Species overview

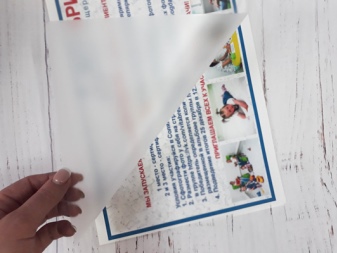

Matt

This type of film is good because it does not leave glare. It can be safely used to protect documents. You can leave an inscription on a matte surface and then remove it with an eraser. The print quality will be higher than when using "plain" paper without a protective layer. A matte finish will help preserve the original color saturation for a long time.

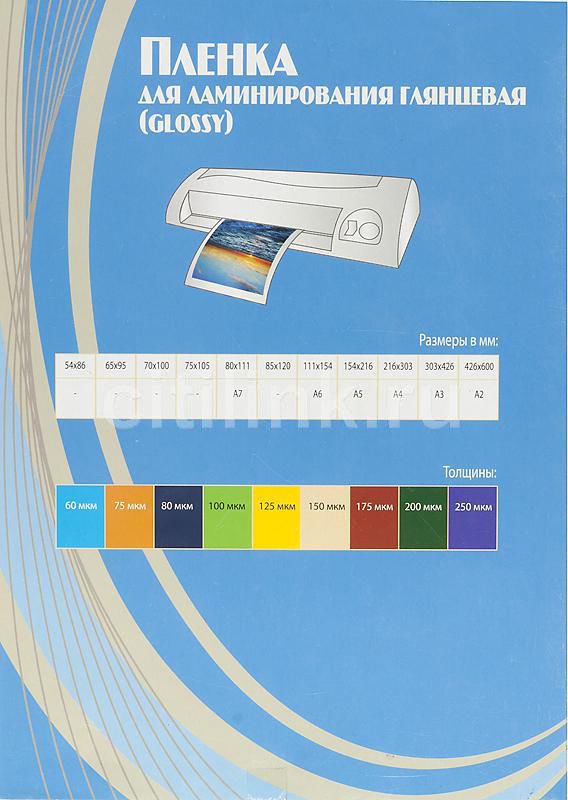

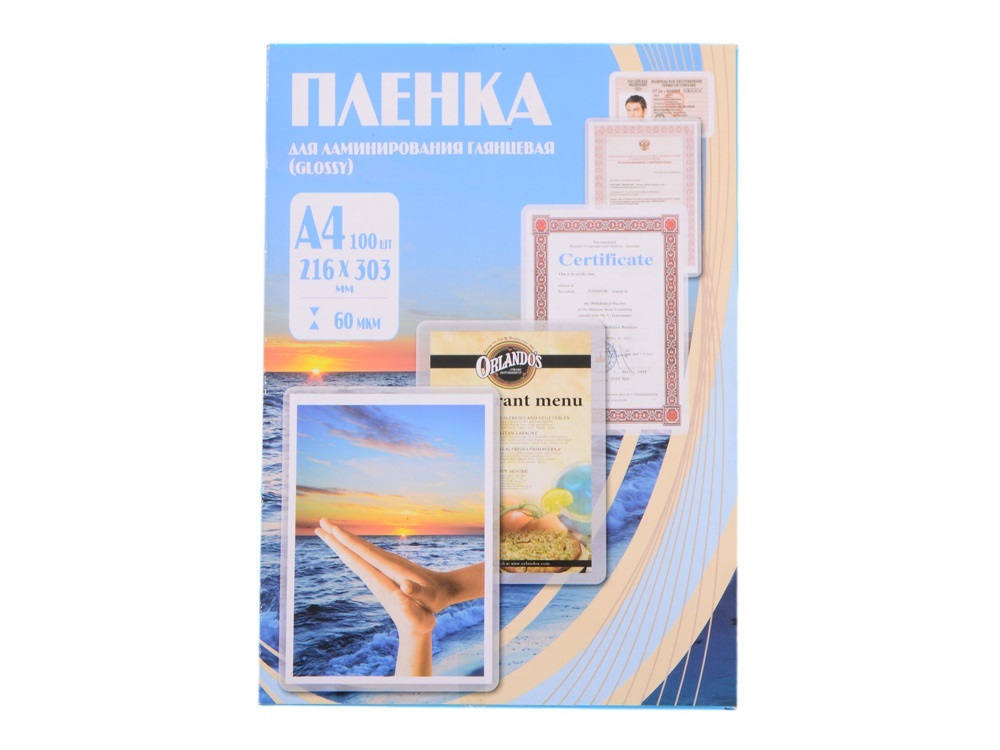

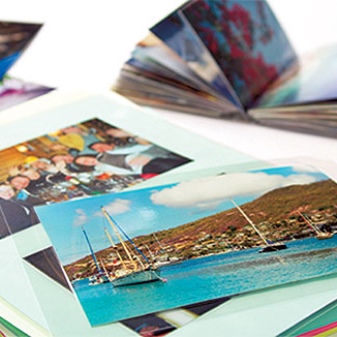

Glossy

This type of consumables is more appropriate not for documents, but for photographs. It allows you to more clearly show the outlines of images. This solution is recommended for posters, book covers. You can use it for other illustrated publications and items. Covering the text with a glossy film, however, is hardly a good idea - the letters will be harder to see.

Textural

This is a great way to simulate sand, fabric, canvas, and so on. Some variants are able to reproduce the appearance of a pyramidal crystal, an original color image or a holographic image. The textured film will mask scratches that would be easily visible on matte and glossy finishes. It is not without reason that it is often used to decorate books and art canvases.

Roll laminating film can be up to 200 m in length. To use it, you just need to cut off a fragment of a suitable size. Therefore, such a coating is perfect for both large and miniature publications. The batch version, on the other hand, allows you to more flexibly vary the thickness of the covering layer. The increased density guarantees better protection than usual.

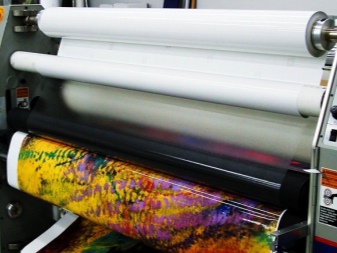

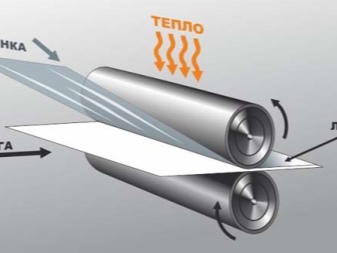

The film can also be hot or cold laminated. The use of increased heating makes it possible to apply a decorative protective coating to any substrate. The required temperature is determined by the density of the material used. The cold lamination film will be activated by the applied pressure. Homogeneous pressure with special rollers presses the cover tightly to the document, and from one edge it is sealed; such processing is possible even immediately after printing. Cold lamination films are a great option when you need to protect heat sensitive products. We are talking primarily about photographs and vinyl records.

But the same is true for a number of document types. The composition of the glue is selected in such a way that the adhesion occurs reliably. However, the same tightness as with the hot method cannot be achieved, and the cost of consumables will be very high. The hot technique involves heating to about 60 degrees or more. The thicker the sheet, the higher the temperature should be. Relatively thin films adhere well to the surface even with minimal heating.

How to choose?

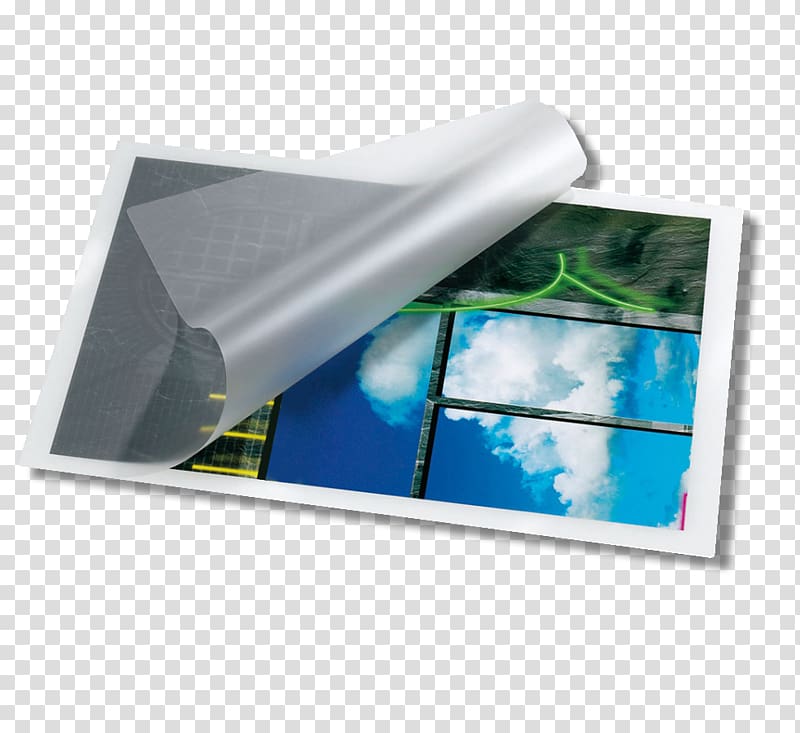

High-quality films for paper and documents are produced using coextrusion technology. This method allows you to get multilayer workpieces, and each layer in them is responsible for its own special function. Individual layers can be very thin (up to 2-5 microns). Good food usually contains 3 layers. Two-layer solutions are rare, but they cannot provide effective protection. The original bottom layer - the base - can be made of polypropylene. It is likely to have both a glossy and a matte surface. Polyester (PET) turns out to be a more versatile solution, more often used in bag products. Such a coating is suitable for one or two sides; the degree of transparency is very high.

Polyvinyl chloride film withstands ultraviolet irradiation. Therefore, it is recommended for active outdoor use.Texture coatings are made only on the basis of PVC. The nylon bottom surface uses substantially less BOPP and PET. Such a substrate will not curl, but its geometry may change when heated and cooled, making it suitable only for cold lamination. The intermediate layer is in most cases made of polyethylene. The adhesive mixture must exactly match the composition of the substrate and the second layer. For him, transparency and adhesion are important.

It is also important to consider the texture of the film. The optical effect depends on it.

Glossy finish is preferable for various photographs and advertising publications. However, it will have to be protected from scratches. As for single-sided and double-sided lamination, the first type is only suitable for storing documents in an office or other controlled environment; by applying a coating on both sides, you can be sure of protection from moisture.

Elementary protection against moisture will be provided by polypropylene films with a thickness of 75-80 microns. This coverage is quite effective for office documents. Crumples and breaks are avoided when using thicker (up to 125 microns) polyester. It can already be used for business cards, diplomas and certificates. The densest coatings (175 to 150 microns) guarantee increased protection even in critical conditions.

Important: Ideally, you should buy a film for a specific model of the laminator. As a last resort, you should focus on products of the same price category as branded products

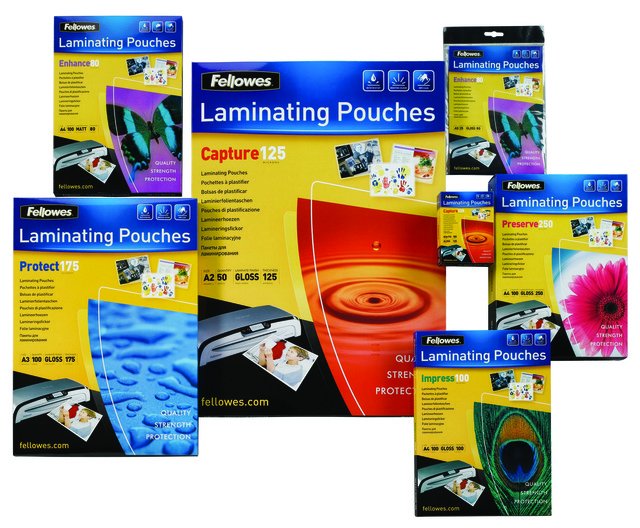

It should be understood that a number of Asian suppliers are saving on intermediate coats and using excessive amounts of adhesive. This can adversely affect the safety of the device and the effectiveness of its use. Inexpensive thin films are often made by applying the adhesive directly to the substrate; the reliability of such a solution is a big question. If a full-fledged solution is used, then the tear resistance is no longer 2, but 4 kgf / cm2. Additionally, it is worth considering that the best products for lamination are made:

- ProfiOffice;

- GBC;

- Attalus;

- Bulros;

- D end K;

- GMP;

- Fellowes.

The film is formally of the same composition and size, supplied by different companies, may differ significantly. Both individual "secret components" and processing modes are affected. The look and feel of the touch does not allow us to judge quite fully the quality of the material. It is necessary to carefully study the reviews and recommendations of specialists. If it is very difficult to figure out what the thickness of the coating should be, you can focus on the almost universal indicator - 80 microns. Glossy transparent type of material - multipurpose. It can cover almost all types of office supplies.

As for special films, this is the name for products with the highest quality and additional functions. Textured or colored surfaces are ideal for color application. Such coatings can even be placed on a metal surface. Fotonex anti-reflective transparent film is praised for its extra UV protection. It can also have a pronounced surface layer texture.

Important: in order not to doubt the safety of the product, you should check the presence of the UV marking. Self-adhesive laminates are valued for their suitability for even the most demanding jobs on any flat substrate.

In the field of printing services, the Tinflex product is in demand, which has a density of 24 microns and gives images a slightly caught gloss.

How to use?

First of all, you need to turn on the laminator and put it in the required thermal mode. Hot lamination is usually set by moving the switch to the HOT position. Next, you will have to wait until the end of the warm-up. Typically, the technique contains an indicator showing when the device can be used. Only at his signal do they put film and paper in the tray. The sealed edge must be facing forward. This will avoid skewing.You can reliably compress materials if the film is 5-10 mm wider than the media. To return the sheet, press the reverse button. As soon as the process is completed, it is necessary to suspend the feed and allow it to cool from 30 to 40 seconds.

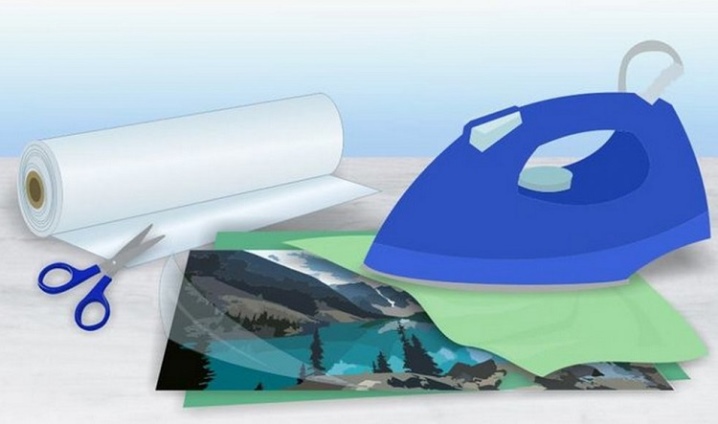

Cold lamination is even easier. This procedure is carried out when the switch is set to Cold mode. If the machine has just been hot, it should cool down. There are no other special differences in the procedure. But paper can be laminated with the most common iron. At home, it is more correct and most convenient to work with A4 sheets. It is also recommended to use a material of small thickness (up to 75-80 microns maximum). The iron is placed on a medium temperature level.

It is necessary to iron first from one, then from another turn. The matte surface will become more transparent. When the film cools down, its hardness will increase. Using a slip sheet of paper helps to prevent the material from sticking to the iron. If an air bubble occurs, it is necessary to wipe the still hot surface with a soft cloth - this will help if the protective layer simply did not have time to adhere immediately.

But sometimes this technique does not help. In this case, it remains only to pierce the remaining bubble with a needle or pin. Next, the problem area is smoothed with an iron. Cutting to exact dimensions can be done on a special stand. You can always buy it in a specialized stationery store.

For information on how to choose the right film for lamination, see the next video.

Materials (edit)

The film for lamination works can be made on the basis of polypropylene. This solution is characterized by increased softness and elasticity. There are both glossy and matte types of this material. It is possible, at the request of the consumer, to lamination on both sides or only on one side. PVC-based products are generally more resistant to ultraviolet radiation, are plastic and can take their original shape even after prolonged rolling into a roll. Typically, PVC-based films have a textured surface. The main area of its use is street advertising. Nylonex is breathable and will not curl. When applied to paper, the underlying geometry will not change. Material such as Polinex is also quite widespread.

For branding purposes, it is designated by the letters OPP. The thickness of this material does not exceed 43 microns. Pressing is carried out at a temperature of 125 degrees. The soft and thin coating turns out to be quite elastic. Polinex is mainly used for roll films. Perfex is usually labeled PET. The thickness of this material can reach 375 microns. It is a tough and, moreover, almost perfectly transparent material. It provides an excellent display of printed texts.