Manufacturers

PF-115 is manufactured by many Russian enterprises. But the tough competition for the consumer led to the fact that the domestic market of paints and varnishes was filled with low-quality cheap enamels produced under the PF-115 brand, only not according to GOST, but in accordance with TU.

Some manufacturers of paint and varnish materials practice the implementation of special marketing solutions in order to distinguish their low quality products from other low-grade products. As a result of such a marketing policy, a brand of pentaphthalic paint appeared under the marking 116 with its other derivatives such as Ultra, Extra, Super.

Only products made in strict accordance with GOST 6465-76 deserve trust, but not with TU - technical specifications of enterprises, which most often establish individual quality indicators in order to reduce the market price of their products.

Lacre

This is a well-known Russian company specializing in the manufacture of decorative paints and varnishes. Universal alkyd enamels "Lakra" have excellent interlayer adhesion, high atmospheric resistance and hiding power. The range of colors includes over 40 color solutions. Most of them form a glossy finish. The guaranteed shelf life of paintwork materials is 24 months.

Prestige

The holding produces paints and varnishes of the highest quality combined with an affordable price. In 2005 the company presented two technological innovations - a budgetary pentaphthalic paint "Kazachka" and a premium high-quality alkyd enamel paint "Poller". Both products are manufactured in full compliance with the standards for this group of paintwork materials.

In the line of alkyd enamels, there are many other decent paint and varnish coatings. This is a super-white PF-115 with a high degree of gloss based on a cleaned, clarified varnish and a heat-resistant, anticorrosive, silver-colored decorative coating with natural aluminum powder as a filling fraction, which can be used to paint radiators, heat pipes, and chimneys.

A very interesting option is an eco-friendly semi-glossy acrylic quick-drying universal enamel, which, when applied, begins to smell like a green apple. As the polymer coating dries, the apple smell weakens and disappears.

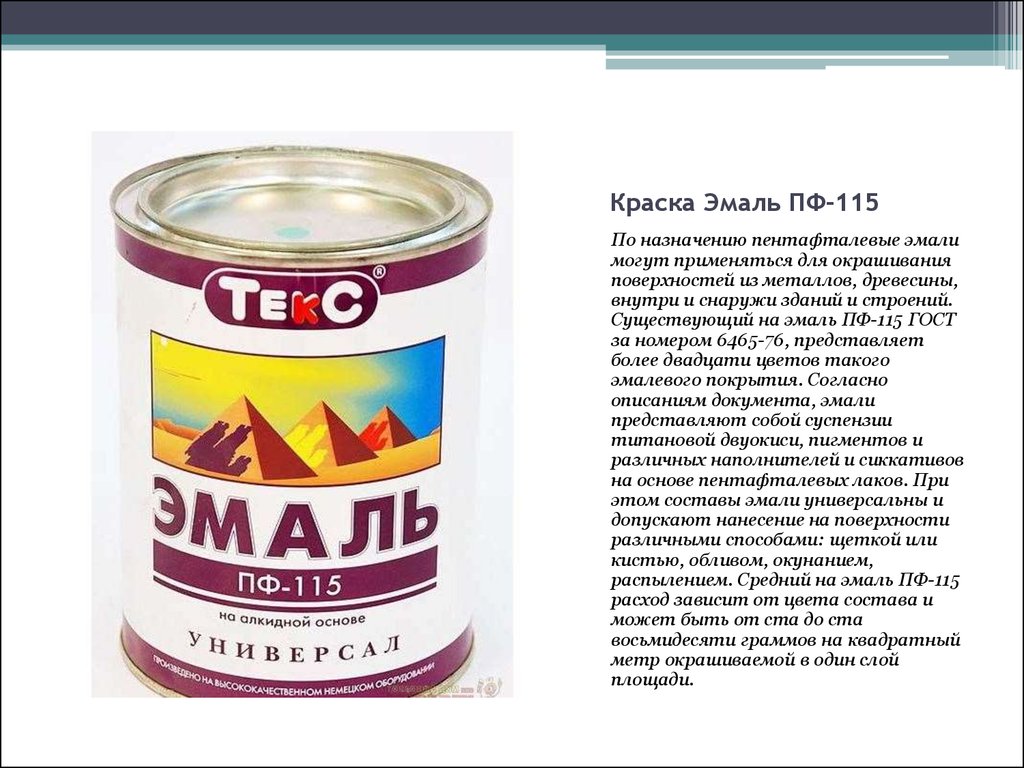

Tex

One of the largest manufacturers of paintwork materials with a wide network of construction stores located throughout Russia.

There are several types of PF-115:

- universal alkyd white matt and glossy with the possibility of tinting according to the catalog;

- universal glossy color, which, in addition to wood and metal, can be painted on plaster bases, building structures made of gypsum plasterboard, fiberboard / chipboard;

- "Fazenda" - enamel forming a glossy finish, characterized by an economical consumption of 1 kg / 6-16 m2 in a single layer application and resistance to weathering;

- "Optimum" - enamel paints with a drying period of up to 7 hours. Interlayer drying interval - 24 hours;

- "Economy" for mass construction and painting of wood and metal structures.

Buyers still consider enamel paint made according to the original recipe to be a good "folk" remedy, noting the elasticity of the film and its resistance to external factors. Many summer residents are happy that, with a limited budget, you can quickly improve the outbuildings on the site after winter or update the old fence covering.

Manufacturers

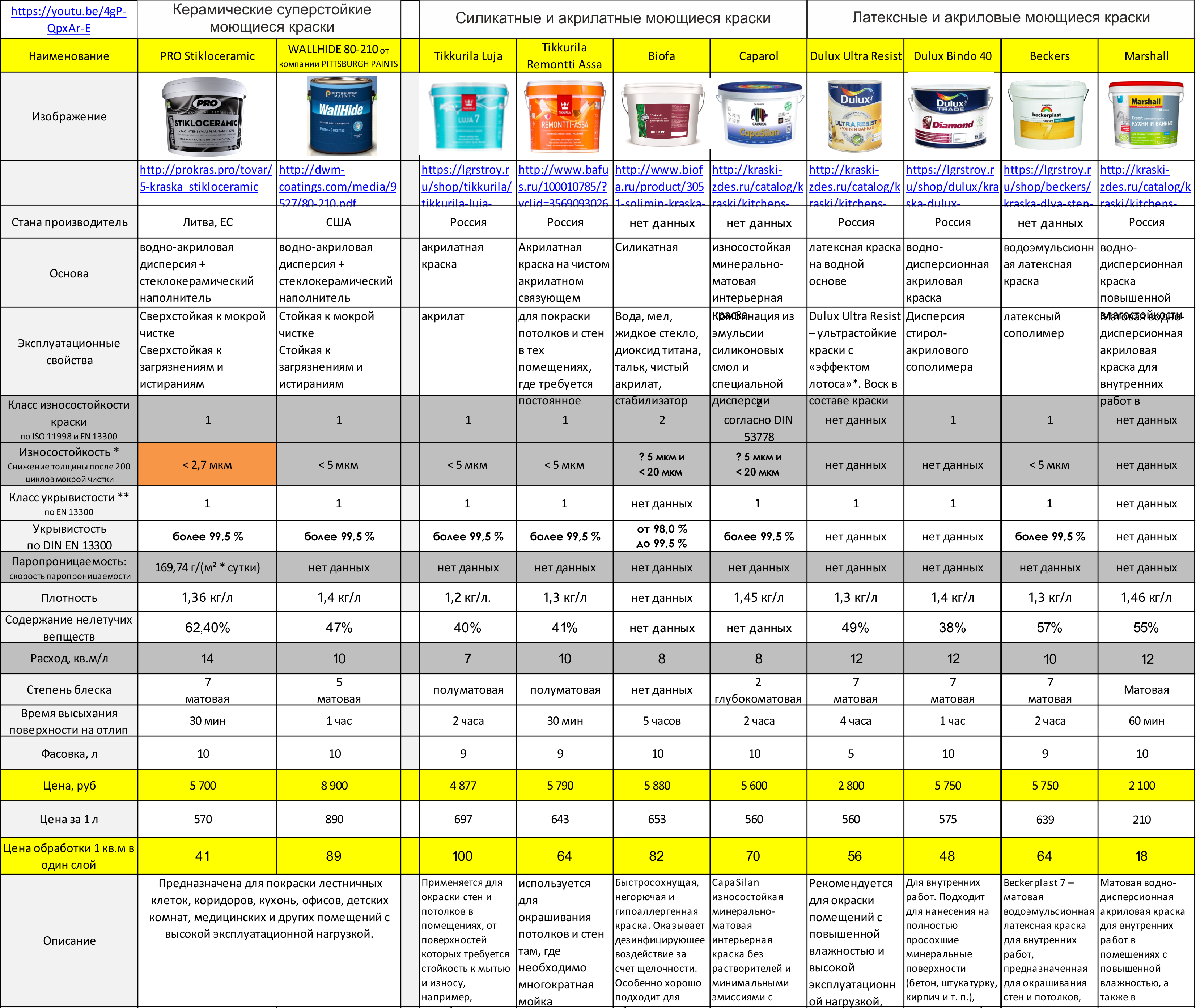

There are a lot of manufacturers offering a wide range of paints and varnishes today. Some of them have a long history of successful development, others offer products that are in demand not only in the domestic market, but also abroad.

In order not to get confused and buy truly high-quality products, we will focus on the most famous and time-tested brands.

-

The rating is opened by the company "Tex" - one of the most popular brands today. The company offers a wide range of interior and exterior finishing materials. The series of coloring compositions PF-115 includes several types.

- "Universal". The paint is presented in a wide range of colors: white, black, beige, cherry, emerald, bright green, caramel, cornflower blue, etc. The paint is suitable for painting structures and surfaces made of wood, metal, concrete, as well as chipboard and fiberboard. 1 kg of enamel allows you to cover an area of 7-13 square meters. m (1 layer). Shelf life is 2 years. The paint is produced in containers of different packaging: from 0.5 to 60 kg. Gloss degree - gloss.

- Optimum. The material is presented in 20 shades of varying degrees of saturation. Suitable for most types of surfaces. Not used for flooring. Consumption - 1 kg for 7–11 m Shelf life - 1.5 years. Gloss level - gloss and matt (only for white enamels).

- "Fazenda". Ideal for cost-effective renovations. Consumption - 1 kg for 6-16 m2. Used for painting wood and metal. Not applicable for floor coverings.

- "Economy". This type is most often used in mass construction. Gloss level - semi-gloss. Used for most types of surfaces. Consumption - 1 kg for 6-10 m2.

-

Empils. Under this brand, several series of paints and varnishes are produced annually, intended for both industrial and private use. Enamel PF-115 is presented in several collections.

- "Dachnaya". Suitable for decorative finishing of surfaces made of most materials. Used to decorate window frames, doors, etc.

- "Plainly colored." For the decoration of structures made of wood and metal that are exposed to the weather, as well as those used indoors.

- "Flourishing". Matt paint for indoor and outdoor use.

- Empils. Glossy and matte variety for interior and exterior use.

The cost of products from different manufacturers can vary significantly. It depends on the use of pigments and fillers of different quality, the popularity and "promotion" of the brand, the technical characteristics of the product, etc. And the quality of the pigment has a direct impact on such technical characteristics of the enamel as hiding power and its resistance to solar radiation. Dyes of the Empils trade mark are among the most "non-combustible" compositions.

In the next video you will find a comparative review of PF-115 enamels.

Enamel PF-133

Enamel PF-133 has a fairly wide range of applications.

It can be used both for painting containers and for wood and metal surfaces that are constantly exposed to the atmosphere.

PF-133 can be of various colors, at the request of the customer.

- externally the film looks glossy

- it is recommended to apply two layers of material

- the guaranteed storage period is six months

PF-133 can be applied to the cleaned and prepared surface in different ways: by jet casting, dipping, brushing, electrostatic spraying, pneumatic and airless spraying. If the material is applied to a primed surface, then the service life of such a coating will be at least three years.

GOSTU

GOST 926-82

TYPE OF

Enamel PF-133 is a suspension of pigments and fillers in alkyd varnish with the introduction of organic solvents, desiccant and other additives.

RECOMMENDED USE

It is used in railway transport for painting containers, rolling stock and other metal and wooden surfaces exposed to the atmosphere.

DESCRIPTION

The enamels are resistant to weathering, mineral oil and various detergents.The coating based on PF-115 enamel is resistant to temperature drops from minus 50 ° C to 60 ° C.

CERTIFICATION

Hygienic conclusion of the Office of the Federal Service of Rospotrebnadzor in St. Petersburg, valid throughout Russia

SPECIFICATIONS

Color - at the request of the customer; Appearance of the film - glossy; Drying time at a temperature of (20 ± 2) ° С up to station 3 - no more than 24-30; at a temperature of (82 ± 2) ° С to st. 3 - no more than 1.5-2 hours; The proportion of non-volatile substances by weight - 46-69%, mass; Consumption per layer - 40-55 g / m²; Thickness of one layer - 18-23 microns; Recommended number of layers - 2 ...

MIX RATIO

DILUENT

If necessary, the enamel is diluted to the working viscosity with solvents: a mixture of solvent with white spirit (nefras - С4-155 / 200) in a ratio of 1: 1 by weight, in an amount of not more than 30% of the enamel weight. PF 133 enamel can also be diluted with a mixture of xylene with white spirit (mass content of white spirit is not more than 50%) in an amount of not more than 30% of the total volume. When applied by electrostatic spraying the enamel is diluted with RE-4V or RE-3V thinner.

CLEANING TOOLS

To clean the instruments, use a mixture of solvent and white spirit in a ratio of 1: 1 by weight.

CONDITIONS OF VALIDITY

Service life: PF-133 enamel with two-layer application on a pre-primed surface is at least 3 years.

WARRANTY PERIOD OF STORAGE

In unopened original packaging - 6 months from the date of production.

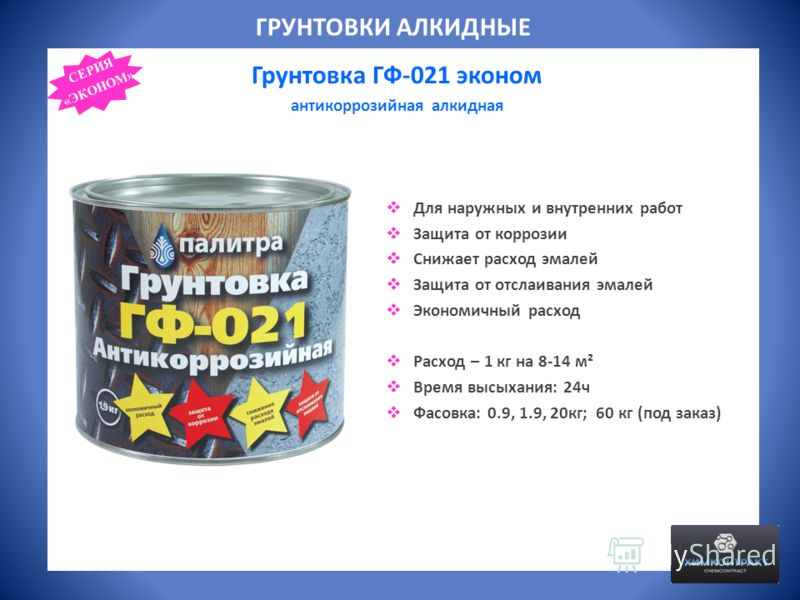

SURFACE PREPARATION

Before application, the surface is cleaned of dirt and dust, degreased. It is recommended to pre-coat metal surfaces with primers such as GF, EF and others, treat wooden surfaces with linseed oil. Before use, the enamel is kept for 24 hours at room temperature, stirred thoroughly until smooth. Dilute with the above diluent if necessary.

APPLICATION METHODS

Pentaphthalic enamel is applied to the surface to be painted using pneumatic and airless spraying methods, jet pouring, dipping, brush, it is possible to apply enamel by electrostatic spraying.

CONDITIONS OF APPLICATION

It is applied at an ambient temperature of 5 ° C to 30 ° C by pneumatic and airless spraying, spray dousing, dipping, brush, application by electrostatic spraying is possible

The interlayer drying time at a temperature of 20 ° C is 24-48 hours.

PRECAUTIONARY MEASURES

The material is flammable! Do not work near open sources of fire. Perform work with good ventilation, wearing rubber gloves, using personal protective equipment

Avoid inhalation and digestion. If the material comes into contact with the skin, wash it with warm water and soap. Store the enamel indoors, excluding direct sunlight and moisture at a temperature not lower than minus 200C.

Certificate PF-133.doc

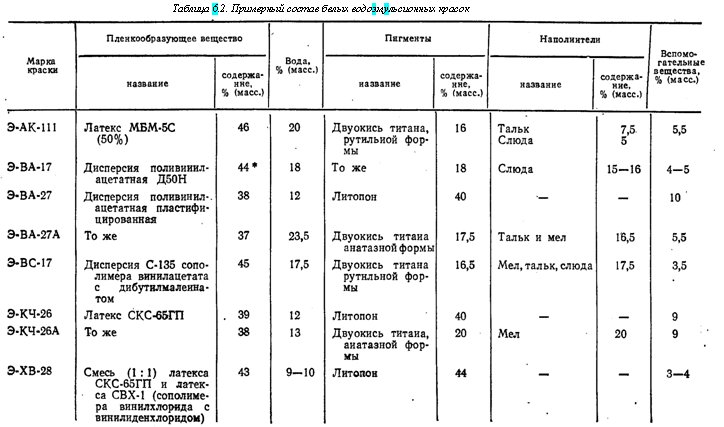

Chemical composition, marking, colors PF-115

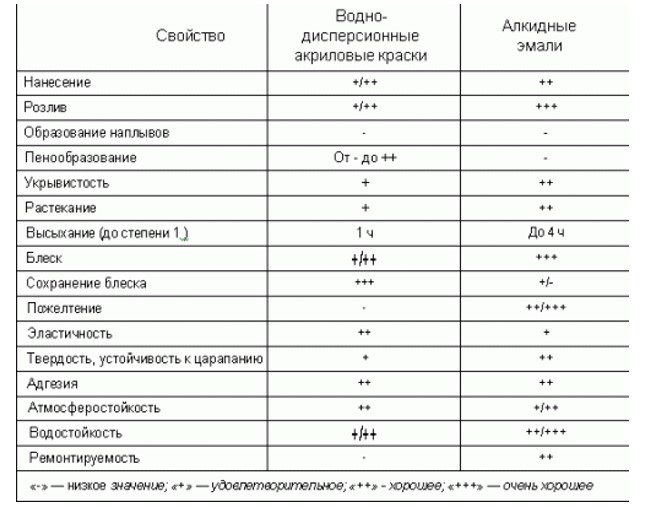

PF enamel refers to alkyd paints. Read more about alkyd paints here

GOST No. 6465-76 has become a regulatory document that once determined the optimal combination of components that make up this alkyd paint. This standard is used to check the quality of the composition before releasing it for sale. It is also allowed to produce pentaphthalic enamel according to technical specifications developed by manufacturers independently. This affects the cost and can affect the quality of the coverage.

From a chemical point of view, alkyd paint-enamel PF-115 is a suspension, which includes:

- solvent;

- pentaphthalic varnish;

- titanium dioxide;

- color pigments.

The proportion of the components changes depending on the color.

- According to technical characteristics, enamel PF 115 white contains: pentafle varnish 28%, titanium dioxide 62%, white spirit 10%;

- Gray - pentafle varnish 20%, titanium dioxide 75%, white spirit 4.5%, carbon black 0.5%;

- Blue - pentafle varnish 26%, titanium dioxide 60%, white spirit 4%, azure 4%, zinc white 6%.

Marking

When painting, it is important to choose the correct enamel. For ease of orientation, manufacturers use the generally accepted markings indicated on the label of the paint container.

So, the standard designation of the universal alkyd enamel PF-115 has five components:

- the name of the type of paintwork - in our case it is paint;

- abbreviation (PF), implying the presence of a pentaphthalic-based varnish in the composition;

- digital key. In this case, it is the number 115, where the first digit means that the material is suitable for outdoor painting or restoration, and the last two reflect the chemical composition that corresponds to GOST.

How to dry a painted product

There are two drying schemes for products, depending on the temperature of exposure to the surface. At a temperature of 20-22 degrees - 16 hours and at 100-110 degrees - 3 hours. If in the first case lacquer bt 177 dries in natural, domestic conditions, then with artificial exposure to heat, certain requirements must be observed. Before using hot dry, hold for half an hour at 22 degrees. Before use, the product should also be exposed to 18-22 degrees for 3 hours.

There are two drying schemes for products, depending on the temperature of exposure to the surface.

There are two drying schemes for products, depending on the temperature of exposure to the surface.

How to choose?

Enamel is considered an ideal coloring agent for floor coverings, as it allows you to update their appearance and provide the base with protection from negative effects and mechanical damage.

But in order for the floor to look beautiful at the end of the painting, it is important to choose the right type of enamel, which depends on the type of surfaces.

For a wooden floor, acrylic, oil and alkyd enamels are most often chosen. At the same time, the surface of the tree needs good preparation. To do this, it is leveled and covered with a protective primer.

Plank floors are often painted with oil enamel, as it is inexpensive and impregnates the array well. However, such a composition dries for a long time and has a pungent smell, so colorful work must be done in ventilated rooms. For areas where there is a large crowd of people, it is recommended to choose a polyurethane paint, since the floors need protection from scuffs, scratches and damage.

As for acrylic paints, they provide the wood with a glossy shine and prevent the formation of mold and mildew. This type of enamel is very popular because it is presented in a chic color spectrum and is characterized by high quality. Most often, acrylic mixtures are used for painting coatings in supermarkets, shopping centers and stores.

Concrete floors are sometimes found in living quarters. They are considered to be durable, but additional protection against abrasion and moisture is needed to extend their lifespan. In addition, concrete can crack and be mechanically damaged.

At the same time, acrylic dye prevails over the epoxy option, since after finishing it, the floor becomes shiny and beautiful.

Concrete coatings need to be painted in two layers, so this fact should be considered when buying enamel and purchased with a small margin. An epoxy mixture will also be a good dye for concrete, since it can withstand temperature changes. However, this material is produced in a small assortment of colors.

How and how to paint a wooden floor correctly, see the next video.

(depending on the volume).

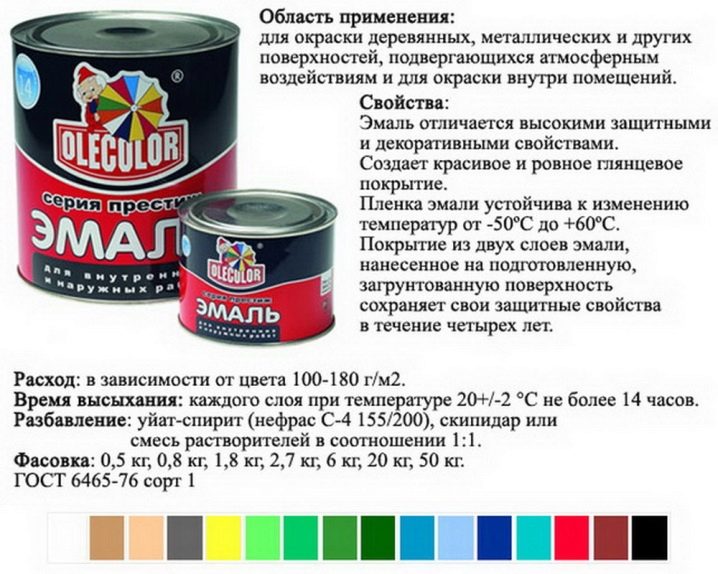

Description

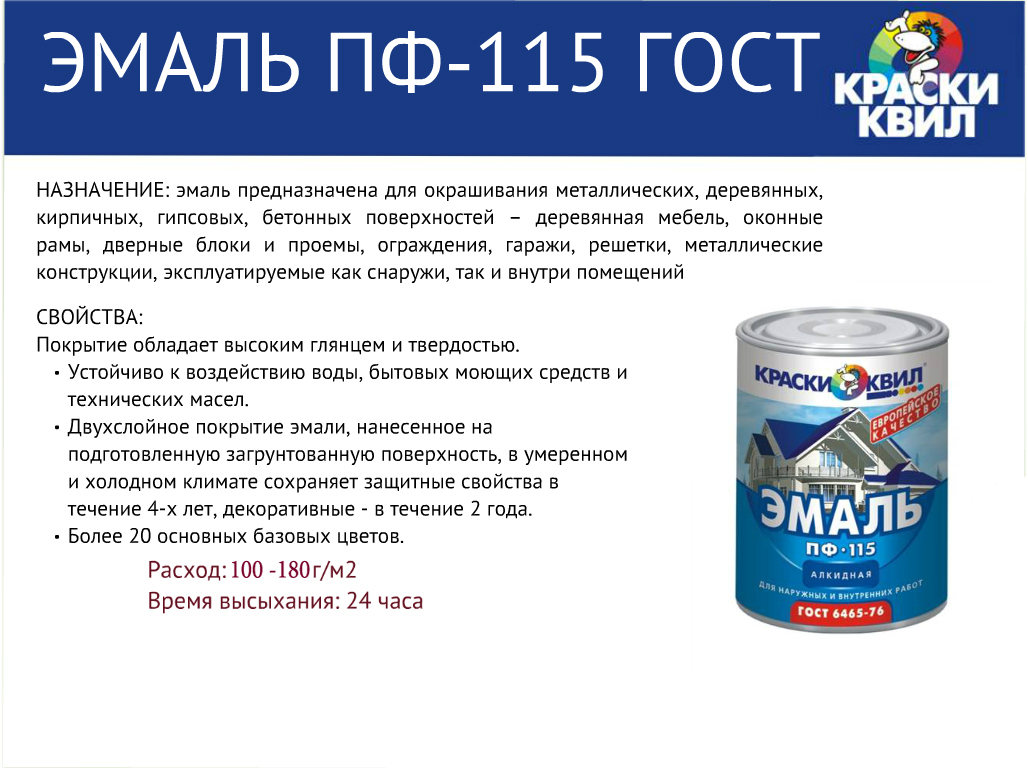

It is a suspension of rutile titanium dioxide and other pigments and fillers in pentaphthalic varnish with the addition of a desiccant, solvents and targeted additives.

Appointment

Designed for painting metal, wood and other surfaces exposed to weathering and for painting indoors. Enamel coatings have high protective and decorative properties.The film combines sufficient hardness with high elasticity and durability. The enamel film is resistant to temperature changes from minus 50 to plus 60 ºС. The coating, consisting of two layers of PF-115 enamel, applied to a prepared primed surface, in a temperate and cold climate retains its protective properties for four years up to a score of no more than AZ1 and decorative properties for one year up to a score of no more AD2 in accordance with GOST 9.401.

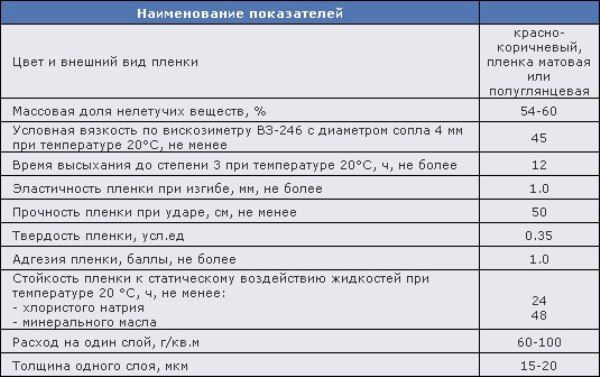

Specifications

| 1. Color of enamel coating | It must be within the permissible deviations established by the color samples of the "Card index" or control color samples, approved in the prescribed manner. | |

| 2. Appearance of the coating | After drying, the enamel should form a smooth, homogeneous surface without delamination, pockmarks, streaks, wrinkles and foreign inclusions. Slight shagreen is allowed. | |

| 3. The gloss of the coating according to the photoelectric gloss meter,%, not less | 50 | |

| 4. Nominal viscosity according to the VZ-246 viscometer with a nozzle diameter of 4 mm at a temperature of (20.0 ± 0.5) ºС, with red, cherry, black steel colors | 60-10080-120 | |

| 5. Mass fraction of non-volatile substances,%, depending on the color | 49-70 | |

| 6. The degree of dilution to a viscosity of 28-30 s according to a VZ-246 viscometer with a nozzle diameter of 4 mm at a temperature of (20.0 ± 0.5) ºС,%, no more | 20 | |

| 7. Degree of grinding, microns, no more | 25 | |

| 8. Hiding power of the dried film, g / m2, not more, depending on the color | 30-120 | |

| 9. Drying time to degree 3 at a temperature of (20 ± 2) ºС, h, no more, for enamels of colors: red, cherry and other colors | 4824 | |

| 10. Flexibility of the film, mm, no more | 1 | |

| 11. Strength of the film upon impact on the device of the U-1 type, cm, not less | 40 | |

| 12. Hardness of the coating according to the pendulum device of the TML type (pendulum A), relative units, not less | 0,10 | |

| 13. Film adhesion, points, no more | 1 | |

| 14. Resistance of the coating at a temperature of (20 ± 2) ºС to static impact of water, h, not less | 2 | |

| 15. Resistance of the coating to the static effect of a 0.5% detergent solution, min, not less | 15 | |

| 16. Resistance of the coating at a temperature of (20 ± 2) ºС to the statistical effect of transformer oil, h, not less | 24 | |

Notes: When using enamels, hot drying of the coating is allowed at a temperature of (105-110) ° C for 1 hour. At the request of industrial consumers, enamels of other colors are produced according to the RAL catalog and control color samples.

Preparation for painting

Coating work, according to SNiP 3.04.03-85, should be performed at an ambient temperature of at least 10 ºС. If the enamel was stored in an unheated warehouse in winter, then before use it should be kept in a warm room for the time required to warm it up to a temperature of at least 10 ºС. Stir the enamel thoroughly before use! If necessary, dilute with solvent, white spirit (nefras C4-155 / 200), turpentine or their mixture in a ratio of 1: 1 by weight.

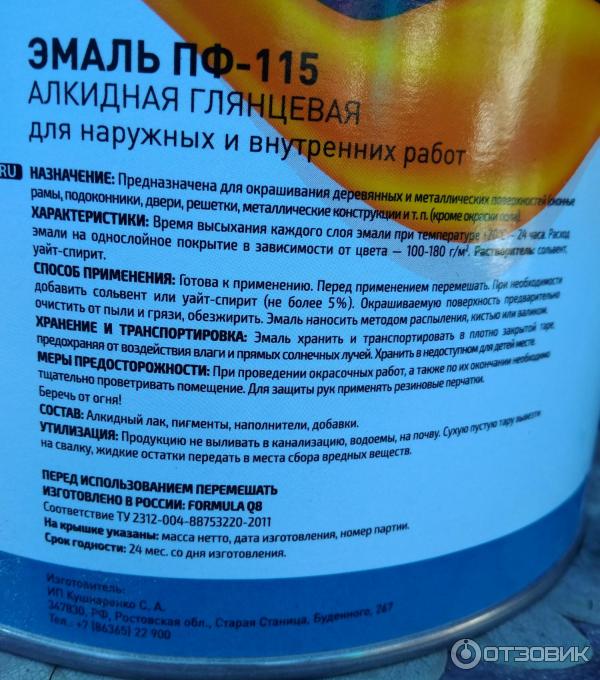

Application

The enamel is applied by spraying, blasting, dipping, brush or roller on a dry surface, previously cleaned of dust, grease and other contaminants, rust, scale and primed surface in two uniform layers. Drying time for each layer of enamel at a temperature of (20 ± 2) ºС - 24 hours. When applying cold enamel or on a cold surface, the drying time increases. Consumption of enamel for a single coat, depending on the color, is 100-180 g / m2.

Safety requirements

Enamel PF-115 is a fire hazardous and toxic material. When carrying out painting works, as well as after their completion, it is necessary to thoroughly ventilate the room. Use rubber gloves to protect your hands. The dried coating is SAFE for humans. Storage conditions Enamel is stored in a tightly closed container, protected from moisture, heat and direct sunlight.

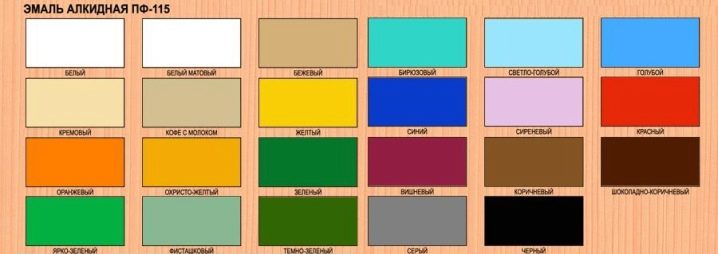

Colors

The range of colors of pentaphthalic paints contains mainly full-fledged colors, and shades are presented in limited quantities.After drying, colored enamels can form a film with a glossy, semi-gloss, matte, semi-matt texture, and the base white enamel paint forms only a glossy or matte finish.

The color range is presented in standard tones:

- yellow, light and pale yellow;

- beige and light beige;

- Orange;

- brown;

- red;

- cream;

- blue;

- blue, pale and grayish blue;

- turquoise;

- green and dark green;

- pistachio;

- emerald;

- gray, light and dark gray;

- white;

- black and others.

The new color palette is presented in the following shades:

- blue spruce;

- salad;

- fresh herbs;

- sack;

- gray;

- turquoise;

- red and blue lilac;

- chocolate;

- green apple;

- emerald;

- lemon;

- smoky gray.

The content of various dyes in the composition of enamel paints affects the performance of the coatings. The creation of some shades leads to a decrease in the quality of the final product. For example, this applies to cherry, red, black paints, which for this reason, instead of the highest grade, are assigned only the first.

Scope, technical characteristics of PF-115

Pentaphthalic-based alkyd paint can be painted on almost any exterior surface - it is used for work on concrete, metal and wood.

Oil paint PF-115 is suitable for processing the facade, walls, basement or roof. Any house, be it a wooden hacienda or a concrete panel-type structure, can be effectively painted in a short time. For each of them, the proportions of the use of components have been determined, which ensure the optimal technical characteristics of the PF-115. By the way, the general technical characteristics of this enamel include:

- the gloss of the film formed during coloring is 50%;

- paint adhesion 1 point or less

- mass fraction of non-volatile substances in the total volume - 50-70%;

- elasticity (when bending) - up to 1 mm;

- impact strength - from 40 cm;

- hardness - from 0.15 to 0.25 conventional units;

- drying time at a temperature of about 20 ° C - no more than 24 minutes;

- viscosity (conditional) - 60-120 s;

- resistance to: water - 2 hours, technical oil - 24 hours, detergent (0.5%) - at least 15 minutes.

These technical characteristics determine both the advantages and some disadvantages of pentaphthalic enamel. Let's analyze in more detail.

Advantages of PF-115

The main advantages of using this enamel are:

- high resistance to external atmospheric factors such as moisture, extreme temperatures (from -50 to +50 degrees) and ultraviolet rays;

- possibility of long-term operation - the shelf life of the coating in normal climatic conditions is about four years. But it is worth considering that with constant exposure to high temperatures and moisture, it can be reduced to one year;

- wide range of colors;

- increased resistance to chemical compounds - the coating can be safely washed using special detergents;

- high adhesion density with the base due to the high adhesion rate in the compositions (according to GOST up to one point);

- versatility of application: concrete, metal, wood. Including application on plaster or wood base covered with varnish is allowed;

- low consumption rates ensuring economy. The consumption of PF-115 enamel paint per 1 m2 according to the instructions is about 150 grams, and depends, among other things, on the technology used, as well as the type of surface;

- low cost. PF 115, in comparison with other paints and varnishes, has a low price - 1 kg of material will cost about 60-70 rubles.

Disadvantages of PF-115

Among the disadvantages inherent in working with enamel, experts point out:

long drying time - complete polymerization of the coating is about a day

This is quite a lot, considering how much the enamel of other types dries;

low fire safety class - despite the fact that a number of brands declare the presence of a KM-1 certificate, for the most part, PF-115 enamels are characterized by increased flammability;

toxicity and specific smell of the composition - working with paint requires compliance with all precautions, since it contains solvents and chemical components that are harmful to the human body and evaporate during drying;

the complexity of cleaning painting tools - as a rule, after the end of the work, it is easier to throw out the brushes than to dissolve PF-115, which has dried up during use.

What is the consumption of PF-115 paint per 1 m2?

Today, most people choose painting for finishing the ceiling and walls. To purchase the required amount of any paint and varnish material, its consumption per 1 m2 is calculated. In this case, the structure of the material and the specifics of the surfaces to be painted should be taken into account. What are the consumption rates of PF-115 paint per 1 m2 and how to find out the exact indicator?

The abbreviation PF in the name of the enamel means PENTAFTAL. It is easy to decipher - the composition of the paint and varnish material includes alkyd resins and semi-dried oils, which allow the paint to dry quickly.

Where is PF 115 paint applied?

Enamel PF 115 occupies a leading position in the market of paints and varnishes. If you can describe it in one word, then the most appropriate would be "versatility". It is used for painting any kind of surface. The paint can be mixed with other compounds as well as with a primer.

With the help of PF 115, such types of work are carried out as:

- interior painting of premises;

- exterior finishing works;

- painting on metal, plastic and wood.

The material perfectly tolerates high or low temperatures, atmospheric precipitation (rain, snow), and is resistant to UV rays. When enamel is applied to the surface, a dense, smooth film is formed. You can paint with brushes and rollers. In the presence of a spray gun, it is allowed to spray the composition over the surface.

On the video: types of paints.

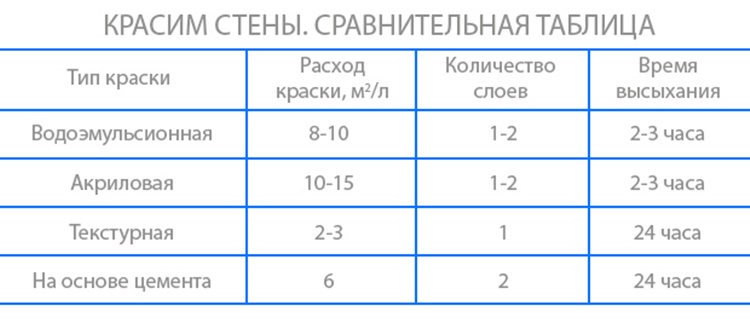

Consumption rates per 1m2

All of the above characteristics have a positive effect on enamel consumption. But if the painting takes place in windy or sunny weather, the amount of paint used per m2 will double. Oil paint of light shades is applied in two layers, one will not be enough, as streaks and gaps will be visible. Therefore, choosing white, gray or yellow, enamel must be purchased with a margin.

If the paint needs to be applied in two layers, wait until the previous one dries, and only then get to work. It dries up to about 24 hours.

Prepare your wall or ceiling surface before painting. First, wipe it with a damp cloth to remove dirt and accumulated dust. In order to save paints and varnishes, level the walls with putty and treat with a primer. The primer increases the adhesion (adhesion) and service life of the material.

The surface must be smooth, free from flaws and cracks. It is from the correct preparation of the walls and ceiling that the consumption of PF paint per 1 m2 will depend.

As practice shows, the consumption rate of the material varies from 100 to 180 g. Professionals also say that, on average, one kilogram cans are enough to paint 15 m2 of the prepared surface. Also, the consumption of PF 115 directly depends on the selected color pigment.

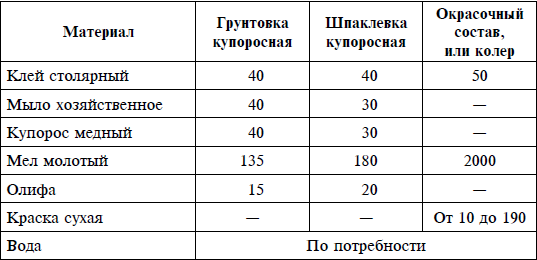

Table of approximate consumption of enamel PF-115 (depending on the selected color)

Enamel paint PF 115 and its consumption per 1 m2

Each paint has its own specific consumption and it depends on the specifics of the material itself and the surface that will be painted. I, like any master, are very interested in these values, because for high-quality preparation and for the purchase of the required amount of paint, you need to know all the nuances.

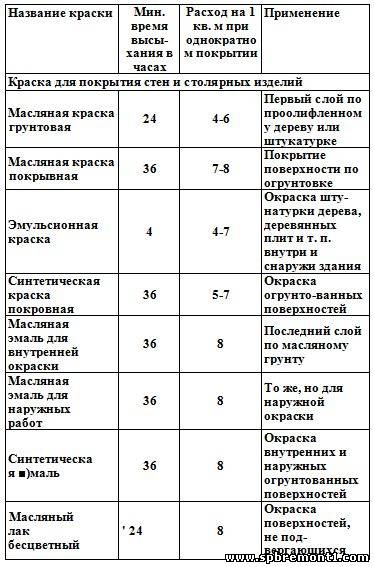

Consumption rates of paintwork materials

I must say that all norms depend directly on the factors under which oil paints are applied.And by the way, in different situations, these values can be completely different. Let's immediately take a look at what are the consumption standards that are used by the majority, both generalists and inexperienced beginners.

- What is the viscosity of paintwork materials

- What is the condition of the surface for painting

- With the help of what tools the material is applied - it can be brushes, rollers and a spray gun

- What kind of work is being done, internal or external

The increase in the consumption of oil paints is due to the fact that there are losses associated with external factors. For a little comparison, I will tell you that when painting the surface inside the house for 1 m2, you can use more paint than when painting outside, if the weather is calm and dry. But if the weather outside changes dramatically, then the consumption of material may even double. Acrylic-based water-dispersion paints, oil paints and water-based paints have different costs. Today I will talk about the PF 115 oil mixture and the consumption rates of such paint per square meter.

Enamel waste rates

PF-115 paint and its consumption per 1m2

LKM PF 115 is used in both external and internal processes. This is, by definition, paint-enamel, which is mainly used for metal objects. If you read the description for the material, you will notice that it has a number of excellent properties:

- Not afraid of negative atmospheric influences

- Moisture resistant

- UV protected

- Not afraid of the wind

But there is a small nuance for these properties, the paint receives all excellent characteristics only after application and complete drying of the surface. But when applied, it is subject to all of the above influences and, of course, in order to avoid incidents, it should be protected as much as possible. Enamel for metal PF 115 will be consumed per m2 in greater quantities if the application will take place in windy and sunny weather.

The enamel consumption for metal depends on the color you choose, and therefore I decided to draw up a small and understandable plate:

Enamel consumption per m2

If painting is carried out in bright sun, then be prepared for the fact that the consumption per 1 m2 will increase greatly due to the evaporation of the enamel. I don't want to talk about specifics, as there are cases when the indicators literally double. Therefore, if you do not want to spend money on purchasing paint, then adjust to the weather. If you look at the table, then simply divide all the m2 data by two and get the area that will be painted in bad weather conditions.

Painted surfaces

PF-115 paint consumption

Enamel PF 115 for metal, can be used for galvanized iron, as well as ferrous or non-ferrous metals. It is from the surface to be painted that what the consumption per m2 will be depends on. Typically, the rate ranges from 100 to 150 g / m2. When carrying out work, make sure that the surface is qualitatively prepared, it must be perfectly flat, since the enamel will show all the flaws.

In order to save a little paintwork, it is worth using primers for adhesion and putty to eliminate wall defects

Pay attention to the color of the metal that will be painted later. The consumption of PF 115 can depend on it, since the intensity of the original color depends on the number of layers applied.

Apply each layer with a roller or brush, and if you need to paint in 2 or more layers, you will have to wait for the previous one to dry. Usually one layer dries up in a day. By the way, if you paint with a brush, the consumption of the material automatically increases, since the tool literally absorbs the mixture. In the case of a roller, everything is much simpler, so think about purchasing this particular tool.

But if, taking into account all the factors, the consumption of paint is still very large, then pay attention to the paintwork itself. Perhaps you are using a low-quality and cheap composition

Pay attention to the manufacturer, the instructions and the expiration date of the product.

Buy enamel in specialized stores, look at the quality certificate and never give preference to paints with a low cost. Usually, it is precisely these mixtures that lack the quality and properties necessary for the correct painting.