Views

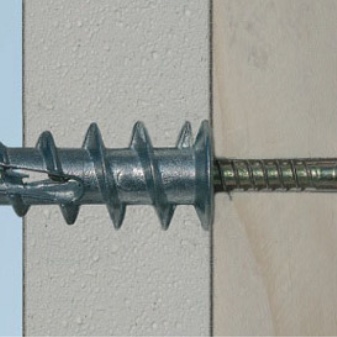

Dowel-nails are classified depending on the characteristics of the bearing surface. In particular, for solid porous concrete, hardware of the M150 brand will be required - it is characterized by a special relief and includes a pair of spacers, additionally they provide a self-tapping screw or a threaded stud. Aerated concrete hardware is equipped with wide-pitch spiral ribs. They are optimal in the case of a large area of contact between the hardware and the hole. For drywall, concrete and many other porous materials, the choice is best made in favor of products equipped with spiral threads. They usually have a twist drill at the end, which allows fixation to be carried out without preliminary hole preparation.

There are the following types of nails for hollow bases:

Molly - the distinctive feature is the release, which provides a strong fixation of the drywall; the maximum load on each hardware reaches 30–35 kg;

There are also self-tapping and wedge hardware. According to the installation technique, the hardware is divided into those installed with a construction pistol, as well as driven ones. To fix the anchor-type hardware, you need to place the pistol in the area of the intended attachment and "drown" the trigger. At the same time, there is no need for drilling holes and this greatly reduces the total time of repair and installation work, and in addition, eliminates the formation of construction dust in the room, which usually appears when using a drill and screwdriver. At the end of such hardware, a thickened rod is provided; a lock washer is attached to it. The inner nail provides for a large hat, it does not allow the hardware to sink into the building material

It is important to keep in mind that such fasteners cannot be reused.

From the point of view of functional purpose, the brass dowel-nail can also be attributed to this category. Its fixation is carried out by screwing it into the drilled holes. A distinctive feature of such products is their anti-corrosion characteristics, which determines a wide scope of their operation. The functionality of the driven dowel-nails varies depending on their dimensions. Most often, their length ranges from 25–70 mm. Such a choice of dimensions allows hardware to maintain the versatility of fastening not only for loose bases, but also for harder surfaces. The lack of strength of loose bases is compensated by a smaller pitch between fasteners.

Characteristic

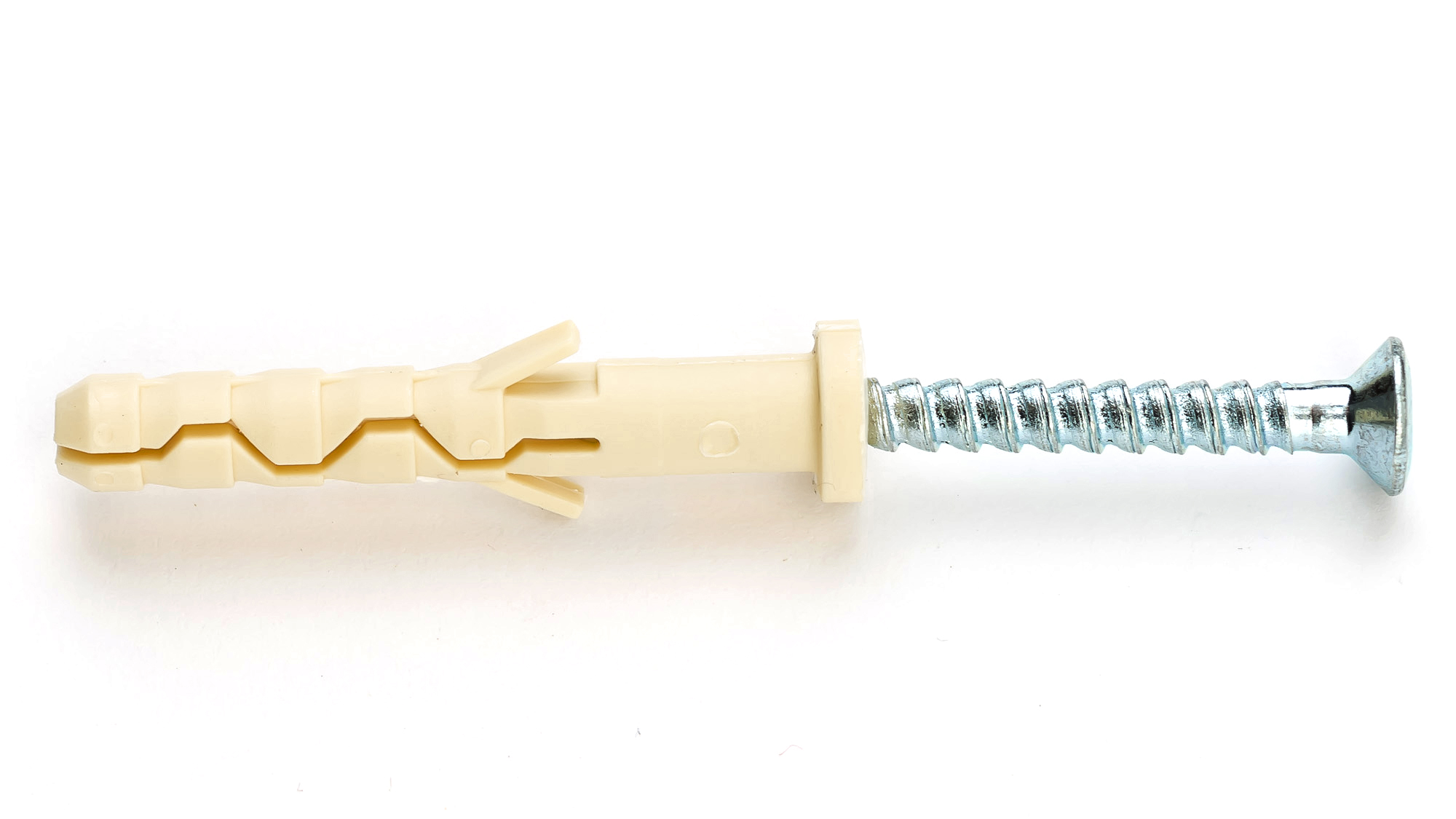

From a technical point of view, any dowel-nail includes several structural elements - the dowel itself and the nail. The dowel looks like a metal cylinder with prefabricated elements located on the sides. When the nail is inserted into the cavity, they begin to straighten, thus ensuring the most durable fastening of the parts in the base. The outer part is complemented by a small cuff. It prevents the entire nail from falling into the inner cavity of the base.

The thread in the nail of the hardware is applied asymmetrically, this excludes the occurrence of obstacles for its introduction into the dowel. However, it does not allow it to be pulled out later, such a dowel can only be unscrewed. For this, a slot for a Phillips screwdriver or a screwdriver is fixed on the head.

Fasteners made with steel nail dowels are very difficult to dismantle. They lead to a long operating period.The most reliable fixing strength can be achieved when working with hard as well as corpulent materials. Among the main advantages of a metal dowel-nail, the following are distinguished:

- increased bearing capacity;

- long period of service;

- resistance to high humidity and temperature fluctuations;

- resistance to rust.

An undoubted advantage can also be called the breadth of the assortment - in modern stores there is a large selection of dowel-nails for any occasion. However, it was not without its drawbacks. So, there are certain restrictions and requirements for the technique of work, since the fasteners create a noticeable stress in the base. In addition, metal hardware is more expensive than their plastic counterparts.

Dimensions (edit)

For fixing various materials, it is necessary to choose an appropriate size dowel-nails. Its marking contains 2 numbers, for example, 5x30 - the first of them shows the diameter of the attachment, and the second shows the size of the hardware itself in millimeters. The most popular are hardware of the following standard sizes:

- 5x25, 5x30, 5x40;

- 6x30, 6x32, 6x49, 6x35, 6x40, 6x50, 6x60, 6x70;

- 8x80, 8x50, 8x60, 8x80, 8x100, 8x120, 8x140;

- 10x80, 10x100, 10x120, 10x130, 10x140, 10x160.

Any types of fasteners have their own limitations on the ultimate load, so the selection of the length directly depends on the size of the material to be fixed. So, a dowel with parameters 6x40 will be a good solution for fixing the profile in buildings of efficiency, where the walls and ceilings do not provide for cavities. For brick blocks, dowel-nails of the size 6x60 or 6x80 are optimal.

Application

The technical and operational properties of universal hardware make it possible to use them everywhere for attachment to planes made of such building materials as:

- cellular concrete;

- concrete;

- plaster;

- GKL;

- hollow brick.

Such hardware has become widespread in the implementation of construction and finishing works. The parameters of using one or another hardware are determined by the characteristics of the base, the number of fasteners, and also their type depends on the technical features of the installation. The following points are usually taken into account:

- type of fastener;

- material;

- place of installation;

- work load;

- axial distance.

The scope of use of hardware is quite wide - they are universally in demand when arranging stretch ceilings and all kinds of metal frames. Dowel-nails are irreplaceable when performing thermal insulation of external facades and internal walls of the house. Features of fixation on solid bases allow using these hardware for wall cladding with insulation and cladding panels. Fasteners designed for fixing with a construction gun are quite convenient to attach metal structures to a wooden or concrete base. It is no coincidence that this dowel is often used when fixing metal canopies over balconies, loggias and windows.

In the next video, you will check the fastening of a metal dowel in a piece of aerated concrete.