Usage Tips

In order for the couplings to serve for a long time, they must be stored and transported correctly. They need to be transported in such a way as to ensure safety and protect them from shock and other types of mechanical damage. These parts should be stored in such conditions that they do not fall on the sun's rays and precipitation. If the warehouse is heated, then no closer than one meter to the heating devices.

"American" is very convenient to use in places where the approach is difficult, and it is not always possible to use welding. This type of connection is very reliable, it can be used almost everywhere, for example, when installing a boiler, heated towel rail, in many other cases.

It is important not to forget about sealing during installation. In the communication systems of residential buildings, there is quite a high pressure and sometimes it happens that manufacturers complete couplings with unreliable rubber seals or the thread is not very accurate

Therefore, it is better to wind fum tape or tow on the sleeve to avoid difficulties in the future.

You can find out what to do if a coupling with a union nut is leaking from the video below.

Peculiarities

A coupling with a union nut was invented in order to interconnect pipes of water supply, heating and other systems. It must ensure tightness and reliability of the connection, be resistant to high temperatures and the effects of an aggressive environment. That is why it is of great importance what this type of fittings are made of.

The distinctive features of a combined fitting with a union nut (popular name - "American") include:

- ease of connection and disconnection of pipelines (there is no need to twist pipes and the material from which they are made does not matter);

- tightness;

- resistance to high temperatures;

- long service life;

- possibility of repeated use;

- speed and ease of installation;

- lack of corrosion;

- light weight.

"American" makes it possible to connect pipes of different diameters. The main document that establishes the general technical conditions for the operation of fittings and pipes, as well as the scope of their use, is called GOST R 52134-2003.

What are they?

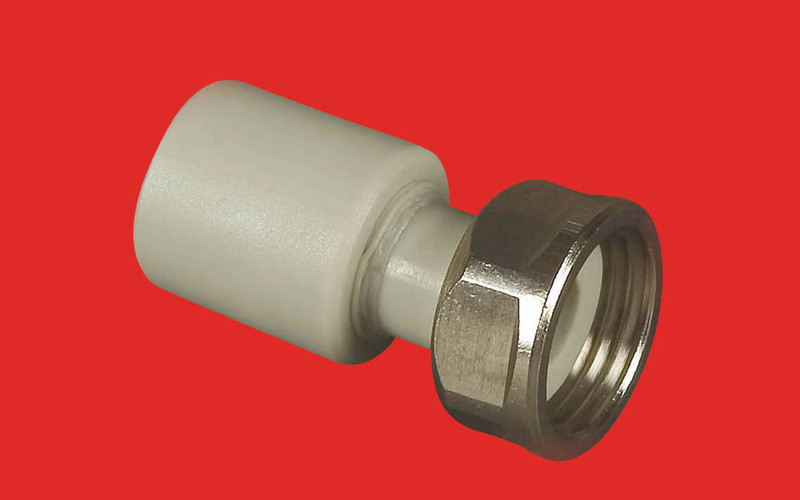

Polypropylene (PPR) couplings meet all these requirements. They are the best option in terms of price / quality ratio. These fittings are more expensive but last longer, about 50 years.

Polypropylene combined couplings are of two types: threaded, cut on the outside or on the inside diameter. The main task of these products is to join pipes made of different materials.

PPR couplings are divided into:

- straight, angular, transitional and combined;

- detachable and one-piece (clutch-press);

- welded and compression;

- repair, connecting and protective.

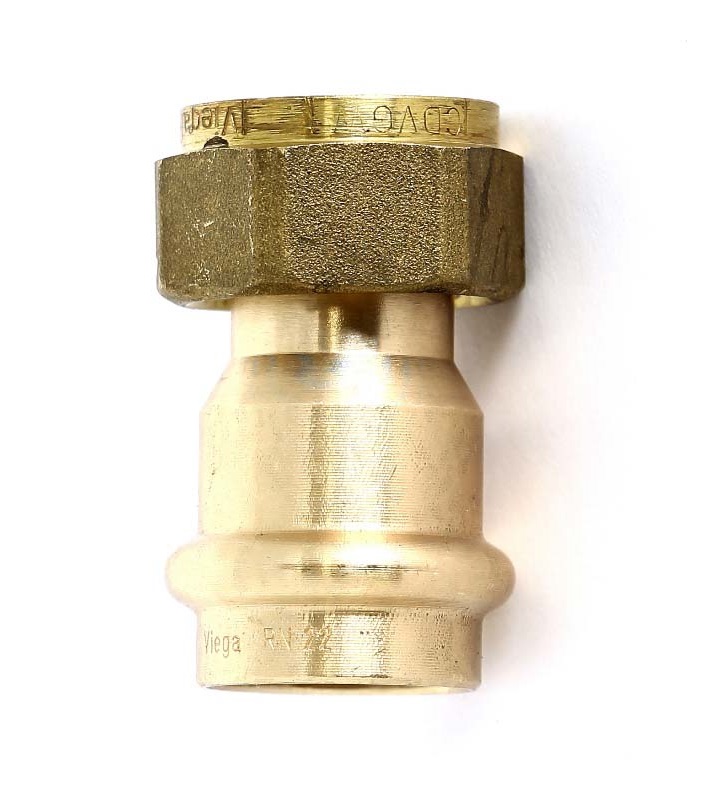

There are also metal fittings. The union nut in these products can be made of copper, brass or stainless steel. Depending on the diameter of the pipes, fittings of certain sizes are also manufactured. Pipe diameter is measured in mm, for example 20, and threads are in inches, for example 1/2.

Combined couplings equipped with a nut can fasten pipes with a welded joint on one side and a threaded male thread on the other. The most common sizes are 32x3, 20x3, 25x1, 20x1, 2x15, 32x1 (first, the nominal outer diameter of the pipe is indicated, and then internal thread diameter in inches).