What is the difference between quarry sand and river sand

For construction, two main types of material are used by origin - quarry sand (gully) and reclaimed from the river bed. In the coastal regions, the material can be mined from the bottom of the sea, but its transportation is rather difficult, therefore, river sand is much more accessible in the central regions of Russia. The sand massif mined in the river and quarry has markedly different properties.

Features of river sand

Sand of river origin is characterized by a pronounced rounded shape of grains, which for thousands of years have been rolled by streams of water, sharpened, and become smooth. In a concrete solution, this means a more even distribution of the mass of grains of sand, which means high plasticity and predictable density.

Construction practice, experience and standards require the use of medium and coarse sands in the concrete solution - with a grain size of 2.8 mm or more. Great importance is attached to the absence of impurities of clay, silt and other deposits of organic and mineral origin. It is this feature of river sand that is highly valued in the production of concrete products, pouring foundations and forming monolithic structures.

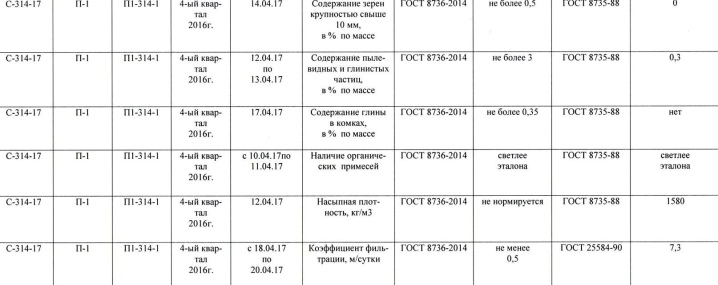

Builders with extensive experience attach importance to the place of extraction of the material. The characteristics of river sand for contamination with silt and clay are indicated in the documentation, and this figure should not exceed 0.3%. The origin and method of extraction create all the conditions for obtaining a mass of high purity, plasticity and the correct shape of the grains.

Features of quarry (mountain) sand

The characteristics of quarry sand (mountain and ravine) make it possible to use it as a filler and base material for brick production, the manufacture of mixtures for screeds, and backfilling of roads and sites. The characteristic uneven shape of the grains and clay impurities make it possible to obtain compositions for the manufacture of bricks and masonry mixtures - they have a pronounced strength of internal cohesion.

For use in a concrete solution, sand of a quarry origin is too fine and non-plastic - its uneven grains do not give the effect of uniform distribution, they settle faster, which leads to a decrease in the quality of concrete. The amount of clayey deposits is somewhat less in alluvial quarry sand, but this is not the main indicator in concrete production and monolithic construction.

Criterias of choice

Most builders in the matter of choosing sand for the foundation agree on one thing - the fraction, the minimum percentage of foreign substances and the density are much more important than the origin or place of extraction.

A quality sand aggregate must meet the following criteria.

- The most acceptable modulus of grain size is from 1.5 to 3 mm.

- The limiting content of organic and clay impurities is 3-5%.

- Should not contain harmful components that can enter into a chemical reaction with cement alkalis - silicon dioxide, sulfur, chlorine, etc.

- Have in the composition of active radionuclides no more than 370 Bq / kg, which corresponds to the I class of radioactivity.

An important point that allows you to control the quality of the supplied products is its bulk weight. The average for clean dry sand is 1500 kg / m3. Less weight indicates the presence of impurities, more - about high humidity.

In its natural form, river sand meets these criteria more. A seeded or alluvial quarry is in no way inferior to him. But if the requirements for future development are low, and the foundation will not be subject to heavy loads, then an inexpensive filler from a nearby quarry is quite suitable.

Types and characteristics of material: its classification

There are a number of indicators that characterize natural river material:

- size module;

- filtration coefficient;

- bulk and bulk density;

- additional characteristics.

For a complete perception of the product gradation, we will consider each indicator separately.

About size

The size module is data on the size of fractions, which includes definitions such as:

- Fine sand with a grain size of 1.5 - 2.0 mm.

- Natural product of medium size with a grain size of 2.0 - 2.5 mm.

- Natural material with coarse grain: 2.5 - 3.0 mm.

- Product with increased grain size: 3.0-3.5 mm.

- Very coarse sand with a grain size of 3.5 mm or more.

- Dusty product with a grain size of 0.5-0.14 mm. The sand of this category is divided into several more subspecies: - with a low proportion of moisture;

- wet;

- material of natural origin, saturated with moisture.

What is filtration coefficient

This indicator makes it possible to understand the physical and technical properties. This parameter indicates the volume of liquid required to permeate 1m3 of sand in 60 minutes. This indicator is influenced by the porosity of the product.

A few words about bulk and bulk density.

The value of this indicator is within the range of 1300-1500 kilograms per meter. With a change in the moisture content of the sand, its volume also changes. This affects the bulk density of the natural product. There are certain requirements from which one should build on and adhere to - this is GOST 8736-93.

What is included in the concept of additional characteristics

Additional characteristics include:

- What class of radioactivity does the product belong to?

- The presence of materials (their types), such as clay, an admixture of silt and other natural components.

Why is it needed?

It will be a difficult task to prepare a concrete composition of the highest quality possible, but without this, no construction goes through.

To begin with, we will list the main components of the cement mortar used in construction work. These are water, cement, sand and gravel. All of these ingredients are designed to perform specific tasks. If you prepare a solution from one cement diluted with water, then after drying it will begin to crack, and it will not have the necessary strength.

Among other things, the presence of bulk materials in the solution significantly reduces its cost.

The strength of the monolithic filling and repair work largely depends on the properties of the solution. The sand will be useful only if it is correctly selected and there is not too much or too little of it. When there is too much of it in the solution, the concrete will turn out to be fragile, and it will easily crumble, as well as collapse under the influence of atmospheric precipitation. If there is not enough sand, then cracks or depressions will appear in the fill

Therefore, it is very important to correctly observe the proportions of the mixture.

Specifications

The requirements for the sand used in the preparation of concrete are reflected in the relevant regulatory documents. Some characteristics can be checked exclusively in laboratory conditions, others can be checked directly on the construction site.

Volume weight

Indicator reflecting the mass of 1 m³ in its natural state. A cube of wet with all sand impurities weighs on average about 1500 - 1800 kg. A lower value is preferred.

Composition

The composition can be:

- granulometric, which reflects the ratio (in percent) of grains of different sizes;

- mineral: quartz, dolomite, feldspar and limestone;

- chemical, depending on the elements present in the composition, the possible area of use is determined.

An example of a particle size distribution:

| Sand group | Total residue on a sieve with a mesh size of 0.63 mm,% by weight | Size module | Water demand of sand,% |

| Increased size | Over 65 to 75 | More than 3.0 to 3.5 | 5 to 4 |

| Large | More than 45 to 65 | More than 2.5 to 3.0 | 6 to 5 |

| Average | More than 30 to 50 | More than 2.0 to 2.5 | 8 to 6 |

| Small | More than 10 to 30 | More than 1.5 to 2.0 | 10 to 8 |

| Very small | To 10 | More than 1.0 to 1.5 | More than 10 |

Chemical composition example:

| Sl02 | Al2O3 | Fe203 | Ti02 | CaO | MgO | SO3 | K2O | Na2O | P.P.P. 1000 C |

Sum | CaCO3 | |

| 78,26 | 6,48 | 1,45 | 0,12 | 5,89 | 0,70 | 0,12 | 0,96 | 0,64 | 5,35 | 99,97 | 4,92 | 11,2 |

An example of a mineral composition:

| quartz | 54,09 — 68,54 % |

| granite | 10,31 — 13,83 % |

| feldspar | 7,07 -7,97 % |

| limestone | 6,13 — 7,96 % |

| dolomite | 0-2,91 % |

| siliceous rocks | 1,24 — 1,98 % |

| quartzite | 0,21 — 0,39 % |

| mica | 0-0,63 % |

| sandstone | 0,05 — 0,92 % |

| shale, gneiss | 0-0,38 % |

| glauconite | 0-0,18 % |

| iron hydroxides | 0,04 -0,25 % |

| ore hydroxides | 0,07 -0,27 % |

| accessory minerals | 0,26 — 0,56 % |

Humidity

As a rule, this characteristic is 5%. If the mixture is dried, the indicator will decrease to 1%. When moistened by precipitation, the value can increase up to 10%. The amount of water added to the solution at this humidity should be reduced.

At the construction site, the humidity level can be checked as follows. If the sand is compressed into a lump, it will have to crumble. If this does not happen, the humidity is more than 5%. Although this indicator is still better controlled in the laboratory.

| Sand volume, cm3 (ml) | Sand moisture,%, at the density of sand particles, g / cm3 | ||

| 2,6 | 2,65 | 2,7 | |

| 448 | 2 | 2,9 | 4,1 |

| 450 | 2,6 | 3,5 | 4,7 |

| 452 | 3,3 | 4,2 | 5,3 |

| 454 | 4 | 4,8 | 6 |

| 456 | 4,6 | 5,5 | 6,6 |

| 458 | 5,3 | 6,1 | 7,3 |

| 460 | 5,9 | 6,7 | 8 |

| 462 | 6,5 | 7,4 | 8,6 |

| 464 | 7,2 | 8 | 9,3 |

| 466 | 7,8 | 8,7 | 9,9 |

Porosity factor and bulk density

The porosity coefficient reflects the ability of sand and, accordingly, in the future, concrete to transmit moisture. It can be determined exclusively in laboratory conditions.

The average bulk density is considered to be 1.3 - 1.9 t / m3. The optimum is considered to be 1.5 t / m3. A lower value may indicate the presence of undesirable impurities, a higher value may indicate excessive moisture. The necessary information must be specified in the accompanying documents.

| Density of addition | |||

| Type of sand | dense |

average density |

loose |

| By the coefficient of porosity | |||

| Gravelly, coarse and medium-sized sands | e | £ 0.55 e £ 0.7 | e> 0.7 |

| Fine sands | e | £ 0.6 £ 0.75 | e> 0.75 |

| Dusty sands | e | £ 0.6 £ 0.8 | e> 0.8 |

Choosing sand for concrete

The difference between quarry and river sand is so noticeable that it is customary to use material of river origin in construction practice. At the same time, it is worthwhile to carefully study the analysis data - the minimum amount of contamination and the uniformity of the fraction significantly increase the predictability of the properties of the concrete solution and the final concrete monolith.

If we rely on the opinion of professionals, then the question of which sand is better for preparing concrete, then the primacy will remain with the river - medium and large fractions, with minimal sedimentary impurities. For the creation of drainages, river material with a throughput (filtration coefficient) of 12 m per day is suitable, which is three times higher than the indicator of quarry sand.

The homogeneity, smoothness and purity of the mass extracted from the bottom of a river or a dried bed allows you to pack and sell sand in 40 kg bags, as a material with predictable properties and a guaranteed level of quality. The properties of quarry and river sand are so different that in the field of professional construction and working with concrete, these are practically different materials with their own specific areas of application. It is possible to save on the use of alluvial sand from a pit in a concrete solution - provided that the monolith does not bear a heavy load and its strength does not become critically low for the integrity of the entire structure.

Similar services

Underwater technical works

Possessing the necessary means, mechanisms and construction equipment, the specialists of the "Flot Nerud" company carry out any underwater technical work. The methods, features and nature of the diving survey largely depend on the goals set by the customer. Possessing the necessary means, mechanisms and construction equipment, the specialists of the "Flot Nerud" company carry out any underwater technical work. The methods, features and nature of the diving survey largely depend on the ones supplied by the customer

SDLG: high quality construction equipment

SDLG is one of the largest construction equipment manufacturers in China. In terms of production volumes, it is second only to brands such as XCMA, Liugong, Longgong. For the past five years, SDLG has been ranked among the top fifty wheel loader manufacturers. Moreover, the date of foundation of this company is 1972. SDLG is one of the largest construction equipment manufacturers in China.

Pit excavation and garbage disposal

One of the types of construction work that is often carried out is the development of foundation pits. Arrangement of a pit is a labor-intensive construction process. The future of construction largely depends on the quality of work at this stage. In addition, it is necessary to take into account the fact that the excavation and the removal of soil are two inseparable concepts, therefore it is necessary to take care not only of the layout of the construction site, but also of

Volume weight and composition

The requirements for the sand used in the manufacture of construction PB are specified in the relevant by-laws. Some characteristics can only be determined in laboratories, some are checked directly at the construction site. A numerical indicator reflecting the mass of 1 m³ of raw materials in a natural state, on average, weighs approximately 1.5 - 1.8 tons. The smallest value is considered to be predominant.

The composition of raw materials, as a rule, is:

- granulometric, reflecting the percentage of grains of different texture;

- mineral, from quartz to limestone materials;

- chemical, based on the elements contained in the composition, determines the potential area of application.

Mineral structure sample:

- quartz up to 68.0%;

- granite up to 13.0%;

- feldspar up to 7.0%;

- dolomite up to 2.9%;

- limestone up to 7.9%;

- siliceous rocks up to 2%.

Other elements: quartzite, mica, sandstone, shale, gneiss, glauconite, ore iron hydroxides, accessory minerals in the total volume up to 2.0%

Thus, one can argue with those users who believe that choosing the right sand for preparing concrete is quite simple. Their judgment is completely wrong. Since there are many types of raw materials with their own characteristic properties. Therefore, you need to know what kind of sand is used for concrete when performing certain construction and installation work.

Thus, one can argue with those users who believe that choosing the right sand for preparing concrete is quite simple. Their judgment is completely wrong. Since there are many types of raw materials with their own characteristic properties. Therefore, you need to know what kind of sand is used for concrete when performing certain construction and installation work.

Quarry and ravine

In the quarry version of the feedstock, impurities of loam and pebbles are found, for this reason, it is possible to use it only in the format of filling directly under the foundations or PB screed. When harvesting PB, the quarry material can be used only after thorough washing with water produced at the field. When carrying out such an operation, clay and small particles are removed from the composition.

The gully raw material is distinguished from the parameters of the river material in terms of external and technical qualities. It is fine-grained and its grain shape has angular unevenness, in comparison with the spherical and smooth geometry of the river, which, in turn, makes it possible to use it in compositions of knitting building materials. It also possesses a significant number of mechanical fragments like clay, silty and fine grains.

The size of the grains of the gully material is in the range of 0.5 to 1.0 mm, however, it is possible that coarse inclusions with a grain size of 2.0 to 5.0 mm can also be found.

The size of the grains of the gully material is in the range of 0.5 to 1.0 mm, however, it is possible that coarse inclusions with a grain size of 2.0 to 5.0 mm can also be found.

Selection Tips

To figure out which sand is most suitable, the first step is to find out what construction work will be carried out.

Based on this, you need to choose the type and type, while paying attention to the price of raw materials

For laying brick products or blocks, river sand will be the best choice. For this task, it has optimal parameters

To reduce the cost, it makes sense to add a sprinkle extracted from a sand cut, but here it is important not to overdo it.

If you need to fill in a monolithic base, then river sand with small and medium particles will be the most suitable for this mixture. You can add quite a bit of washed sand from the quarry, but it is worth remembering that the inclusions of clay are not completely removed from it.

They will give the products strength. Due to the greater porosity, water comes out of the solution faster than from other types of sandy raw materials. In turn, these types have worked well for plastering. But due to the fact that their production is difficult, then they will cost significantly more - and you need to know this.

Quarry sand is the most widespread and at the same time the most contaminated with various additives. It is not advised to look for an application for it when erecting any elements where special reliability is required. But it is perfect for laying under tiles, leveling areas for foundation blocks, creating paths in the garden. A huge plus is the low price.

Is it possible to independently check the purity of the sand

Laboratory research provides the most accurate results of the quality check. The user can find out not only the availability and the number of inclusions, but their percentage state in the total volume of building materials. In fact, peer review is a rather expensive and time-consuming procedure. It is incomparably easier to diagnose a composite for consumer qualities by a manual method.

The order of the manual method of checking which sand for concrete is better:

- Take an ordinary 1.5-2 l plastic bottle and pour the material into it for about a third of the total volume.

- Pour water on top of up to fifty percent of the volume of the bottle.

- Shake thoroughly and wait 5 minutes.

- The transparency of the water is assessed.

When foreign particles float in the water, the raw material is not suitable for use. If the liquid is impure and turbid, there are many foreign inclusions in the substance. The transparent composition and the absence of third-party inclusions indicate that the user has in his hands high-quality raw materials suitable for the application.

Loose building materials are divided into 2 classes based on the size of fractions: I and II. In the volume of the best class I, there are not many microscopic substances that are undesirable components for the PB mixture.

Loose building materials are divided into 2 classes based on the size of fractions: I and II. In the volume of the best class I, there are not many microscopic substances that are undesirable components for the PB mixture.

For the manufacture of a high-quality strong solution, it is more desirable to use a coarse fraction, mainly with particles of 2.0-2.5 mm. At the lowest rate, the cost of the prepared composition will significantly increase, and the consumer quality will decrease.

Types of sand

The composition and parameters of the sand largely depend on the place of extraction.

When choosing sand, it is important to know that there is river, sea, quartz and quarry sand for concrete.

Features of river sand

The river has grains of a pronounced rounded shape, it is constantly washed by streams of water, making it smooth and turned

For the preparation of a high-quality mortar, this is very important, since the particles are distributed evenly and the density of the substance in the concrete can be adjusted.

Thinking about which sand is best for concrete, they often stop the choice on the river version, since there is no clay in it, and there are almost no stones. Subsidence in it is natural and occurs at a high speed, therefore, when using the river type for the preparation of concrete, it must be mixed all the time. The degree of sand clogging with silt and clay is indicated in the documents for it and cannot be higher than 0.3%.

Thinking about what kind of sand is needed for concrete, you need to be aware of what is more important for you: the lower price of concrete or its higher strength.

Features of quarry rock sand

Taking into account the parameters of quarry sand (mountain and ravine), it is usually used in the production of bricks, mixtures for screed, filling for roads and sites. Due to the irregular shape of the grains and clay additives, products using the quarry type are very strong with a high internal bond strength.

If you use a quarry option for preparing concrete, then the solution will turn out to be of low quality. The grains of sand in it are very small with low plasticity, the substance itself in the solution is distributed unevenly and settles too quickly

The volume of clay additives is slightly reduced in the alluvial form of quarry origin, but it does not take an important place in the creation of concrete

Due to the fact that clay additives and stones can be found in the quarry, it is only suitable for preparing bedding for foundations or concrete screeds.

In the preparation of concrete, the quarry type is also used, but only after it has been washed with water, immediately after extraction. This procedure removes clay and dust particles.

Marine and quartz

By its properties, sea sand resembles river sand. Its main positive side is the uniformity of the composition. This option can be called the cleanest. Additional cleaning may be necessary due to the suspected abundance of shells. Due to the constant washing with salt sea water, particles of this type have the correct shape and are all approximately the same size. Offshore has the highest cost because it is mined on the seabed at great depths and requires expensive technology.

Quartz sand is reproduced as a result of mechanical crushing of rocks that contain quartz. This variant is pure, chemically inactive, all of its grains of sand are the same size and shape. Extraction is carried out artificially.

Construction sand

Natural sand is a loose loose rock of sedimentary origin, has a crystalline structure with a grain size of up to 5 mm and consists of destroyed mineral remains, most often quartz with a small amount of other inclusions.

Requirements for it as a building material, according to GOST 8736-93, include parameters such as grain size, its bulk and true density, the permissible limit for the content of dust and clay particles, harmful impurities, radionuclides.

River sand

River sand is mined in river beds. It has a homogeneous consistency, good fluidity, and an average granule size in the range of 1.5–2.5 mm. Thanks to long-term natural washing, it is clean, the grains have the correct rounded shape.

It is believed that this is the highest quality aggregate for concrete mortar, the strength of which is especially important in the construction of load-bearing structures. The pluses of the material, as a rule, include the following features.

- It does not contain clay and silty particles, which are unacceptable in cement-sand slurries and degrade their quality.

- Oval-shaped crystals during the preparation of the concrete mixture are not compacted, the cement milk envelops them evenly, and the finished concrete practically does not shrink.

River sand

He also has disadvantages.

- Mixing with this type of aggregate requires more cement and more thorough mixing.

- This is the most expensive building sand.

Quarry sand

The most common and affordable concrete aggregate. Careers with its development are everywhere, manufacturers are abundantly saturating the market with inexpensive and demanded products.

Unlike the river analog, open pit sand has a wider range of fractions, its granules are irregular and angular. Contains a fairly large percentage of impurities, including dust, organics, clay, debris.

There are several ways to enrich it.

Washed (alluvial) product is obtained using the technology of special directional hydraulic impact on the rock mass with its subsequent sedimentation.As a result, there is a cleaning of foreign substances, primarily clay deposits.

The second method of enrichment is sifting through a system of sieves, which retain large fragments of stones, lumps of clay, etc.

Sand pit development

Despite the fact that quarry sand is inferior in quality to river sand, it is in demand in the construction industry and has a number of advantages.

- Much more common.

- Less cement is used for the preparation of concrete - this is due to the property of crystals of irregular shape to become more compacted.

- Differs in an attractive price.

- The fortified product meets the highest standards.

Among the shortcomings, experienced builders note the following.

- Quarry sand contains a higher percentage of organic clay and dusty particles - up to 7% versus 0.05% in the river analogue.

- Due to its structural composition, it settles, compresses at the time of setting and hardening of concrete. The finished structure shrinks up to 1 mm per 1 cm.

Factors and properties of construction sand

Density reference values are derived under laboratory conditions. The characteristic is necessary for carrying out assessment work on the quality of the completed order and compliance with the requirements.

To determine the quality of the material, regulatory documents are used in which reference values are prescribed. Most of the prescriptions can be found in GOST 8736-93, GOST 7394-85 and 25100-95 and SNiP 2.05.02-85. Additionally, it can be specified in the project documentation.

In most cases, the compaction ratio is 0.95-0.98 of the standard value.

| Type of work | Compaction factor |

| Re-filling of pits | 0,95 |

| Sinus filling | 0,98 |

| Reverse filling of trenches | 0,98 |

| Repair of trenches near roads with engineering structures | 0,98 – 1 |

"Skeleton" is a solid structure that has some parameters of looseness and moisture. Bulk density is usually calculated based on the interdependence of the mass of solid particles in the sand, and that which the mixture would acquire if water occupied the entire space of the soil.

The best way to determine the density of quarry, river, building sand is to conduct laboratory studies on the basis of several samples taken from the sand. During the survey, the soil is gradually compacted and moisture is added, this continues until the normalized moisture level is reached.

After reaching the maximum density, the coefficient is determined.