Product classification

Such areas of production need stainless steel as:

- chemical industry;

- construction;

- medicine;

- oil production;

- food industry;

- mechanical engineering and much more.

The specificity of each of them assumes different requirements for quality, volume, diameter and size of the material.

That is why there are several types of stainless steel wire:

- knitting;

- welding wire;

- cold-worked;

- spring stainless.

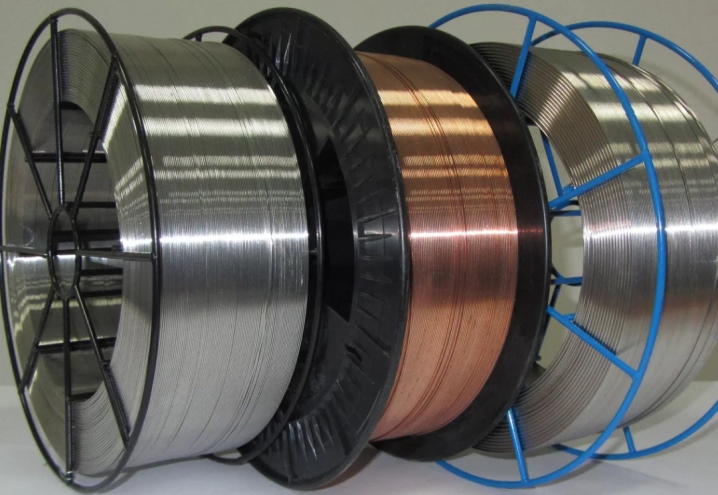

Hot-rolled and cold-rolled wire are distinguished according to the production method. Based on the type of processing of manufactured products (metal surface), stainless steel wire is divided into the following types:

- light wire (no oxides);

- copper-plated;

- oxidized.

According to the accuracy of the execution of the stainless steel wire, it is subdivided into increased and normal accuracy. Depending on the physical properties of the stainless steel wire, the first and second classes of plasticity of the finished product are distinguished.

Stainless wire is also distributed on:

- non-corrosive wire of normal accuracy, made of high-alloy heat-resistant steel 12X18H10T;

- non-corrosive wire for welding.

It is difficult not to appreciate the benefits that the use of stainless steel brings us. The automotive, agricultural, petrochemical, food, shipbuilding, pharmaceutical and other industries can no longer do without the use of stainless steel.

Main areas of application

The cold drawn stainless steel welding wire is ideal for all kinds of welding applications. The welding wire has a matt surface without any coating.

The cold drawn stainless steel welding wire is ideal for all kinds of welding applications. The welding wire has a matt surface without any coating.

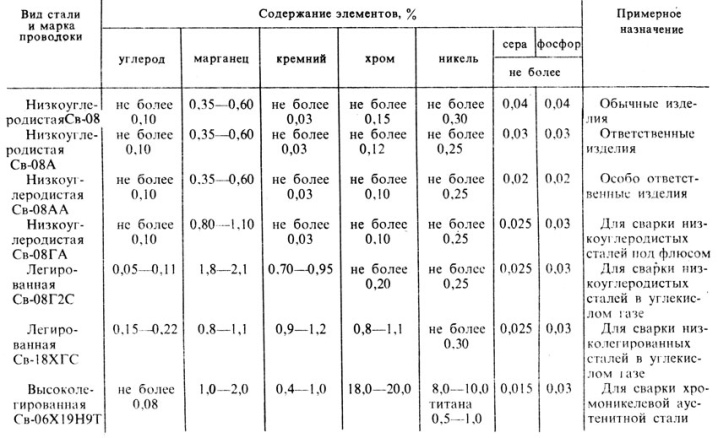

For its manufacture, the grades Sv-04X19N9 and Sv-06X19N9T are quite often used, which are high-alloy steels (the designation of the steel grade itself usually goes after the inscription St.). Sv-12Kh11NMF and Sv-10Kh17T brand are equally used for the production of wires. In the last two steels, the percentage of alloying elements is more than 10%. The diameter of the stainless cold-drawn wire Sv-04X19N9 is in the range from 1.2 to 4 millimeters.

For the product Sv-06X19N9T, the cross-section range is from 1 to 4 millimeters.

GOST 2246-70 is intended to monitor compliance with technical conditions in the production of products from these steels. The finished wire comes in bays. If necessary, it can be wound up to the length specified by the customer.

The material is freely used in the following areas:

- Electrical power engineering and electrical engineering is one of the most demanded areas of application. Stability at high temperatures and chemical attack allows the use of critical components and electrical equipment in the production;

- In the oil industry - in the production of equipment for oil rigs and for welding seams;

- In the manufacture of furniture - due to its properties, furniture, which contains stainless wire components, will serve for many years;

- In the food industry. Non-corrosive steel is recognized as the most suitable material for the manufacture of equipment for the preparation and transportation of food supplies, food, and this is because such material has high hygienic properties and inertness;

- In chem. industry;

- In honey. industry for the production of surgical devices, as well as medical equipment that requires high precision;

- In the manufacture of building materials, the material can be used mainly for the manufacture of welded and woven seams, as well as as an additional reinforcing component;

- For welding stainless steel. Due to the possibility of using in aggressive environments and resistance to chemical influences, this material is actively used in aircraft and shipbuilding, making it possible to achieve maximum strength and accuracy of joints;

- Manufacture of cables, braids and springs for the automotive industry. Stainless steel exhibits extraordinary resistance to mechanical stress, and therefore products from it show themselves perfectly in the composition of structures, and in independent use;

- For household purposes. At the moment, many parts of household appliances and household utensils are made from stainless wire.

Undoubtedly, this material and this product are one of the most important components in modern industry. It was thanks to him that it became possible to significantly improve the quality of life of a modern person.

Usage

Stainless wire 10Х17Н13М2Т has high corrosion resistance, resistance to chlorides, alkaline solutions and acids. In addition, it is distinguished by high strength, resistance to deformation, a high degree of wear resistance, and visual appeal. It is in demand in mechanical engineering, energy, oil, chemical, food industries, agriculture, medicine and construction. The grade 12X18H10T has a high nickel content. It is made of chromium-nickel steel with the addition of titanium, it can be operated at t ° 400 - 800 ° C in the chemical, oil refining industry in equipment resistant to extreme heat. Grade 20X23H18, very strong and heat-resistant, capable of withstanding t ° up to 1100 ° C.

| Classification | welding stainless | welding stainless | heat resistant | corrosion-resistant heat-resistant |

|---|---|---|---|---|

| GOST | 06Х19Н9Т | 07Х20Н9Г7Т | 13X25N18 | 07X19N10B |

| UNS | Er 308 | Er 307 | Er 347 | |

| analogue | 06Х19Н9 | 07Х21Н10Г6 | ||

| Coefficient of (linear) thermal expansion (t ° 100 ° C) | 16 [1 / Grad] | — | — | — |

| Density of material | 7850 [kg / m3] | — | — | — |

| Specific electrical resistance | 800 | — | — | — |

| Alloy classification | corrosion-resistant heat-resistant | heat resistant | Copper-nickel | Copper-nickel |

|---|---|---|---|---|

| UNS | 310 | Er 309 | — | — |

| GOST | 08Х20Н14С2 | 07Х25Н13 | MUFA | Punch 11 |

Marking

The designations of steel wire according to GOST 1972 are as follows:

-

X - cold rolled products;

-

T - heat treatment (including products of the oxidized type with signs of tarnishing);

-

TC - a light metal that does not contain oxides and is devoid of signs of tarnishing;

-

P - increased manufacturing accuracy.

The weight (mass) of a stainless steel wire of circular cross-section with a length of 100 m is taken as follows (depending on the diameter):

-

0.5 mm - 0.31 kg;

-

1 mm - 0.62 kg;

-

1.5 mm - 1.4 kg;

-

2 mm - 2, 48 kg;

-

2.5 mm - 3.88 kg;

-

3 mm - 5.58 kg;

-

4 mm - 9.93 kg;

-

6 mm - 22.3 or 22.6 kg.

The smallest possible diameter is 0.3 mm. But finding such a wire is quite difficult. Most often, wire made of metal of the AISI 321 category is used abroad. In domestic practice, its close analogs are 08X18H10T or 12X18H10T. Cold rolled products can be from 0.51 to 1.01 mm in diameter, and hot worked from 0.3 to 6 mm. When marking steels, those substances that are less than 1% are allowed not to be indicated. Alloy 12X18H10T stands for:

-

no more than 0.12% carbon;

-

up to 1% titanium;

-

exactly 18% chromium;

-

exactly 10% nickel;

-

everything else is iron.

Despite being chemically inert, stainless wire deserves careful handling. Its diameter is wound on spools or packed in skeins.

For cover from mechanical stress, a film or standard wrapping paper is used. It is highly recommended to transport the wire in a closed transport protected from rain. Its storage is allowed only in heated rooms.

Packaging, labeling and storage

Stainless wire is produced in accordance with GOST 18143−72 from heat-resistant, anti-corrosion and alloy steel with a cut from 2 mm to 7.5 cm. Wire marking contains information:

- about the chemical composition;

- production technology;

- the form of grinding the surface of steel.

The numbers show the percentage of elements that determine the key properties of the product.

For example: stainless wire 12X18H10T:

- number 12 indicates the carbon content (that is, it is not more than 0.12%);

- X18 - percentage of chromium - 18%;

- H10 - nickel content 10%;

- T is the percentage of titanium within 1%.

The presence of other elements, the content of which is not more than 1%, is not indicated in the marking. In the indication of cold-rolled n / f wire, the final letter is "X". Oxidized stainless steel wires are usually tarnished and are marked with a “T”. Basically, this type of marking is applied to a product produced by the method of heat treatment (the same hot-rolled steel, hot-rolled wire). Stainless wire of a light shade without oxides and tarnishing is designated "TC". The letter "P" is added to the marking of the product of increased strength.

The presence of other elements, the content of which is not more than 1%, is not indicated in the marking. In the indication of cold-rolled n / f wire, the final letter is "X". Oxidized stainless steel wires are usually tarnished and are marked with a “T”. Basically, this type of marking is applied to a product produced by the method of heat treatment (the same hot-rolled steel, hot-rolled wire). Stainless wire of a light shade without oxides and tarnishing is designated "TC". The letter "P" is added to the marking of the product of increased strength.

Another parameter that should be mentioned is the so-called plasticity class. It is marked accordingly: 1 - the first, 2 - the second.

Stainless steel wire assumes careful handling during storage and transportation. It, depending on the diameter, is wound on spools and packed in skeins and is protected from mechanical damage by wrapping paper or film.

It is desirable to carry out transportation mainly in closed vehicles. Store the stainless steel in heated indoor warehouses.

The wire comes in coils or coils, the length of which varies at the request of specific customers. When laying stainless steel wire into coils, its winding is performed without overlap of the turns themselves, with folding in correct, clear rows. As a result, as needed, the unwinding of the required footage of wire, nothing prevents its deployment: it happens without difficulty, freely and easily and does not require the use of any physical force. A similar stainless steel is suitable for the engineering industry for the production of:

The wire comes in coils or coils, the length of which varies at the request of specific customers. When laying stainless steel wire into coils, its winding is performed without overlap of the turns themselves, with folding in correct, clear rows. As a result, as needed, the unwinding of the required footage of wire, nothing prevents its deployment: it happens without difficulty, freely and easily and does not require the use of any physical force. A similar stainless steel is suitable for the engineering industry for the production of:

- small parts;

- creating springs;

- ropes.

Such a stainless steel wire is especially needed in such areas as energy, medicine, mechanical engineering, as well as a number of other significant areas of life.

Classification

Modern stainless steel wire is not just made of steel with a minimum level of corrosion. It is also always a high-level alloyed material that is resistant to strong heat. The universal long design is easy to recognize - it looks like a thread or string. The predominantly stainless wire has a circular cross-section. It is used in a wide variety of areas, therefore it is represented by a number of modifications.

Knitting wire is very popular. It is used for fixing reinforcement - and it is not surprising that this material should not rust for as long as possible during normal use. The main requirements are stated in GOST 3282-74. Experts have long noted that the thicker the reinforcement, the larger the cross-section of the wire used should be. It should be positioned as evenly as possible, because otherwise the loads will be distributed incorrectly.

But welding wire can also be stainless. This material is valuable because the finished weld also has excellent anti-corrosion properties. Basically, special steel fibers are used for fully or partially automated welding processes. It is useful both for work in an inert gas atmosphere and for welding powdered metal.

Work-hardened wire deserves special attention. It is needed to:

-

make brushes for manual cleaning and various cleaning machines;

-

to produce metal fiber (one of the types of reinforcement for concrete);

-

make cables and ropes;

-

receive simple springs;

-

perform parts for cars and trucks;

-

form fences and other enclosing structures.

Stainless steel spring wire is made of steel with a high carbon content. It is used when it is necessary to make especially complex and important springs. The section of the metal thread can be in the form of a circle, oval or rectangle - depending on what is needed in a particular case. The fiber diameter is 0.3 to 5 mm. If alloy steel is used, the largest diameter is increased to 8 mm.

It is customary to highlight the following types:

-

hot rolling products;

-

cold rolling products;

-

light metal (free from oxides);

-

oxidized products;

-

copper-plated wire;

-

products of normal and increased accuracy;

-

wire of 1 and 2 categories of ductility.

Product sales on the domestic market

The sale of stainless steel products is carried out directly by manufacturing enterprises and firms engaged in metal rolling. The peculiarities of the sales of such firms can be found in detail on various sites for the sale of metal. MetProm Star is a striking example of a major seller of stainless steel. It offers a wide range of stainless steel wires of all kinds and sizes.

The sale of stainless steel products is carried out directly by manufacturing enterprises and firms engaged in metal rolling. The peculiarities of the sales of such firms can be found in detail on various sites for the sale of metal. MetProm Star is a striking example of a major seller of stainless steel. It offers a wide range of stainless steel wires of all kinds and sizes.

A matte surface without traces of oxide spots on it is characteristic of a stainless steel wire. The limiting diameter will be 6 millimeters, the minimum is 0.3 millimeters. The AISI 321 model is considered the most used, the Russian analogue is 08X18H10T steel, 12X18H10T is also close to it. This variety is characterized by heat resistance, high alloying, meets industrial conditions in accordance with GOST 18143−72.

According to the production method, the wire is divided into heat-treated and cold-drawn steel. For products made of cold-drawn stainless steel, the diameter is in the range from 0.51 mm to 1.01 mm. For heat-treated products, the diameter will be between 0.3 and 6 mm.