Advantages and disadvantages

Material advantages:

- strength;

- reliability;

- comes with flame retardants;

- multifunctionality;

- environmental Safety;

- ease of installation;

- vapor permeability;

- resistance to high temperatures (suitable for use even in bathrooms and saunas).

Due to its structure, Izospan prevents the penetration of condensate into walls and insulation, protecting their structure from the formation of mold and mildew. Many positive reviews have ensured the popularity of the material for many years. Izospan A is a film membrane impermeable to air and moisture. Its use reduces drafts, prevents moisture ingress and helps to improve the quality of the indoor atmosphere. No additional primer is required prior to laying the membrane on most building surfaces.

Isopan A is an innovative material that has components in its composition, thanks to which it can be used on surfaces with elevated temperatures

This is important in the construction of the roofs of baths and saunas. Unique properties allow to extend the construction season and ensure year-round construction of buildings in areas with cold climates

The product can withstand up to 12 months of direct exposure to UV radiation while maintaining the integrity required for long term construction projects. The material is lighter in weight than competitive products. This property is indispensable when it is necessary to reduce the load on the structure. Long sections of web can be installed to increase the speed of work on site. The vapor barrier is installed horizontally or vertically, always with a 5 centimeters crossing of the canvases.

Overlapping installation avoids drafts. The membrane is compatible with various building materials such as gypsum, plywood, OSB, cement board, concrete, CMU, sealant. You can save on the level of heat consumption, which allows you to install and use heating equipment in smaller rooms. Energy costs can be reduced by as much as 40%. The risk of mold and mildew growth is also reduced.

Among the main disadvantages, it is worth highlighting:

- poor moisture resistance;

- small area of application.

If too much water accumulates on the surface of the film, moisture will begin to roll inward. You should not use a single-layer film for the roof. In this case, a multilayer membrane is best suited. The manufacturer's instructions indicate that Izospan A can be used in the roof structure, but it is desirable that the slope does not exceed 35 degrees. You should not purchase the material if you plan to have a metal roof covering.

Vapor barrier fixing instructions

For each structural element of the building: floor, walls inside and outside, interfloor overlap (ceiling), roof, balcony, attic there are technologies for laying a vapor barrier film. You need to know which side to fix the vapor barrier in the frame house.

Floor

Floor insulation is carried out in several ways: under the "floating screed", "floating floor" and along the logs. Consequently, there are different vapor barrier schemes.

By lags. There are two ways to protect your wooden floor from steam.

- If the joists have not yet been installed, the film (type C) is simply rolled over the base of the floor with an overlap and overlapping the walls. Fastened with tape only along the walls. Lags will be rigidly fixed at the bottom. The joints are glued with self-adhesive tape.

- With installed logs, the film not only closes the base of the floor, but also wraps the logs, leaving a small fold near each of them, so that when laying the insulation, the film does not stretch and break. As in the first case, entering the walls is required. Fastened to the joists with staples with a leg of 8-10 mm and a pitch of 50 cm. The attachment points are sealed with tape.

Under the screed. Steam protection of the floor covering is not always carried out. So there is enough waterproofing work under the ceramic tiles.

Under the laminate as a vapor barrier, a substrate is used from:

- expanded polystyrene (Penoplex trademark);

- polyethylene foam;

- bitumen-cork material (trade mark "TUPLEX").

If the substrate is coniferous or cork, then a simple plastic film is laid under it. Double vapor barrier with polyethylene is gaining popularity: between the base of the floor and the screed, additionally between the screed and the laminate.

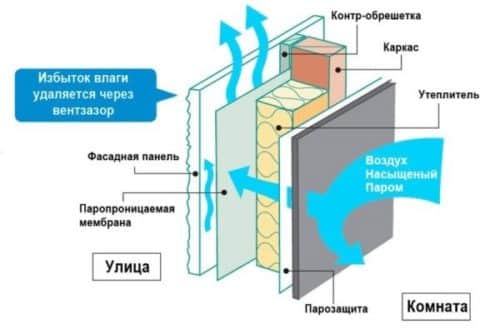

Frame house

When insulating walls in a frame house, vapor barrier is carried out from two sides: from the inside of the building with a film with complete vapor impermeability (type C), from the outside - with a windproof membrane (type A). From the inside, the film is fastened with staples to a wooden frame, from the street side - with a counter lattice. Such a mount allows you to solve several problems at the same time:

- fix the windproof membrane;

- create a ventilation gap;

- serve as a crate for facing material.

Facade

The facade vapor barrier scheme does not depend on whether the house is wooden, brick or concrete. The membrane is always laid over the thermal insulation layer. Fastened with a counter grill to create a ventilation gap.

An exception to the rule is the "wet" method of insulation. Vapor barrier works are not carried out here.

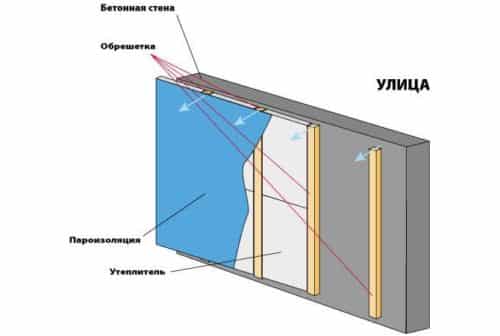

Wall from inside the room

When insulating a wall from the inside, regardless of the type of wall material, the vapor barrier is made of a vapor barrier film (type B). It is attached to the crate with a stapler, but the best solution is with locks (it is then convenient to fasten drywall along them). It is laid with the smooth side to the insulation. The attachment points are sealed with tape.

Sometimes you can find recommendations to lay vapor barrier membranes between the wall and the insulation. In the opinion of the editors of the StroyGuru website, such a proposal is absurd. Let's try to explain.

- If the membrane is single-sided, then it makes no sense to install it for one simple reason: the higher partial pressure inside the room directs the flow of vapor molecules outside. Nothing should interfere with the removal of steam from the insulation.

- If you attach type B film, the air flow from the room side will reach the wall surface and condense there.

- Installation of vapor barrier films outside the insulation and between the wall stops the steam inside the thermal layer - it will break through the inside of the insulation material in any case.

Attic

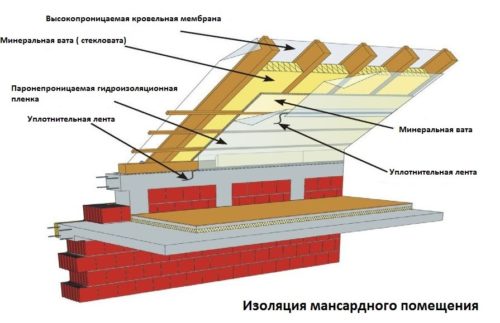

When insulating the attic from the inside of the room, it is best to use a vapor-proof film (type B), outside - membranes of type A. They are laid on the insulation with the smooth side. Attached to the rafter system and beams with a stapler. The staples are sealed with construction tape.

The foil material is laid with aluminum spraying inside. Fastened with wide-headed nails or a stapler. The attachment points are sealed with a metallized self-adhesive film. Outside, a ventilation gap is mandatory.

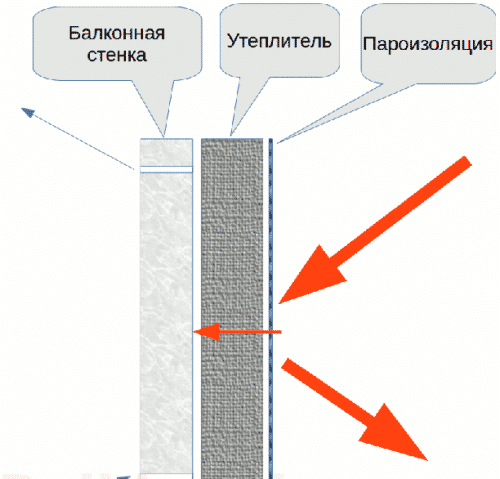

Balcony

When insulating a balcony with basalt wool, experts recommend abandoning vapor barrier. The use of other types of insulation requires the fastening of a vapor barrier material according to the technology used for wall insulation from inside the room.

Purpose and characteristics of Izospan vapor barrier

Izospan is a vapor barrier material that is produced in rolls and is used to insulate walls and roofs of buildings, floors and ceilings, from the ingress of steam and moisture from the inside.In addition, this film limits the formation of condensation on wall and roof surfaces, which can significantly increase the life of the materials used.

If you do not use such a material, then the insulation, which is usually placed in the layer between the roof, walls and the interior, will quickly lose all its heat-saving properties, or it may even completely collapse.

However, calling isospan a film is not entirely correct, because, despite the fact that the polymer film is the basis for its manufacture, after adding various minerals and substances, the polymer acquires much more useful properties.

Today, Izospan is produced by a lot of different companies, and therefore it should not be difficult for you to find and purchase it.

Roof and wall vapor barrier. Where is it installed and why is it needed?

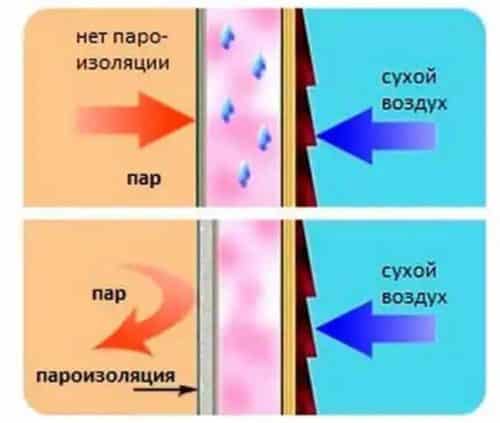

Let's consider a different situation. Steam has entered the structure and moves outward through the layers. Passed through the first layer, the second ... and then it turned out that the third layer is no longer so vapor-permeable as the previous one.

As a result, steam trapped in the wall or roof does not have time to leave it, and a new "portion" is already propping up behind it. As a result, before the third layer, the vapor concentration (more precisely, saturation) begins to grow.

Remember what I said earlier? Steam moves from warm to cold. Therefore, in the region of the third layer, when the steam saturation reaches a critical value, then at a certain temperature at this point, the steam will begin to condense into real water. That is, we got a "dew point" inside the wall. For example, at the border of the second and third layers.

There was an obstacle in the way of the steam. Steam saturation has increased and condensation is likely to form

This is what is often observed by people whose house is sewn up from the outside with something that has poor vapor permeability, for example plywood or OSB or DSP, but there is no vapor barrier inside or it is made of poor quality. Rivers of condensate flow along the inner side of the outer skin, and the cotton wool adjacent to it is all wet.

Steam easily enters the wall or roof and "slips through" the insulation, which usually has excellent vapor permeability. But then it "rests" on the outside material with poor penetration, and as a result, a dew point forms inside the wall, right in front of the obstacle in the path of steam.

There are two ways out of this situation.

- It is long and painful to select the materials of the "cake" so that the dew point does not end up inside the wall under any circumstances. The task is possible, but difficult, given that in reality, the processes are not as simple as I am describing now.

- Install a vapor barrier from the inside and make it as tight as possible.

It is along the second path that they go in the west, they make an airtight obstacle on the way of steam. After all, if you do not let steam into the wall at all, then it will never reach the saturation that will lead to condensation. And then you can not rack your brains over what materials to use in the "pie" itself, in terms of the vapor permeability of the layers.

Moreover, the most popular material for this "they have" is ordinary polyethylene 200 microns. Which is inexpensive and has the highest vapor permeability after aluminum foil. Foil would be even better, but it's tough to work with.

In addition, I pay special attention to the word sealed. In the west, when installing a vapor barrier, all film joints are carefully glued. All openings from the wiring of communications - pipes, wires through the vapor barrier, are also carefully sealed

The installation of an overlap vapor barrier, popular in Russia, without gluing the joints, can give insufficient tightness and, as a result, you will get the same condensate.

Vapor barrier does not let steam into the wall and, accordingly, the likelihood of getting enough steam for condensation is greatly reduced

Non-glued joints and other potential holes in the vapor barrier can cause a wet wall or roof, even if the vapor barrier itself is present.

I would also like to note that the mode of operation at home is important here. Summer cottage houses, in which you visit more or less regularly only from May to September, and maybe several times in the off-season, and the rest of the time the house is standing without heating, can forgive you for some flaws in vapor barrier.

But a house for permanent residence, with constant heating - does not forgive mistakes. The greater the difference between the external "minus" and the internal "plus" in the house - the more steam will enter the external structures. And the more likely it is to get condensation inside these structures. Moreover, the amount of condensate in the end can amount to tens of liters.

The principle of operation of a vapor barrier

In the warm season, the air temperature and humidity outside and in the house are close in value. In this case, no negative processes occur inside or on the surface of the structural elements of the building.

The situation in winter looks completely different. In the cold outside, the humidity is much lower (if it rises, it will settle in the form of frost), and in the apartment (house) it is much higher, as a result of which the partial pressure inside the room increases. With a pressure difference, the air always tends to where the pressure is lower. With it, vapor molecules are also removed through the building structures to the street.

Passing through the walls, floor, ceiling, steam cools down. At a certain point in the structure, a situation arises when humidity and temperature come to such a ratio, when the process of transition of steam to a liquid state starts. This conditional place in the building regulations (SP 50.13330) is called the "plane of maximum moisture", and among the people - the "dew point".

Protecting building structures from the harmful effects of humidified warm air can be a barrier for vapor molecules. It can be any material (metal, glass, plastic, etc.) that does not allow humid air to pass through. But air is not only vapor molecules, but also oxygen, nitrogen, carbon dioxide, etc. As a result, in a tightly sealed apartment or house, poorly working ventilation is not able to provide normal air exchange - mustiness appears.

But there is one caveat - the vapor molecules in the air are one of the largest. Therefore, on its way, you can put such protection that vaporous moisture does not pass, and other components of the air freely penetrate through it.

This protective system is called vapor barrier. This leads to another conclusion: a vapor barrier is not a vapor barrier film, but a functional purpose of a protective layer.

Differences between vapor barrier films and waterproofing

With the advent of new types of materials, not only "home craftsmen", but also professional builders began to confuse the concepts of vapor barrier and waterproofing. To understand the difference between them, let's look at the terms in more detail.

Vapor barrier provides for the creation of a barrier to water in any state of aggregation, liquid or vapor. This means that the vapor barrier material is at the same time waterproof.

The main task of waterproofing is to combat moisture, for which a large number of types of materials are used. Among them, a novelty appeared: diffusion membranes with microperforation, through which steam passes along with air.

These membranes, in many cases, began to be used for other purposes: instead of vapor barrier. Laying films with a change of attachment points leads to a gross violation of the rules for the operation of the building, which over time can lead to serious problems.

In order not to be mistaken with the place of laying each type of films, it should be remembered that when insulating the roof and facade, the waterproofing membrane is always laid from the side of the street, and the vapor barrier film from the side of the attic and the wall.

Waterproofing and vapor barrier films

Waterproof and vapor barrier film is intended for indoor installation. It is used to protect insulation and structures from moisture, which increases the thermal conductivity of the thermal insulator, contributes to the destruction of wood and metal. The use of films that do not allow steam and condensation to pass through prolongs the service life of insulation and building structures, if correct installation has been performed.

Scope of application of hydro and vapor barrier films:

- arrangement of the base of the floors;

- installation of an insulated roof (protection of the material that insulates a flat or pitched roof);

- insulation of enclosing structures from the side of the room, soundproofing of partitions;

- protection of floors - basement, interfloor, attic (serves as a waterproofing barrier);

- laying wood-based or wooden floor coverings (parquet boards, floor slats, laminate).

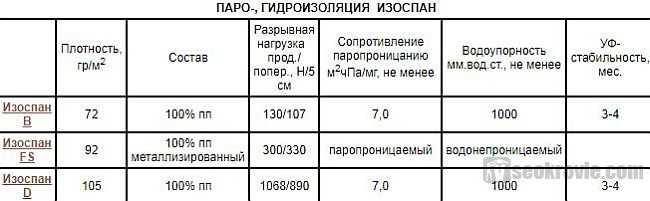

Izospan B, C, D, DM, RM, RS

The manufacturer offers a wide range of materials that serve as vapor barrier and waterproofing. All types of Izospan differ in density and functional purpose:

- Izospan B (density index 72 g / m2). Izospan V vapor barrier is one of the most popular types of material due to its characteristics and affordable prices. With its help, internal walls, a ceiling with basement and interfloor ceilings, attics and attics under an insulated roof are vaporized.

- Izospan C (90 g / m2). Concrete floors are waterproofed with foil. The material is laid to protect the heat insulator on pitched roofs.

- Izospan D, DM (105 g / m2). Izospan D and DM are varieties of high strength material. DM brand has an anti-condensation surface. Izospan D, DM is designed for high loads. Izospan D and DM is primarily used for waterproofing flat or pitched roofs. The material is suitable for use as a temporary roof covering. Izospan D will also help to resolve issues with a concrete floor or basement floor, if structures require reliable protection from moisture.

- Izospan RS (84 g / m2), RM (100 g / m2). Like Izospan D, these types of films are characterized by high strength. In particular, it is achieved due to the three-layer structure of Izospan RS and RM - there is a polypropylene mesh in the middle. Application of Izospan RS and RM - arrangement of hydro and vapor barrier for ceilings, wall structures, floors, ceilings, for any type of roof.

The wide scope and technical characteristics of Izospan D, C, B, Izospan RS and RM materials make them the most demanded among all roll materials of the brand..

Izospan D, like other members of the group, has two outer layers with different functions. One of the surfaces is smooth, the other is rough and fibrous. The roughness of the outer side contributes to the properties of the material to retain and dissipate deposited steam and condensate over the surface, allowing it to evaporate quickly.

High-strength canvases (Izospan D, Izospan RS, RM) are treated with water-repellent compounds during the manufacturing process. The hydrophobic material is suitable for use as a waterproofing layer during the installation of earthen floors, cement screeds on concrete substrates in damp rooms.

When installing the vapor barrier, Izospan must be laid with a smooth surface to the insulating material... Depending on the operating conditions of the structure, it may be necessary to provide a ventilation gap of 40–50 mm to allow moisture to escape.

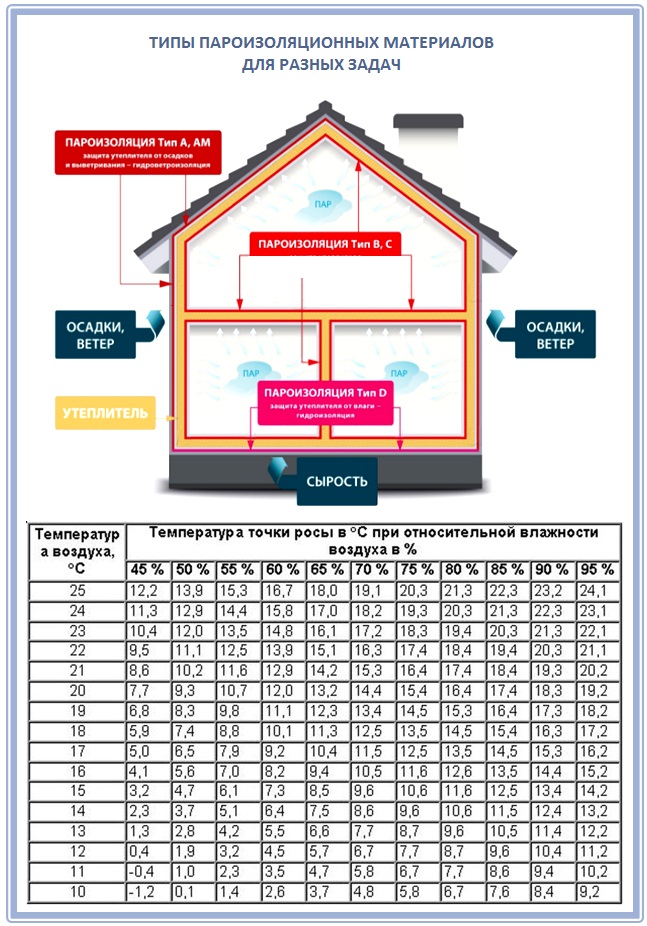

Vapor barrier types: A, B, C and D

To understand, after all, which side of the vapor barrier should be laid and why, for example, it suddenly turned out to have both sides smooth, you must first determine its type. After all, not every species has two different sides at all!

Insulation type A: only for steam outlet on the other side

For example, type A cannot be used as a roof vapor barrier because, as a result, all the vapors will end up in the insulation.After all, the main task of such isolation is precisely to provide them with an unobstructed passage, but not to let rainwater pass from the other side.

Such insulation is used in roofs with an angle of inclination of 35 °, so that water droplets can easily roll down and evaporate (and the ventilation gap between such insulation and the insulation helps them evaporate).

Vapor barrier B: classic double-sided installation

But B is a real vapor barrier material. The vapor barrier B has a two-layer structure, which avoids condensation, due to the fact that moisture is absorbed into its villi in the morning and disappears already during the day.

That is why type B vapor barrier is always laid with the smooth side to the insulation (film side), and the rough side outward. Vapor barrier B is used only in the insulated roof, because for non-insulated, it has too little strength.

Type C diaphragm: for enhanced protection against water vapor

Vapor barrier type C is a two-layer membrane of increased density. It differs significantly from type B in the thickness of the vapor barrier film. It is used in the same place as the type B vapor barrier, but in itself is more durable.

Additionally, such a vapor barrier is used in non-insulated roofs to protect the wooden elements of the attic floor and in flat roofs to enhance the protection of thermal insulation. Vapor barrier C must also be installed with the rough side inside the room.

Polypropylene insulation D: for heavy loads

The new-fashioned type D vapor barrier is an extra strong polypropylene fabric with a laminate on one side. This can withstand significant mechanical stress. It is used not only for insulating the attic floor as a waterproofing layer, but in the insulated roof to protect it from leaks. Moreover, type D vapor barrier is indispensable for rooms with particularly high humidity.

Here are the cases and where all these types of insulation are needed:

General installation rules

In order for the material to function as expected, it is important to study the instructions well before starting to work with it. Otherwise, it is easy to make mistakes when laying and, thus, there will be no sense from Izospan B, and the owner of the house will think that he has thrown money down the drain.

In order for the material to work as expected, the following rules must be observed during work:

- it is necessary to fasten the material from top to bottom when working on inclined or vertical structures;

- individual sheets of material are attached with an overlap of at least 15 cm;

- the joints between the canvases must be glued with special tape;

- Izospan B is laid in such a way that its fleecy side is turned towards the insulation;

- Izospan can be fixed using small bars, a stapler, clamping bars.

Izospan in the vapor barrier of the floor

What is it and how does it work?

The vapor-moisture insulating film is a barrier for water vapor entering the structure of the building from the inside of the room. The film counteracts the formation of condensate moisture on the heat insulator and structural elements, protects structures from the formation of mold fungi and thus increases the service life of the building.

The atmosphere of the room contains a decent amount of moisture, because in it people are engaged in cooking, washing in the shower, and so on. When the temperature outside is lower than in the building, the moist air will begin to "break" out.

When there is no vapor barrier in structures, moisture remains in the heat insulator. Excessive dampness leads to a decrease in the quality of the insulation. In addition, corrosion processes begin, which lead to sad consequences: wooden components become infected with fungus, and metal components are corroded by corrosion.The principle of operation of a vapor barrier film is based on the protection of insulated structural elements of the structure from the influence of water vapor.

Which side to put the vapor barrier

After the end of the installation of the insulation, vapor barrier work is carried out. Surprisingly, not all builders know which side to lay the vapor barrier film to the insulation. In this situation, what can we say about “home craftsmen”? There is a general rule - the film is always laid with the smooth side to the insulation layer, rough - inside the room (attic) or on the street.

But you don't have to bother at all - large manufacturers always supply each roll with instructions. And to make it clear where which side is, they put pictograms. The problem arises only if the film has already been cut from the roll and the instruction has fallen out. But here there is a simple solution: take a picture of the instruction from another similar roll with a smartphone.

How to distinguish the inside from the outside

Experienced professionals use other tips:

- the outer side is fleecy, the inner side is smooth. Easily identified by tactile, touch;

- with different colors of the sides, the lighter one fits into the insulation;

- when unrolling the roll, the inner side always faces the floor;

- the logo is always at the top;

- foil materials are stacked with foil towards themselves.

If there are no markings on the roll at all, then this is a vapor barrier film, not a membrane. It does not matter which side it is laid on, since it creates a barrier for steam in both directions in the same way.

How to check which film you purchased

When buying several types of film, sometimes it becomes necessary to find out what type it belongs to. For this, a piece of material is cut off, two glasses are taken (two circles). Boiling water is poured into one. The second glass is placed on the first, with hot water, previously covered with foil. If condensation does not appear on the walls, turn the film over and put the glass back.

A dry surface indicates type B - the classic type of vapor barrier. If the walls of the container are wet only once - type A, one-sided membrane. The appearance of condensation twice indicates that the film belongs to waterproofing materials and has nothing to do with vapor barrier.

Features of laying specific vapor barrier materials

Above are considered theoretical recommendations for the device of vapor protection. Many site visitors are interested in which side to put the vapor barrier of different classes or specific manufacturers:

- "Izospan AM" - is laid with the brown (dark) side outward, white to the insulation;

- "Izospan V" - the smooth side should fit snugly to the insulation, the rough coating should look inside the room;

- plastic wrap is stacked on either side;

- foil-clad reflective vapor barrier ("Penofol") is mounted with the metallized side inside the room (baths, steam rooms, saunas);

- the membranes are laid in accordance with the pictogram printed on their seamy side;

- polypropylene with a one-sided lavsan coating with a smooth side is stacked to the insulation, wicker - inside the room;

- foil films in rooms with a standard temperature regime are laid with the metallized side to the insulation.

What happens if you put it on the wrong side

Among experts to this day there is no single point of view on the processes taking place inside the insulation when laying the vapor barrier material on the wrong side.

Some believe that condensation will begin to form not outside the film, but in the insulation, causing destructive processes in it, others - nothing terrible has happened and it is not worth running to redo the thermal insulation carried out if a mistake was made.

There is generally an original explanation for the rough side - this is the result of joining two strips of vapor barrier film during the production process.It is easier to glue to such a surface, and it costs money to additionally grind the other side. To explain to the buyers such a technological technique, a fairy tale about different sides of the film with different functions was invented.

If we take anti-condensation protection as a basis, then those who claim that nothing terrible will happen are right. But here, the parties in dispute are missing an important point. The film is called windproof. And here there is a very big difference in how it is laid.

To make it easier to understand what we are talking about, you need to conduct a simple experiment: take a fabric with a pile on one side and alternately on each side, putting it tightly to your mouth, blow through it. There will be practically no resistance from the smooth side, since the villi flutter freely in the wind. From the side of the pile, everything is not so simple. You will have to make an effort, since the villi, pressing against the fabric, clog the pores through which air passes.

A simple experiment shows that it is still worth following the recommendations of the manufacturers.