2.4. Determination of the coefficient of relative compaction of sand, taking into account winter conditions

2.4.1. In winter, the shipped sand is

in a free-flowing state, therefore, the coefficient of relative compaction should

installed through the bulk density, determined in accordance with GOST 8735-88 at

natural state of the sand.

2.4.2. Standard tank temperature for

determination of bulk density should correspond to the ambient temperature

air.

2.4.3. Bulk determination procedure

density and the calculation of the coefficient of relative compaction are similar to those indicated

in p.p.

—

and adj. ...

SCROLL

regulatory documents and standards

1. SNiP 2.05.0.2-85 "Highways".

2. SNiP

4.02-91 and SNiP

4.05-91 “Collection of estimated norms and prices for construction work. Collection 1.

Excavation".

3. SNiP 3.02.01-87

"Earthen structures, foundations and foundations."

4. GOST 25100-95 “Soils. Classification".

5.GOST 11830-66

"Construction Materials. Weighing accuracy rate ".

6. GOST 8735-88 (STSEV5446-85) “Sand for construction work. Test methods ".

7.GOST 8736-93

“Sand for construction works. Technical conditions ".

8.GOST

12536-79 “Soils. Methods for laboratory determination of granulometric (grain)

and micro-aggregate composition ".

9.GOST

22733-77 “Soils. Method for laboratory determination of maximum density ”.

10.GOST

5180-84 “Soils. Method of laboratory determination of physical characteristics ".

11.GOST 30416-96

“Soils. Laboratory tests. General Provisions ".

12.GOST

12071-84 “Soils. Selection, packaging, transportation and storage of samples ”.

TERMS AND DEFINITIONS

Compaction factor (Kat) - the ratio of the density (skeleton) of dry soil in the structure

subgrade to the standard maximum density (skeleton) of dry soil,

determined by the device Soyuzdorniya (GOST

22733-77).

Required soil compaction factor (Ktr) - the compaction factor (fraction of the standard density) provided for

in the project of work or established in SNiP 2.05.02-85 for a specific horizon from

top cover.

Relative compaction coefficient (K1) - the ratio of the required density (skeleton) of dry soil in the embankment (), set taking into account the compaction coefficient according to table. 22

SNiP 2.05.02-85, to its

density adopted in calculating the volume of soil.

Roughly K1 it is allowed to take according to the table. 14 compulsory adj. 2 SNiP 2.05.02-85.

Required volume of earthworks () —

product of the design geometric volume of the soil in the embankment or otherwise

structural element of the road structure (V2) and the values of the coefficient of relative compaction (K1).

Design geometrical volume of soil (V2) - the volume of soil, determined by the calculation in the project for the corresponding

constructive subgrade element or the underlayment of the road

clothing, taking into account the required compaction coefficient.

Average weighted density of dry soil in

career (reserve) - the ratio of the sum of the densities of dry soil

individual layers () multiplied by the layer thickness (hi), to the total thickness of the layers (еhi) presented in the quarry passport.

Bulk density of sand - the ratio of the mass of sand, dried to

constant weight, to the volume poured into a standard container with a capacity of 10 liters

at natural humidity (GOST 8735-88).

Application

3

TECHNICAL CHARACTERISTICS OF VEHICLES

|

Index |

The value of the indicator for a car brand |

||||||||

|

MMZ-585 |

MAZ-503, MAZ-503B |

KrAZ 256B |

KamAZ 5511 |

KamAZ with side loading |

MAZ 5516 |

MD 290, Magirus 380-30 |

Tatra 815, 815S1 |

Volvo FH 420 |

|

|

Carrying capacity |

4,5 |

7 |

11* |

10 |

7 |

16,1 |

14,5 |

15,3 |

27 |

|

Capacity, m3 |

3 |

3,8 |

6 |

7,2 |

7,9 |

11 |

14 |

9 |

17 |

|

Body dimensions, mm |

|||||||||

|

length |

2595 |

3280 |

4585 |

4525 |

5000 |

4450 |

5400 |

4300 |

6500 |

|

width |

2210 |

2284 |

2430 |

2310 |

2320 |

2300 |

2650 |

2290 |

2500 |

|

height |

650 |

676 |

650 |

816 |

635 |

1080 |

1200 |

970 |

1700 |

|

The same, dump truck, mm |

|||||||||

|

length |

5475 |

5970 |

8190 |

7140 |

7570 |

7530 |

8400 |

7190 |

9900 |

|

width |

2415 |

2600 |

2650 |

2500 |

2320 |

2500 |

2800 |

2500 |

2500 |

|

height |

2510 |

2700 |

2780 |

2700 |

2900 |

3160 |

3530 |

2900 |

3200 |

|

Weight, kg |

4570 |

6750 |

1140 |

9000 |

8480 |

12400 |

15500 |

11300 |

16000 |

*)

12 - for work in a career

Application

4

EXAMPLES options for determining the value of the coefficient of relative compaction and

calculating soil volumes

How is it checked?

As mentioned above, the building material must meet a number of stringent requirements. The conformity of the material to certain properties and characteristics is checked during specially designed tests. All of them are regulated by official documents and GOSTs.

- Determination of the composition of grains. In order to correctly assess the composition of the sand (to determine the properties of its fractions), the material is sieved through a sieve specially designed for this purpose. After all the sand has been sifted, but especially large particles remain in the sieve, they are measured and weighed. In this way, the average grain size is determined.

- Determination of the presence or absence of impurities. In order to assess the level of purity of the sand, experts select the viscous particles of the material from its total volume.

- Calculation of the amount of clay and dust. To make such calculations, the method of varying the weight after soaking the fractions is traditionally used. In some cases, so-called pipette and photoelectric methods can also be used.

- Determination of the presence of organic matter. The composition of building sand quite often includes various substances of a humic nature. In order to understand how many of these components are present in the composition of the material, experts began to carry out a comparative analysis. To do this, the sand itself is painted with ethanol, and then the resulting mixture is compared with the coloring of an alkaline solution.

- In relation to the sand that is mined by processing various rocks, the method of analyzing the amount of minerals in the composition is used. For these purposes, devices such as a binocular loupe or a microscope are used.

- For a clear determination of the density index, a pycnometric method is used.

- An important step in assessing the quality of sand is determining the presence or absence of voids between grains, as well as calculating an indicator such as bulk density. For these purposes, use specific measuring glassware.

- In order to analyze the moisture content of the sand, compare the material in its natural state, as well as the sand in the state of the material dried in a special cabinet.

Density indicator

It determines the quality of this material, but depends on the moisture and porosity that it possesses. For construction work at home, the density of sand is not particularly important and its average value is taken for calculations. And in the industrial sphere, the density calculation is interconnected with the strength and service life of the buildings being erected.

This indicator is also taken as the basis for determining the total amount of bulk building material.

It changes from the moisture content of this substance. If the moisture content increases, water flows into the voids between the grains of sand, filling them. Thus, the bulk density indicator grows upwards.

The greatest loosening of sand occurs at a moisture content of 4-7%. Bulk density in this case will decrease by 10-40%. Density is controlled with the help of special devices - density meters or penetrometers, humidity - moisture meters. The average density of sand is considered to be a coefficient of 1.3 t / m3.

Density

The actual specific gravity of the sand is usually not used. It is calculated by laboratory assistants of special institutions.

Thus, the density of river sand (kg per m3) ranges from 1.5 t / m3 to 1.45 t / m3. It is taken into account when dosing for the preparation of concrete mixtures (volume determination). The specific gravity of river sand is 2.65 g / cm3.

To find out the mass, the following formula is used: m = V ∙ p (m - mass, V - volume, p - density). Let's find out its quantity in 20 m3: m = 20 ∙ 1.3 = 26 tons (1.3 is the average density coefficient).

When preparing a solution, you always need to know that at low density, voidness can be increased. Therefore, it is necessary to double the amount of binders. Raising the consumption of binders is not profitable for construction, because it increases waste and, consequently, the cost of concrete.

Ultimately, all this is reflected in the return on costs, which is very important for construction companies and firms. For household use, such a rise in price does not play a significant role, because the scale of work is much smaller.

As mentioned above, the higher the humidity, the lower the density. Moreover, its decline continues until it reaches 10%. Then the density begins to grow due to the increase in the volume of the liquid. Changing this parameter affects the quality of the concrete.

The density of the sand can be calculated by yourself. They do it like this: sand is poured into a ten-liter bucket from a height of 10 cm. The container is poured full with a slide. Then it is cut off so that in the end a guaranteed flat surface comes out.

The remaining amount of sand in the bucket is weighed, then the density is calculated: the kilograms that have been received are converted into tons and divided by 0.01 m3. To refine the result, it is good to repeat this procedure twice. Then the received data is summed up and divided by two.

You can also define voidness on your own. Pour a sample of sand into a liter container and weigh it.

By the way, the measured values can be converted into the desired values.

Physical and mechanical properties of rocks

Strong breeds

Volume weight γ, t / m3

Specific gravity γO, t / m3

Humidity w %

Clutch in the sample C, kg / cm2

Internal friction angle φ, deg.

Elementary block size, cm

1

2

3

4

5

6

7

Erupted

Granitoids

2,62

425

36,5

Quartz

Porphyry

2,56

2,65

0,36

395

37

40

Syenites

2,76

0,37

363

37

40

Granodiorites

2,63

2,78

0,39

560

32

50

Porphyrites

3,02

0,50

365

33

45

Gabbro-diorites

2,70

373

35,5

Gabbro

3,11

300

36

Gabbro-diabase

2,86

353

32

80

Diabases

2,95

460

30

Peridotites

2,80

323

36

70

Pyroxenites

3,23

35

35,5

Metamorphic and

sedimentary

Quartzite

2,64

2,84

0,50

350-700

36

50-70

Jespilites

3,43

36

36

40

Hornfelses

2,58

305

35

40

Hornfelses

hydrohematite

3,17

300

32

40

Slates

siliceous-clayey

2,82

0,24

380

33,5

30

Slates

quartz-chlorite-sericite

2,73

21

33

30

Phyllites, tuffites

2,87

300

28

40

Serpentinites

2,7-3,1

0,40

230-300

35

60-100

Skvarns

2,75

0,28

587

31

4-50

Quartz

sandstones

2,50

2,65

2,5

250

35

50-150

Limestone

2,70

2,77

0,14

220

33

30-100

Medium strength breeds

Continue

tables

|

Name |

Volume |

Specific |

Humidity |

Clutch |

Injection |

The size |

|

Erupting weakly weathered |

||||||

|

Granitoids |

2,56 |

220 |

36,5 |

30-50 |

||

|

Quartz porphyry |

2,50 |

2,64 |

0,20 |

227 |

34 |

30-50 |

|

Syenite, syenite-diorite, diorite |

2,50 |

2,66 |

1,00 |

205 |

32 |

30-50 |

|

Granodiorite, granodiorite porphyry |

2,57 |

2,75 |

1,05 |

285 |

36,5 |

50 |

|

Porphyrites |

3,00 |

260 |

37 |

|||

|

Gabbro diphytes |

3,00 |

21 |

36 |

|||

|

Gabbro |

2,83 |

275 |

35 |

|||

|

Gabbro-diabase |

2,98 |

260 |

36,5 |

|||

|

Diabases |

2,75 |

200-260 |

36-37 |

|||

|

Syenites |

240 |

36 |

70 |

|||

|

Erupted weathered |

||||||

|

Syenite-diphytes |

120 |

32 |

||||

|

Keratophyry |

165 |

33 |

||||

|

Granodiorite porphyry |

2,40 |

2,74 |

0,90 |

180 |

36 |

30-50 |

|

Porphyrites |

170 |

31 |

||||

|

Gabbro diphytes |

2,66 |

180 |

36 |

|||

|

Diabases |

70 |

34 |

Medium strength breeds

Continue tables

|

Name |

Volume |

Specific |

Humidity |

Clutch |

Injection |

The size |

|

Metamorphic |

||||||

|

Quartzite |

2,61 |

2,78 |

0,40 |

165 |

34 |

50-70 |

|

Kaolinized quartzites |

2,24 |

2,59 |

0,94 |

48 |

30 |

20-30 |

|

Sandy-clayey shale |

2,78 |

180 |

37 |

40 |

||

|

Chlorite-quartz and chlorite shales |

2,86 |

140 |

35 |

30 |

||

|

Phyllites |

152 |

27 |

30 |

|||

|

Talc carbonate rock |

2,89 |

115 |

30 |

|||

|

Magnetite |

4,32 |

190 |

34 |

20-30 |

||

|

Weathered serpentinites |

2,50 |

84 |

34 |

20-30 |

||

|

Sheared serpentinites, strongly weathered |

2,50 |

23 |

33 |

5,0-30 |

||

|

Sedimentary |

||||||

|

Limestone |

2,44-2,67 |

2,83 |

0,1-4, |

140-165 |

27-32 |

30-80 |

|

Weathered limestones |

2,37 |

— |

— |

73 |

31 |

|

|

Arkose sandstones |

2,26 |

175 |

38 |

|||

|

Clay sandstones |

2,67 |

— |

— |

170 |

37 |

|

|

Sandstones with carbonate cement |

2,57 |

2,68 |

2,27 |

170 |

36 |

40 |

|

Sandstones with clay-iron cement |

2,31 |

2,70 |

2,70 |

87 |

36 |

30 |

|

Sandstone |

2,53 |

2,75 |

50-90 |

35 |

30-80 |

|

|

Siltstones |

2,51 |

2,72 |

4,00 |

35-70 |

33 |

35-70 |

|

Mudstones |

2,45 |

2,80 |

8,00 |

40 |

29 |

20-55 |

|

Coal |

1,26-1,58 |

5,00 |

28 |

36 |

3,0-60 |

Weak breeds

Continue tables

|

Name |

Volume |

Specific |

Humidity |

Clutch |

Injection |

The size |

|

Heavily weathered |

||||||

|

Gabbro diphytes |

2,40 |

14,3 |

36 |

|||

|

Slates |

2,12 |

18,0 |

1,2-13,6 |

26-30 |

||

|

Sandstone |

7,5 |

36 |

||||

|

Diabases |

2,07 |

19,6 |

3,2 |

34 |

||

|

Dolomites, siderites |

2,00 |

31,6 |

1,39 |

32 |

||

|

Sedimentary |

||||||

|

Sandstone |

2,11 |

2,65 |

11,0 |

11,0 |

35 |

|

|

Siltstones |

2,13 |

2,48 |

20,0 |

3-17 |

31 |

|

|

Mudstones |

2,02 |

2,67 |

18,0 |

3-1 |

29 |

|

|

Fractured chalk |

1,90 |

2,64 |

31 |

1-40 |

35 |

5. Loess and

loess-like soils

In accordance with the requirements of SNiP II-15-74 and SN

449-72 Loess and loess widespread on the territory of the USSR

soils are

to subsiding.

Soils that collapse from soaking should be

include soils that have G ≤ 0.6 and value

,

where: EO - coefficient of porosity of a sample of natural constitution and moisture;

ET -coefficient

porosity of the same soil sample with moisture at the yield point;

G -degree of humidity.

Grading

loess species is shown in the table. The deformation modulus values are given in the table. Indicators of physical properties of loess rocks in different regions of the USSR

are given in the table. Average

the values of shear resistance indicators are in the table. Tabular data can be

used for preliminary,

approximate calculations.

How to calculate the bulk density of sand?

Sand classes in accordance with GOST.

To carry out such measurement calculations, the sand is initially sieved with a sieve (0.5 cm). Then they fill a measuring vessel (1 l). Further, the sand should be freely poured into it from about 0.1 m in such a way that a cone forms below the edge of the vessel. Then, using a ruler, the upper part of the cone is removed, that is, to the edges. Separately, it is necessary to weigh the container with and without the substance. The following formula is used to calculate the density factor: (empty weight - full weight) / container volume.

Here it is immediately worth stipulating that such calculations are made only with those measuring containers that initially have a certain shape and size, since this significantly affects the results. To make this issue easier to solve, there is GOST.

The average density of substances is influenced not only by moisture, but also by the presence of voids. The less space between the granules, the higher this characteristic.

The average density indicator for each type of sand is different: quartz dolly in a loose state has an indicator of 1500-1550 kg / m³, while if it is compacted, the characteristic will increase to 1600-1700 kg / m³. If it is planned to mix frost-resistant concrete, then one of its components will be sand with an increased average density coefficient.

Non-compacted density of material - technological and commercial value

Mass in construction practice is the ratio of mass to volume that a material occupies in a compacted or non-compacted state. This number is especially significant from the economic and technological point of view.

To make a concrete mixture or mortar in order to create a sand cushion, it is necessary to use a material with known characteristics.

Determining the density of sand is important in terms of the ratio of its mass to the actual volume occupied. From an economic point of view, density affects money, what the customer is willing to spend - he must purchase a suitable material for use, of sufficient volume.

Density

To do this, it is advisable to establish the number of particles in a volumetric unit without seals and take into account moisture indicators, which significantly affect the weight.

Determination of the density of a material in an uncompacted state in accordance with GOST should be carried out according to a standard procedure.

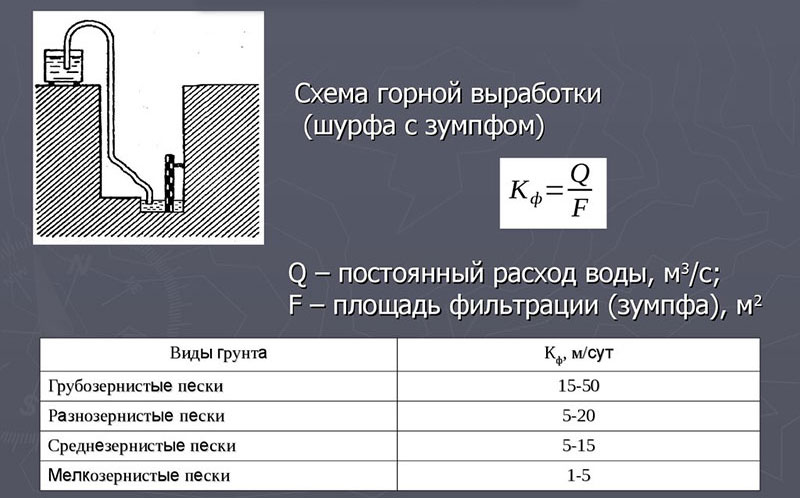

How to calculate the sand filtration coefficient

Sand is used for the preparation of mortars and mixtures (wet or dry) in the construction of a wide variety of objects and structures - from housing to strategic structures and for road construction, from foundations to moisture-tight sealed structures. When choosing the required fraction and the degree of sand purification, the size modulus, the presence of clay impurities, the bulk density, and the filtration coefficient are taken into account. The reference values of the sand filtration coefficient are given in the table:

| Priming | CF | CF |

| Gravel, pebbles | 0,125-0,175 | 0,135-0,25 |

| Sandy soil | 0,175-0,30 | 0,20-0,40 |

| Sandy loam | 0,22-0,32 | 0,28-0, 5 |

| Loam | 0,3-0,38 | 0,45-0,65 |

| Clay soil | 0,35-0,45 | 0,55-0,75 |

| Coarse soil | 0,25 | 0,35 |

An accurate determination of the filtration coefficient of sand is necessary in order to find out its ability to pass water (water permeability). The rate of passage of water through a certain thickness of sand is calculated by applying a hydraulic gradient with a value of 1, the unit of measurement is m / day (meters per day).The measurement result reflects the distance that water seeped through the sand layer in 24 hours, that is, the density of the sand.

Determination of the filtration coefficient of soils

Determination of the filtration coefficient of soils

The sand filtration coefficient (CF) determines its penetrating ability and quality parameters. The smallest sand capacity has KF = 0. By the KF values, one can determine the volumetric presence of clay impurities and, according to this indicator, use sand for certain solutions or mixtures.

The lower the filtration coefficient, the smaller the range of application of sand, since its quality determines the strength of a concrete or cement-sand structure. The highest CF has coarse-grained sand, since more air remains between the grains of the material and water can freely and quickly seep through the thick layer of sand.

In order to find out the CF of sand in a laboratory way and conduct research, use a measuring tube: water is poured into it at a level above the "0" mark by 0.5 cm or more. When water flows down through the perforated bottom with holes, the chronometer measures the time it takes for the water to fall below 5.0 cm in the measuring tube.This measurements are carried out 4 times in a row, and each time the water is added to the measuring tube by 0.5 cm.When the level drops for ten minutes water measurements can be made at an initial pressure gradient of 2.0. The measuring tube and stand are removed from the beaker and placed on a special tray. When taking measurements, it is necessary to ensure that the water in the measuring tube does not fall below the upper level of the building material.

Sand filtration value tester

Sand filtration value tester

Density of dry bulk material in the tank (ρdi, g / cm3) is calculated as follows: ρdi = m1 / (Vi x (1 + Wi)), where:

Vi - volume of soil in a measuring tube, cm3;

Wi - soil moisture in a measuring tube.

CF is calculated by the formula: K = h / t x α (S / H) x 864 / T, where:

h is the height of the sand filling for filtration in a measuring tube (cm);

S - visual decrease in the level from the initial (cm);

H is the value of the maximum minimum fluid pressure (cm);

t - time of the level fall (sec);

T = (0.7 + 0.03 Tf) Is the coefficient used to bring the KF of sand to acceptable filtration conditions for a liquid at a temperature of 10C, where:

Tf - temperature during experiments, C;

T = (0.7 + 0.03 x 18) = 1.24.

Density

GOST 8736 sand is a material that is poured. The indicator under consideration is based on the dimensions of the air layers that are located between the main elements.

There are some types of body weight per unit of its volume:

- real;

- technical;

- bulk. It is determined by the ratio of the mass of the material used to the volume that it will take. Few take into account the void for the final indicator, as well as the porosity of the material itself;

- conditional or true indicators. This is the maximum limit of the density ratio that the material occupies, while the cavities N2 and O2 are not taken into account.

The true indicator will always be higher than the real one. This value is inherently conditional or theoretical. From a practical point of view, it is, in terms of its density, similar to bulk.

Density

For sand with different characteristics, it is allowed to use the following bulk density (tons per m3):

- for dry extracted from the river - 1.4-1.65;

- for a wet river - 1.7-1.8;

- for a compacted river - 1.6;

- for fine-grained material extracted from quarries - 1.7-1.8;

- for a dry, based on a mineral, one of the crystalline varieties of silica — 1.5;

- for ground, made on the basis of a mineral, one of the crystalline varieties of silica — 1.4;

- for a compacted, based on a mineral, one of the crystalline varieties of silica-1.6-1.7;

- for material extracted by mining, grade 500-1000 - 0.05-1;

- for material made from blast-furnace, dump and granular solid residue after metal smelting from ore - 0.06-2.2;

- for molding material with normal moisture content in accordance with GOST standards - 1.7;

- for material with dust impurities - 1.6-1.7;

- for material that was mined high in the mountains - 1.5-1.6;

- for building material, normal moisture according to the standards of GOST - 1.5-1.7.

According to the degree of saturation of the sand with various valuable minerals, several types of placers are distinguished.

For more information on determining density, see the video:

Properties and characteristics of sand

All the necessary requirements for the quality of the sand used in the preparation of concrete are documented. Certain characteristics of this substance can only be studied in the laboratory, but there are those that are checked by eye just before the construction is carried out.

Particle size

To know what kind of sand to take for the preparation of concrete, first of all, you need to decide on one of the most important parameters of the material - the size of the grains of sand. The following types of this substance are distinguished according to the size of its particles:

- consisting of large particles (grains of sand have a size exceeding 3.5 mm);

- increased coarseness (size of grains of sand from 3 to 3.5 mm);

- large (within 2.5-3 mm);

- medium size (2-2.5 mm);

- fine fraction (1.5-2 mm);

- very small (1-1.5 mm);

- thin (0.7-1 mm);

- very thin (up to 0.7 mm).

To find out the size of the grains of sand, experts pass the substance through a sieve with an appropriate hole diameter.

In fact, such a division is more conditional, only documented.

In real life, 3 types of sand are distinguished for the particle size: small, medium-sized and with coarse fractions.

What sand is used for mortar? To make the structure really strong, you need a large type, but so that there are many small grains of sand in it.

Otherwise, a huge amount of voids will be noted in the concrete, which can reduce the strength of the finished structure. In addition, the resulting voids can be filled with cement, which is equal to an increase in the cost of the finished product. It is an irrefutable fact that particles of the same size do not adhere tightly to each other, so the number of voids is much greater. Based on this, a mixture of sand with different sizes of grains of sand is mainly used in order to achieve the maximum density between the concrete components at the output.

Based on the size of the grains of sand, the substance itself can be divided into 2 classes. In the first class, there are no particles below 1.5 mm in diameter. It is an optimal material for construction, because the presence of such a fine aggregate has a negative effect on the settling of coarse grains of sand. The second class is characterized by the presence of small particles.

Volume weight

This indicator characterizes the weight of 1 m³ of sand in its natural state. Typically, the weight of a cubic meter of this element is approximately 1.5 -1.8 tons. It is desirable that this figure is lower.

Composition

According to its constituent elements, sand is divided into:

- Granulometric (combines the combination of grains of sand of different sizes).

- Mineral: quartz, dolomite, feldspar and limestone.

- Chemical (in accordance with the components available in the composition, the intended scope of application is determined).

Humidity

Usually, this figure is 5%. If the substance is dried, then its moisture content will be 1%, with the addition of moisture in the form of precipitation - 10%. Moisture determines the amount of water that must be mixed into the concrete mix.

Immediately before use, you can independently check the moisture level of the sand. If you squeeze it with your palm and it crumbles, therefore, the humidity is optimal, if not, then its indicator is more than 5%. But it is better to check this characteristic in the laboratory.

Porosity factor and bulk density

The coefficient characterizes how sand, and then concrete can resist moisture transmission. Verification of this coefficient is carried out only in the laboratory.

On average, the optimal density should be kept at the level of 1.3 - 1.9 t / m3.If the indicator is lower, then this indicates that there are unnecessary additives in the substance, higher - about high humidity. All information must be submitted in the appropriate documentation.

Physical and mechanical properties of peat soils ("Guidelines for the design of road beds of highways on soft soils", Soyuzdornii, 1978)

View

Subgroup

Impeller shear resistance Cconv.

kgf / cm2

Compressibility

Name

Natural moisture w

Decomposition rate R, %

Fiber grade F,%

Deformation modulus E, kgf / cm2

under load R

Modulus of settlement Сg mm / m at load R kgf / cm2

in natural bedding

after compaction under R

R = 0.5 kgf / cm2

0,5

1,

0,5

1,

1

2

3

4

5

6

7

8

9

1

11

Drained (or compacted)

25

> 75

m3

0,49

2,50

> 2,5

> 3,3

200 (

300 (

c3

0,42

1,72

25-40

75-60

m3

0,30

1,25

c3

0,33

1,05

> 40

m3

0,19

0,80

c3

0,26

0,73

Low-moisture

> 75

m3

0,49-0,26

2,5-1,36

2,5-1,5

3,3-2,3

200-350

(100-250)

300-430

(200-370)

c3

0,42-0,22

1,72-0,90

25-40

75-60

m3

0,33-0,17

1,25-0,60

c3

0,33-0,16

1,05-,56

> 40

m3

,19-0,08

0,80-0,36

c3

0,26-0,13

0,73-0,36

Average humidity

600-900

> 75

m3

0,26-0,16

1,36-0,87

1,5-1,1

2,3-1,90

350-450

250-400

420-530

370-500

c3

0,22-0,16

0,90-0,66

25-40

75-6

m3

0,17-0,1

0,60-0,42

c3

0,16-0,11

0,56-0,35

> 4

m3

0,08-0,05

0,36-0,21

c3

0,13-0,08

0,36-0,22

Very wet

900-120

25

> 75

m3

0,16-0,11

0,87-0,62

1,1-0,90

1,90-1,70

450-55

(400-470)

530-600

(500-550)

c3

,16-0,11

0,62-0,46

25-40

75-60

m3

0,1-0,06

0,42-0,28

c3

—

—

> 40

m3

0,05-0,03

0,21-0,15

c3

—

—

Excessively wet

> 75

m3

0,11-0,07

0,62-0,38

0,90-0,85

1,70-1,50

550-60

(470-490)

600-650

(550-570)

c3

0,11-,06

0,46-0,20

25-40

75-60

m3

—

—

c3

—

—

> 40

60

m3

—

—

c3

—

—

Production methods

Under natural conditions, the most common sand is medium size without significant inclusions of clay and other impurities.

There are several ways of mining, these are:

With this method, mining is carried out in quarries located above sea level, in areas with deep groundwater. To carry out the work, heavy equipment is used (excavators, bulldozers, dump trucks, etc.), as well as special equipment, through which the extracted raw materials are cleaned and divided into fractions and classes.

When organizing extraction from the bottom of water bodies (seas, lakes, rivers and other large water bodies), special means, dredgers (dredgers) are used, which are installed on floating crafts or pontoons, where they are fixed at a certain point in the water body. In the process of work, the soil (sand) is absorbed with water, after which it is crushed and fed to the storage areas. The water pumped in together with the raw material flows into the reservoir.

In addition to the two main methods, depending on the technical capabilities of the mining enterprise, as well as the natural conditions, a method can be used when sand is washed in an open pit with special equipment, or the quarry is filled with water, after which the mining is carried out underwater.

With an open-pit mining method, depending on the equipment used, the following types of sand are obtained:

- Seeded - when grain size separation (fractionation) is performed during the production process:

- Alluvium is the purest material, which is due to several degrees of leaching during production.

- Soil - obtained by direct shipment of material, without processing. The most "dirty" material, finding various impurities, can reach 40.0% of the total volume of the mined rock.

Output

The material in question is versatile and mandatory for use during construction. It is also an environmentally friendly component for mortar mixture, it is resistant to combustion and does not lend itself to decay.

Having information about the given weight of sand in 1 m3, it will not be difficult for you to make approximate calculations of the amount of material required for the construction of future real estate. We also recommend that you read the article on the transfer of crushed stone from m3 to tons.

Sand of medium size, depending on the method of extraction, is natural, crushed and fractionated, and according to the method of extraction: open-pit, alluvial and sea, its size determines the size of the grains of sand. For medium sand, this is 2.0 - 2.5 mm.

In accordance with the Interstate Standard GOST 8736-2014 “Sand for construction works. Specifications ", the category of" medium size "includes sand, with a modulus of size (Mk) ranging from 2.0 to 2.5 units.

Medium sand is of I and II class, depending on the percentage of the content of grains of various sizes, to the value of the main size of the batch. For different classes, it looks like this:

| Class | Content of grains by size,% | ||

| Over 10.0 mm | Over 5.0 mm | Less than 0.16mm | |

| I | 0,5 | 5,0 | 5,0 |

| II | 5,0 | 15,0 | 15,0 |

When separating by size, sieving is performed, in which the total residue is determined, characterized by the filtration coefficient. For medium sand, the total residue when sieved on a # 063 sieve should be in the range of 30.0 to 40.0%.

The composition of the sand is regulated by the content of clay, dust and clay particles. For different classes, this ratio, in percentage terms, should correspond to the following parameters:

| Class | Content of dust and clay particles | Clay content in lumps |

| I | 2,0 | 0,25 |

| II | 3,0 | 0,5 |