Distinctive properties of river sand and its area of application

The two main features of river sand are: natural purity and fractional homogeneity. The particles of this material have rounded, smoothed shapes: which contributes to its high flowability and moisture capacity.

Advice! When buying bulk material, take into account the fact that its weight depends on moisture content: that is, there is more in one cube of dry sand than in 1 mᶟ of wet sand. Otherwise, you run the risk of buying a lot by weight, but not enough in volume.

When calculating the required amount, take into account that in the reference books the specific gravity is indicated for dry material.

River sand is included in the composition of ready-made building mixtures; used for arranging floor screeds; used for water purification (from mechanical impurities) as drainage; and gardeners mix this bulk material with soil to make it lighter and more crumbly.

The sandy mass mined in the quarry and containing stones, clay and various impurities is washed with water and a fairly clean material is obtained, which is called quarry washed.

In the event that quarry sand is sieved (to clear stones and large fractions), it is called quarry seeded. Such material is very much in demand in the production of construction work: mortar for masonry, arrangement of the foundation and plastering work.

It is impossible to answer unequivocally the question of which material is better: river or quarry, since it all depends on the type of construction work. But it can be argued for sure that sand for concrete is most often used quarry washed. The fact is that the grains of river material, due to their roundness and the absence of sharp edges, do not adhere well to cement: this can negatively affect the quality of the final product. But river sand does not contain any inclusions, but the composition of the quarry contains some organic impurities that can behave unpredictably, reacting with the chemical components of the mixture. Therefore, make the decision for yourself: use quarry washed or river sand.

Advantages and disadvantages

The most important material in enterprises engaged in the extraction of sand, as well as the sale of its various types, is the use of the quarry sand itself.

This is explained by such factors:

- enterprises do not use their own reserves for cleaning the resulting sand. Based on the fact that quarry sand cannot be processed and resorted to other methods, production saves money on cleaning and screening of the mined material.

- it is not at all difficult to get sand with the help of special devices. The open-cut method is the most accurate and inexpensive, so most enterprises resort to using this mining method.

- Delivery of quarry sand is also not a big financial cost. Today, there are a large number of sand deposits in the quarries, so at any time you can find the right amount of sand nearby.

The norms and coefficient ratio of this sand are not always equal to that of alluvial or sown sand, however, the low cost and a number of other characteristics that indicate high-quality material make the sand more popular and in demand than similar types of quarry sand.

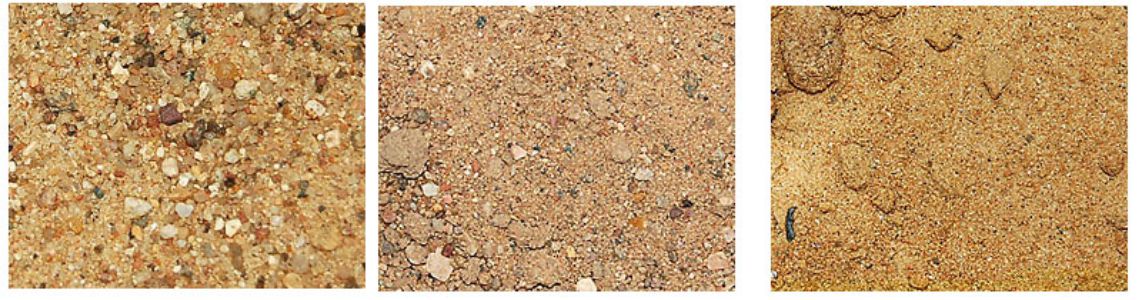

Comparison with river sand

Despite the fact that quarry sand is often confused with river sand, they have several differences. For example, they have different density and size of grains of sand. In river sand, they do not exceed 0.5 mm. This type is used in drainage systems and when creating a cement screed.The scope of application of quarry sand is more extensive, besides, the methods of extracting the river variety are more costly. The key difference is also the purity of the formulation. River sand has practically no foreign inclusions, while quarry sand has them, and in different volumes (sometimes this percentage ratio can reach 1: 9).

In small proportions, this is insignificant, but the presence of organic matter can cause fermentation of the mortar. In other words, if the quarry type of sand is not cleaned, it will be unusable for many different applications. Differs in two types and type of faction. Due to the constant exposure to water, river grains of sand are smooth and roundish. This can affect adhesion to building materials. The price of river-type material also differs: sometimes it is one and a half times higher than the cost of sand extracted from a quarry. However, if the product of the second type has undergone high-quality processing, its characteristics will exceed the river type.

Applications for dry sand

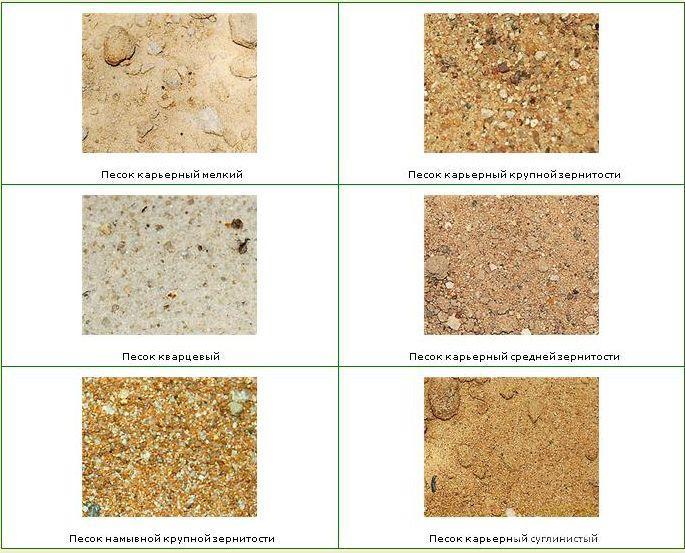

Dry sand is divided into three main fractions:

- fine - grains up to 0.5 mm in size;

- medium - 0.5–2 mm;

- large - 2–5 mm.

The scope of application of the material depends on this indicator. The most popular and convenient medium-grained sand for construction.

Depending on the type of work to be done, sand of a certain fraction is selected

Coarse sand is used for drainage and arrangement of base cushions when laying foundations, building roads, laying communications. It is also used by designers and artists in decoration and landscape architecture.

The fine fraction is suitable for creating filters, filling sports and children's playgrounds, making ceramics, glass. It is added to masonry and plastering compounds.

Medium-grained sand is considered the best option for concrete and cement mixtures. According to IS&A research, the maximum strength of a concrete stone is achieved when using dry sand with the following composition: 30–50% - fraction 0.325–1.25 mm; 50% - 1.25–5 mm; 10% and more - fractions 0.325–0.16 mm (for filling micropores). It is preferable to use dry quarry sand with coarse grains that have not been rolled in water.

Dry sand of the middle fraction is optimal for creating a high-quality concrete mix

Additional areas of application:

- as an abrasive for sandblasting machines;

- filler for paints and grout;

- in the production of paving slabs;

- when decorating garden and park spaces;

- in the improvement of adjoining territories;

What should be the sand for a sandbox

There are four main criteria for determining which sand is best for a sandbox.

The size. The optimum diameter of grains of sand is 1-3 mm. The larger ones will be inconvenient for playing, the smaller ones will easily rise into the air, creating excess dust. The latter are dangerous to the health of the child, since they can settle in the lungs and lead to various diseases. The absence of dust particles is the main difference between children's sand and construction sand. We recommend staying on a homogeneous material - it molds better.

It is especially important to make sure that there is no garbage when buying material of river origin. It may contain sharp-edged seashells, needle stones, sulfur

The material must go through at least two stages of processing - washing and calcining. Certification. Most of the properties can be checked by examining the material certificate. If the seller does not have such documentation, it is better to refuse the purchase. The certificates must state that the sand is intended for children's play. This means that the products have passed all the necessary studies, are not radioactive, do not contain toxic substances. Color. In nature, the sand is light brown, it can be yellow or reddish. Other differences in color indicate unwanted impurities and may be harmful to the child.If you ask the question of which sand is best for a sandbox, for children, the answer will definitely be colored. Materials with safe dyes will help to diversify the game. All colors of the rainbow are offered by manufacturers!

When buying, you need to check the material for moisture content. In no case should you settle for wet or damp sand. After drying, it may not meet the declared properties.

Better to buy sand in bags. You need to make sure that the packaging is intact. This will be an additional guarantee that the sand is not old and that all the rules for its storage and transportation are followed.

Criterias of choice

The choice of sand is of great importance to the end result of your work. That is why in the process of choosing and buying material, you should be as careful and responsible as possible. Experts recommend focusing on the following key parameters:

- compliance with GOST characteristics - for verification, do not hesitate to ask the seller for certificates of quality and compliance, as well as any other documents that he can provide you;

- the purity of the sand - as mentioned above, the material should not contain impurities;

- cost - remember that quality washed sand is expensive;

- seller - it is recommended to purchase material only from trusted bona fide sellers and in appropriate specialized stores;

- customer reviews - it is recommended to study this information before purchasing bulk material.

For information on how the sand is washed, see the next video.

Specifications

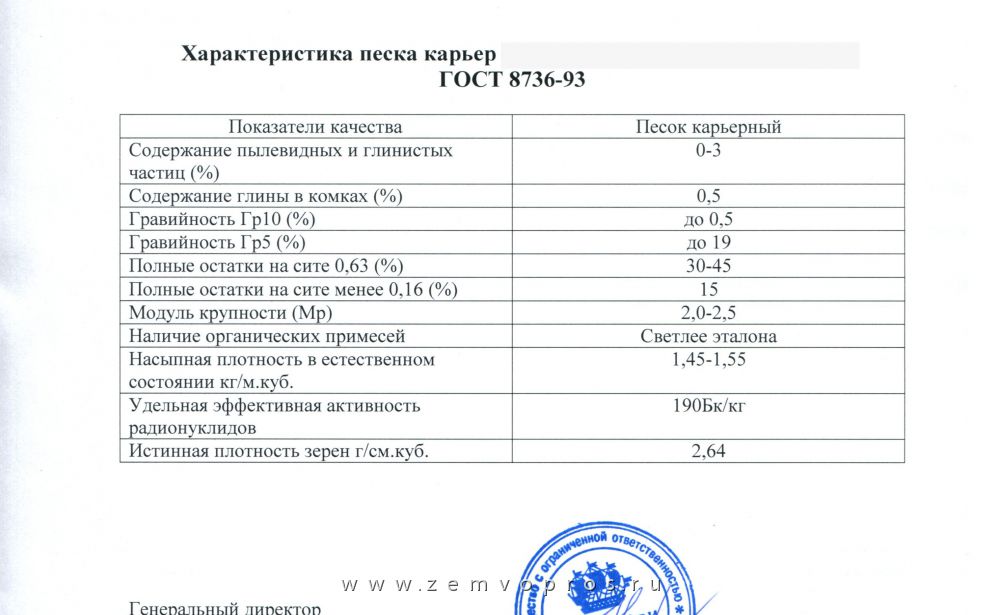

To determine sand by category, the following properties are taken into account:

- specific gravity (bulk density);

- the degree of radioactive radiation;

- moisture percentage;

- the amount of impurities;

- filtration coefficient.

1. The specific gravity shows how much building material is in one cubic meter of the container. This parameter depends on the size of the fractions and the size of the free space between the grains. Therefore, the bulk density of coarse-grained and fine-grained grains will differ markedly. The specific weight of sand grains of coarse fractions is about 1500, medium - 1600, small - 1700-1800 kg / m3.

2. Bulk density is the weight of the un-rammed building material. Its indicator is influenced by the degree of humidity and mechanical stress. The density decreases if the sand becomes wet, as each grain is enveloped in water. Because of this, the distance between adjacent grains increases. After transportation, on the contrary, the bulk density increases, as it is compacted.

3. The degree of radioactive radiation from quarry sand depends on the place of extraction. They are divided into 3 categories - first, second and third. The scope of the first is the construction of residential buildings for people and animals, the second and third classes are allowed for the construction of roads.

4. The weight of bulk material is influenced by the percentage of moisture. The higher it is, the more it weighs. The optimal norm for sand from quarries is 5-7%. The amount of clay impurities should not exceed 3%, sulfur and sulfides - up to 1%.

5. The ability to pass water depends on the filtration coefficient. For sand from quarries, this indicator should be in the range of 0.5-7 m / day.

Application area

It must correspond to its quality and properties. Low-quality sand is intended for bedding (filling ditches, leveling the surface), for improving the soil, storing vegetables and for decorative purposes. It is also selected for the manufacture of mixtures with crushed stone and gravel and for the construction of highways. It is also used for the filter in sewage treatment plants. High quality sand is required for glass production.

The scope of application of the sifted is the erection of the foundations of buildings, it is also necessary as a filler in the production of cement-sand mortars and asphalt.Since seeded sand has good adhesion properties, it is often selected for plasters and paving slabs.

Coarse sand is added to mortars for paving slabs, and it is also used as a pillow in the construction of highways and as a drainage layer. Fine-grained is used in the production of putty mixtures, as a filling component for self-leveling floors and decorative finishes.

Cost per cube and what it depends on

A cubic meter of sand from a quarry is cheaper than a river one, since it took less money and labor to extract it. The washed type of building material is similar in technical characteristics to the river one, but externally differs. Its grains are not smooth oval, but angular and porous. It is for this reason that it is most common in the manufacture of mortars. But due to the additional processing costs, the cost of sand also rises.

Prices also depend on the size of the fractions. The smaller the grain, the more expensive it is. But at the same time, the smallest option is intended for a narrow scope of use. The average fraction is in the greatest demand. When choosing the type of sand, one should take into account the purpose for which it is needed. When choosing a low-quality building material for the construction of a building, large defects (cracks) may appear.

Table with prices for a cube of quarry sand:

| Type of | 1 m3, rubles |

| Construction quarry | 600 |

| Washed | 800 |

| Seeded | 680 |

| River | 800 |

Before purchasing sand obtained from a quarry, it is recommended to check its composition and technical characteristics, especially the degree of radiation and the percentage of impurities. The area of its use depends on these factors.

The lower the cost, the less costs were spent on processing it, but also the narrower the scope of application.

Such material is recommended in places where quality and technical characteristics are not particularly important. For construction work, such as building foundations, production of plaster mixes or for laying bricks, it is best to buy cleaned sand

Varieties of sand

When removing the old coating, you can purchase ordinary sand for sandblasting, but it can not always provide a positive result. Therefore, they choose other options:

- river - popular, but has low strength and hardness;

- career - it is necessary to wash and sift, while smaller than the river;

- industrial quartz - it is simple sand, previously divided into fractions, therefore, more expensive;

- special crushed - formed by crushing quartz rocks, acquires an acute-angled shape, cleaning the coating much more efficiently. It has low consumption and high processing speed.

In addition to them, there are other abrasives that have gained popularity in the modern market:

1. Cooper and nickel slag. Formed during the mining of copper and nickel in production. They have high strength properties, while the price is almost the same as for ordinary sand.

2. Steel or cast iron shot. Other enough, it is able not only to clean the surface, but also to give a hardening effect like forging. It surpasses quartz sand by 8-10 times and is produced in round (for accurate cleaning) and chipped (for rough processing) shapes.

3. Garnet sand. Very hard, but the strength is comparable to that of quartz. It is used for separating metal products by hydraulic cutting.

4. Electrocorundum. These are crystals of aluminum oxide, which are considered to be the hardest. Suitable for absolutely all types of coatings, while practically does not deteriorate after the first sandblasting. It is collected and reused.

Selection recommendations

Consideration should be given to the type and condition of the material. The abrasive determines the consumption, speed and quality of cleaning 1 m². In order to purchase a high-quality consumable, you need to rely on the following factors:

- Strength and thickness of the coating.If it is very strong, then the sand should be hard and coarse. When taking a fine and insufficiently strong abrasive, the plane will not be cleaned, and the consumption will increase significantly.

- The hardness of the product itself. If it is soft (non-ferrous metals), the particles must be fine and medium strength, otherwise the surface may be damaged.

- Reusability. In order to save money, you can buy coarse quartz or copper slag. After the first treatment, they can be sieved and reused for the sandblaster.

- Speed. If the strength permits, an angular shape of the abrasive is recommended, since a round one cannot always give a positive result from the first cleaning.

- Final state. If a near perfect finish with a minimum of dents is required, it is better to use strong but fine sand.

Before choosing a suitable abrasive, it is worth knowing its characteristics and degree of safety. Today, many types are produced in bags that are less harmful to health, while having good operational parameters.

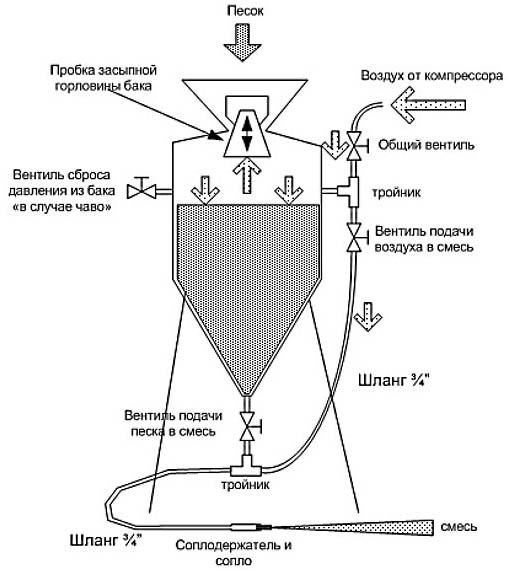

Description of equipment

For this type of work, a sandblasting gun is needed, which helps to clean the surface of the products and degrease them. Therefore, after processing, you can immediately start welding or paintwork. The equipment provides high performance and cost-effectiveness, characterized by repeated use.

The device includes not only a sprayer (gun), but also a compressor, a tank for abrasive, and a set of hoses (pipelines) that provide an uninterrupted supply of compressed air and a flow of sand with air (air-abrasive mixture). At the same time, its transportation takes place under high pressure, which provides for the observance of safety measures. When working with the equipment, special clothing, safety footwear, as well as a respirator and goggles should be used to protect the face from accidental ingress of grains.

Price

| Name | Fraction, mm | Price per ton, rubles | |

| Quartz sand | fine-grained | 0,1-1 | 2 400 |

| coarse-grained | 1-3 | 2 700 | |

| Cooper / nickel slag | fine-grained | 0,125-1,6 | 1 800 |

| coarse-grained | 1,6-3 | 2 400 | |

| Pomegranate sand | W30 / 60 mesh, W40 / 80 mesh, W100 / 120 mesh | 35 000 | |

| Steel shot (steel / chipped iron, steel / cast iron) | 0,3-3,6 | 37 000 |

The amount of sand under the house

Many people wonder how to correctly calculate the volumes of the constituents of the concrete mixture required for the construction of the base of the house.

To fill the foundation, concrete is needed at least M300. The preparation of 1 m3 takes about 650 kg of sand. Calculate the volumetric indicators of your foundation (multiply the height by the width and the depth) and calculate the tonnage of sand, then convert it to volume at the rate of 1.5 t / m3.

Sand should always be bought with a small margin (15–20%) to the calculated figure - this material tends to thicken, some of it will scatter over the site during transportation, something will come in handy for backfilling.

Most people associate sand with yellow. But this is far from the case. In Hawaii, green beaches are not uncommon, the Bahamas are pleasing to the eye with pink tones, Iceland is mesmerizing with black tones, and Mauritius boasts rainbow placers.