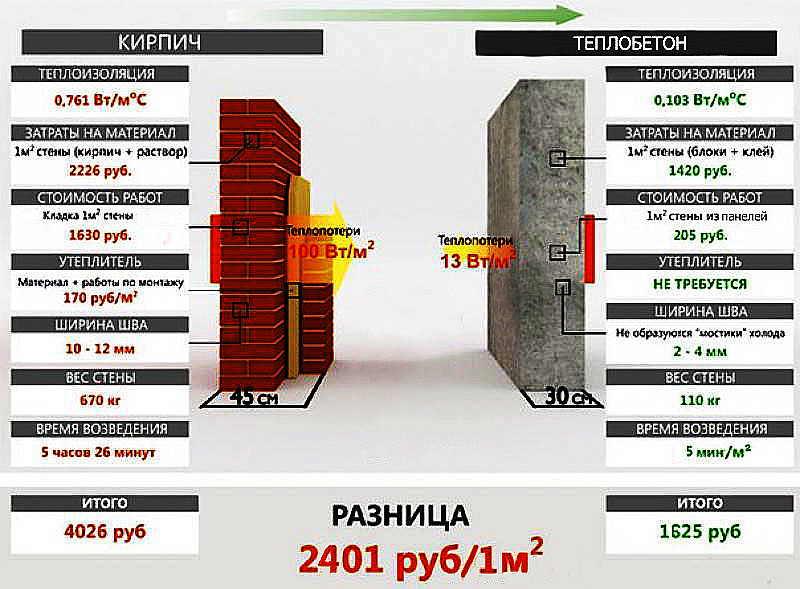

- excellent thermal insulation qualities. According to manufacturers, a wall thickness of 20 cm will be sufficient to provide the required resistance to heat transfer in regions with mild climates.In regions with more severe winters, a wall 30 cm thick will be needed, but the most common option in this case is 20 cm of polystyrene concrete and foam insulation. The thermal conductivity of the material depends on the density, but in any case it is several times lower than that of many analogues;

- excellent soundproofing qualities. A wall 20 cm thick is capable of retaining 72 dB of sound;

- the small weight of the blocks and its large dimensions make it possible to significantly simplify and speed up the work on the construction of the house. There is no need to use complex heavy equipment. Moreover, it is easy to give the blocks the necessary shape, therefore, in fact, it is possible to build a house from them even with complex architectural elements, however, the consumption of material will greatly increase in this case;

- high resistance to moisture, mold and rodent resistance;

- high frost resistance. The material can withstand up to 100 freeze / thaw cycles, which is three times more than the same foam concrete;

- the material belongs to the G1 flammability class, i.e. it is practically non-flammable. Experiments confirm: after an hour exposure to a polystyrene concrete wall at a temperature of 1000C, it does not collapse. However, there is another side of the coin. If a building suffers a fire, it will most likely withstand, but become unsuitable for further use, since the walls will lose sufficient strength;

- no shrinkage;

- low load on the foundation;

- acceptable strength;

- the ability to create a monolithic house from polystyrene concrete, without cold bridges;

- low price.

The main cons:

- low vapor permeability of the material will not allow excess moisture from the room to pass through it, therefore, it is necessary to equip a good ventilation system, otherwise the problem of high humidity and stuffiness inside the house is provided;

- the complexity of the device of fasteners. Ordinary nails and screws will hold very poorly in a wall made of polystyrene concrete, they can literally be pulled out with bare hands, so you have to stock up on special anchor bolts designed for this material. On the one hand, such a fastener is pulled together by a nut and a washer, on the other, the outer sleeve opens in the form of a petal;

- the quality of the block is highly dependent on the accuracy of adherence to the production technology. If the ratio of concrete and foam granules has been violated, then the strength of the block will be small, and if there is insufficient adhesion, the granules may even begin to fall out of the block. When buying, always ask for the quality certificate;

- with prolonged exposure to high temperatures, the foam balls burn out, leaving virtually one concrete frame. Its strength and thermal insulation are not high and do not allow it to be used as an external wall. However, wall cladding with non-combustible materials and high-quality plaster make it possible to protect walls from fire well, and the very ability of walls to withstand high temperatures is expensive, so this disadvantage cannot be called significant;

- the low density of the material complicates the installation of windows and doors. If you do not take into account the numerous features of the installation, then after a couple of years you can encounter loose mountings;

- walls must be plastered. A layer of plaster inside - at least 20 mm, outside - at least 15 mm, and the adhesion with the plaster mortar is not quite perfect.

The properties of polystyrene concrete make it possible to consider it as a material for the construction of load-bearing walls of a house. It can also be used for the construction of fences, sheds, garages and as a heat insulator.

What is polystyrene concrete

Polystyrene concrete wall blocks

Polystyrene concrete wall blocks

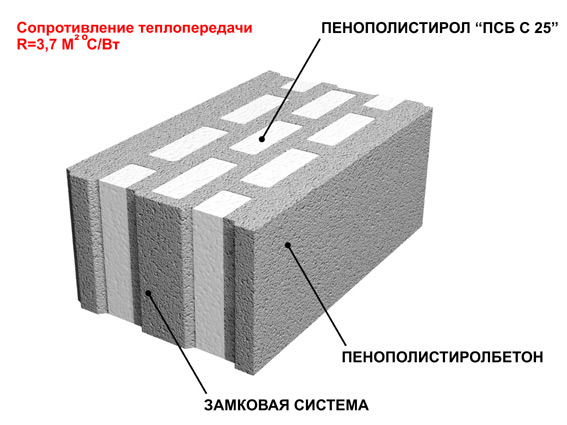

When creating this material, the engineers were faced with the task of coming up with a building material for the walls, which, with a limited thickness, will not need additional insulation, and to make sure that the flammable foam becomes safe in this regard.As a result, we got what we have.

The composition of polystyrene concrete includes: Portland cement, granules of expanded polystyrene (aka polystyrene), quartz sand, plasticizing additives to reduce the delamination of the mixture and increase its elasticity, as well as water. Together, this gives the material the following positive and negative properties (let's start with the first ones):

Low Density Polystyrene Concrete Building Blocks

Low Density Polystyrene Concrete Building Blocks

The material can be used in a very high temperature range. If we take into account the possible drops on the entire planet, then we can say that it has no restrictions at all.

Polystyrene concrete perfectly tolerates its sharp drops, which is important.

Humidity for polystyrene concrete is also not a problem. The presence of polymer granules in the structure greatly reduces the absorbency of the blocks, which is especially good for regions with high humidity.

Due to the fact that moisture practically does not penetrate into the material, its frost resistance also increases.

Manufacturers claim that the material is able to withstand from 150 to 300 defrosting cycles, which, as you know, is a lot. And, importantly, this does not in any way affect its thermal insulation characteristics.

Polystyrene concrete wall blocks - material structure

Polystyrene concrete wall blocks - material structure

Thermal insulation and sound insulation characteristics of expanded polystyrene concrete are at a very high level

What can I say, the creators managed to achieve the desired effect.

Polystyrene concrete is lightweight, thanks to which a lightweight foundation can be laid under walls and ceilings from it, which is important for private low-rise construction, as it can significantly reduce material costs.

The material can be purchased in liquid form or prepared by yourself to be poured into the desired forms. Thus, you can make overlaps and lintels over door and window openings - we will talk about this a little later.

If desired, the building box can be made monolithic using the same liquid mixture - this construction technology is also gaining popularity today.

Construction from such blocks is much faster than from bricks, since they have large dimensions.

We also remind you that the material is light, which means that you can do without large lifting equipment.

The material is easily cut with a conventional hacksaw, which allows you to fit parts quickly and accurately.

Polystyrene concrete block construction - panel house

Polystyrene concrete block construction - panel house

The material has many advantages, but it is not without its disadvantages.

Among their total number, it is worth highlighting the most important:

The polystyrene itself is moisture- and vapor-proof. It also endows the walls with ceilings made of it with the same property. For this reason, moisture gradually begins to accumulate inside buildings, since it simply has nowhere to go. High humidity means a decrease in thermal insulation characteristics, a violation of the microclimate, as well as the possibility of mold on the finish over time.

Filling the screed with liquid polystyrene concrete

Filling the screed with liquid polystyrene concrete

Polystyrene concrete blocks are not as strong as expanded clay concrete and similar materials. However, in this regard, it is much better than gas blocks that have no filler at all. Weights can be hung on polystyrene concrete walls, but it is still recommended to use special fasteners.

Dowel for polystyrene concrete blocks

Dowel for polystyrene concrete blocks

- Polystyrene concrete is a new material, and, despite all the assurances of manufacturers, we can judge about its durability only by some forecasting systems. That is, there are no real examples, and there cannot be.

- There are no precise toxicity studies, as styrene is harmful and can be released into the ambient air.

- The fire safety of polystyrene foam blocks has been established, but it is also known for certain that with strong heating, the polymers in the composition begin to emit toxic substances.At the same time, the strength of the material itself is greatly reduced, which means that if a fire breaks out, but the building resists, it will still have to be dismantled.

Advantages and disadvantages

To begin with, it should be noted that polystyrene concrete blocks have been known to the construction world for a long time. However, the material only became widespread in the 1960s. This is due to the fact that initially the production of such a material as polystyrene concrete was rather complicated and expensive. However, with the development of technology, the situation has changed. Today, expanded polystyrene concrete blocks are in demand in the process of building low-rise suburban buildings. The material is used not only in Russia, but also in other countries of the world, for example, the United States of America, Germany, France and so on.

The raw materials for the production of polystyrene concrete blocks are as follows:

- Portland cement (which is essentially a type of cement);

- water;

- granular polystyrene;

- quartz sand;

- plasticizers.

There are several methods for the manufacture of polystyrene concrete blocks, namely:

- handicraft (or foundry) - this method is similar to the procedure for making non-autoclaved aerated concrete, since all the necessary elements are interconnected, poured into specially designed molds and contained there until hardening;

- vibrocompression (or vibroforming) - this method is used in industrial production, it is quite complex and lengthy.

Polystyrene concrete blocks are not ideal building materials. They are characterized by a set of individual characteristics (both positive and negative). Thus, before purchasing a material and using it in construction, it is necessary to evaluate all the advantages and disadvantages.

To begin with, consider the existing advantages of the material.

- Availability. Polystyrene concrete blocks have a budget price. Thanks to this, the material is available for purchase to almost every person (regardless of his economic and social status in society).

- Low thermal conductivity. Thanks to this property, in the process of building a house, there is no need to equip additional wall insulation with the help of other materials.

- Low density and low weight. Due to this property of the material, you have the opportunity to reduce the load on the foundation of the house. This also reduces the material and financial costs of transportation and masonry.

- Low water absorption. Due to this characteristic of polystyrene concrete blocks, water (and any other liquid) is not absorbed into the surface. In addition, this property is associated with such a characteristic as low thermal conductivity.

- High quality soundproofing. In this regard, polystyrene concrete blocks can be used for the construction of buildings of any purpose.

- Simple handling. You do not need to have a lot of specialized theoretical knowledge or practical skills to process the material. Polystyrene concrete blocks are easily fed by sawing or chasing.

- Resistant to low temperatures. Due to their frost resistance, polystyrene concrete blocks are used for construction in various regions of our country (including the northern ones).

- Ecological cleanliness. Since polystyrene concrete blocks are environmentally friendly, they can be used for a variety of purposes.

Despite the large number of advantages, it is necessary to remember about the existing disadvantages.

Low level of compressive strength. In connection with this property of the material, it should be remembered that polystyrene concrete blocks are a material that is not suitable for the construction of tall buildings. They can be used to build structures no higher than 2 floors.

Low vapor permeability

In this regard, it is important to create a special system for removing unwanted moisture, for example, an air conditioning or ventilation system.

Flammability. Polystyrene concrete blocks are decomposed by fire

A similar process is the reason for a decrease in the strength and heat-shielding characteristics of the material.

Fasteners. In order to attach something to a polystyrene concrete block, you need to use high-quality and reliable fasteners, for example, anchors and dowels.

Thus, you were able to make sure that the advantages of the material significantly outweigh its disadvantages.

Briefly about production technology

Polystyrene concrete is a composite material consisting of beads-granules of foamed polymer and cement stone, forming a strong structural lattice. To improve the homogeneity of the material, air-entraining and surface-active chemical additives are used.

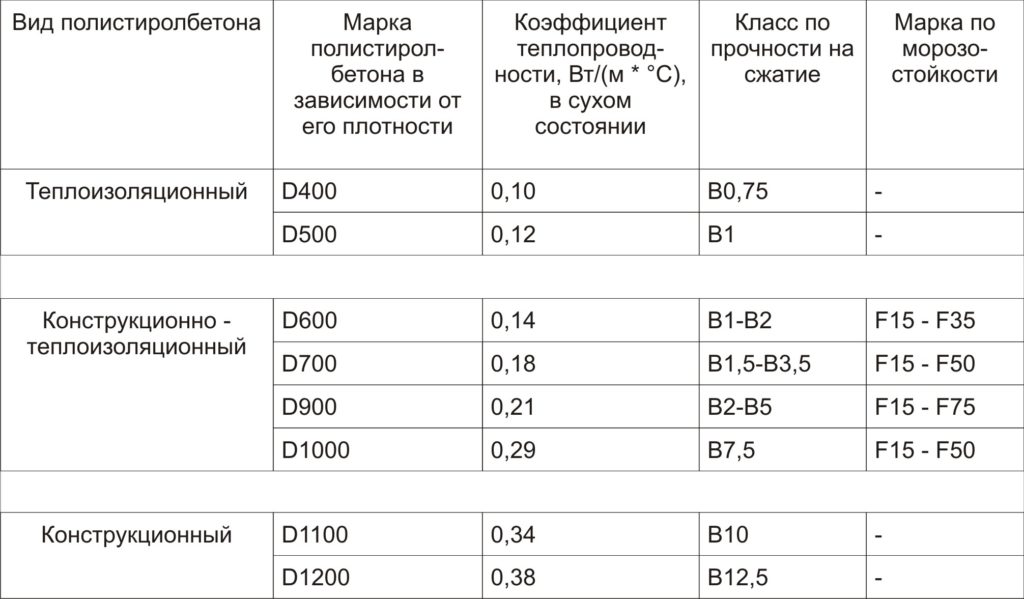

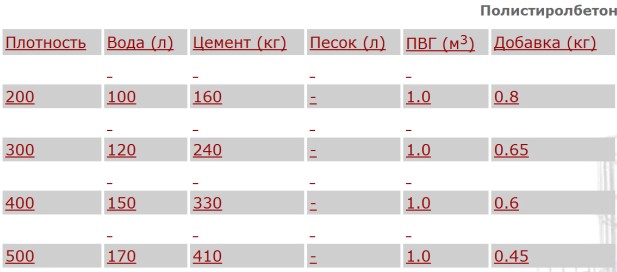

By adjusting the ratio of cement and water in the initial mixture (table 1), concrete of various densities can be produced.

Table 1 Note * PVG - polystyrene granules

Table 1 Note * PVG - polystyrene granules

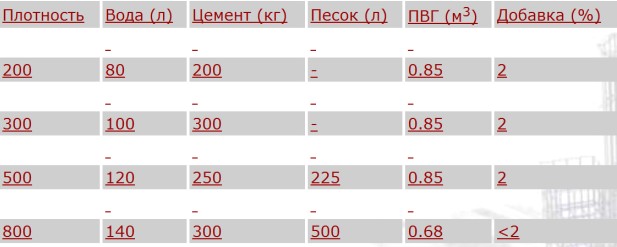

In addition to water and cement, some manufacturers use sand by adding it to the feedstock.

Table 2 (percentage composition of polystyrene concrete with the addition of sand)

Table 2 (percentage composition of polystyrene concrete with the addition of sand)

Characteristics of polystyrene concrete

The next type of "lightweight" concrete is polystyrene concrete, a versatile material that is used at all stages of construction.

It is used not only for the construction of walls, but also for laying floors between floors, separating the basement and attic. The main distinguishing feature is the presence in the composition of a light filler - polystyrene, which gives concrete additional strength, density and thermal insulation.

The composition is quite simple, it includes:

- Portland cement;

- Sand;

- Water;

- Plasticizers;

- Polystyrene granules.

3> Advantages of polystyrene concrete blocks

Polystyrene concrete is a versatile material, experts prefer its use everywhere, since it has a large list of positive properties:

- Reliability - buildings made of polystyrene concrete blocks are durable, do not shrink, do not deform and withstand the effects of the environment;

- Lightness - despite their large dimensions, the blocks are lightweight, which significantly reduces the pressure on the foundation of the building;

- Low rate of thermal conductivity - the foamed granules included in the structure provide blocks with high rates of thermal insulation;

- Convenience in work - the blocks are easy to move and store, they lend themselves to additional processing - you can saw, drill, chisel. The dimensions allow you to reduce the time for construction work.

- Noise isolation;

- Resistant to mold and fungal infections;

- Resistant to moisture;

- High indicators of frost resistance - buildings can withstand up to 100 cycles;

- The ability to carry out work at any time of the year.

Cons of polystyrene concrete blocks

Among the negative properties are the following:

- Destruction under the action of fire - the material belongs to the class of hardly combustible, it does not burn, but the polystyrene granules melt, and this leads to a loss of technical properties;

- Poor adhesion - the blocks are smooth, therefore they do not hold the decorative coating well without preliminary preparation (priming).