Classification of facing bricks

The gradation of the facade cladding is determined by the technology of its manufacture.

There are four categories of facing bricks:

- Ceramic.

- Clinker.

- Hyper-pressed (concrete).

- Silicate.

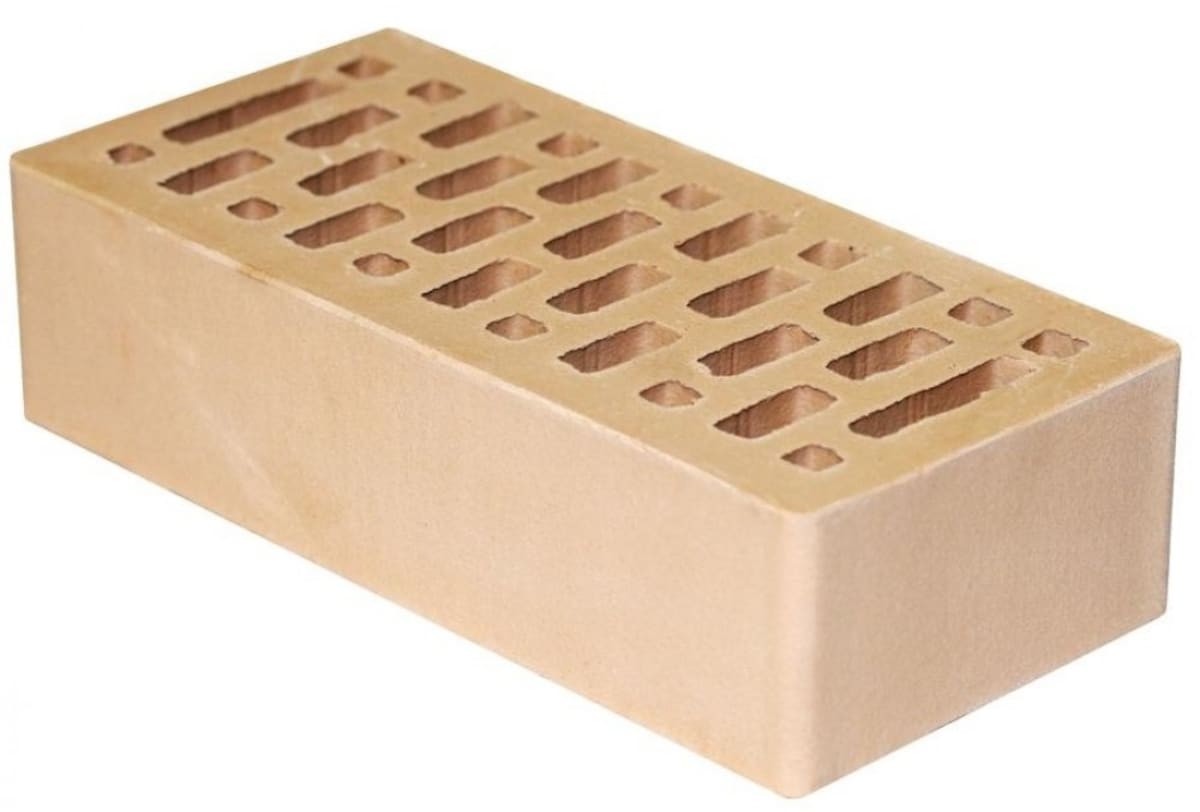

Brick in each of the listed categories is available in two versions: solid and hollow. The weight of hollow bricks is on average 25-35% less, and its resistance to heat loss is about 10-15% higher.

Ceramic cladding brick

It is produced by firing a raw mixture consisting of red low-melting clay, organic and mineral additives that regulate plasticity. In this capacity, coal dust, slag, chamotte, sawdust, ash and quartz sand are used. The initial mixture successively goes through the processes of forming, drying and firing. The main difference between facing ceramic bricks and ordinary ones is the thorough preparation of the components before molding. Therefore, there are no foreign inclusions and cracks in it.

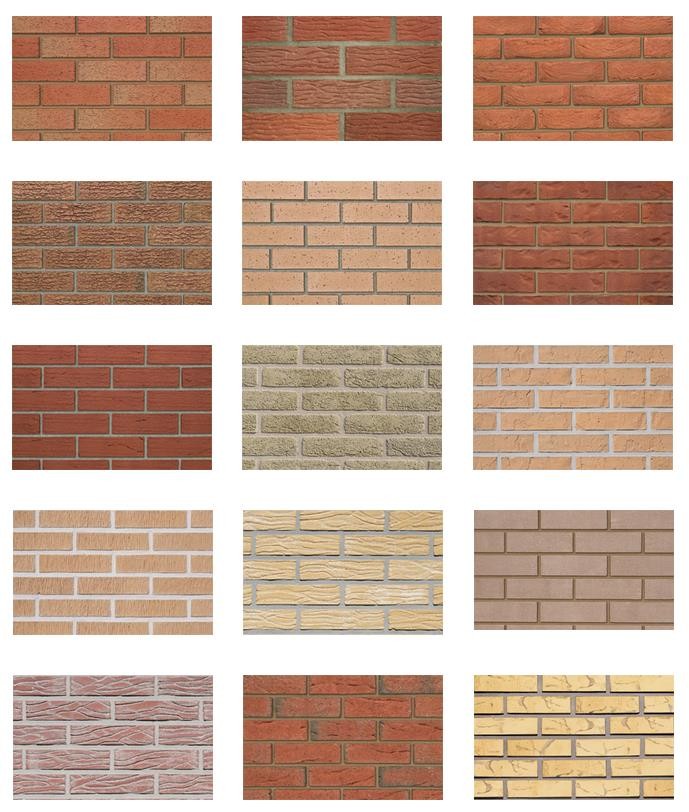

The material obtained at the exit from the firing chamber is characterized by resistance to moisture, high strength and good energy-saving properties. Types and colors of ceramic facing bricks are varied.

On sale you can find not only ordinary, but also shaped material (for laying complex architectural elements). To expand the color gamut, manufacturers use mineral dyes (chromium oxide, finely ground iron or manganese ore), adding them to the composition of the feedstock.

Decorating the surface of ceramic bricks is performed in several ways. In addition to the smooth matte and glossy surface, there are available finishes that give this material a similarity to wild stone.

Clinker brick

The closest "relative" of ceramic bricks. The main difference between the two is the feedstock and the firing temperature. For the production of clinker, medium and refractory clays are used. Accordingly, they are fired at a higher temperature. The result is a very dense and durable facing brick with minimal water absorption. These qualities make it possible to use it not only in the decoration of the facade, but also for the cladding of the basement of the foundation, the construction of fences and the paving of paths.

The thermal conductivity of clinker stone is higher than that of ceramic. This disadvantage is compensated for by its high resistance to cracking at low temperatures.

The color palette and texture of clinker stone are extremely diverse, since each manufacturer offers its customers its own collections. The size range of this cladding is also not boring. In addition to the standard single version 250x120x65 mm, you can buy bricks of reduced thickness and height, as well as long clinker (528x108x37 mm).

Hyper pressed brick

Firing clay is an energy-intensive and not very cost-effective process. Therefore, many manufacturers are switching to pressed fired bricks. Its basis is granite screening, water and cement. At its core, it is super-dense concrete that has been shaped into masonry bricks.

The main requirement for facade finishing is weather resistance. According to this indicator, hyper-pressed brick is perfect for finishing external walls.

In terms of strength and other quality characteristics, it is practically not inferior to clinker. Due to the texture of the surface (like a rock, torn stone) and the use of persistent dyes, this material looks great in masonry.

Facade decoration with hyper-pressed bricks looks elegant, solid and reliable

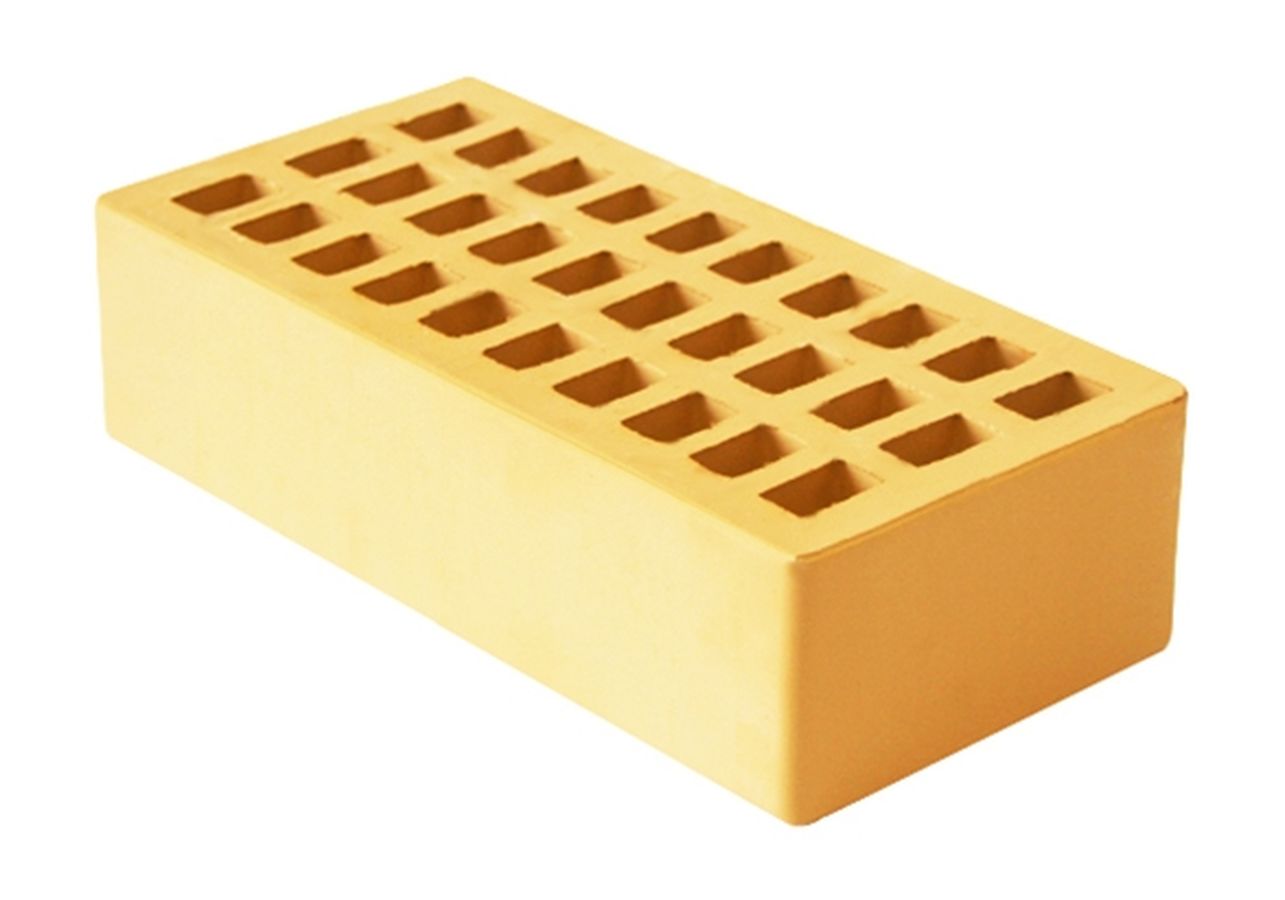

Silicate brick

Belongs to the category of non-firing materials. It differs from hyper-pressed brick in its raw material composition.There is no cement in it. High mechanical strength is achieved here due to the hardening of a mixture of silicate sand and hydrated lime in an autoclave installation (elevated temperature and pressure).

Nowadays, silicate facade brick as a facing material is losing its former popularity. In the struggle for a buyer, manufacturers have developed several color options for the silicate mixture. Unfortunately, they all look rather pale and cannot compete with the rich colors of ceramics and clinker.

This material behaves well in the facing of the building. Compared to clinker bricks, it absorbs moisture more strongly, but at the same time better than ceramics withstands repeated soaking, freezing and thawing.

Figured (shaped) brick

Today, no one is satisfied with the straight lines of the facade, therefore, each type of facing brick is complemented by a wide range of shaped elements. Using them, you can lay out complex architectural elements without time-consuming cutting and cutting, dressing up the house in a beautiful "stone lace".

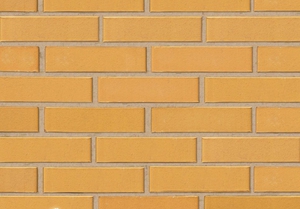

Characteristics of yellow bricks: what to look for?

Composition and properties

The brick is made in standard sizes and yellow in color. Quality material is made from several types of raw materials: a mixture of limestone, cement and iron oxide. The result is a light yellow tint. These ingredients are pressed into a mold and dried. This material is called silicate. Yellow ceramic bricks are made from dye and clay. This type is popular for large houses. Clay, which does not lend itself to melting, produces a yellow clinker building material. Clinker is a fireproof and waterproof construction resource. Country houses are built from it, because the clinker material is frost-resistant. So, because of the chamotte in the composition, they called the yellow chamotte brick. It has a rough surface and a variety of shapes.

Varieties of yellow facing bricks

- Corpulent. Facades and internal walls are made of it.

- Hollow. The demand for it is much greater, because it has thermal insulation properties. During construction, the size of the material plays a role.

The hollow view of the product is divided into two types, more about which in the table:

| Name | Dimensions (edit) |

| Single | 200×100×60 |

| One and a half | 200×100×82 |

In practice, builders buy a one and a half view, because much less of it is needed for construction. The meaning is given by the form of the building material. They are:

- rectangular, which are used for external walls or internal partitions;

- curly - for openings of windows, arches or supports.

Other products are divided according to the type of surface, which happens:

- Smooth. Provides an attractive look outside and inside the home.

- Corrugated. Needed to create an unusual appearance and non-standard.

- Decorative. It is decorated with drawings and used in the interior of the house.

Popular types of ceramic products

- Facing (facing brick and front). Durable, mechanically stable. There are dark and light bricks.

- Glazed. It is characterized by a glaze finish, ease of maintenance and a long service life.

- Double layer type. A clay layer is applied to the workpiece, which can be fired. This creates twice the strong protection of the product.

- Engobed. The basis is a high-strength clay mixture. Such a product does not lend itself to external influences.

Silicate varieties of building materials

For their production use:

- lime;

- quartz sand;

- plasticizers;

- additives.

Such a composition ensures safety and testifies to the environmental friendliness of the material.

One-and-a-half (silicate) yellow brick is made from 10 percent lime and 90 percent sand and is exposed to steam and high temperature processing. This method is called autoclave. Products from this material get their own color depending on what dyes were used. As a result, the shades of bricks can be very different.

There are 2 types of silicate brick products for facade decoration:

- Double. Provides high thermal insulation;

- Front with a decorative surface. Provides excellent appearance.

A significant feature of the finishing with silicate products is that they do not tolerate high humidity and exposure to low temperatures. Therefore, this option will not be relevant to every territory of our country. For example, in the northern regions, as well as those that are characterized by a high location of groundwater, this type of finishing material is completely unsuitable. There it is more expedient to choose a ceramic analogue. Here it is, under the same conditions, and will provide the same properties as silicate building material, and will last much longer. That is, the best solution for them is a ceramic one-and-a-half brick.

A significant feature of the finishing with silicate products is that they do not tolerate high humidity and exposure to low temperatures. Therefore, this option will not be relevant to every territory of our country. For example, in the northern regions, as well as those that are characterized by a high location of groundwater, this type of finishing material is completely unsuitable. There it is more expedient to choose a ceramic analogue. Here it is, under the same conditions, and will provide the same properties as silicate building material, and will last much longer. That is, the best solution for them is a ceramic one-and-a-half brick.

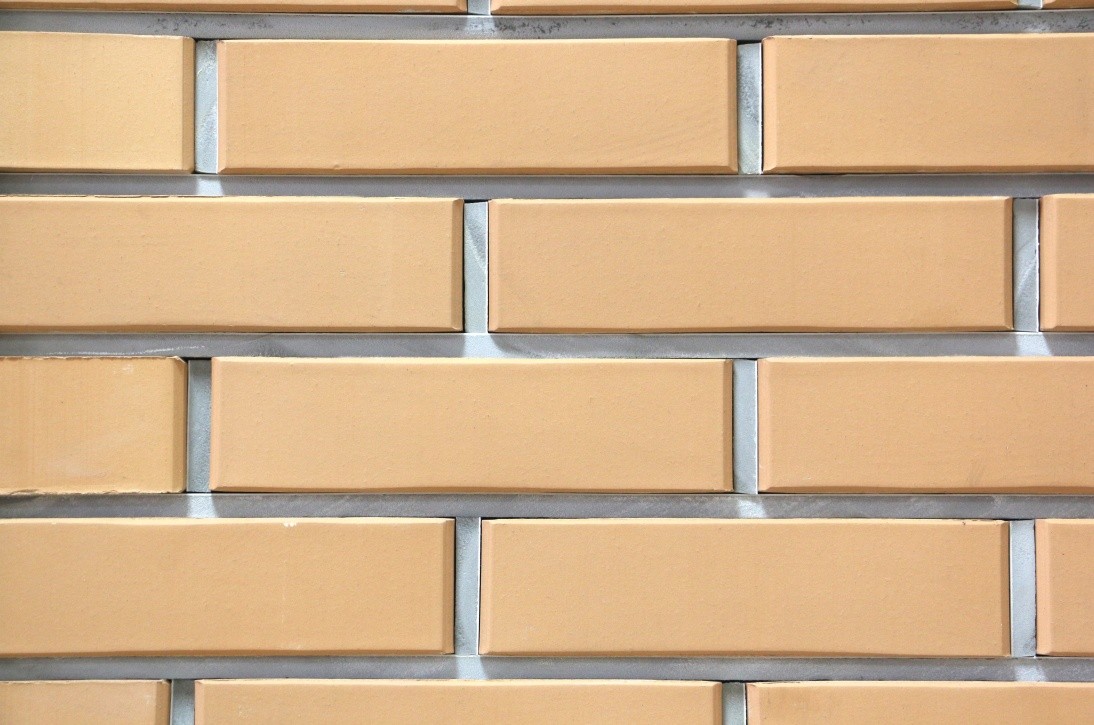

Peculiarities

Facing brick is a versatile finishing material that allows you to hide flaws in the brickwork of load-bearing walls, additionally insulate the facade and give the building a spectacular and noble look. The house, faced with decorative bricks, becomes the center of attention and looks very presentable. The main difference between the face stone and ordinary silicate or ceramic products is the surface texture, color scale and composition.

High consumer demand for facing material is due to a number of its indisputable advantages. Among them, one can single out the high decorative properties of bricks, which is explained by a wide color palette and a wide variety of shapes, textures and designs. In addition, the lined surface significantly reduces the heat loss of the premises and does not allow extraneous noise from the street to penetrate inside.

The advantages include the high thermal stability of most models, as well as their ability to withstand sudden temperature changes. The brick-lined facade tolerates high humidity conditions and is not afraid of frequent and prolonged precipitation. Due to the high resistance of the facing stone to aggressive environmental conditions, the material can be used in any climatic zone, including areas with a sharply continental climate and northern territories.

However, along with numerous advantages, the material has a number of disadvantages. The disadvantages include the risk of excessive load on the foundation, the high cost of some types and the need to use expensive adhesive mixtures for facing. The scope of use of facing bricks is quite extensive. In addition to cladding the basement and the facade, the material is actively used in the construction of fences and columns, as well as for finishing small architectural forms: arches, gazebos and garden and park fences.

All facing stone is available in 2 versions: solid and hollow. Hollow models weigh 30% less than their solid counterparts and are distinguished by higher thermal insulation characteristics and a low price. The use of hollow bricks increases the heat-saving properties of the cladding by 15% in comparison with the use of solid products. Therefore, when using full-bodied models as a finish, the necessary measures should be taken to additional insulation of the facade.

About the size of facing bricks

The most commonly used bricks are single size. Their long part is 25 cm in size, and the other two sizes are 12 and 6.5 cm. One and a half bricks are thicker - instead of 6.5 centimeters, this parameter is 8.8 cm for them. There are also double products in which the thickness reaches 13.8 cm. These are all domestic measurements.

If we talk about European standards, then they mainly use bricks of slightly different dimensions: 24 cm long, 11.5 cm wide and 7.1 cm thick.

For Americans, too, everything is in its own way: 25 by 6 by 6.5 cm or 24 by 6 by 7.1 cm (the latter option refers to clinker, it is often made in Europe using NF - German standards).

Pros and cons of brick cladding

Now let's see why so many developers prefer brick cladding.

Let's consider the main advantages:

- High indicators of strength and density of products;

- Relatively low coefficient of thermal conductivity;

- Small percentage of water absorption;

- Frost resistance of products can reach 300 cycles (for clinker bricks);

- External characteristics;

- For ceramic products - extremely wide architectural possibilities;

- A wide range of choice in shapes, sizes, colors and shades;

- Sound insulation and vapor permeability characteristics;

- Non-flammability and relative environmental friendliness of products;

- The durability of brick-faced buildings is noticeably increased;

- Ability to withstand atmospheric and biological influences.

There are also disadvantages.

These include:

- For the most part, the high cost of products;

- Heavy load on the foundation;

- Low masonry speed due to small dimensions;

- The complexity of installation, the need, in most cases, to attract specialists, which undoubtedly portends additional costs;

- Efflorescence may appear on ceramic bricks;

- Products can crumble and crumble.

Facing bricks do not have more significant disadvantages.

Dimensions (edit)

The dimensions of each type of facing brick are strictly stipulated by the norms of the state standard and are always spelled out in the accompanying documentation. This greatly facilitates the calculation and acquisition of the required amount of material. The norms of a single standard were determined in the first half of the last century, namely in 1927, and have remained unchanged since then. The standard applies to both ordinary construction and front models, and has the following meanings: the dimensions of a silicate and ceramic single stone are 250x120x65 mm, double - 250x120x138, thickened or one-and-a-half - 250x120x88 mm.

However, GOST also provides for non-standard options, the most popular of which are narrow 0.7NF marking products, the size of which is 250x85x65 mm. The one-and-a-half version of such specimens has dimensions of 250x85x88 mm. These products are used in the restoration of old buildings, allowing to significantly reduce the load on their foundations. The dimensions of clinker bricks are somewhat different from the size of silicate and ceramic, and in addition to the standard 250x120x65, they have options 250x90x65 and 250x60x65 mm. As you can see, only the height of the product changes, while the length and width remain the same. An exception is the elongated model with dimensions of 528x108x37 mm, which is more than twice as long as the base versions.

Non-fired hyper-pressed bricks are also available in four standard sizes: 250x120x65, 250x90x65, 250x60x65 and 250x120x88 mm. In addition to the Russian GOST, the European standard is widely represented on the market, in which there are 2 categories: NF and DF. The NF index denotes products of the traditional format measuring 240x115x71 mm, while DF includes thin models corresponding to the architectural classics with dimensions of 240x115x52 mm. In order to avoid problems with the bandaging of the seams when facing the facade, it is recommended to purchase products of only one of the standards.

Standardization of dimensions allows you to calculate the required amount of material for facing a certain area, as well as calculate the weight of the facing. So, to finish one square of the surface, 61 single (25x12x6.5 cm), 45 one-and-a-half (25x12x8.8 cm) and 30 double bricks with a size of 25x12x13.8 cm will be required.However, these calculations are given without taking into account the seams. Taking them into account, the required number of products will look like 51, 39 and 26 pieces, respectively.

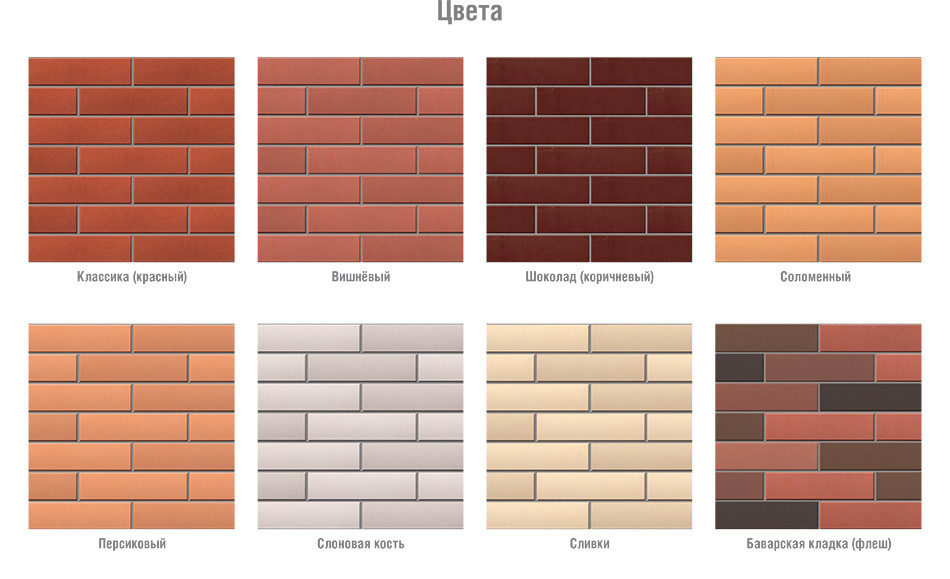

Color scheme and choice of material shape

Modern manufacturers produce front building materials in various colors - classic red, gray, white, brown, yellow.In addition, there are many shades of building material, which allows a person to choose the most appropriate option for himself. Before finishing work, you need to take into account the color of the seam, which should be combined with the stone. When choosing a red finishing material, white, red, brown, black joint mixtures are used.

When designing the facade of a building, it is better to pay attention to the shape of the brick. Most often, a rectangular building material is used for work, and it is desirable that the bars are the same

It is recommended to give preference to building material without chips, as they can lead to a violation of the geometry of the structure.

If the walls have a perfectly flat surface, then you can give preference to thin brick, which is similar in shape to ceramic tiles. In order for the window to have an interesting design and stand out, you can use building material of an unusual shape. For facing corners, brick with rounded or sharp edges is used.

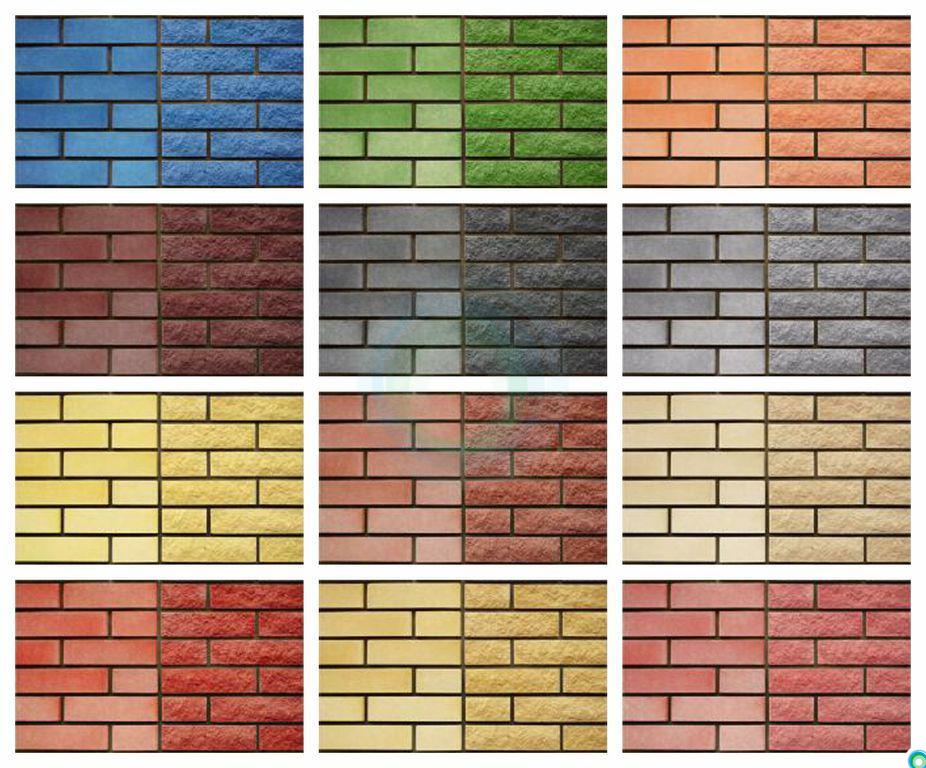

Facing bricks in other colors

For any facing material, its decorative effect is a priority, which is considered first of all. Further, the characteristics of the product and other parameters are taken into account, and therefore manufacturers over time expand the range of their products and produce bricks not only of yellow color, but also of other shades. The color of the product is primarily influenced by the type of clay and the amount of iron in its composition.

If necessary, a pigment can be used in the production, with the help of which the composition is painted in the desired color. The firing method also plays a significant role, which is why the similarity of the shades of stones, depending on the production batch, mainly depends.

In addition to the yellow shades of this material, peach or apricot colors are popular. These shades are warm and look good. With professional work, as well as the correct combination of bricks of different colors, you can create patterns or combinations that will decorate and make any structure unusual. And also with bricks of a different color, you can trim certain elements on the facade, for example, window or door openings.

The peach color is ideal for decorating single-storey buildings, in addition, it is effectively used and emphasizes the practicality of multi-storey buildings. Therefore, today everyone can choose the color of the brick and its type that will best suit the conditions of its use.

When such material is purchased from the sellers or dealers of the manufacturing plant, you must first check the quality certificates and make sure that these products are manufactured in the factory, meet all the specified parameters. In this case, you can be sure that the brick will stand for many years and will not lose its characteristics.

For practical advice on laying and choosing bricks, see the video.

Let’s block ads! (Why?)

Brick cost for cladding

The prices for facing bricks depend on its size, quality and the required quantity.

The prices for facing bricks depend on its size, quality and the required quantity.

When choosing a building material, its cost is of great importance. It is determined by a number of factors, from size to the amount of material required. All buyers are interested in choosing various options at the best price.

The façade is dark, brown or straw in color and does not differ in its characteristics from the yellow version. In any case, the choice remains with the owner of the house.

It is important that the new cladding retains its original appearance for a long time.

Types of colors of facing bricks

When choosing a shade for finishing the facade of a house, they look at the range of windows, doors, roof and other elements. The choice of color also depends on the size and shape of the building.

So, if the cladding area is small, then the eye is able to see fewer color tones of the brick.Many of them will seem dimmer and paler than they really are. Therefore, when decorating small details, choose brighter colors, so that they play properly.

If you want to see in all its glory some not very bright or darkish tone, then use a sufficient area. Let's say you lay out an entire large wall with such a brick. Keep in mind that very dark colors are often perceived as solid blacks.

Also, remember about the combination of colors when they are around. Together they look different than alone.

If their brightness is approximately equal, then they can change tones (this is important in a Bavarian-type masonry). This effect is especially noticeable when framing one color with another.

But on the border, the opposite is noticeable: the colors acquire a saturated edge (dark - dark, light - light), as if trying to isolate themselves from each other.

Colors of facing ceramic and clinker ceramic bricks

The range of colors for these products is extensive, but even one color can vary in shades by batch. After all, the resulting color depends on the firing, as well as on the presence of certain impurities (usually metallic). For example, iron gives redness. The more it is, the brighter the brick.

And if the cladding is carried out, in turn using products from different batches, then not very aesthetic multi-colored groups of bricks may turn out on the walls. Experienced bricklayers, however, figured out how to cope with this: they take bricks from one batch, then from another, then from a third. As a result, the wall comes out with a uniform color - the color differences are small and not striking.

And a number of manufacturers also decided to help consumers by releasing packs of bricks, the color of which is different. Moreover, sometimes even the surface of individual parts has smooth transitions of shades. All of the above features are the norm for this type of brick.

So that you can appreciate all the color features of ceramic facing bricks, below we give a photo of not individual bricks, but masonry made of certain colors of ceramic bricks:

Hyper-pressed brick colors

There is no firing here, so the color pigment added to the molding mass sets the tone for the products. Thanks to this fact, all the bricks are painted exactly over the entire volume, and the batches do not differ in scale from each other. However, the added cement, with its dirty gray color, reduces the brightness of the products. They can always be distinguished from clinker and ceramic bricks by their slightly grayish tint - the so-called "concrete".

Photo of facing hyper-pressed brick and its color:

White.

Black.

Pistachio.

Brown.

Red.

Peach.

Gray.

Chocolate.

Blue.

Ivory.

Straw.

Terracotta.

Green.

Colors of silicate facing bricks

The easiest way is to paint such a brick throughout the mass, for which the dye is added to the mixer container, where the mixture is prepared. To measure out the required amount of paint, use a dispenser

It is important not to overdo it here: too much paint will be expensive and can lead to a deterioration in strength. And if you put a little dye, then the products will turn out pale and ugly

Sometimes, in order to save money, only the front layer is stained on both sides.

The main colors in which silicate bricks are painted are presented below:

The main properties of the product and its application

Yellow facing brick - types and properties

Yellow silicate facing brick is made of lime-sand mixture and has high strength characteristics, correct geometry, neat texture. The product is also endowed with soundproofing properties and is made in a wide range of colors.

There are two types of products: solid and hollow bricks. The characteristics that determine the specific feature are present in each of them.But there are basic properties inherent in all types of cladding, among them frost resistance, moisture absorption, self-cleaning, resistance to decay and durability.

The long service life of the building material allows you to save money in the future on reconstruction and repair of structures. The high cost of yellow facing bricks on the market is fully justified by its performance characteristics.

Solid yellow brick has high strength due to the absence of voids. It is used for the construction of load-bearing walls and partitions, massive supporting structures. In addition, the product has exceptional thermal insulation properties.

The advantage of hollow bricks is its lightness and low thermal conductivity. Thanks to these qualities, the material is very popular in the decoration of facades and exterior elements.

The building material is used not only for facade cladding. Yellow ceramic facing brick is used for the construction of fences and fences, finishing loggias, balconies, verandas, decorating door and window openings. The product is perfectly combined with various materials, therefore it is often used in textured masonry and when creating original compositions.

Varieties in shape

The shape of the products and the texture of the surface affect the resulting design of buildings or objects. Distinguish between shaped and textured appearance.

Shaped (figured) brick is made in special shapes and can have rounded parts, trapezoidal, wedge shape. It is used when decorating walls around window or doorways, for laying out arched transitions. Twisted shaped bricks are used to build original columns and pillars.

Textured the appearance can have completely smooth sanded surfaces or edges without processing (torn surfaces). The most popular variety is considered to be facade bricks with rolled surfaces: they are given the texture of a stone through a larger protrusion of the central part and uneven transitions along the perimeter of the edge. Based on the photo of textured brick, you can choose the type that is suitable for the restoration of old buildings or stylish decoration of new buildings.