Installation of a spiral security barrier on a fence

When working with barbed tape, increased safety measures are required. Steel cutting blades can cause serious cuts, and small scratches are very painful and take a long time to heal.

For installation you will need the following:

- Tight clothing and gloves with wrist protection;

- Barbed tape;

- Galvanized staples or wire to secure the barrier;

- Brackets;

- Welding machine or bolts;

- Broach strings (instead of them, you can use a stretched barbed tape);

- Mounting pliers.

Work order

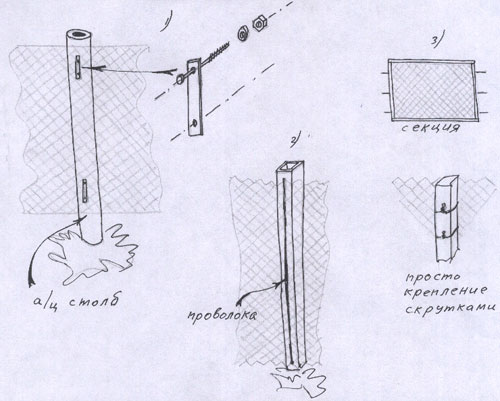

- Mounting brackets by welding or other fasteners.

-

The barbed spiral tape is installed over the fence and secured with staples or wire to the brackets. The density of the spirals can be arbitrary, but the more there are per meter of hedge, the more reliably the territory will be protected from penetration. Usually, 5-6 turns per linear meter of the fence are enough.

- Two strings are pulled through the spiral, which will give the structure reliability and protect it from sagging. The strings should be taut.

- The spirals of the tape are aligned with the strings and are securely fixed with staples or twists.

How to paint?

The netting must be painted correctly. There are several ways to do this.

- You can use a roller or brush. This process will take a long time, especially if you use a brush. The fur-coated roller will paint the netting very well.

- It is advisable to use a spray gun. So the work will go much faster and better. True, the material consumption will then be quite large. In addition to the fence itself, all surrounding surfaces will be painted.

- It is convenient to paint the fence with a fur mitten. It is dipped in a dye composition and the chain-link is manually painted.

The chain-link is prepared before painting. If there is an old coating, it is sanded and removed. It is necessary to degrease the mesh with a solvent, coat it with anti-corrosion primer. Then the paint itself is applied.

Metal facade mesh for a fence: general information

Despite the high quality of the facade plastic mesh, its service life is somewhat limited. Instead of it, a metal sheet is most often purchased for giving. Particularly in demand is a galvanized fence mesh, which resists corrosion well. Such material has a long service life, during which it retains its appearance unchanged.

PHOTO: ms1.dom.by Metal mesh will last longer than plastic

PHOTO: ms1.dom.by Metal mesh will last longer than plastic

Characteristics and features of a metal mesh for a fence by type

The performance and appearance of the fence around the cottage can vary significantly depending on which metal fence mesh was used during the installation process. For this purpose, wicker and welded fabric can be used. Each option has its own characteristics, which you should definitely get acquainted with before starting installation work.

PHOTO: aafencing.co.uk The characteristics of a metal fence directly depend on the manufacturing technology

PHOTO: aafencing.co.uk The characteristics of a metal fence directly depend on the manufacturing technology

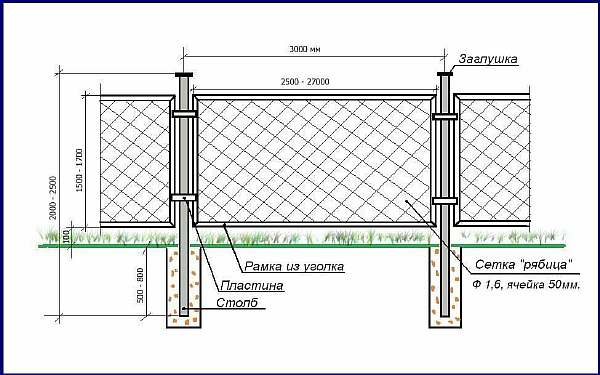

Rabitz

Among the woven fabrics, the chain-link mesh traditionally occupies a leading position. For its manufacture, black and galvanized steel wires with different cross-sectional sizes are used. The diameter of the wire and the dimensions of the formed cells are regulated by the requirements of regulatory documents. Supplied in rolls of 10 m. The height of the fence around the cottage can vary from 1 to 2 m.

Netting mesh - a universal solution for a summer residence and a private house

Netting mesh - a universal solution for a summer residence and a private house

Welded grating

This material attracts with its low cost, ease of installation and ability to hold its shape well during operation. For the fence around the cottage, a grate covered with a special polymer composition is used. The protective coating gives the product the desired color and provides reliable protection against moisture.

In the absence of a polymer coating, the fence installed around the dacha must be painted periodically to protect it from external negative factors.

Choose a welded mesh with a polymer coating

Choose a welded mesh with a polymer coating

Pros and cons of metal fences

The advantages of metal fences include:

- the possibility of free circulation of air and the penetration of sunlight due to the sufficiently large size of the cells. This contributes to the beneficial development of plants grown in the country;

- availability. Compared to other types of metal fences, metal mesh fences are much cheaper;

- light weight. This greatly simplifies transportation and installation;

- sufficient strength. A properly installed fence can support a lot of weight. This is especially true when growing climbing plants near a fence or finding a summer cottage near a forest;

- operational safety. The design has no sharp corners, which significantly reduces the risk of injury;

- lack of sail. The fence can withstand strong gusts of wind.

However, like any mesh structure, such a fence around the dacha will not hide the courtyard area from prying eyes, which for many is a significant drawback. In addition, its appearance cannot be called presentable.

When planning the installation of a protective structure for long-term operation, it is better to pay attention to other options

PHOTO: 29A metal mesh fence will last for many years

PHOTO: 29A metal mesh fence will last for many years

Installation of metal grids

The ease of installation allows you to install the metal mesh yourself. The work is carried out as follows:

| Illustration | Description of action |

|

The site is being prepared. Garbage is removed. Plantations that can interfere with the installation process are cut down |

|

The markup is in progress. The pegs indicate the location of the support pillars, wickets and gates. A thread is pulled between the pegs, along which the fence will be mounted |

|

Support elements are installed. For this, small pits are dug into which the pillars are placed. Then they are driven into a depth of at least a third of the height. |

|

The mesh is mounted using suitable fastening systems. For a chain-link mesh, you can use special fasteners or ordinary knitting wire |

In more detail, the procedure for installing a fence from a chain-link mesh can be seen in the following video:

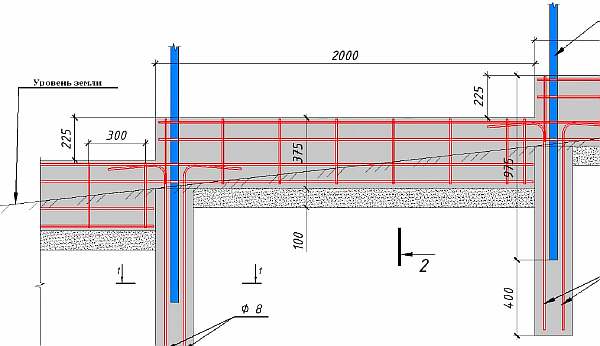

Construction of a stepped base

The erection of a stepped base on a slope almost does not differ from a tape one. There is only one difference: its construction begins with the marking of areas for attaching support posts. The distance between the supports is one step.

Drawing for the device of the steps of the base

Drawing for the device of the steps of the base

The formwork device on the slope also has nuances. The formwork is poured from the bottom point. The work is performed taking into account the established steps. Only after preparing one step on the slope, the next one is poured. For pouring, concrete M250 is used.

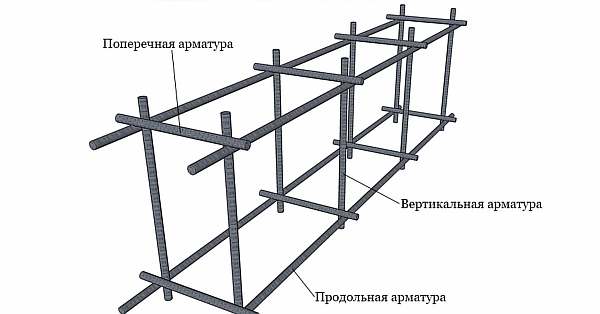

For the reinforcement of the stepped foundation, corrugated reinforcement with a diameter of 8–12 mm is used. It is knitted with a step of 200x200 mm and laid in the form of a double net.

Visual reinforcement diagram

Visual reinforcement diagram

When the base is prepared along the entire perimeter of the slope and hardens, they begin to weld the transverse logs and fasten the fence profile.

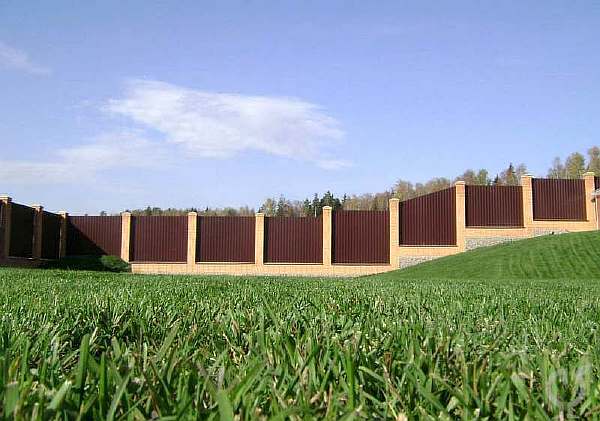

The photo shows a stepped foundation on a slope.

Fence with steps

Fence with steps

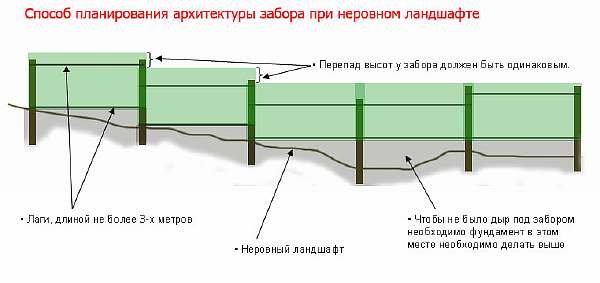

Plot with a small slope

If there is a small slope on an uneven territory, then you need to dig a foundation pit from its top point, taking out the earth at the same level.Usually, the deepening and height of the base for the fence along the contour of the site are unchanged, unless in a certain place the border of the fertile soil is deepened below. In this situation, the depth of the pit is made deeper until the soil is completely removed from the trench.

Barrier installation option on uneven terrain

Barrier installation option on uneven terrain

Arrangement of the foundation of the fence is carried out in the same way as for the belt. When the concrete mortar has completely hardened and the formwork is dismantled, backfill the earth on the slope along the base. The surface of the earth is leveled so that the embankment and blind area are at the same level along the perimeter of the structure.

Below is a photo of a fence on an uneven area on a small slope.

Fence from a profiled sheet in the country

Fence from a profiled sheet in the country

Plot with a medium slope

If the slope is more than 25 cm, then this slope is called average. This is taken into account when marking the base. You cannot choose the highest section of the future fence as a starting point. So, the lower part is chosen as the main one. This is due to the fact that in such places of the slope, the lower part of the foundation may be higher than the ground level.

Sketches

Sketches

While digging a trench under the base of the fence at the lowest point of the territory, it is necessary to control so that the depth of the pit is deeper than the fertile soil layer.

Then they dig a trench, heading to the highest part of the slope, and observe the same depth. If the height difference exceeds the depth of the base on the slope, fill the ground in the lower part of the foundation.

Strip foundation drawing

Strip foundation drawing

When everything is ready, begin the vertical filling of the earth. Any soil can be used to fill the pit on the slope. Specifically, previously selected from the trench.

With this option for constructing a foundation on a slope, labor costs are minimal, and the consumption of concrete mortar will be insignificant. With the right technology, the land will not crumble, and the fence will stand for a long time.

Below is a photo of a fence on a slope with an average slope.

Metal picket fence

Metal picket fence

Plot with a steep slope

If the mountain is very steep and the difference in the extreme parts of the base is more than 100 cm in depth, this slope is called large. In such a territory, the best solution is to build a stepped foundation. It will require more laborious and costly work.

Reinforcement scheme for a step under a fence with brick pillars

Reinforcement scheme for a step under a fence with brick pillars

The specificity of the construction lies in the fact that in the lower part, the base for the fence on an uneven territory is made at ground level, and in the upper part, taking into account the calculated deepening. To move from level to level, several steps are made.

Below is a photo of a fence on an uneven area with a large slope.

Installation by steps

Installation by steps

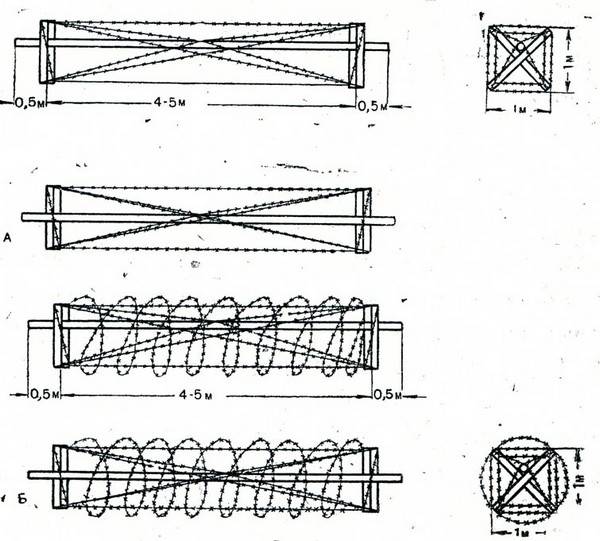

Installation methods

Depending on the type of fencing, completely from Egoza or only the top, various types of barbed wire are installed.

Flat canvas

When replacing an obsolete fence and installing barbed wire, fastening is made to the old base. For settlements, the Akatsia flat belt barrier is recommended. It is a frame with strips stretched between horizontal profiles. The barbed strip is mounted at an angle and forms rhombuses 380–400 mm high and 140–160 mm wide. At the intersection, the strips are interconnected by wire or brace. All elements of the fence are covered with zinc.

Variant of installation of the product of the "Acacia" type

A flat fence has its positive qualities for installing it on the streets where people walk:

- the canvas does not go beyond the dimensions of the fence;

- has a threatening appearance;

- transparency 100%;

- height up to 4 m;

- it is very difficult to overcome.

At first glance, the openwork design is actually quite strong and traumatic. When cutting the wire in several places, it is impossible to get inside the area.

Cell appearance

Transparency is also a disadvantage. Passers-by can clearly see what is happening in the yard.New supports must be installed under the barbed wire frames.

By installing a fence made of corrugated board or polycarbonate parallel to the inside of the site, you can hide the yard from prying eyes.

Layout drawings

Spiked spiral fence

Fencing of large areas in open space can be done with Egoza volumetric spirals. Ribbons with thorns are pulled in several rows. When repairing a fence, old racks are used. The distance between them should be no more than 3 m.

An example of a wire arrangement in the form of a spiral

Brackets are welded to the posts and barbed wire is attached to them. The fasteners themselves can be of various types and shapes:

L-shaped bracket diagram

Horizontal fasteners are bent from a profile or a rod at an angle of 90 ° and screwed with one side to the post, the other is parallel to the ground.

The vertical brackets are straight and stick up above the post. The spirals located in the upper row of the fence are attached to them.

Fixing with Y-brackets

Depending on the height above the end of the fence, Y-shaped ones can have a stand and rise above or be welded to the posts by the center of the V bend. Spiky spirals are laid on top, between the beams of the bracket.

Spiky spirals are alternately laid out, putting on racks. A strong metal cable or alloyed galvanized wire is pulled through the brackets. It is the base to which the Egoza staples are attached. The tension is done with great effort, with a special device.

The spirals of the barbed strip can have the same diameter or the bottom row is 900 mm, the topmost one is 600–400 mm.

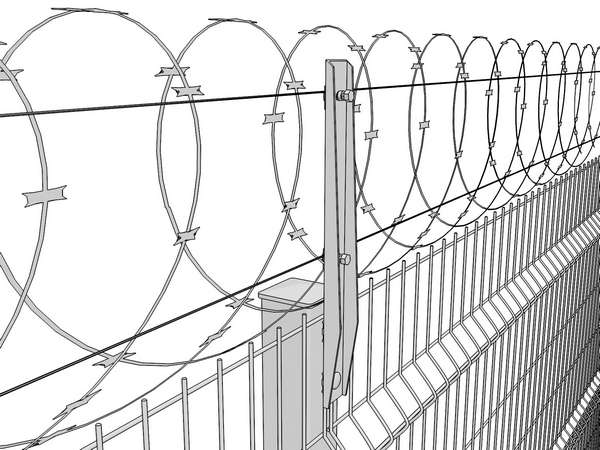

Fence

On the fence, a barbed spiral is installed in its upper part. Various mounting methods:

- vertical;

- with a slope;

- combined - multi-row.

It is necessary to firmly fix the protective structure, to increase the safety class of the territory. The fence is made flat and three-dimensional. At a height of more than 2.2 m - higher than the height of a person, it is assumed that sharp edges protrude beyond the outer dimensions of the fence.

Layout on the fence

Classic wire is attached to the brackets. The threads are pulled in several rows. A support wire is pulled on the same devices along the edge and a flat Egoza spiral is fixed.

Bulky prickly skeins are installed vertically above the fence or tilted towards the yard. The most reliable is a two-row combination of fencing. One spiral is placed vertically, the second one below it from the side of the yard on inclined or horizontal brackets.

Diagram of guide cables and turns

Installation of barbed wire

The fence can be made entirely of barbed wire or complement the finished fence. The first method is well suited for limiting areas for pastures for livestock or temporary fences, the second option is more often used for reliable protection of private territory, as well as industrial buildings, warehouses and other specially protected facilities.

Types of brackets for fastening Egoza wire

Depending on the type of fence and the type of Egoza, various fasteners and brackets made of steel are used. With their help, the installation of a barbed fence is greatly simplified. Fastening to the support posts is carried out using welding or self-tapping screws.

-

Straight bracket. Designed for fastening wires in several rows and installing spiral barriers. The straight bracket can be replaced by using the upper part of the support post, which should rise above the fence;

- L-shaped bracket. Used to install barbed tape in several rows. A bracket with taut wire lines is angled to the outside or inside of the fence. A volumetric spiral tape can also be suspended on the L-shaped bracket;

- Y-shaped bracket. Used for the installation of volumetric spirals or the installation of rows of barbed tape;

- Semicircular bracket.Can be installed straight or tilted to the ground, convenient for attaching spiral safety barriers.

Installing a barbed wire fence

The installation of a barbed fence requires a certain skill and accuracy.

Installation of barbed wire on a concrete fence

- Protective clothing. For the installation of a barbed fence, you will need thick clothing. The hands and wrists should be especially carefully protected: the barbed tape can even cut veins. Thick leggings for welding work are suitable for this purpose;

- Brackets and welding machine;

- Brackets and mounting pliers for them;

- Egoza and steel wire broach.

Stages of installing SBB on the fence

- Installation of brackets. A suitable fastening is welded onto the posts or screwed with anchor bolts.

- Installation of a broach. A simple galvanized or barbed wire is stretched between the brackets, which will serve as a support for the spiral structure and will not allow it to sag. The broach should be taut, for this it is advisable to use some kind of tensioning mechanism, for example, a winch. Depending on the diameter of the spiral, one to three rows of wire are installed.

- Stretching the SBB. The spiral barrier is stretched very neatly with the required number of spirals per meter. It is recommended to leave 5-6 turns per linear meter.

- Fastening barbed wire. With the help of staples and pliers, Egoza is attached to the tensioned wire and brackets.

Installation of a spiral barrier on the ground

To install a barbed fence on the ground, it is better to use spirals of a larger diameter in 2-3 rows.

The beginning of the installation of barbed wire on the ground is carried out in the same way as when installing a conventional fence. Pillars are installed with a step of 2.5–3 m and concreted. Metal pipes are used as support pillars. The cross section can be even the smallest. The wire is pulled depending on how the barbed wire is installed. The Egoza is mounted on a supporting wire and secured with staples.

The appearance and design of the barbed wire fence

Barbed wire, and especially its new varieties in the form of Egoza spiral barriers, is an excellent way to quickly and inexpensively protect a summer cottage from invasion. Any fence, even the most fragile, can be turned into a dangerous obstacle in the way of intruders.

Painting after installing the fence in the garden

For each material used in the building, you need to use the most suitable coloring agent.

There are a lot of types of paints and varnishes, so we will consider only the most popular ones that are suitable for the previously described materials for fences.

After installation, painting the fence with your own hands is done with a brush, spray gun or paint roller. It is not difficult to paint a forged fence, which cannot be said about a mesh-netting, and the smaller its cells, the more difficult it will be to paint over them. A mesh fence is best painted with a brush. The paint roller is suitable for painting solid surfaces such as sheet metal, solid sections, or a solid wood fence. The spray gun is also not suitable for painting through structures, since most of the paint will be wasted. This fixture is suitable for painting large parts or a solid fence.

Wooden fences are most susceptible to rot and mold damage, so they need constant careful maintenance. Covering and glazing antiseptics, as well as acrylate and oil paints are used to protect them.

Antiseptics penetrate deep into the wood and help protect it from destructive external influences.

Covering opaque materials allow you to completely hide the texture of the wood, preserving only its relief.

Oil paint penetrates deeply into the wood and serves as a reliable protection against atmospheric agents, but it dries slowly and fade over time. Service life - 5-7 years.

Watch a video of painting a do-it-yourself wooden fence:

Acrylate paint protects wood well from dampness and mold, retains its shine and color longer than oil paint. In addition, it is vapor-permeable, that is, it allows the tree to breathe and has a pleasant elasticity. Service life - 7-9 years.

Before painting, the surface of metal and slate must be cleaned with sandpaper, removing roughness, rust or old peeling paint.

For painting metal structures, paint should be used, first of all, that can protect the surface from corrosion. There are a number of anti-corrosion paints and enamels that help preserve metal structures. Even if rust appears on the metal, it can be dealt with by using a special “converter” paint designed to cover corroded areas.

It is customary to paint galvanized and aluminum fences with dispersion paint. The service life of such a coating is 5 years.

Slate fences are considered the lowest budget. They are often installed for temporary fencing of the site, although after staining such fences acquire a more aesthetic appearance and look quite dignified. For slate, there is a special paint of both foreign and domestic production, which protects it from the appearance of moss and lichen on it. You can apply paint to the surface with a regular brush, spray gun or roller. Its service life is 8 years.

How to paint a slate or metal fence after installation with your own hands is demonstrated in this video:

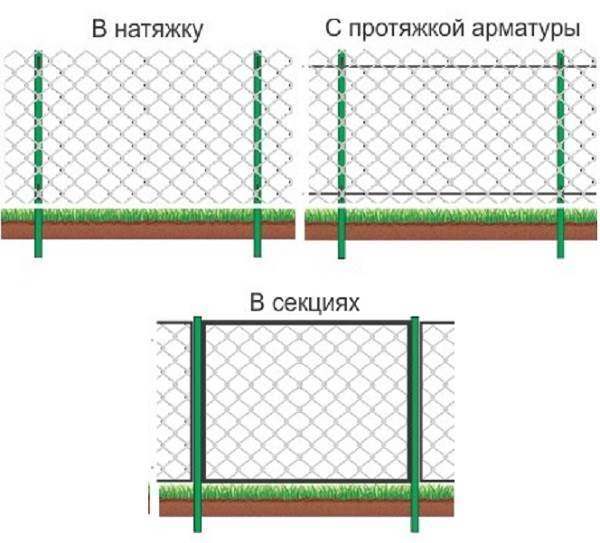

Installation options

Installation options are of several types. Let's take a closer look.

By the fence

Barbed wire can be pulled over existing fencing structures without any problem. There should be no difficulties when installing it at the level of the existing fence, in addition to it. It is this solution that is most often used when it is necessary to provide reliable cover for private dwellings. But wire barriers are also rolled over fences near industrial facilities, warehouses, ports, television centers, military installations, and so on.

To install a barbed barrier with your own hands, you must use a variety of mounts and steel brackets. The choice of connection means depends on the specifics of the fence. So, if support pillars are used there, most often the support elements are welded or screwed on with self-tapping screws. Straight brackets allow you to fix the wire in several rows and put spiral barriers. They can be replaced with the upper parts of the support posts. The main thing is that they rise above the fence.

With the help of brackets in the shape of the letter L, you can put several strips of barbed ribbons at once. The fastening of the working element with the wire stretched over it is carried out with an inclination inward or outward. The L-shaped support block also allows you to suspend volumetric belts in the form of a spiral. A volumetric spiral and rows are also mounted on a Y-shaped bracket. The difference between them is only in the convenience of using a specific form of the product. With semicircular brackets, everything is no more complicated: they are placed directly or at a certain angle, mainly for the purpose of creating spiral fortifications.

When the brackets are delivered, the wire itself is mounted between them, used as a support. If this is not done, the main protective barrier will inevitably sag.

Important: the broach is pulled tighter using winches and other mechanisms. It is very difficult to correctly tighten this element by hand and it does not always work out at all.

The number of strips of the installed wire (1-3) is determined by the diameter of the spirals.

Further:

-

stretch the SBB (as carefully as possible, making sure that the required number of turns falls on 1 meter);

-

attach the wire itself;

-

check the result obtained visually and by the level of tension.

On the ground

When arranging a ground fence, it is better to fasten spirals of a large diameter, and in 2 or 3 rows. It is believed that the safest barrier is when the skeins are laid out in the manner of a pyramid. The initial stage of work is no different from installing a simple fence. First of all, pillars are placed with a step between the installation points from 2.5 to 3 m (it is not recommended to deviate from this corridor of values). Many experts consider ordinary metal pipes to be ideal support pillars.

The cross section of the pipes used is not too important. You can take the smallest pipe. The wire is pulled according to the selected obstacle installation method. When this is done, the Egoza is mounted on the original wire. It is advised to fix it with staples.

How to make a fence?

Arranging an all-barbed wire fence is a reasonable option for those who want maximum security. This solution is sometimes used by the owners of cottages where there is something to steal. However, in warehouses, in industry and agriculture, it is found much more often. In any case, a solid wire fence will definitely require the use of poles. They are made from dissimilar materials, mainly metal or solid wood.

Even the best breeds, thoroughly protected by chemical compounds, cannot boast of resistance to precipitation. The metal is better in this regard, however, it is required to select high-class stainless steel. Whether to make a flat or volumetric fence - you have to decide on your own. You will have to work as carefully as possible, because barbed wire sometimes provokes serious injuries.

For your information: in some cases, the posts are made of concrete. Regardless of the specific material, it is advisable to concrete the supporting structures. It is much more durable. The diameter of the wellhead for concreting must exceed the cross-section of the support by 0.15-0.2 m. A pillar is hammered into this place, and then it is poured with concrete with the necessary fillers.

Installation of fence posts

Methods of mounting a fence to a professional pipe are different. But, one way or another, this is a crucial stage - marking the site and fastening the netting mesh to the support.

Fence installation diagram

Fence installation diagram

Selection of section and dimensions

Before you fix the netting to the posts, you need to clearly, taking into account the documentation, measure the fence under construction, calculate the location of the gate and wicket. The site for building a hedge must be cleared of debris.

Next, you should drive in wedges made of wood or reinforcement in place of the corner posts. To find out the location of the intermediate supports, you need to stretch a strong rope or cable between the wedges, and then measure the distance.

Mounting schemes

Mounting schemes

It is best to install supports from a professional pipe every 2 meters. That is, the resulting length of the fence will need to be divided by 2, rounding up. This method allows you to determine the total number of posts.

Areas of future racks also need to be marked with stakes. Taking into account the type of land, the thickness of the professional pipe and the type of fencing, several methods of installing the pillars are chosen.

Fixing sketch with cable

Fixing sketch with cable

The board support is short-lived, concrete fence posts can create difficulties during the fastening of the chain-link. The solution is a round or rectangular pipe with a section of 50x50 or 60x60 mm.

The photo shows metal pillars from a professional pipe.

Metal fence in the village

Metal fence in the village

Installation of pillars

Installation of a professional pipe for a fence is done in the following ways:

- partially or completely fill in concrete in previously dug holes;

- zabout - set in the hole and cover with stones;

- drive into the ground.

Installation diagram of a fence post made of metal

Installation diagram of a fence post made of metal

This takes into account the type of soil, the level of groundwater and soil freezing. But for the installation of the chain-link, the probable movements of the racks in a couple of centimeters are insignificant in length and width.

In practice, the rule is applied - at least 30% of the professional pipe must be buried in a pit.So, the pillars of 2.5-meter professional pipes must be buried 80 cm for any installation option.

Installation drawing of fence posts

Installation drawing of fence posts

Tension option

A characteristic feature of all chain-link fences is the ease of construction. You can do everything with your own hands, even for a person without any construction skills. For example, you can consider how to properly pull the netting on the fence from the professional pipe.

Wire mounting

Wire mounting

Territory marking

At the corners of the perimeter, you need to install stakes and pull the rope. Its length is the total length of the mesh for the fence, but the canvas is acquired more by several meters.

Next, you need to mark the areas for attaching the racks. Usually the distance between the posts is no more than 2.5 m, since the chain-link is a flexible material.

Installation diagram of fence posts

Installation diagram of fence posts

To calculate the required number of supports and then pull the chain-link, the length of all sides of the perimeter must be divided by 2.5. For example, the length is 57 m. Such a length will definitely not be divided by 2 or 2.5. If you divide by 2.5, you get 22.8. Further, there are several options for the development of events.

The first one is to put 22 supports with the same interval between themselves, 57/22 = 2.59 m. But it is almost impossible to calculate the place of fastening of the supports so accurately. Another way out to pull the banner over the fence is to put 22 supports with a distance of 2.5 m, and the last pillars will stand a little closer. This way you can determine how many racks are required to pull the canvas.

It is necessary to drive stakes along the rope with an interval of 2.5 m. All the time it is necessary to control that they are on the same line. Then in the end it will turn out to beautifully pull the chain-link.

Sketch with mounting options

Sketch with mounting options

If the area has a large slope, it will not work to pull the chain-link, since the mesh will be poorly fixed in an inclined state. There is only one way out - to terracing the site.

Where there is a significant transition and difference in ground level, a longer and reinforced rack is placed, where the canvas is fixed on one side at one level, and on the other side - on the other. Why should the material be cut. Another way is to build a fence with free-standing frames.

The photo shows a fence in the country.

Near a private house

Near a private house

Installation of supports

In places for the installation of fence posts, you need to drill holes. The depth of the well is usually 1.4–1.6 m. To prevent the racks from moving when the earth swells in spring, they should be deepened 20–25 cm below the freezing of the soil.

First, they put corner posts, they have the greatest pressure. A layer of gravel (20 cm) is poured onto the bottom and tamped well. Then sand (20 cm) is added and also tamped.

Sectional fence drawing

Sectional fence drawing

Insert a professional pipe, before covering the underground part with an anti-corrosion compound. A concrete solution is prepared: 2 parts of cement (concrete grade not lower than M250) and 1 part of sand. We knead, then 4 parts of crushed stone are added and everything is mixed again, water is poured and also mixed. The main thing is to control so that the concrete does not turn out to be very liquid. Then we pour it into the well under the post.

It is imperative to look at the level of the pillar. It should be clearly vertical. This can be checked with a plumb line.

We pierce the concrete solution with the reinforcement, removing the air. The next is the corner support from the opposite part of the fence. Then all other racks are mounted using the same technology. You can stretch the canvas only after the solution has hardened, that is, after 10-14 days.

Dimensional diagram

Dimensional diagram

Metal facade mesh for a fence: general information

Plastic facade mesh is cheap and easy to use. But its mechanical strength does not satisfy everyone. The metal mesh is much stronger.

Characteristics and features by type

Existing metal meshes are classified by type

- galvanized welded mesh in rolls;

- masonry welded mesh or armopoyas;

- wicker mesh, the popular name for mesh-netting;

- hinge mesh;

- crimped mesh;

- woven mesh.

The mesh is made on special machines either by resistance welding or by weaving. The starting material is steel wire, which can be galvanized, black, alloyed or PVC coated. The main technical and consumer indicator characterizing the mesh is the cell area. Mesh sizes in the range from 5 × 5 mm² to 200 × 200 mm². The weight of a roll depends on the size of the cell, and on the thickness of the wire, and on the length and width of the tape rolled into a roll.

Rabitz

The most popular mesh among summer residents is a wicker mesh netting. It is believed to be named after its inventor Karl Rabitz. Its structure is formed by the interlacing of wires. Low carbon steel is galvanized to protect it from corrosion. In areas with a maritime climate, polymer-coated wire is used.

The chain-link mesh is widely used in the construction business - when screed floors, to strengthen plaster, to strengthen the insulation of pipelines. In road construction, it is used to filter bulk materials.

Related article:

Welded grating

The welded mesh is produced by resistance welding of two perpendicularly spaced wires. Constructions made on the basis of welded meshes are more rigid in comparison with their counterparts made of chain-link mesh. To protect against corrosion, the wire is either galvanized or covered with a polyvinyl chloride sheath. In the latter case, the mesh becomes more aesthetically pleasing.

Pros and cons of metal fences

The main advantage of metal fences is their reliability and durability. In this case, we mean functional reliability, that is, reliable protection against unwanted intrusions. The fence assembly technology is simple. The downside is the increased cost of the finished fence. Moreover, the need to protect it from corrosion in the open air.

Installation of metal grids

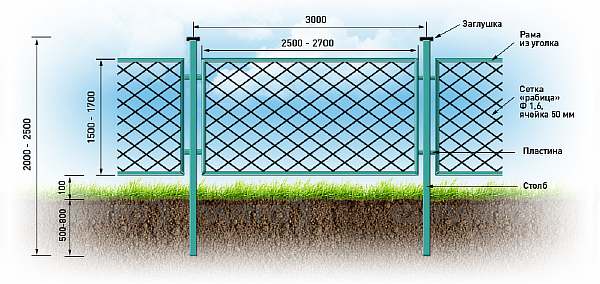

It is not reasonable to make a temporary fence from a metal mesh, you need to immediately build it thoroughly. Steel pipes with a diameter of at least 10 cm should be taken as pillars. The pillar should be buried 1 m into the ground and poured with concrete. The use of special concrete posts is also possible. A wire is pulled along the tops of the pillars. The net roll is unwound and the top edge is attached to the wire along its entire length. For strength, you can stretch along the bottom edge of the mesh.

Brackets for wire fastening are installed on the top of the post. If the structure of the fence is sectional, then sections are mounted on the brackets. Their fastening can be welded (non-collapsible) or bolted (collapsible). This is at the discretion of the owner of the site.

Gitter mesh fence PHOTO: Leonid Shalman

Gitter mesh fence PHOTO: Leonid Shalman Metal fence made of rods PHOTO: Leonid Shalman

Metal fence made of rods PHOTO: Leonid Shalman