Types of white bricks and sizes

There are quite a few varieties of white bricks, they can differ in size, appearance, weight, this often determines their purpose.

Types of white bricks

There are two main varieties - decorative bricks and work bricks. The worker has only white color and is more often intended for the construction of walls and interior partitions of the house. The walls of the house laid out of it, in order to give a more interesting design, need a decorative coating. At the same time, many owners of private houses built of white brick often leave its outer walls uncovered. After all, even, smooth white rectangles do not look so bad.

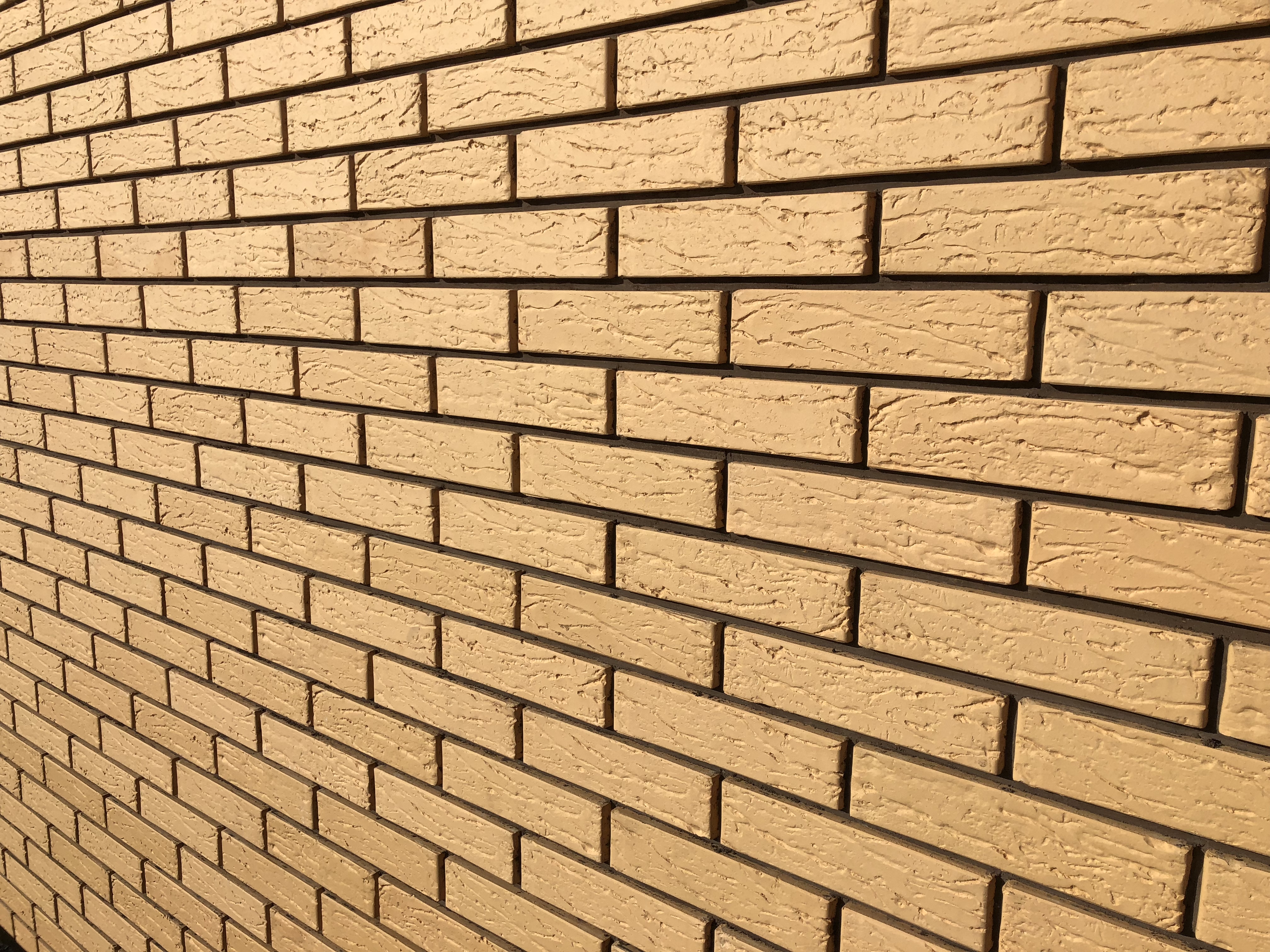

But decorative (facing), it is also called "Eurobrick", has a more interesting appearance. Its dimensions are somewhat smaller, and the colors and shapes are diverse.

White cladding brick photo

In addition, there are also special bricks that speed up and simplify the laying of walls - these are half and quarter bricks. And also the types intended for laying out arches - end wedge, rib wedge.

White brick can be divided into types depending on the size and structure.

Dimensions of white brick

The size of white bricks for laying out walls can vary significantly, there are:

- Ordinary

- One and a half

- Double brick

All the difference between them is in height, dimensions of a standard brick 250х125х65 mm

... One-and-a-half and double bricks have the same width and length, but the heights are 88 and 138 mm. Thanks to such dimensions, the laying out of walls can be 1.5 and twice as fast.

White brick weight

Silicate weight bricks above red - one solid brick the standard size weighs 3.7 kg, which is quite a lot, it is for this reason that hollow white bricks are used for the construction of three-story and taller buildings. This significantly reduces the pressure on the foundation as it has a lower mass. And all thanks to the special holes in the cavity. This not only reduces weight, but also partially compensates for heat loss. Such a brick is also divided into types, or rather into classes, depending on the volume of voids. There are three of them: a brick with a void volume of 15% of the total mass, with a volume of 23-26% and a class with a void volume of 29-32%.

Hollow white brick photo

White brick can be of different quality, remember, the better the brick, the more reliable the walls of the house! Therefore, when buying, you should ask the seller for a specification for the product, it is in it that the technical parameters of the product are indicated. It is enough to compare them with those recommended for construction and you can draw conclusions whether it suits you or not. Also, the quality can be determined by the amount of battle - the more there is, the correspondingly lower the quality.

In conclusion, we offer a small photo gallery on the topic of the article.

Peculiarities

Facing brick is a versatile finishing material that allows you to hide flaws in the brickwork of load-bearing walls, additionally insulate the facade and give the building a spectacular and noble look. The house, faced with decorative bricks, becomes the center of attention and looks very presentable. The main difference between the face stone and ordinary silicate or ceramic products is the surface texture, color scale and composition.

High consumer demand for facing material is due to a number of its indisputable advantages. Among them, one can single out the high decorative properties of bricks, which is explained by a wide color palette and a wide variety of shapes, textures and designs. In addition, the lined surface significantly reduces the heat loss of the premises and does not allow extraneous noise from the street to penetrate inside.

The advantages include the high thermal stability of most models, as well as their ability to withstand sudden temperature changes.The brick-lined facade tolerates high humidity conditions and is not afraid of frequent and prolonged precipitation. Due to the high resistance of the facing stone to aggressive environmental conditions, the material can be used in any climatic zone, including areas with a sharply continental climate and northern territories.

However, along with numerous advantages, the material has a number of disadvantages. The disadvantages include the risk of excessive load on the foundation, the high cost of some types and the need to use expensive adhesive mixtures for facing. The scope of use of facing bricks is quite extensive. In addition to cladding the basement and the facade, the material is actively used in the construction of fences and columns, as well as for finishing small architectural forms: arches, gazebos and garden and park fences.

All facing stone is available in 2 versions: solid and hollow. Hollow models weigh 30% less than their solid counterparts and are distinguished by higher thermal insulation characteristics and a low price. The use of hollow bricks increases the heat-saving properties of the cladding by 15% in comparison with the use of solid products. Therefore, when using full-bodied models as a finish, the necessary measures should be taken to additional insulation of the facade.

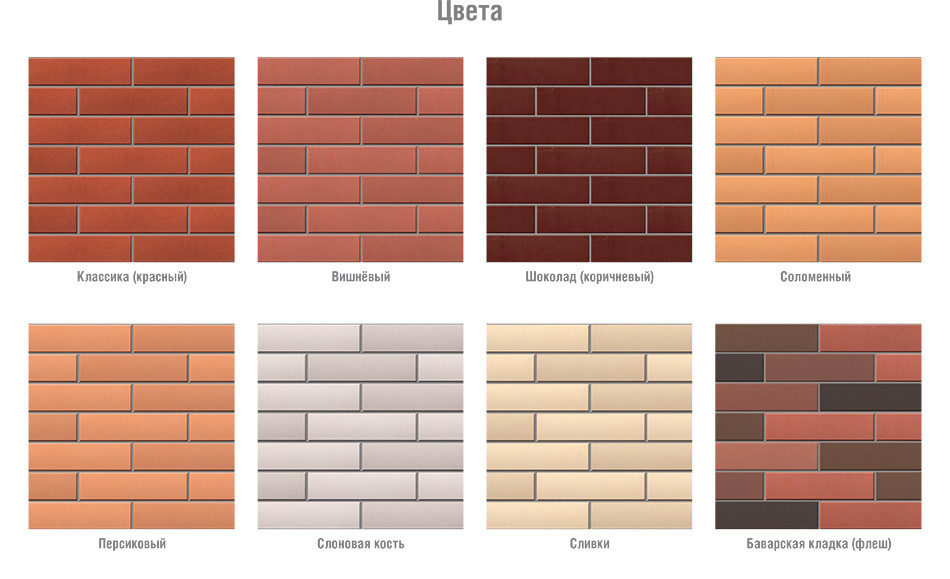

Color palette

The modern market of facing materials presents a huge number of brick colors. Ceramic models are presented mainly in red and brown tones, but the variety of their shades is so huge that it will not be difficult to choose a material for every taste. But despite the great variety of color solutions, many consumers prefer natural, without the use of dyes and pigments, clay color.

However, when choosing products in natural colors, you need to be very careful. Bricks of different batches often differ from each other, which is very noticeable on the facade and spoils its appearance. The difference in color is due to the quality and ratio of the additives used when kneading the clays, as well as a violation of the firing technology.

Hyper-pressed bricks have perhaps the widest color palette. The material is painted in the desired colors by adding dyes and pigments. This technology makes it possible to achieve the same uniform color throughout the volume of the brick, and, subject to the necessary proportions of the coloring components, makes the products of different batches absolutely indistinguishable in color.

Sand-lime brick is painted according to the same principle as concrete. Pigment or dye is added using a special dispenser during kneading. However, it should be noted that colored brick is somewhat inferior in strength to unpainted silicate. This is due to the significant proportion of paint in the total volume of raw materials, and in order to avoid a decrease in the performance of the material, many manufacturers paint only one of its sides. The most popular colors of sand-lime bricks are white, yellow and pink.

Something about the color wheel, or what colors brown is most in harmony with

Naturally, the choice of color for the exterior of a private house is entirely determined by the tastes and habits of its owners. Nevertheless, we must not forget about the fundamental rules for choosing the color of facing bricks. The colors that are next to each other on the color wheel are perceived best. The exception is white - it is not by chance that it is not there, since such a color does not exist in nature.

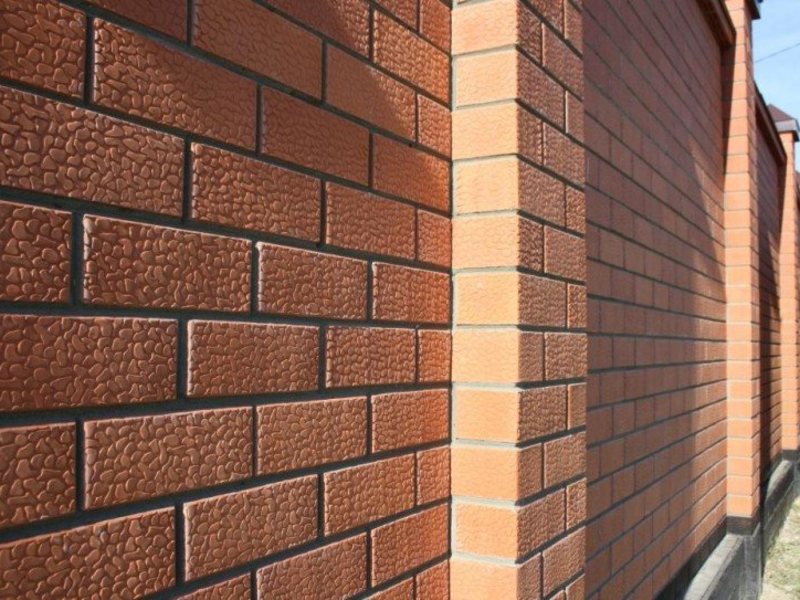

Even Newton proved that white is obtained by adding all the colors of the spectrum. Therefore, this color is the most friendly and in perfect harmony with all the colors of the color wheel. In particular, a white brick house with brown brick in the photo is a great way to highlight its individual parts without experiencing any visual discomfort.

As the individual colors of the spectrum approach each other, the organic appearance of the house increases. This can, for example, look like a house made of red and brown bricks. Beautiful projects are also considered to be those where the color scheme of the exterior is sustained in the appropriate color scheme. Therefore, houses made of yellow and brown bricks in the photo will look organic, and a combination of brown and pink shades will look much less balanced.

Skeptics believe that brown facing brick houses are quite monotonous and cannot be adequately perceived, even despite the obvious design decisions in the exterior. They should object: the variegation of the facade is never a sign of good taste.

The project of a brown brick house can benefit not only due to the color scheme of its individual fragments, but also due to the variety of the building's decor and the methods of laying facing bricks. That is why beautiful house designs are so popular, in the external design of which, along with brown, there are also white, red, yellow and other colors that organically complement the main one.

Ways to diversify the exterior of a house under construction

In addition to justified color options for finishing, you can also increase the level of visual perception by other means. For example, use joining in a color contrasting to the main one. For example, a plain brown facade, but with white seams, will immediately dramatically change the look of the house. Decorative bricks generally look very good with yellow or white seams.

The opposite option is much less common: white or yellow brick with dark (for example, red) seams. But this is already a tribute to expediency and durability, since all visible defects that may form over time on a white or yellow background will be much more noticeable. Brown facing brick with white jointing is a much more acceptable decor option.

You can also diversify the exterior of a brown brick house by the reasonable presence of embossed masonry sections on the facade. This method, however, is less popular for the following reasons:

- The complexity of maintenance of the facade increases, which must be periodically cleaned of external contamination.

- The labor intensity of the masonry increases.

- Not always in the assortment of building supermarkets there is a brick of the required texture.

Beautiful projects of houses using facing decorative bricks of brown colors and shades also have a purely pragmatic basis: such a material has good thermal insulation properties. Therefore, it will be more comfortable to live in such a house.

An example of calculations of the required amount of material

Let's calculate the required amount of bricks, provided that the perimeter of the house is 20, and the height of the walls is 3 meters.

When calculating, it is worth considering:

- The thickness of the masonry mortar (horizontal and vertical seam);

- The size of the product itself;

- Laying method (in a brick floor, in 1 brick, in 1.5, in 2).

Suppose that the thickness of the seam will be 10 mm both horizontally and vertically; the brick will have a size of 250 * 120 * 65; laying will be done in half a brick.

Calculation of brick facades, with such initial data, will look like this:

- The area of the brick is 0.25 * 0.065 = 0.01625 m2.

- The area of all walls is - 20 * 3 = 60m2

- We will need 60 / 0.01625 = 3692 pieces of bricks without taking into account openings, doors and seams.

To calculate the final result, we must subtract the above.

Dimensions (edit)

The dimensions of each type of facing brick are strictly stipulated by the norms of the state standard and are always spelled out in the accompanying documentation. This greatly facilitates the calculation and acquisition of the required amount of material. The norms of a single standard were determined in the first half of the last century, namely in 1927, and have remained unchanged since then.The standard applies to both ordinary construction and front models, and has the following meanings: the dimensions of a silicate and ceramic single stone are 250x120x65 mm, double - 250x120x138, thickened or one-and-a-half - 250x120x88 mm.

However, GOST also provides for non-standard options, the most popular of which are narrow 0.7NF marking products, the size of which is 250x85x65 mm. The one-and-a-half version of such specimens has dimensions of 250x85x88 mm. These products are used in the restoration of old buildings, allowing to significantly reduce the load on their foundations. The dimensions of clinker bricks are somewhat different from the size of silicate and ceramic, and in addition to the standard 250x120x65, they have options 250x90x65 and 250x60x65 mm. As you can see, only the height of the product changes, while the length and width remain the same. An exception is the elongated model with dimensions of 528x108x37 mm, which is more than twice as long as the base versions.

Fired hyper-pressed bricks are also available in four standard sizes: 250x120x65, 250x90x65, 250x60x65 and 250x120x88 mm. In addition to the Russian GOST, the European standard is widely represented on the market, in which there are 2 categories: NF and DF. The NF index denotes products of the traditional format measuring 240x115x71 mm, while the DF includes slim models corresponding to the architectural classics with dimensions of 240x115x52 mm. In order to avoid problems with bandaging the seams when facing the facade, it is recommended to purchase products of only one of the standards.

Standardization of dimensions allows you to calculate the required amount of material for facing a certain area, as well as calculate the weight of the facing. So, to finish one square of the surface, 61 single (25x12x6.5 cm), 45 one-and-a-half (25x12x8.8 cm) and 30 double bricks with a size of 25x12x13.8 cm will be required.However, these calculations are given without taking into account the seams. Taking them into account, the required number of products will look like 51, 39 and 26 pieces, respectively.

Scope of use

Such a brick can be used for laying external and internal walls, but due to its high cost, it is advisable to use the material in the place where it is necessary to obtain a decorative beautiful surface. So, hollow cladding brick can be applied:

- for facing the facades of buildings;

- as a decor in the interior of premises (for facing fragments of walls, fireplace);

- frames of window and door openings are made from it;

- arches and columns are decorated with such bricks;

- the material is suitable for arranging a beautiful and respectable fence of a country house;

- a gazebo, barbecue or shed using this brick will acquire an expensive and elegant look;

- with the help of facing bricks, you can hide façade imperfections (cracks, darkening and other defects).

Pros and cons of brick cladding

Now let's see why so many developers prefer brick cladding.

Let's consider the main advantages:

- High indicators of strength and density of products;

- Relatively low coefficient of thermal conductivity;

- Small percentage of water absorption;

- Frost resistance of products can reach 300 cycles (for clinker bricks);

- External characteristics;

- For ceramic products - extremely wide architectural possibilities;

- A wide range of choice in shapes, sizes, colors and shades;

- Sound insulation and vapor permeability characteristics;

- Non-flammability and relative environmental friendliness of products;

- The durability of brick-faced buildings is noticeably increased;

- Ability to withstand atmospheric and biological influences.

There are also disadvantages.

These include:

- For the most part, the high cost of products;

- Heavy load on the foundation;

- Low masonry speed due to small dimensions;

- The complexity of installation, the need, in most cases, to attract specialists, which undoubtedly portends additional costs;

- Efflorescence may appear on ceramic bricks;

- Products can crumble and crumble.

Facing bricks do not have more significant disadvantages.

Varieties

Depending on the production technology,

brown facing brick is divided into four types:

- Clinker;

- Ceramic;

- Silicate;

- Hyper-pressed.

Ceramic brick has the greatest

resistance to mechanical damage, as well as fire. Coated from

it is not afraid of temperature drops, processing takes place at 10000C.

They make ceramic products in the classic version - a rectangle,

sometimes curly varieties are required. The three sides can be used as

facial. The addition of additives to improve performance is acceptable.

The silicate

facing brick, which consists of lime and quartz sand. Receive

by pressing at a temperature of 1800C. The main disadvantages - will not protect against

open fire and weighs a lot. Poor resistance to temperature extremes can

lead to rapid destruction.

Therefore, sometimes silicate products are subjected to

additional treatments to improve its performance. Full-bodied execution

and proportions allow you to use all sides of such

bricks.

But silicate brick is often used in

the purpose of thermal insulation of the building, therefore special voids are made in it. it

leads to a decrease in weight and loss of one of the sides as a facial.

Hyper-pressed brick as easy

guess from the name, during the manufacturing process it undergoes an additional

high pressure firing. The mixture includes cement, limestone and

shell rock. Differs in a number of positive properties - resistant to fire, moisture and

mechanical shock.

But the only drawback is high

thermal conductivity, forces to make a layer for thermal insulation. This leads to

additional expenses, but then the house will look solid and not be subject to

temperature differences.

Clinker facing bricks are

balanced options from all points of view - even slightly better than ceramic.

As a material, special clay is processed, which is first dried,

and then fired. Its characteristics are suitable for outdoor use,

no downsides.

Manufacturers and pricesCompanies selling

facing brown bricks are usually divided into domestic and foreign.

The former are distinguished by low prices, the latter are of high quality. This is the general

tendency, however, it is quite possible to find a successful combination of both criteria.

One of the best cladding manufacturers

materials are the German company ABC, which has gained fame as a manufacturer

facing clinker and elite materials. The price for a facing brick can

reach 100-150 rubles for

piece.

Heylen is a Belgian company producing

different bricks with a unique shape, for which the demand is very high. Price per

such a delicate work is appropriate - not less than 150 rubles apiece. If

interested in a combination of different colors and even rare ones, it is worth taking a closer look at the product

Finnish manufacturer Terca.

Russian manufacturers of facing bricks

known abroad, one of the striking examples is the Slavyansky Brick company,

which produces nearly 150 million bricks a year. Astronomical number

due to the presence of its own clay mining quarry. Unit price usually

fluctuates between 18-30 rubles.

To order silicate bricks, you need

consider the "Kirovsky brick factory", which specializes in this

varieties of brown facing bricks. You can purchase hollow and

full-bodied products at an adequate price.