Peculiarities

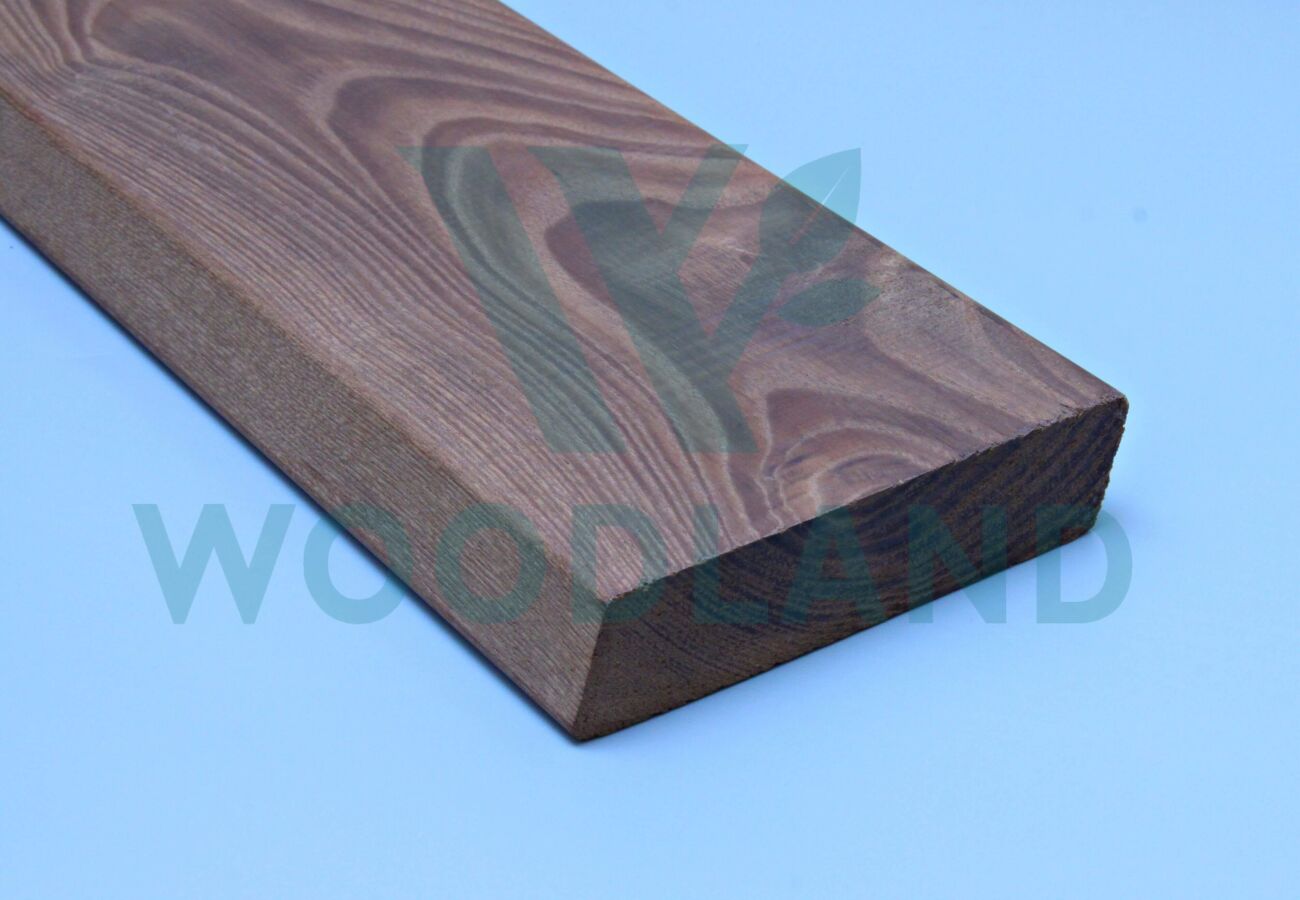

This material is one of the varieties of the facade board made of heat-treated ash. At the same time, chamfers are removed on all 4 edges. As a result, the edges of the finished material have either beveled or rounded corners. If we talk about the external characteristics of the thermo ash plank, then it is a bit like a deck or terrace board. In addition, it is not inferior in quality to expensive wood species.

The width of the board varies from 7 to 14 centimeters. To obtain planken, wood is initially processed in a sealed chamber. After that, it acquires several unique features.

Among the pluses, it is worth noting the following:

- planken differs from other boards in its low weight, therefore, when using it for facades, the owners should not worry about the load on the foundation;

- a thermal tree differs from other materials in that it does not swell, and also does not warp;

- the service life is quite long, in some cases, repairs are not required up to 50 years;

- the material is not affected by mold and mildew; in addition, he is not afraid of any insects;

- thermo ash lends itself to tinting;

- facade decoration with thermal wood is simple and convenient, because work does not require the use of special equipment, which allows even beginners to cope with the work;

- ash planken is not afraid of temperature changes, and is also not exposed to moisture;

- this material increases the performance of thermal and sound insulation;

- in case of damage to a certain area, it can be easily restored;

- the texture, as well as shades are quite different, so each person will be able to choose the right material for himself;

- the scope of application is huge.

The main disadvantage of ash planken is its high price.

Myth four: a thermal tree does not need impregnation

Thermo ash and other types of heat-treated wood are initially dark in color, in addition, they do not rot and burn out very slowly. Therefore, some owners of thermo-ash floors and facades may have doubts about the need to use impregnation or paints and varnishes. This is a fundamentally wrong opinion. The thermal tree must be impregnated with special oils or deep primers, with which the board can be protected:

- From burnout in the sun - tinted compounds will remove the traces of natural aging of wood irradiated by solar ultraviolet light.

- From dirt and dust - varnishes and oils create an additional layer of protection on the surface of the board, filling all microroughnesses. Therefore, dirt is swept away from an oiled or varnished floor with a broom, and clean boards will have to be sanded or scraped.

- From water - clogging the capillaries of the end part and the face, the oil protects the board from excess moisture and drying out.

An oiled board will survive a harsh winter, a rainy summer, and a slushy autumn. She is not afraid of frost, direct sunlight and dirt. But the oil film must be restored at least once a year.

Myth five: you can't take care of a thermal tree

Some retailers claim that thermowood is maintenance-free. This is an erroneous opinion due to the inclusion of an artificial wood-polymer composite in the segment of thermally treated sawn timber. Yes, WPC does not need to be cleaned, painted or repainted. But a wood-polymer composite is not a thermal board. The latter remains natural wood, despite the complex, multi-stage processing. Therefore, it must be sanded, polished, polished, painted and oiled.If this is not done, the floor or facade made of thermal board will lose its external gloss after 5-6 years of service. The WPC will age much more slowly - in 8-10 years, but after this period the composite strips will have to be thrown away, and the thermo ash lamellas can be looped and used for another 5-10 years.

Application

The direct purpose of ash planks is vertical as well as horizontal decoration of facades of various buildings, for example, residential buildings. In addition, this material is very often used for arranging interior space.

It is worth familiarizing yourself with all this in more detail, namely:

- first of all, with the help of a plaque, you can decorate the facade of a house, a bathhouse, or even outbuildings on the site;

- in this way, you can arrange the floor and ceiling in the house or bath;

- this material is perfect for finishing handrails, veranda or terrace steps;

- ash facade board will serve as an excellent material for the construction of a fence or any other fence;

- planken will be a good material for making benches;

- some experts use this material to decorate gazebos.

If it was damaged during transportation, the boards should be placed in a well-ventilated area.

One of the options for planking the facade of the house in the video below.

Coating

Coating with protective oils in production conditions costs +1200 rubles / m2. The service includes: grinding, covering the underside in 1 layer, covering the front side in 2 layers. We use only proven materials Kreidezeit and Leinos, in our range of more than 50 possible shades to choose from.

Thermo ash

Thermos pine

Any natural wood must be protected with high-quality tinted oils from:

BURNOUT. When exposed to sunlight, the tree begins to fade and, over time, takes on a dirty gray tint. At the same time, ONLY tinted oils protect against burnout. DIRT AND DUST. Various particles of dirt and dust, when they hit an unprotected surface, begin to destroy it. Also, dirt can penetrate deeply into the porous surface of the wood and leave unpleasant stains that will be very difficult or impossible to sand off. CRACKS. Once on a surface unprotected with oil, water is instantly absorbed into the porous surface of a living tree. When the temperature drops, moisture crystallizes and cracks appear on the surface of the wood, which spoils the appearance of the decking.It is also imperative to protect the ends, this is the weakest point in a living array. We recommend covering the planken not only from the top, but also from the bottom. Any cheap formulations can be used below. This inexpensive symbolic layer on the back of the deck will provide additional protection.

Manufacturers

Many construction companies are engaged in the manufacture of planken, because the material is very popular. The most popular among them are several manufacturers.

Green Forest. The main specialization of this plant is the manufacture of planken. For several years in a row, products have been sold to various regions of the country. You can buy boards at the main office of the factories, which is located in Voronezh.

The factory makes boards not only with oblique, but also with a straight cut. For their treatment, G Nature oil is used, which has been able to prove itself well. Thanks to him, the planken is protected from the effects of ultraviolet rays. In addition, the oil helps to emphasize the existing pattern on the wood.

As a result, the surface of the boards is smooth, moreover, it does not have pores, unlike ordinary wood. Moisture absorption after such treatment is reduced by five times. Thus, thermowood is not afraid of any weather conditions: no snow, no rain, no dew, no ice.

Views

There are such varieties of planken, which differ from each other in the cut of the chamfers, as:

A straight cut resembles a rectangle with slightly rounded edges; such panels are mounted end-to-end, while maintaining small gaps, the facade is voluminous and beautiful;

In addition, planken can also be distinguished by grades, namely:

- Products of the "extra" class differ from others in their high quality; boards have no chips or minimal damage; such a planken will be an excellent decoration for any facade;

- Prima boards can have slight chips or damage, as well as cracks on the entire surface;

- Products of class "AB" can have not only small cracks, but also knots or other small flaws along the entire perimeter;

- Boards of the "BC" class are distinguished by the presence of a large number of defects over the entire surface of the boards; in addition to knots, there are also areas with dark spots.

Myth one: complete absence of deformation

If this is the case, then why are expansion gaps left during installation? Of course, in order to prevent warping of the board, which is swollen from excess moisture. Even seamless installation requires a millimeter gap between the planks. And the profiled boards, during the installation of which the spike-in-groove assembly is used, are laid with a gap of 2-3 millimeters.

Therefore, the absence of deformation in natural wood is a myth. Any board expands in length, width and height, absorbing moisture from the air. Or decreases in size, falling into an environment with insufficient humidity. And heat treatment of wood in this case does not change anything. The installer must leave:

- 2-3 mm between 10 cm strips;

- 3-4 mm between strips 11-12 cm wide;

- 5-6 mm between lamellas 14-16 cm wide;

- up to 10mm between 20cm boards.

If this is not done, the floor will “catch the helicopter”, arched, or “go into the boat”, bending towards the base.

Myth three: thermowood is prone to decay

This is not true. Heat-treated wood is not plastic or metal, but it does not rot like regular lumber. The fact is that the heat treatment process involves heating the finished board to 190-230 ° C, which is lower than the ignition temperature, but enough to transform the fiber, resins, olefins, essential oils and other chemicals that make up the wood. Heat treatment changes the chemistry of wood, destroying the environment that feeds the decay process. Therefore, natural thermal boards do not rot under any circumstances, remaining wood in the physical sense, but not at the chemical level.

Recommendations

The starting material for the manufacture of front, terrace, deck, floor boards, lining, etc. is natural wood that has undergone an environmentally friendly heat treatment process using WESTWOOD technology. The color and texture of the products are natural characteristics of natural wood and cannot be absolutely identical in the delivered consignment. After heat treatment, the wood still has a tendency to deform, but on a much smaller scale than a non-heat-treated board.

Before installation, the board should be stored in the manufacturer's packaging. Water penetration into the package is not allowed.

Do not store an unpacked board that is not protected by oil or varnish outside under the influence of sunlight.

It is forbidden to drive screws or hammer nails into the thermal tree without first drilling the holes (the board will crack).

It is forbidden to cut the board (saw / trim) with non-sharpened saws (heat-treated board has a high density, very fragile for chips).

As guides, it is recommended to use rocks close in density to the used board (for thermo-ash - larch, for thermo-fir - thermo or pine / spruce treated against decay).

During installation, it is required to leave technical gaps between the boards, depending on the width of the board (board width - gap):

100mm - 1mm, 120mm - 2mm, 140mm - 4mm, 160mm - 6mm, 180mm - 8mm, 200mm - 10mm

The recommended step of the lag for the terrace is 300-400mm, for the facade 400-700mm

It is forbidden to use the "thorn-groove" profile (imitation of a bar, lining, etc.) for external finishing (there is no technological gap for expansion)

Before applying oil, the board must be sanded with P100 / 150 grit sandpaper (removes dynamic waves and opens pores)

The thermal tree burns out in the sun, so it is necessary to tint the board with colored oil in two layers on the front side and colorless on the seamy side. Colorless oil (even with UV filters) does not protect against burnout. We recommend tinted oils Kreidezeit (Germany) and Leinos (Germany).

The ends of the wood should be sealed with wax to minimize the occurrence of end cracks. Moisture penetrates into the wood precisely in these places, and when the temperature drops, it crystallizes and tears the board inside which it is located.

To renew the coating, you need to wash the thermal tree with a solution of Marseilles soap, let it dry for 24 hours and apply a thin layer of oil. The terrace needs to be renewed once a year, the facade once every 4 years

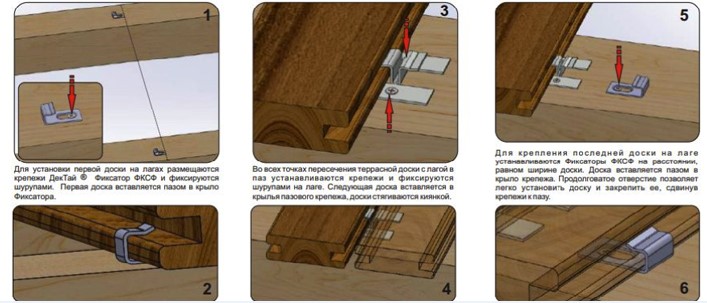

Mounting

There are 2 main types of HIDDEN terrace fasteners - "Crab" and "Duet". We recommend larch logs 45x70 mm for the lathing under the Thermoash terrace. In this case, the step between the lags should be 300-400 mm. Very often logs and fasteners (Crab) are tinted to match the Thermo Ash.

Fasteners "Crab"

The use of Crab fasteners allows you to create a flat flooring surface without visible fasteners with the same technological gaps between the boards of 6 mm; creates a rigid structure that resists the internal stresses of the wood, since after installing the previous board, there are no distortions of the next board due to the strong fastening with a log and quick joining of the boards. The fasteners are made of stainless steel, which ensures a long service life of the mounted terrace flooring.

Fasteners "Duet"

made of composite polymer material and does not condense moisture,

ensures the durability of the terrace structure due to effective ventilation of the hidden part of the structure,

convenient for installation as it is equipped with a mounting stopper that positions the fasteners relative to the edge of the board,

compensates for the swelling-shrinkage of the cladding board and does not cause warping,

can be used with boards from 90mm to 200mm wide,

Placing the head of the screw in the groove of the fastener ensures a perfectly flat terrace surface.

In the Thermo Wood company you can buy products that will serve you for more than a decade. The cost of delivery in Moscow and the region will depend on the area and distance from the Moscow Ring Road. You can check the price with the managers of the company.